Bluevua RO600X7 User manual

Table of contents

Other Bluevua Water Filtration System manuals

Popular Water Filtration System manuals by other brands

amiad

amiad Omega 13.5K Installation & operation manual

Anetsberger Brothers

Anetsberger Brothers GoldenFRY FFM-150 Installation, user operation & maintenance manual

Pentair

Pentair IntelliChlor Installation information

Beko

Beko DRYPOINT M PLUS Instructions for installation and operation

Kessel

Kessel EasyClean Instructions for installation, operation and maintenance

Giebel

Giebel VG-R 1L Assembly and maintenance instructions

Watermark

Watermark Puretec PureMix Z6 user guide

Culligan

Culligan WH-HD200-C Installation and operating instructions

Anchor

Anchor AF-4003 Quick setup guide

Lincat

Lincat L3 User and installation instructions

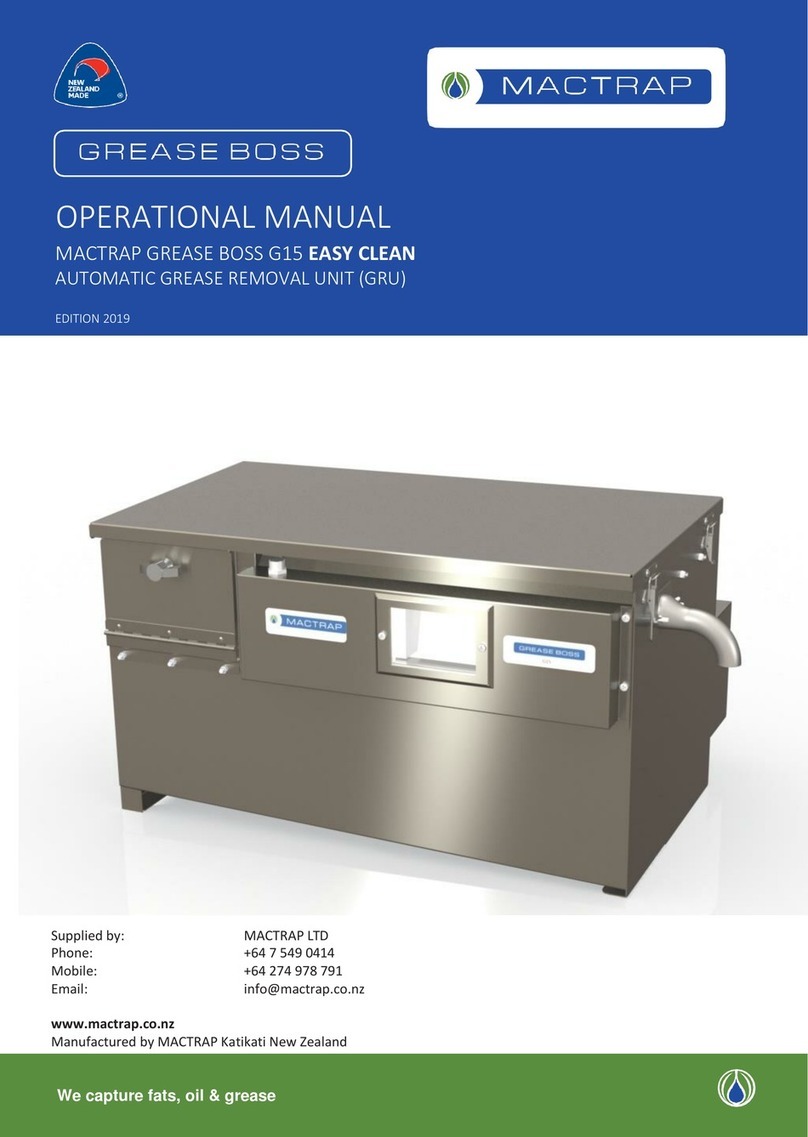

MACTRAP

MACTRAP GREASE BOSS G15 EASY CLEAN Operational manual

Waterdrop

Waterdrop WD-D6-B instruction manual

Aucma

Aucma AUS-S2 operation instruction

AQUAMAXX

AQUAMAXX cTech Nano Calcium Reactor user manual

Perfect Water Technologies

Perfect Water Technologies Home Master HMF1C Installation & service manual

SpectraPure

SpectraPure SpectraPlus 2000 Installation and operating manual

SteriPEN

SteriPEN Ultra manual

EcoWater

EcoWater 3500 Series owner's manual