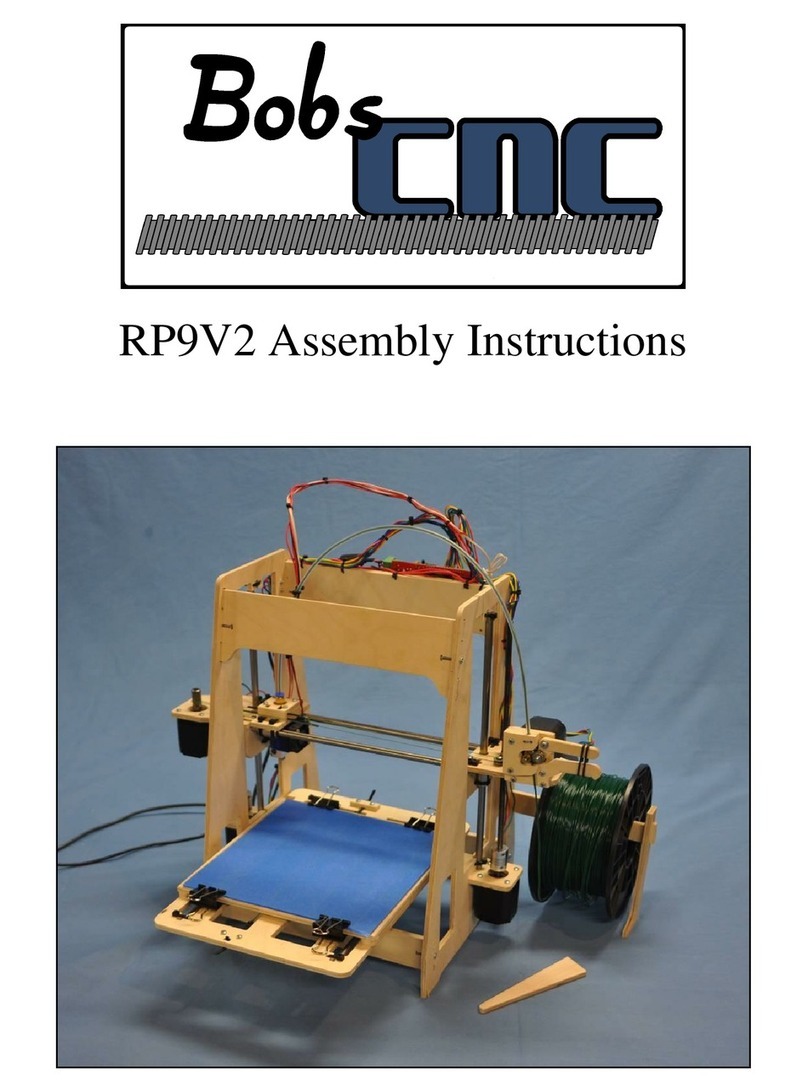

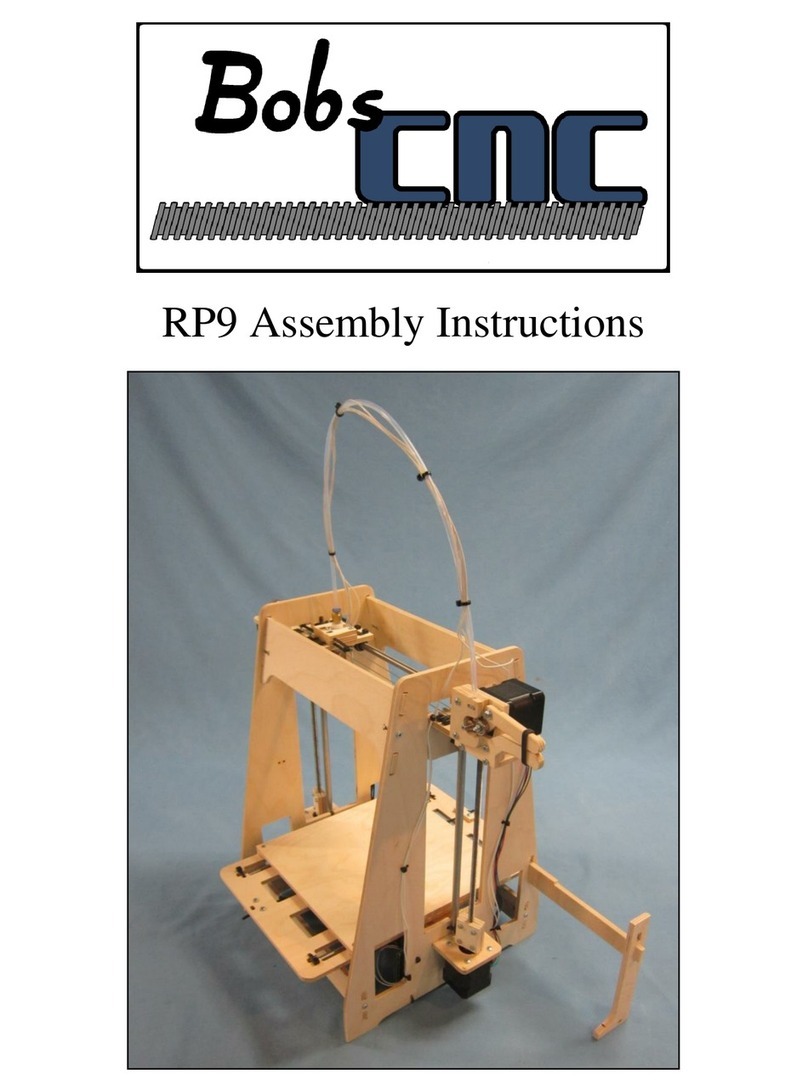

BobsCNC RP9 User manual

RP9 Assembly Instructions

2

Specifications...................................................................................................................... 3

Getting Started.................................................................................................................... 3

Safety first....................................................................................................................... 3

Required tools..................................................................................................................... 3

Building the Printer............................................................................................................. 4

Extruder Assembly.......................................................................................................... 4

Y Sub-assembly.............................................................................................................. 7

X-Subassembly............................................................................................................. 13

Frame assembly ............................................................................................................ 14

Z Assembly................................................................................................................... 15

Z - Rod Assembly........................................................................................................ 16

X Assembly................................................................................................................... 18

Extruder (cold end) Assembly...................................................................................... 20

Adding the Electronics...................................................................................................... 22

Controller Assembly..................................................................................................... 22

Motion Stepper motors ................................................................................................. 23

Limit Switches.............................................................................................................. 25

Adding The String Drive .................................................................................................. 26

Tying the knots (Uni-knot) ........................................................................................... 27

X string Drive ............................................................................................................... 27

Y String Drive............................................................................................................... 29

Adding the Extruder Driver.......................................................................................... 31

Build Platform Assembly.................................................................................................. 33

Connecting the Controller................................................................................................. 34

Ramps1.4 Connections ................................................................................................. 34

Wire Routing With Nylon Ties..................................................................................... 35

Filament Spool Holder...................................................................................................... 36

Initial Controller Setup ..................................................................................................... 37

Arduino 2560 Firmware settings .................................................................................. 37

Power supply................................................................................................................. 38

First print (quick guide)................................................................................................ 39

Appendix........................................................................................................................... 42

Warranty and Return Policy.......................................................................................... 42

Parts included in the basic kit ....................................................................................... 43

Added parts included in the deluxe kit ......................................................................... 44

3

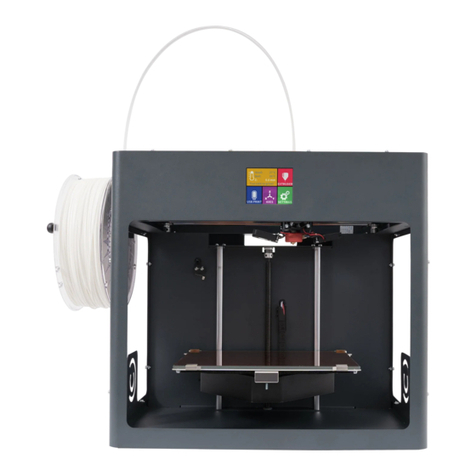

Specifications

5 ply Baltic birch frame

Oil hardened drill rod linear rails

Filament drive with high grip v-groove threaded coupler drives

Remote extruder with 1.75 mm drive

Foot print

Width 520 mm (20.5") - including spool holder

Depth 550 mm (21.7" - with max travel

Height 660 mm (26") - room for filament guide tube

Print Area

X 200 mm (7.9")

Y 200 mm (7.9")

Z 200 mm (7.9")

The complete printer part list can be found in the appendix.

Getting Started

Safety first

Safety is your responsibility. Always use the

proper protective equipment and "safety

sense" when building or operating a 3D

printer.

Printers have high voltage power supply, and extruder operating temperatures can be over

250 degrees Celsius (482 F). The operator should understand the hazards before

operating a printer.

Required tools

Please browse through the instructions and get familiar with the steps before you

begin.

To put the kit together you will need:

a Phillips screwdriver for the screws

a pair of pliers to hold the nuts

a sharp knife or a pair of side cutters to trim the zip ties and string

sand paper to clean up the plywood parts and remove sharp edges.

4

Tools you may need for the electronic setup include:

25 to 40 watt soldering iron/solder

Diagonal Cutters (dikes)

multimeter to correctly set up the power supply and stepper motors and general

trouble shooting.

For the printing you will want to have:

computer with a USB to program and run the printer

calipers to measure motion distance and extrusion width

calibration block STP file that can be modeled or downloaded at BobsCNC.com

Building the Printer

We recommend a large working surface for assembling the printer. The plywood

may require some minor sanding and can be painted, stained or finished for a different

look. A coat of sealer or lacquer on all surfaces of the plywood will add stability.

Extruder Assembly

Parts for the extruder mount

assembly include:

A. 1 Extruder mount

B. 1 Extruder top mount

C. 1 Extruder lock

D. 3 M3 x 20 machine screws

E. 3 M3 nuts

F. 2 LM8UU bearings

G. 4 Large nylon ties

H. 1 Extruder

B

C

A

5

1. Place the bearings into the rectangular slots of the extruder mount.

2. Wrap the 2 bearings by inserting large nylon ties through the side opposite of the

bearing into the slotted holes of the extruder mount. The slots on one side are larger to

make room for nylon ties during a later step.

3 Pull the bearing snug against the extruder mount (use pliers if needed).

4. Cut off the excess of the nylon tie.

For a clean look and string clearance, insert the nylon straps first in the inboard

holes.

6

5. Insert the 4 extruder wires through the extruder mount from the same side as the

bearings through the wire slot.

6. Place the extruder through the extruder plywood mount.

7. Pull the wires through and re-coil them to keep them out of the way and undamaged.

8. Install the extruder lock.

9. Install the extruder top mount.

7

11. Insert the 3 M3 x 20 screws into the holes.

12. Install the 3 nuts and tighten.

Check to ensure that the thermistor is inserted into the small hole in the

aluminum block.

Y Sub-assembly

Parts for the Y sub-assembly include:

A. 1 Left mount

B. 2 Bearing holders

C. 1 Extruder assembly

D. 1 M3 x 16 machine screw

E. 1 Right mount

F. 4 M3 x 20 machine screws

G. 6 M3 nuts

H. V groove bearing 623VV

I. 2 LM8UU bearings

J. 12 Large nylon ties

K. 2 8mm rods

A

B

B

E

H

8

1. Place the bearings in the rectangular slots of the 2 plywood bearing holders.

2. Wrap the bearings by inserting large nylon ties through the side opposite of the bearing

into the slotted holes of the bearing holders.

3 Pull the bearing snug against the 2 bearing holders (use pliers if needed).

4.Cut off the excess of the nylon tie.

9

5. Insert the bearing and then the nut on the M3 x 16 machine screw.

6. Tighten the nut

7. Install the screw and bearing through the top of the right mount through the bearing

mounting hole.

8. Install and tighten the nut.

The bearing should rotate freely once installed.

Bearing mounting hole

TOP

TOP

10

9. Press in the 2 M3 nuts into the slots on both of the 2 bearing holders.

10. Assemble the left and right mounts to the bearing holders with 2 M3 x20 machine

screw.

11. tighten the screws.

Note orientation is important. The bearing center should line up with the hole on

the left and right mounts.

Bearing centers

11

12. Slide both 8mm rods through the bearings on the extruder assembly.

13. Slide both rods into the left and right assemblies with the extruder nozzle facing

down. The large slots in the extruder, bearing and large stepper motor hole are on the

same side as shown.

Note that the nylon tie under the Y limit (see page 25) switch slots will be

installed differently.

14. For 7 of the nylon ties, wrap the rods by inserting large nylon ties through the side

opposite of the rods into the slotted holes of the left and right mounts.

Note orientation

Note orientation

12

15. Pull the rods snug against the left and right mounts (use pliers if needed).

16.Cut off the excess of the nylon tie.

17. Wrap the rod by inserting the last large nylon tie through the same side as the rod into

the remaining slotted holes of the left mount.

18. Pull the rod snug against the left mount (use pliers if needed).

19. Cut off the excess of the nylon tie.

The extruder assembly should slide on the 8mm rods freely.

13

X-Subassembly

Parts for the x-subassembly

include:

1 Plywood cross member

4 LM8UU bearings

8 Large nylon ties

1. Place the bearings in the u-shaped slots of the cross member.

2. Wrap the bearings by inserting large nylon ties through the side opposite of the bearing

into the slotted holes of the bearing holders.

3 Pull the bearing snug against the extruder mount (use pliers if needed).

4. Cut off the excess of the nylon tie.

14

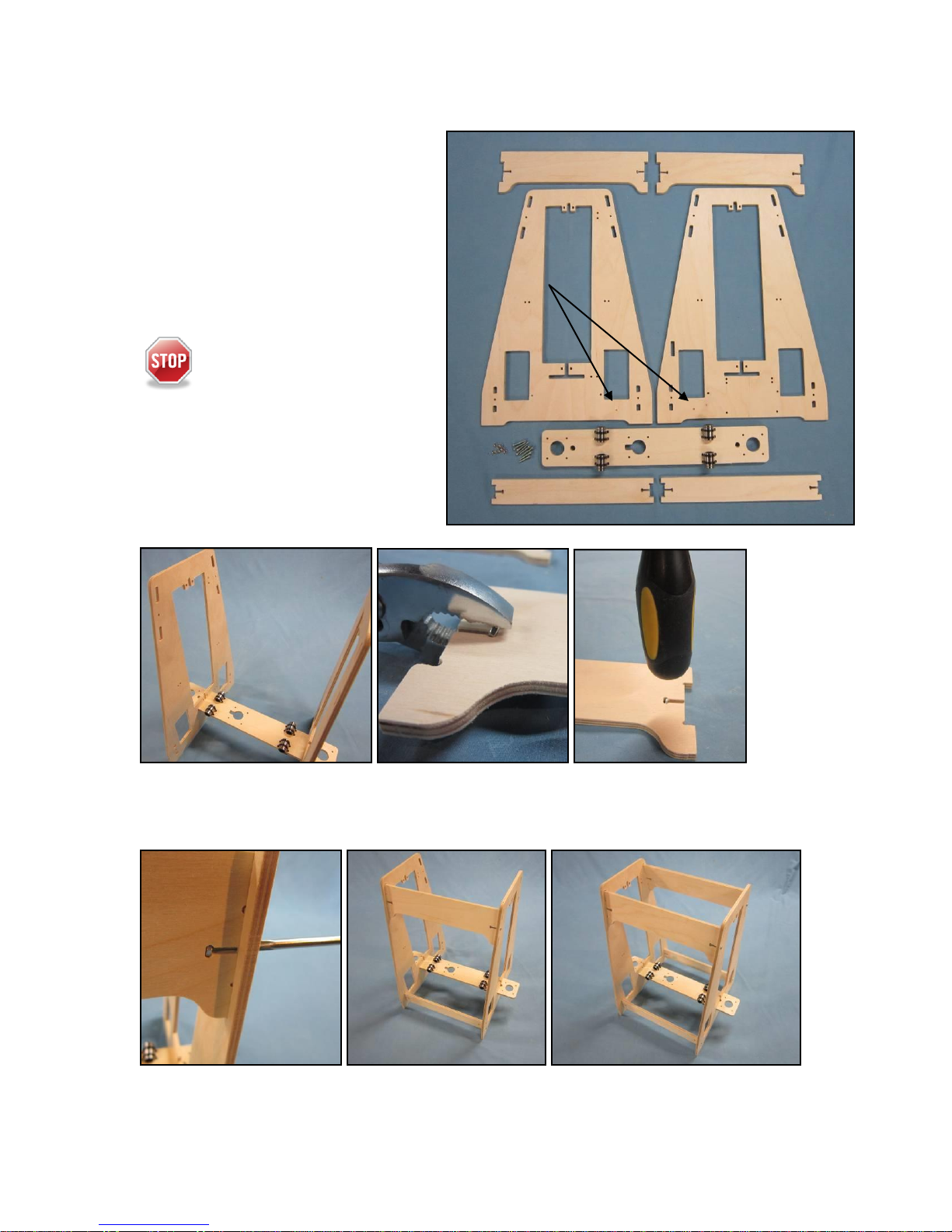

Indicator drill

marks

A

A

B

C

E

D

E

Frame assembly

Parts for the frame assembly include:

A. 2 Top braces

B. 1 Left frame

C. 1 Right frame

D. 1 X sub-assembly

E. 2 Bottom braces

F. 8 M3 x 20 machine screws

G. 8 M3 x 20 nuts

The orientation of B, C, and D

is important.

Indicator marks on the frame

should be at the back facing inward.

The middle stepper mount

(key hole shaped hole) should be

closer to the left frame

1. Properly orient and insert x sub-assembly into the left and right frame.

2 Press with pliers or tap the 8 M3 nuts into the 8 slots of the 4 braces. ( the handle of the

screw drive works well)

3. Insert the top and bottom plywood braces into the slots.

4. Install and tighten the 8 M3 x20 machine screws.

15

Z Assembly

Parts for the z assembly include:

1 Frame assembly

1 Y assembly

2 8mm rods

4 Large nylon ties

The orientation of top nylon ties is

important. The nylon locking block needs to be on

the outside to give maximum Y axis travel.

1. Place the Y assembly into the frame.

2. Insert the rods through the Y assembly and position them into the holes of the cross

member at the bottom and u-shaped slots at the top of the frame

2. Wrap the top of the rods by inserting large nylon ties through same side as the rod into

the slotted holes of the extruder mount.

3. Pull the rods snug against the frame (use pliers if needed).

4. Cut off the excess of the nylon ties.

16

5. Wrap the bottom of the rods by inserting large nylon ties through the side opposite as

the rod into the slotted holes of the extruder mount.

6. Pull the rods snug against the frame (use pliers if needed).

7. Cut off the excess of the nylon ties.

The Y assembly should slide on the 8mm rods freely.

Z - Rod Assembly

Parts for the Z rod assembly include:

1 Frame assembly

2 1/4-20 threaded rods

4 Coupler halves

8 M3 x 20 machine screws

8 M3 nuts

The orientation of the coupler is

important. The larger slots are paired and

connected to the threaded rod.

17

1. Assemble each of the threaded rods into the larger coupler slots.

2. Connect the coupler halves with 4 M3 x20 screws and nuts.

3. Only snug up the screws, they will be tightened in a later step.

6. Thread both of the coupler assemblies into the threaded inserts on the Y assembly. The

coupler halves may need to be removed to get the threads started through the inserts on

the Y assembly.

18

X Assembly

Parts for the x assembly include:

A. 2 X string holders

B. 1 X bed mount

C. 1 Frame assembly

D. 2 8mm rods

E. 4 Large nylon ties

F. 4 M3 x16 machine screws

G. 4 M3 nuts

Note orientation. The string holder

is mounted on bottom on the front and it

is mounted on top in the rear. The cut

groove in the string holder mates with

the bed mount.

1. Install the string holders into the bed mount using 2 M3 x 16 machine screws.

2. Install the M3 nuts and tighten

2. Insert the rods into the bearings on the cross member and install the bed.

B

A

A

19

5. Wrap the bottom of the rods by inserting large nylon ties through the side opposite of

the rod into the slotted holes of the extruder mount.

6. Pull the rods snug against the frame (use pliers if needed).

7. Cut off the excess of the nylon ties.

20

Extruder (cold end) Assembly

Parts for the cold end include:

A. 1 Backing plate

B. 1 Bearing arm

C. 1 Mid plate

D. 1 Front plate

E. 1 Drive bearing

F. 1 Nylon bushing

G. 1 Stepper motor

H. 1 Extruder drive gear

I. 1 Filament guide tube

J. 1 Filament guide tube nut

K. 1 Large washer

L. 2 M3 x16 machine screws

M. 1 Small washer

N. 1 M3 nut`

O. 2 M3 x 20 machine screws

P. 2 O-rings

1. Insert the M3 x 16 through the extruder arm.

2. Install the small washer on the screw.

3. Install the bearing on the screw.

4. Install the nut on the screw and tighten

5. Press the nylon bushing into the extruder arm.

6. Insert the big washer onto the M3 x 16 machine screw.

B

D

A

E

C

F

H

Other manuals for RP9

1

Table of contents

Other BobsCNC 3D Printer manuals