2

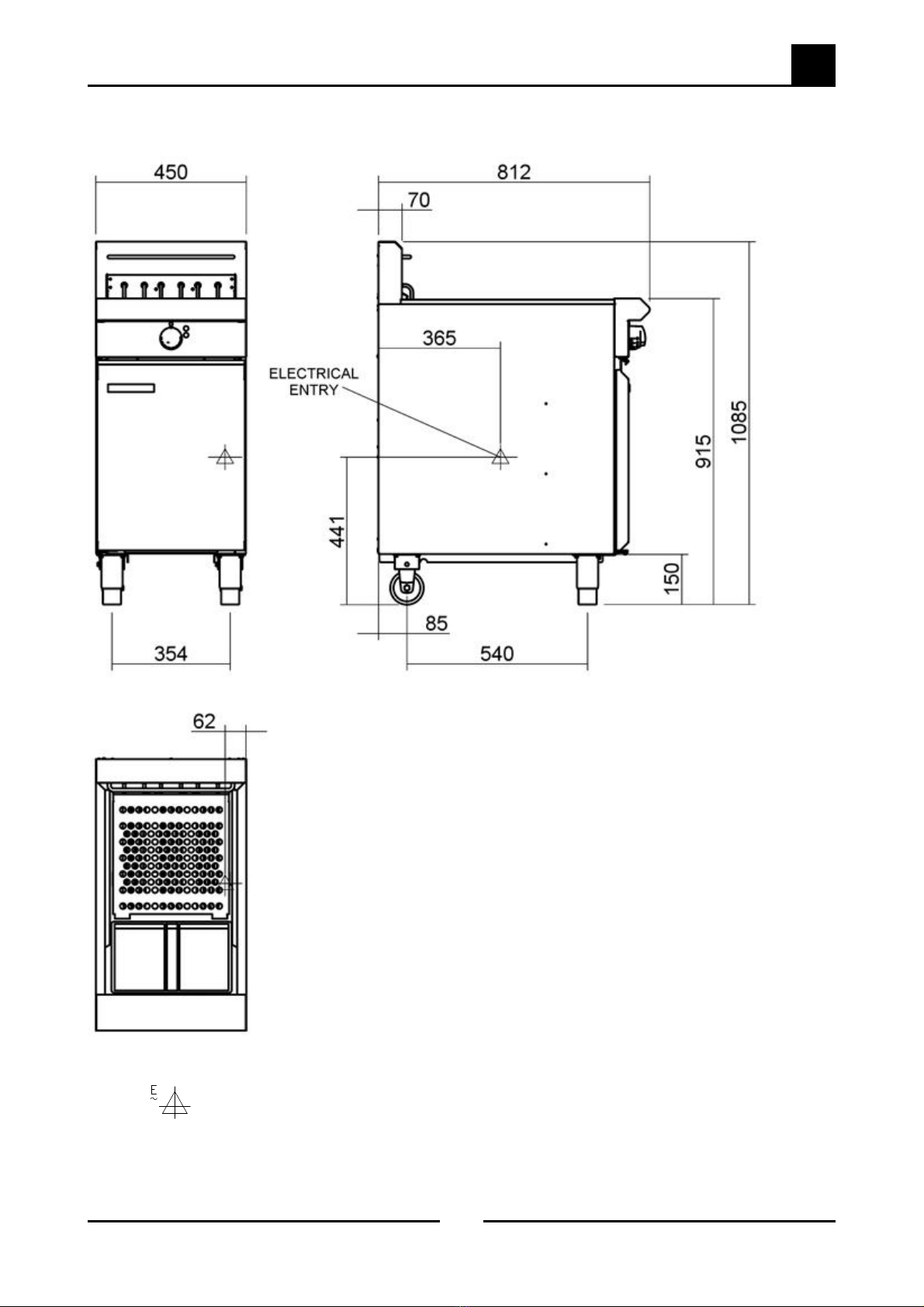

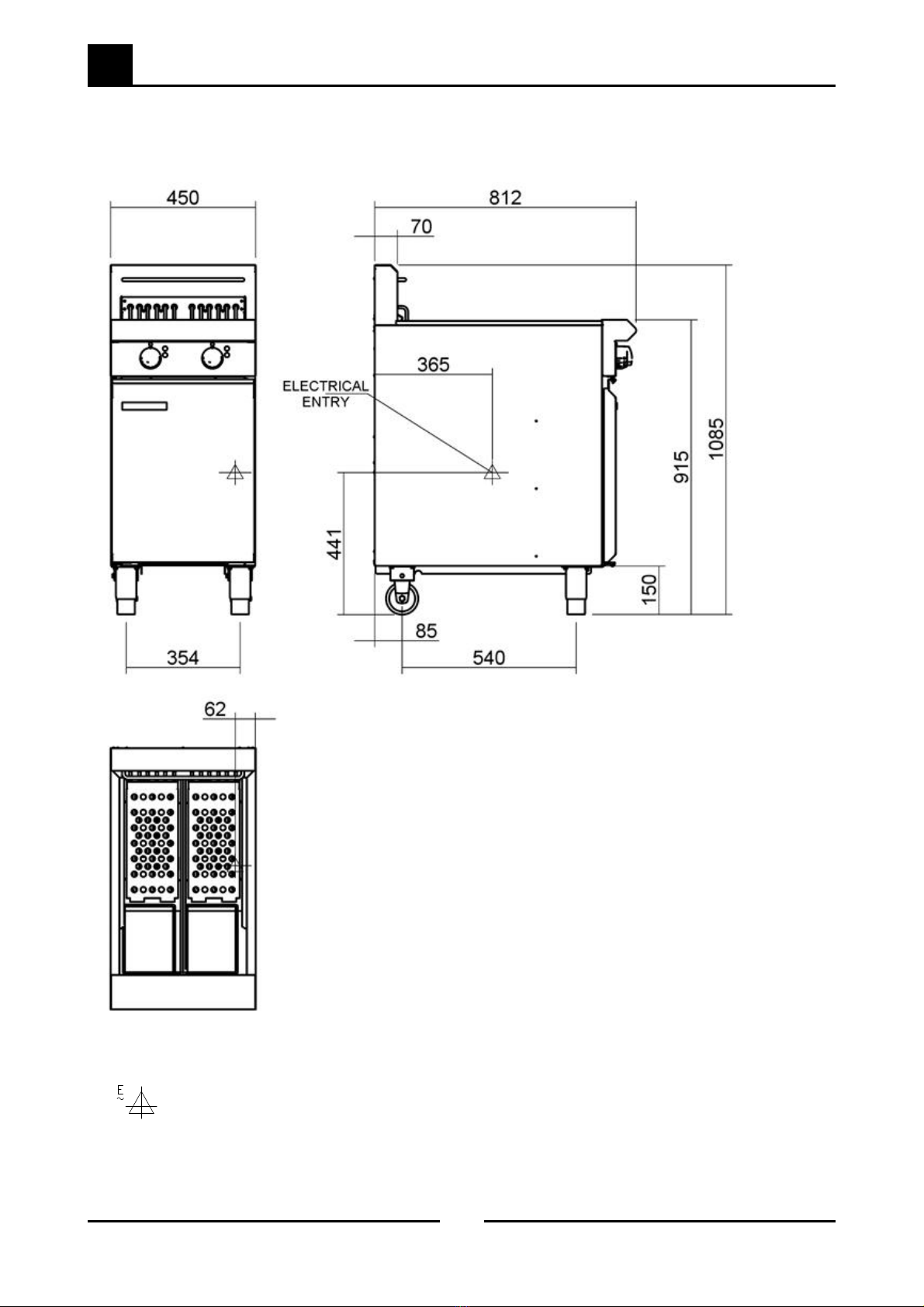

Installation

8

Blue Seal Evolution Series E43 / E44 Electric Fryers Service Manual © Copyright Moffat Ltd. June 2016.

Amendment 7

Installation Requirements

NOTE: It is most important that this appliance is installed correctly and that operation is correct before

use. Installation shall comply with local electrical and health and safety requirements.

Blue Seal Deep Fryers are designed to provide years of satisfactory service, and correct installation is

essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering electrical, fire safety and health and safety.

Australia / New Zealand AS/NZS3000 - Wiring Rules.

United Kingdom: BS 7671 - Requirements for Electrical Installations.

Installations must be carried out by authorised persons only. Failure to install equipment to rele-

vant codes and manufacturers specifications in this section will void warranty.

Unpacking

Remove all packaging and transit protection from the appliance including all protective plastic

coating from the door outer panel and exterior stainless steel panels.

Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

Report any deficiencies to the distributor who supplied the appliance.

Check that the available electrical supply is correct to that shown on the rating plate located on the inside

of the access door.

Check that the following parts have been supplied with the appliance:

E43 / E43E E44 / E44E

Baskets 2 2

Sediment Trays 1 2

Lid 1 1

Adjustable Legs 4 4

Drain Stick 1 1

Drain Extension 1 2

Location

1. Any appliance requires adequate clearance and ventilation for optimum and trouble-free operation. The

minimum installation clearances shown below are to be adhered to.

2. Position the Deep Fryer in its approximate working position.

3. The legs must always be fitted. Ensure that the legs are securely attached.

Clearances

NOTE:

Only non-combustible materials can be used in close proximity to this appliance.

In order to facilitate easy operation, drainage and servicing of the appliance, a minimum

of 600mm clearance should be maintained at the front of the appliance.

Assembly

This model is delivered completely assembled. Ensure that the legs are securely attached.

NOTE:

This appliance is fitted with adjustable feet to enable the appliance to be positioned

securely and level. This should be carried out on completion of the electrical connection. Refer to

the “Electrical Connection” section below.

Combustible Surface Non Combustible Surface

Left/Right hand side 50 mm 0 mm

Rear 25 mm 0 mm