IMT 3203i User manual

IOWA MOLD TOOLING CO., INC.

P.O. Box 189

Garner, IA 50438

Tel: 641.923.3711

Fax: 641.923.2424

www.imt.com

Revised 08-18-2020

Copyright © 2020 Iowa Mold Tooling Co., Inc.

All rights reserved

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise without the prior written permission of Iowa

Mold Tooling Co., Inc.

Iowa Mold Tooling Co., Inc. is an Oshkosh Corporation Company

3203i

Parts &

Specifications

Manual # 99904380

ii

3203i - Manual # 99904380

Operating, servicing and maintaining this vehicle

or equipment can expose you to chemicals

including engine exhaust, carbon monoxide,

phthalates, and lead, which are known to the

State of California to cause cancer and birth

defects or other reproductive harm. To minimize

exposure, avoid breathing exhaust, do not idle the

engine except as necessary, service your vehicle

or equipment in a well-ventilated area and wear

gloves or wash your hands frequently when

servicing. For more information go to

www.P65Warnings.ca.gov.

70490167

70490167

PROP 65

BKS 5-29-18

ORANGE , BLACK AND WHITE

3.27” 2.70”

CN

iii

3203i - Manual # 99904380

Table of Contents

Introduction 1

Introduction ....................................................................................................................................................2

Specications 3

3203i Technical Data......................................................................................................................................4

Load Capacity Chart ......................................................................................................................................6

Geometric Conguration ................................................................................................................................7

Pump & Motor Performance ..........................................................................................................................8

Assemblies & Grease Zerk Locations..........................................................................................................10

3203i Recommended Spare Parts List ........................................................................................................ 11

Crane Installation (99904394)......................................................................................................................13

Electric Crane Battery Circuit (99904884) ...................................................................................................20

Telescopic Crane Orientation.......................................................................................................................21

Electric Crane Control..................................................................................................................................22

Parts 23

Parts Information..........................................................................................................................................24

Electric Crane Power Safety ........................................................................................................................26

Base & Mast Assembly (99904315).............................................................................................................28

99904315 With Mte Power Unit ...................................................................................................................32

MTE Replacement Power Unit Instuctions (52725032-SERVICE) ..............................................................35

Valve Bank (73734304)................................................................................................................................36

Cylinder, Lower (51721267).........................................................................................................................38

Boom Assembly (99904316)........................................................................................................................40

Crane & Winch Assembly (99904317) .........................................................................................................50

Cord Reel – 6.7m, Electric 2 – Wire (70735052) .........................................................................................58

Cord Reel Assembly, 4.17’ W/Packard Connector (51727064) ...................................................................59

Snatch Block (51724950).............................................................................................................................60

Cylinder, Extension (51725007)...................................................................................................................62

Cylinder, Extension (51722111) ...................................................................................................................64

Cylinder, Extension (51721291)...................................................................................................................66

Winch (71570922)........................................................................................................................................68

Power Unit (73511432) ................................................................................................................................69

Power Unit 73511283 (12V) & 73511305 (24V) ...........................................................................................70

Hydraulic Installation (99904361) ................................................................................................................72

Tethered Control Installation (99904593).....................................................................................................77

Radio Control Installation, Standard (99904594).........................................................................................78

Radio Control Installation, Proportional (99904595) ....................................................................................79

Lighting & Electrical 81

Electrical Installation (99904389).................................................................................................................82

Cable Assembly (51726427)........................................................................................................................84

Light Kit (99906234).....................................................................................................................................85

275 & 225-Amp Contactor Replacement (99904578 ...................................................................................92

Harness, Radio (77441270).........................................................................................................................94

Harness, Tethered (77441269) ....................................................................................................................96

Harness, LED Boom Tip Jumper (77441689) ............................................................................................102

Harness, Light SW A2B CRD Reel (77441674) ........................................................................................104

Harness, Limit Switch Jumper (77441678) ................................................................................................106

Protective Sleeve Installation (70034573) .................................................................................................107

iv

3203i - Manual # 99904380

General Information 109

Decal Installation (99904375) .................................................................................................................... 110

Turntable Bearing Thread Tightening Sequence ....................................................................................... 113

Thread Torque Chart.................................................................................................................................. 114

v

3203i - Manual # 99904380

vi

3203i - Manual # 99904380

Introduction 1 Section - 1

3203i - Manual # 99904380

IntroductionSection - 1

Introduction 2 Section - 1

3203i - Manual # 99904380

Introduction

This manual includes parts, specications, and installation information for your particular crane. It is your

responsibility to maintain and operate this unit in a manner that will result in the safest working conditions possible.

Warranty of this unit will be void on any part of the unit subjected to misuse due to overloading, abuse, lack of

maintenance and unauthorized modications. No warranty - verbal, written or implied - other than the ocial,

published IMT new machinery and equipment warranty will be valid with this unit. In addition, it is also the user’s

responsibility to be aware of existing Federal, State and Local codes and regulations governing the safe use

and maintenance of this unit. This crane was designed and built to meet the standards of ANSI/ASSE A10.31-

1995, Safety Requirements, Denitions, and Specications for Digger Derricks. Contact the American National

Standards Institute (www.ansi.org) for more information.

Throughout this manual, four means are used to draw the attention of personnel. They are NOTE, CAUTION and

WARNING and DANGER are dened as follows:

NOTE

A NOTE is used to either convey additional

information or to provide further emphasis for

a previous point.

CAUTION

A CAUTION is used when there is the very

strong possibility of damage to the equipment

or premature equipment failure.

WARNING

A WARNING is used when there is the

potential for personal injury or death.

DANGER

Danger indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. Danger is used in the

extreme situations.

For a safe work environment, treat this equipment with respect and service it regularly

Specications 3 Section - 2

3203i - Manual # 99904380

SpecificationsSection - 2

Specications 4 Section - 2

3203i - Manual # 99904380

3203i Technical Data

GENERAL SPECIFICATIONS

CRANE RATING (crane rating (ft-lb) is the rated load (lb)

multiplied by the respective distance (ft) from centerline

of rotation with all extensions retracted and lower boom in

horizontal position.)

12,000 ft-lb at 7’-6” (1.6 tm at 2.3 m)

Horizontal Reach (From Centerline Of Rotation) 15’-0” (4.6 m)

Hydraulic Extension (1) 48” (122 cm)

Manual Extension (1) 48” (122 cm)

Lifting Height (From Base of Crane to Centerline of Sheave) 16’-2” (4.9 m)

Crane Weight (1H1m) 635 lb (288 kg)

Crane Storage Height 29” (73.7 cm)

Mounting Space Required (Crane Base) 14” x 18” (35.5 cm x 45.7 cm)

Hydraulic System Operating Pressure 2500 psi (172 Bar)

Maximum Hydraulic Flow 1.6 gpm (6 L/pm)

Oil Reservoir Capacity 1.5 gallons (5.7 L)

Oil Type O VG32, low pour, anti-wear hydraulic oil

CENTER OF GRAVITY

Horizontal from Centerline of Rotation (Booms Retracted) 22.88” (58.1 cm)

Horizontal from Centerline of Rotation (Booms Extended) 22.88” (58.1 cm)

Vertical from Bottom of Crane Base 12.75” (32.4 cm)

Tie-Down Bolt Pattern (On Center) 12” x 12” or 11.5” x 14.75”

(30.5 cm x 30.5 cm) or (29.2 cm x 37.5 cm)

Rotation Torque 2500 ft-lb (3.4 kN-m)

CYLINDER SPECIFICATIONS

Lower Boom Cylinder 2.75” bore; 16” stroke

(7 cm bore; 40.6 cm stroke)

Extension Boom Cylinder 1.5” bore; 48” stroke

(3.8 cm bore; 122.0 cm stroke)

WINCH SPECIFICATIONS

Winch Pull Line 2000 lb (907 kg)

Pull Line Speed Without Load 23 ft/min (7 m/min)

Rope Diameter 7/32” (5.56 mm)

Wire Rope Length 65’ (19.81 m)

Cable Nominal Strength 5600 lb (2540 kg)

PERFORMANCE CHARACTERISTICS

SPECIFICATIONS SPEED

Rotation 360º (Continuous) 44 seconds

Lower Boom Elevation -5º to +75º 10 seconds

Extension Cylinder 48” (122.0 cm) 10 seconds total

Specications 5 Section - 2

3203i - Manual # 99904380

CHASSIS REQUIREMENTS

GVWR 11,500 lb (5216 kg) (Minimum)

ELECTRICAL REQUIREMENTS

System Voltage 12 Volts

Battery

Minimum of 2 identical batteries in parallel

750 CCA MIN per battery.

Must meet chassis manufacturer’s specications.

Batteries must be fully charged prior to use.

Alternator 200 Amperes MINIMUM

Engine Elevated RPM required if additional high amperage draw systems will be in use

while crane is being operated.

Duty Cycle

Duty cycle and absolute continuous on-time according to the crane user

manual.

Winch is not operated simultaneously with any other function.

Specications 6 Section - 2

3203i - Manual # 99904380

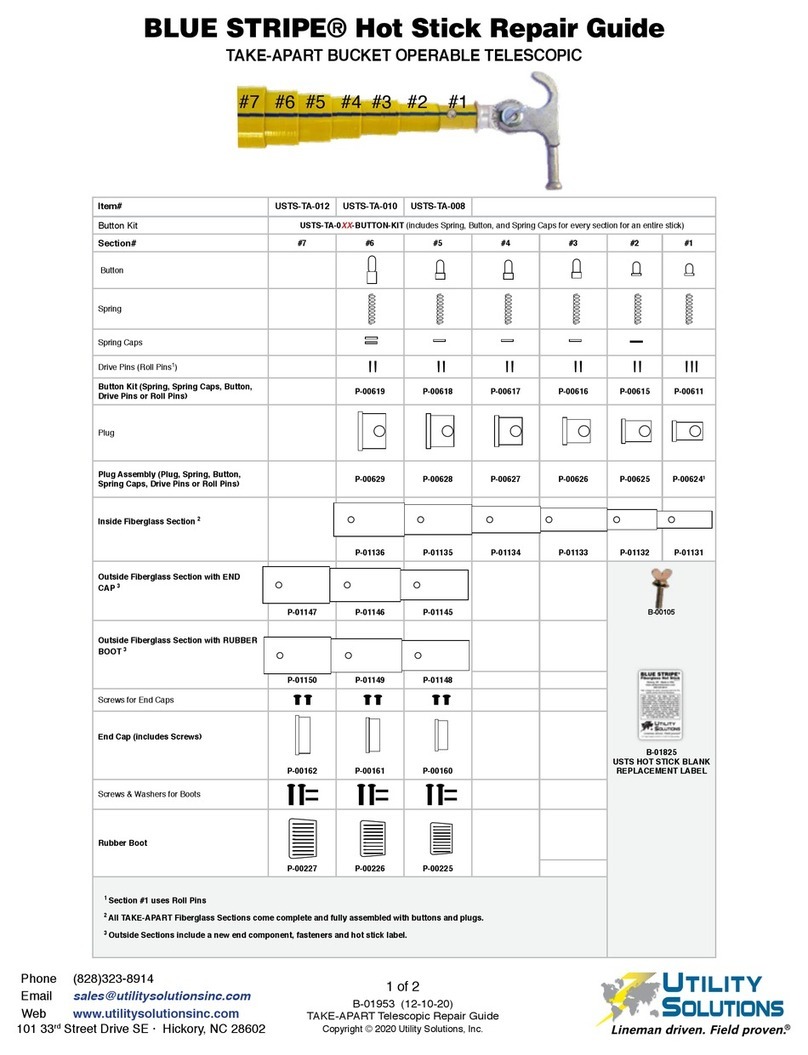

Load Capacity Chart

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711 FAX: 641-923-2424

70397348

3203i CAPACITY CHART

10'

3.0m

12'

3.6m

14'

4.2m

16'

4.8m

0

75°

60°

45°

30°

15°

2'

0.6m

4'

1.2m

8'

2.4m

0

(Base)

6'

1.8m

DISTANCE IN FEET/METERS / LOAD IN POUNDS/KG.

Weight of load handling devices are part of the load lifted

and must be deducted from the capacity.

4000

1815 3050

1385

2460

1115

2140

970

3135

1420

2350

1065

1450

660

1990

905

1575

715

1350

615

1195

540

1140

520

975

440

850

385

1905

865

1670

755 1050

475

730

330

LB

KG

10'

3.0m 12'

3.6m 14'

4.2m

2'

0.6m 4'

1.2m 8'

2.4m

6'

1.8m

Maximum 1-part line

capacity is 2000 lb (907 kg).

For greater loads, use

2-part line.

NOTE: Boxes denote

2-part line.

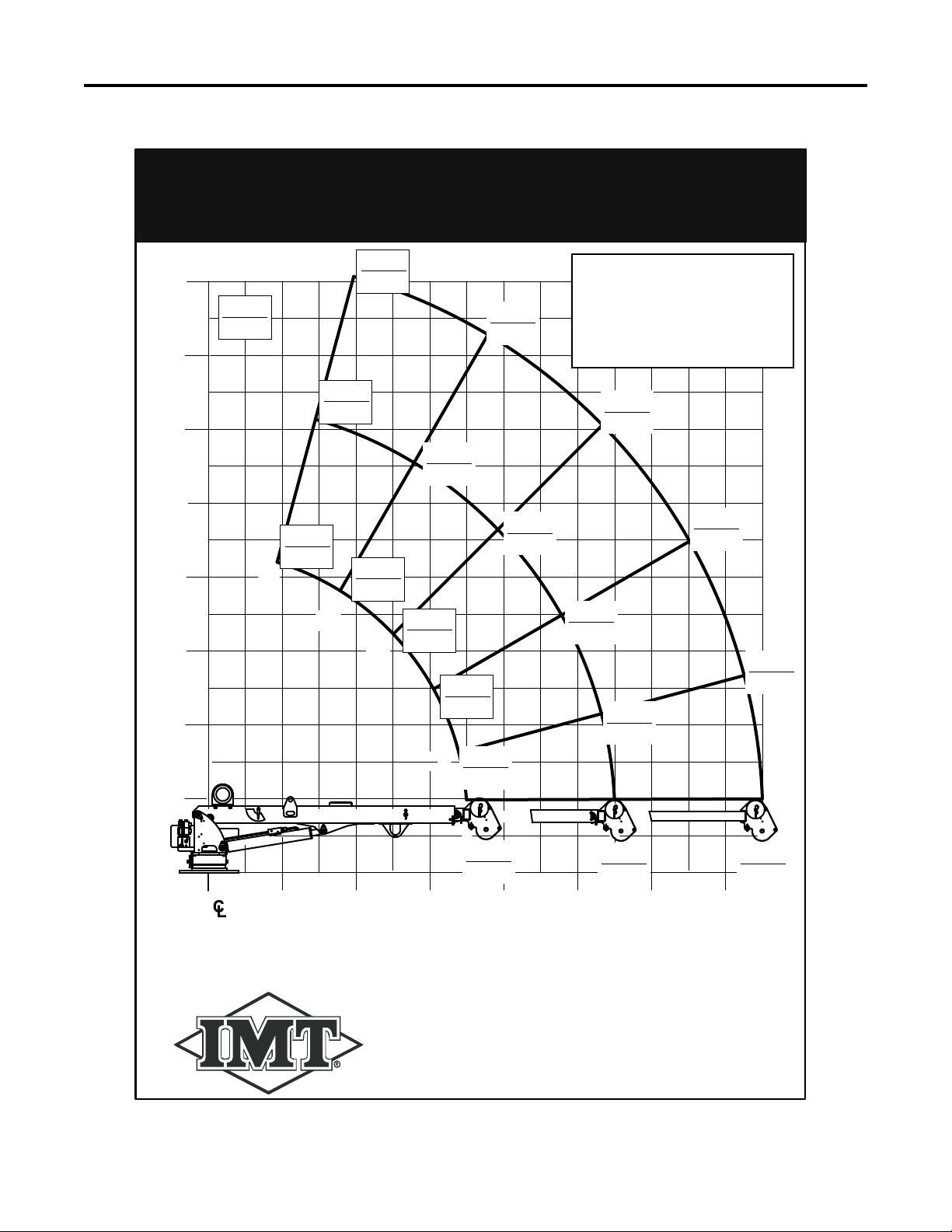

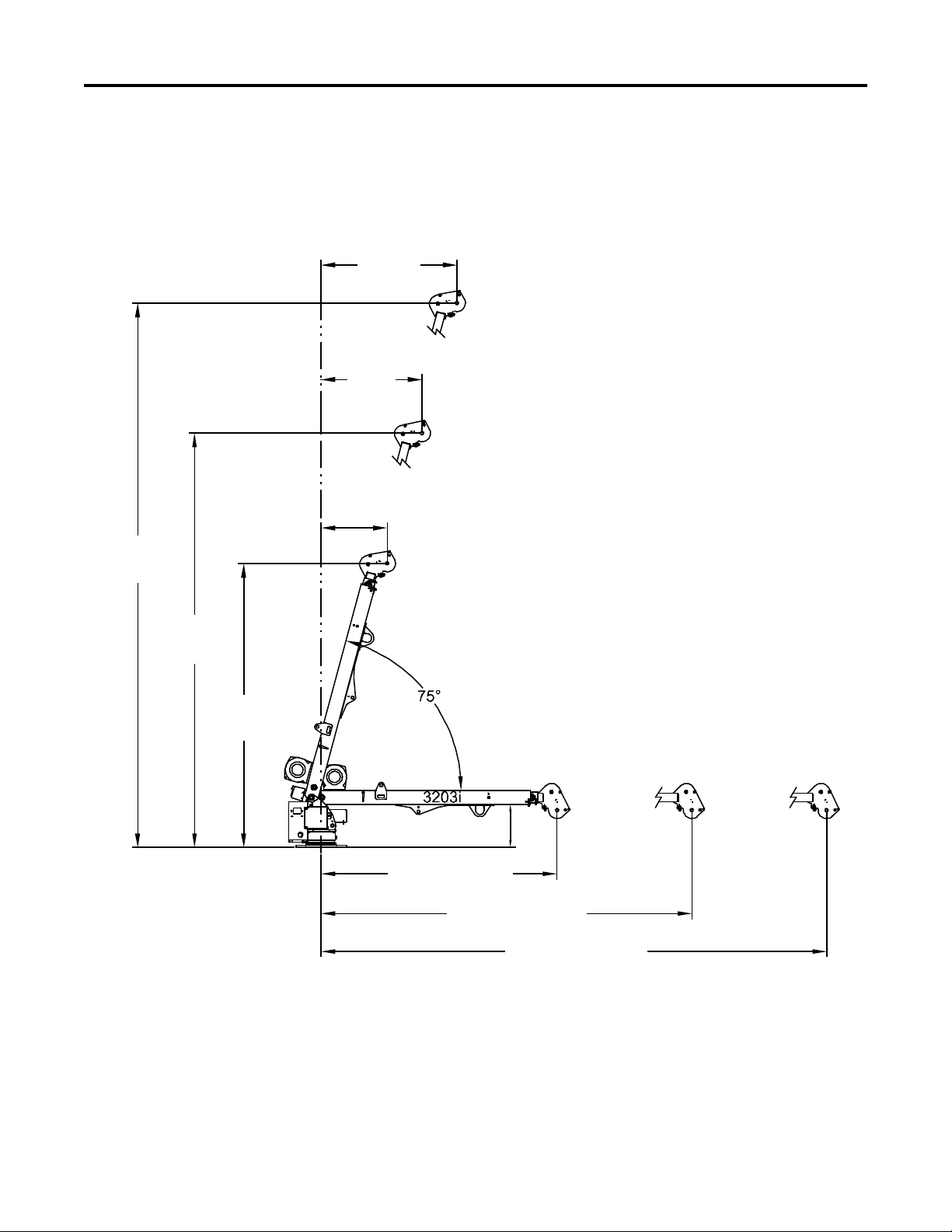

Specications 7 Section - 2

3203i - Manual # 99904380

GeometricConguration

4'-0"

(1.22 m)

3'-0"

(0.91 m)

1'-11"

(0.39 m)

16'-2"

(4.92 m)

12'-3"

(3.75 m)

8'-5"

(2.60 m)

7'-0" (2.13 m)

11'-0" (3.35 m)

15'-0" (4.57 m)

1'-3" (38 cm)

Specications 8 Section - 2

3203i - Manual # 99904380

Pump & Motor Performance

The ve minute duty cycle must be adhered to. Operators have a choice of running the crane intermittently all

day, using the duty cycles per the S2 and S3 curves, or at full power for 4.5 minutes, which MUST be followed by

a complete cool-down to ambient.

180 AMPS

0

1

2

3

4

5

6

0.0

5.0

10.0

15.0

20.0

25.0

Q - 1.6 CC

I - 1.6 CC

0

50

100

150

200

300

250

0 500 1000 1500 2000 2500 3000 3500 4000 4500

PSI

BAR

0 25 50 75 100 125 150 175 200 225 250 275 300

2500 PSI

CAUTION

Avoid motor damage! Operate within

performance curves shown.

Specications 9 Section - 3

3203i - Manual # 99904380

Crane ReferenceSection - 3

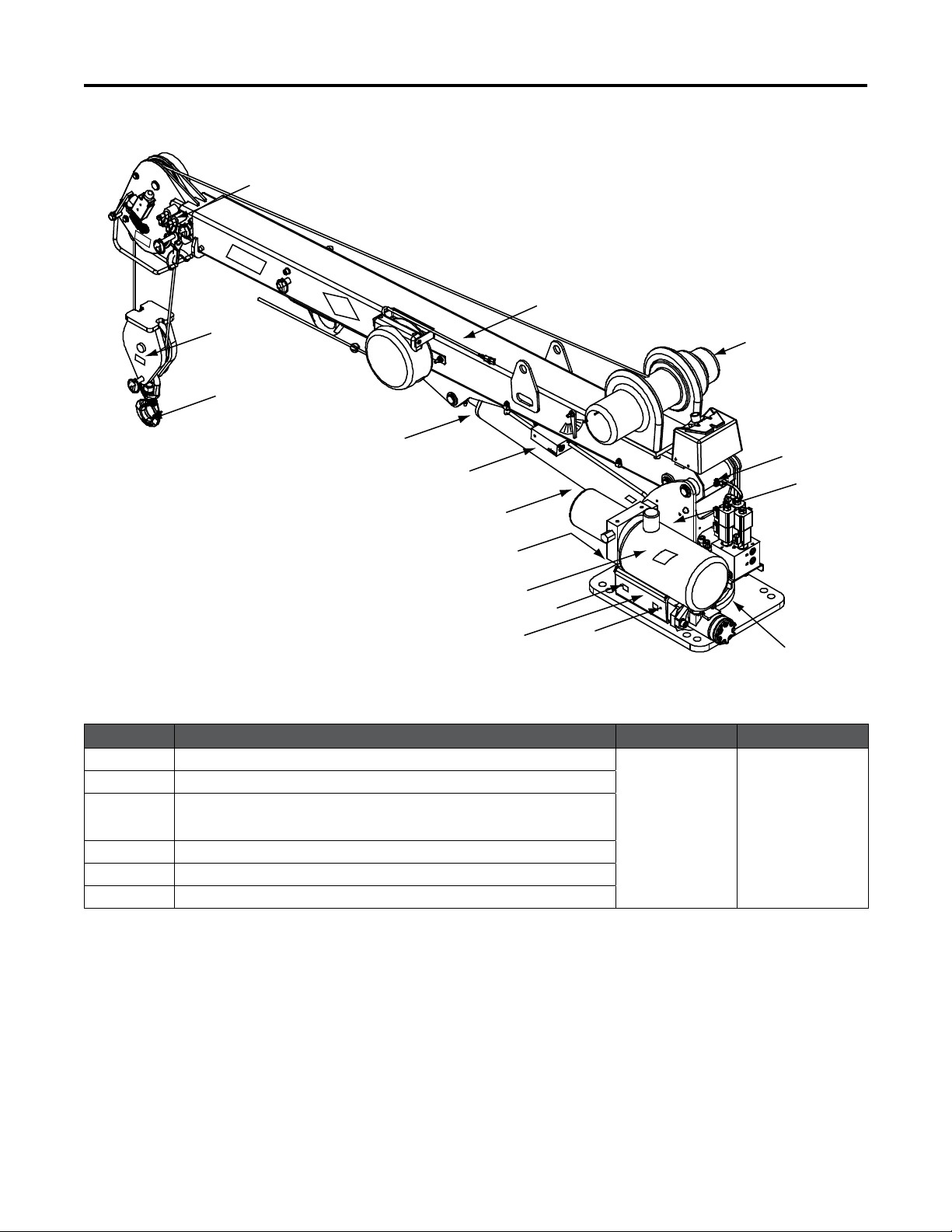

Specications 10 Crane Reference

3203i - Manual # 99904380

Assemblies & Grease Zerk Locations

ITEM NO. LOCATION DESCRIPTION LUBRICANT FREQUENCY

1LOWER CYLINDER ROD

SHELL

ALVANIA 2

EP

OR

SHELL

RETINAX “A:

WEEKLY

2LOWER CYLINDER BASE

3GEAR ROTATOR GREASE EXTENSION

*ROTATE CRANE WHILE GREASING.

4POWER UNIT

5POWER UNIT

6LOWER BOOM PIN

NOTE:

All application points must be greased weekly under normal workloads and moderate weather conditions.

Under severe operating conditions, lubricate more frequently. See the IMT Electric Crane Operation &

Safety manual P/N: 99905190, for additional lubrication requirements.

NOTE:

Image may be dierent depending on production date. Grease points should be identical.

4

5

LOWER

CYLINDER

3

6

CRANE

BASE

WINCH

SNATCH

BLOCK

MAST

POWER

UNIT

LOWER

BOOM

EXTENSION

BOOM

HOOK

2

1

HYDRAULIC

RESERVOIR

Specications 11 Crane Reference

3203i - Manual # 99904380

3203i Recommended Spare Parts List

51721267 LOWER CYLINDER QTY.

51744137 SEAL KIT-IMT 2.75B 1.75R 1.50 S 1

60127432 PISTON-2.75 BORE X 1.75 ROD 1.63 STGR 1

60127434 HEAD-2.75 BORE X 1.75 ROD 1

73054999 VALVE-COUNTERBALANCE 1

77041786 SWITCH-PRESS 2750 PSI 1

51722111 EXTENSION CYLINDER

94397290 SEAL KIT-IMT 1.50 BORE 1.00 ROD .75 1

60135105 HEAD-1.50 BORE X 1.00 ROD 1

60135106 PISTON-1.50 BORE X .75 STGR 1

73054999 VALVE-COUNTERBALANCE SUN01 CBBC-LHN 1

99904315 BASE & MAST ASSEMBLY

60118032 CABLE CONNECTOR MODIFICATION 1

72601931 CAP SCREW .44-14X 3.00 HH 156 KSI PROOF L 16

73511156 MOTOR-HYDRAULIC 101 1035 009 1

76039295 GASKET-GEAR 1

77441534 SWITCH- 225A CONTACTOR (12 OR 24V) 1

77441281 CABLE CONNECTOR-FEMALE 1

77441285 TERMINAL RING, INSULATED 3/8 STUD

73734304 VALVE BANK (12V)

73540327 COIL (VALVE BANK) (12V) 3

73540326 VALVE ASSEMBLY (VALVE & COIL) (12V) 6

73734375 VALVE BANK (24V)

77040527 COIL (VALVE BANK) (24V) 3

73540336 VALVE ASSEMBLY (VALVE & COIL) (24V) 6

73511283 POWER UNIT (12V)

70733826 FILL CAP ELECTRIC CRANES 1

73511171 PUMP-GEAR ELECTRIC CRANE 1

73540323 VALVE-RELIEF ELECTRIC CRANE 1

73734332 KIT-TUBE POWER UNIT ELECTRIC CRANE 1

74397392 RESERVOIR TANK ELECTRIC CRANE 1

77043060 MOTOR-POWER UNIT ELECTRIC CRANE 1

73511305 POWER UNIT (24V)

77043066 MOTOR (24V) 1

73511306 PUMP 1

73540517 RELIEF VALVE ASSEMBLY 1

74399495 RESERVOIR 1

70734788 BREATHER CAP 1

73734791 TUBE-SUCTION 1

70734792 STRAINER 1

Specications 12 Crane Reference

3203i - Manual # 99904380

99904316 BOOM ASSEMBLY QTY.

60030373 WEAR PAD- EXT CYLINDER 1

60030374 WEAR PAD-ROUND 1.00 DIA X .50 DIA X .75L 6

60030375 WEAR PAD-ROUND 3.00 DIA X 1.00 DIA X .55L 1

60030376 WEAR PAD-ROUND 3.50 X 1.00 DIA X .615 LG 2

60132302 STOP SCREW 3/8-24 X .50 4

71734311 PIN-QUICK RELEASE.62D/4.5 CRIT 1

71734314 PIN-QUICK RELEASE.62D/6.5 CRIT 1

72661543 PIN-QUICK 316-10QP 2

60030372 SHEAVE- 5.5 NYLATRON 2

60133938 WEAR PAD-ROUND 0.25 X 1.00 X 0.50 X 0.50 2

72661711 CLEVIS PIN 0.5 X 3.00 1

60030483 SHEAVE-8.0 NYLATRON 1

99904317 CRANE & WINCH ASSEMBLY

51721494 CORD REEL ASSEMBLY- 5FT PACKARD CONNECTOR 1

70580059 WIRE ROPE ASM-.22(7X19)X65FT PGA 1

71413185 SPRING-.105WIRE 0.75OD 2.875 LG 1

70735101 HOOK-SWVL POS LOCK BBRG 2TON (EFFECTIVE 1/1/2018) 1

72601798 WASHER-LOCK 12MM 4

72601935 CAP SCREW M12-1.75X 40 SH PLAIN 4

72601938 BOLT-EYE # 8-32X 1.125 1

77041459 SWITCH-LIMIT ZE-N-2S 1

77441096 CONNECTOR- .50 STR RLF .25-.38 1

71570922 WINCH (12V)

77041801 CONTACTOR (12 OR 24V) 1

77566638 BRAKE ASSEMBLY 1

77744175 BRUSH KIT 1

71570922 WINCH (24V)

77041928 CONTACTOR (12 OR 24V) 1

77566638 BRAKE ASSEMBLY 1

77744175 BRUSH KIT 1

99904394 ELECTRICAL INSTALLATION

77441116 FUSEHOLDER, HIGH AMP 1

77441219 FUSE-225 AMP 1

Specications 13 Crane Reference

3203i - Manual # 99904380

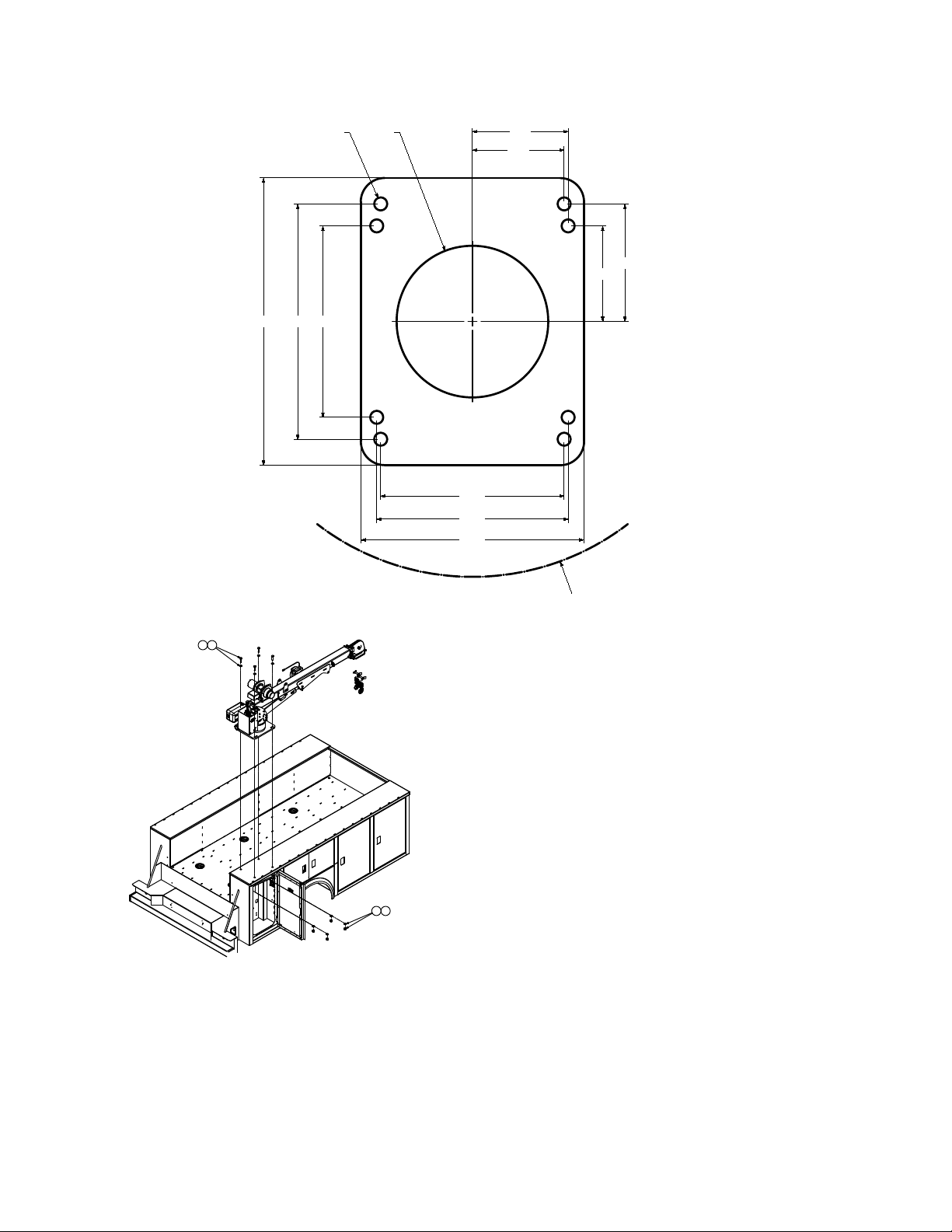

Crane Installation (99904394)

In addition to meeting the chassis requirements noted in the Technical Data section of this manual, make sure

there is sucient room for mounting the crane, and the platform is strong enough to support the crane and rated

load. Install the crane only on an IMT designed and approved truck body. The body must be designed to sustain

the forces imposed by the crane when lifting the full rated load. Install the body on the chassis before installing the

crane. Refer to the following table for parts referenced in the following crane installation drawings.

ITEM NO. PART NO. DESCRIPTION KIT NO. QTY

1. 51721572 ELECTRIC CRANE BODY INSTALLATION 1

2. 91721647 HARDWARE KIT- 3203I/4004I ELEC CRANE

BODY INSTALLATION 1

3. 91721751 HARDWARE KIT- 5005I ELEC CRANE BODY

INSTALLATION 1

5. 51725572 DRAWING-CRANE & WINCH ASSEMBLY 3203I REF

6. 60251272 BRACKET-SWITCH 300 AMP ELEC CRANE 1 & 4 1

7. 70734331 SWITCH-300A KEYED BATTERY DISCONNECT 1 & 4 1

8. 72042097 LEVEL INDICATOR LEVEL 1 & 4 1

9. 77040209 TERMINAL-RING NI .38 STUD 1 WIRE 1 & 4 1

10. 77040529 TERMINAL-RING NI .31 STUD 1-2 WIRE 4 9

11. 77441116 FUSEHOLDER-HIGH AMP2 BOLT WITH COVER 4 2

12. 77441219 FUSE-225 AMP 4 2

13. 89044276 CABLE-#1 WELDING 1 & 4 35 FT

14. 89392333 TUBE-HEAT SHRINK AMP 1 & 4 0.50 FT

15. 72060208 CAP SCREW .75-10X 2.50 HH GR8 Z 2 4

16. 72601862 NUT .75-10 HEX NYLOC GR8Z 2 4

17. 72063116 WASHER .75 N FLAT H ASTMF436Z 2 8

18 72060002 CAP SCREW .25-20X .75 HH GR5 Z 2 & 3 4

19. 72060634 SCREW-MACHINERY #10-24X .50 RDH 2 & 3 4

20. 72062000 NUT .25-20 HEX 2 & 3 4

21. 72062106 NUT 10-24 HEX NYLOCK 2 & 3 4

22. 72063001 WASHER .25 FLAT 2 & 3 8

REV. E 20120918

1. To install the crane: Use a lifting device capable of lifting the weight of the crane as indicated in the Technical

Data section of this manual. Attach fabric slings to the crane lower boom, centered approximately 18 inches (46

cm) from the mast hinge. Make certain the crane is well balanced on the slings by slowly lifting approximately

6” (15 cm) o the ground. Lift the crane and apply a bead of waterproof compound, such as silicon based caulk,

to the bottom of the base. Move the chassis under the crane and lower the crane into the desired position.

NOTE:

Install the 3/4-10x2.5” mounting cap screws (item # 15) and 3/4” washers (item #16) to secure the crane base to the

truck body (see gure on next page). Torque the cap screws to 280 ft-lb.

Specications 14 Crane Reference

3203i - Manual # 99904380

CRANE INSTALLATION - CONTINUED

14.75 12.0018.00

11.50

12.00

14.00

5.75

6.00

6.00

7.38

9.50

0.81

3203I/4004I

MOUNTING PATTERN

16.00 16" RA

D

IUS

ING CLEARA

N

CE

1620

20

SEE NOTES #1, #2 & #3

ALLOW R 16.00 16” RADIUS

FOR SWING CLEARANCE

SEE NOTES

1, 2, 3

NOTE:

1. FOR Ø0.75 SAE HARDWARE TORQUE

TO 280 FT-LB

2. FOR Ø1.00 SAE HARDWARE TORQUE

TO 680 FT-LB.

THE .75-10 X 2.50" BOLTS SUPPLIED ARE FOR USE ON BODIES WITH A CRANE BOX TOP

PLATE THICKNESS OF 1/2"ONLY. DETERMINE THE CRANE BOX TOP PLATE THICKNESS

PRIOR TO MOUNTING. IF DIFFERENT LENGTH BOLTS ARE REQUIRED, THEY MUST BE

3/4-10, GRADE 8, ZINC COATED OF PROPER LENGTH. FAILURE TO USE PROPER LENGTH

BOLTS MAY CAUSE THE BOLTS TO BOTTOM OUT BEFORE TORQUING.

THE 1.00-8 X 3.00 " BOLTS SUPPLIED ARE FOR USE ON BODIES WITH A CRANE BOX TOP

PLATE THICKNESS OF 7/8" TO 1.00" ONLY. DETERMINE THE CRANE BOX TOP PLATE

THICKNESS PRIOR TO MOUNTING. IF DIFFERENT LENGTH BOLTS ARE REQUIRED, THEY

MUST BE 1.00-8, GRADE 8, ZINC COATED, OF PROPER LENGTH. FAILURE TO USE PROPER

LENGTH BOLTS MAY CAUSE THE BOLTS TO BOTTOM OUT BEFORE TORQUING.

Other manuals for 3203i

1

Table of contents

Other IMT Construction Equipment manuals