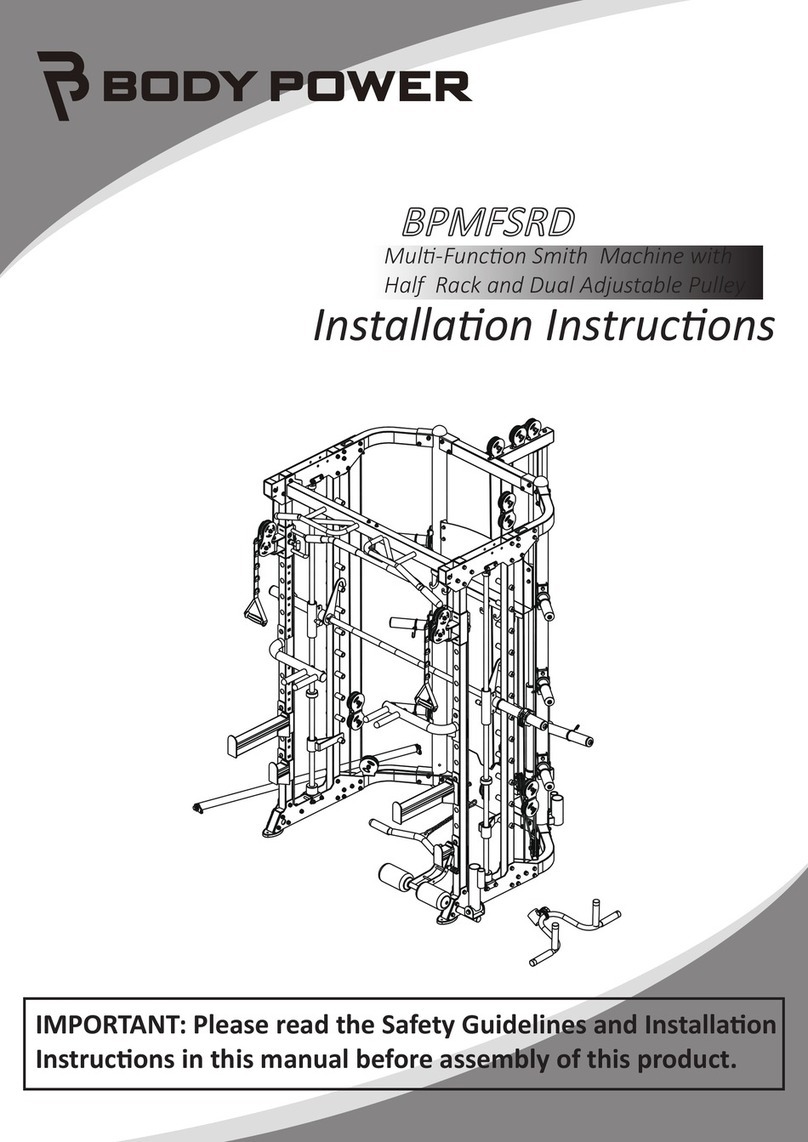

body Power BPMFSRD User manual

Installaon Instrucons

BPMFSRD

Mul-Funcon Smith Machine with

Half Rack and Dual Adjustable Pulley

2

• Before beginning assembly, please take the me to read the instrucons thoroughly.

• Read each step in the assembly instrucons and follow the steps in sequence. Do not skip

ahead. If you skip ahead, you may learn later that you have to disassemble components and

that you may have damaged the equipment.

• Assemble and operate the product on a solid, level surface.

• Locate the unit a few feet from the walls or furniture to provide easy access.

• The product is designed for your enjoyment. By following these precauons and using

common sense, you will have many safe and pleasurable hours of healthful exercise with

your new product.

• Aer assembly, you should check all funcons to ensure correct operaon.

• If you experience problems, rst recheck the assembly instrucons to locate any possible

errors made during assembly. If you are unable to correct the problem, call our product

service team who will be able to assist.

• It is highly recommended that you consult your physician before beginning any exercise

programme. This is especially important for individuals over the age of 35, or persons with

pre-exisng health problems.

• Always warm up before starng a workout. Try to do a total body warm up before you

start. It is especially important to warm up the specic muscle groups you are going to be

using. This can be as simple as performing a warm up set of high repeons and light

weight for each

Safety Guidelines When Using This Prduct

Persnal Safety during Assely

Successful resistance training rgraes have ne rinent feature in

cnsafetyResistance training has se inherent dangers, as dall hysical

acviesThe chance f injury can e greatly reduced r cletely reved y using

crrect liing techniques, rer reathing, and aintaining equient in gd

wrking cndin, and y wearing the arriate clthing

Assistance may be required during assembly of this

product.

exercise.

• Use proper form. Focus on only working the muscle groups intended for the exercise you

are doing. If there is strain elsewhere, you may need to re-evaluate the amount of weight

that is involved with the li. Keeping proper form also includes maintaining control through

an enre range of moon.

3

• Breath properly. Inhale during the eccentric phase of the exercise, and exhale during the

liing, or concentric phase. Never hold your breath during any part of an exercise.

• Always wear the appropriate clothing and shoes when exercising. Wearing comfortable

athlec shoes with good support and loose ng, breathable clothing will reduce the risk of

injury.

• Maintaining equipment in proper operang condion is of utmost importance for a safe

resistance training program. Pulleys and cables should be checked for wear frequently and

replaced as needed. Equipment should be lubricated as indicated by the manufacturer.

• Read and study all warning labels on this machine. It is absolutely necessary that you

familiarize yourself and all others with the proper operaon of this machine prior to use.

• Keep hands, limbs, loose clothing and long hair well out of the way of all moving parts.

• Do not aempt to limore weight than you can control safely.

• Inspect the machine daily for loose or worn parts. If a problem is found do not allow the

machine to be used unl all parts are ghtened or worn or defecve parts are repaired or

replaced.

When the machine is not in use carefully run your ngers along the cable to feel for thinning

or bulging areas. Replace cables immediately at the rst sign of damage or wear. Do not

use equipment unl damaged cable has been replaced.

Visually inspect the cables for fraying, cracking, peeling or discoloraon.

Check slack in cables and re-adjust cable tension if needed.

Check that the jam nut on the selector rod top bolt is ght.

Wipe down aer every workout.

Periodically take the me to use a mild soap or a mild vinyl upholstery cleaner. Avoid using

any abrasive cleaner not intended for use on vinyl.

Keep sharp or pointed objects out of your pockets and clear of all upholstery.

Periodically inspect all nuts and bolts. Tighten if needed. If bolts seem to loosen

periodically, use Locte 242 for a long-term cure.

Go through a re-ghtening sequence periodically to ensure that all hardware is properly

tensioned.

Prduct Maintenance

CABLES:

UPHOLSTERY:

NUTS/BOLTS/FASTENERS:

GUIDE RODS:

ADJUSTMENTS / LOCKING PINS / TIGHTENING KNOBS:

ANTI-SKID SURFACES:

WARNING INSTRUCTION LABELS:

Prduct Service Tea;

Tel N: 01604 673029

Eail:

Wipe clean with a dust free rag. Lubricate with a Silicon or Teon based lubricant.

Check all pieces for signs of visible wear or damage.

Check springs in Snap Links and Pop Pins for proper tension and alignment.

If the spring scks or has lost its rigidity, replace it immediately.

Replace if they appear worn or become slippery.

Inspect and familiarize yourself with all safety warnings and other user informaon on

decals.

service@dywercuk

GUIDE RODS:

ADJUSTMENTS / LOCKING PINS / TIGHTENING KNOBS:

ANTI-SKID SURFACES:

WARNING INSTRUCTION LABELS:

Prduct Service Tea;

Tel N: 01604 673029

Eail:

Wipe clean with a dust free rag. Lubricate with a Silicon or Teon based lubricant.

Check all pieces for signs of visible wear or damage.

Check springs in Snap Links and Pop Pins for proper tension and alignment.

If the spring scks or has lost its rigidity, replace it immediately.

Replace if they appear worn or become slippery.

Inspect and familiarize yourself with all safety warnings and other user informaon on

decals.

service@dywercuk

4

spare part list....................................................................................................................5-9

Assembly step 1.............................................................................................................10-12

Assembly step 2.............................................................................................................13-18

Assembly step 3...........................................................................................................19-22

Assembly step 4...........................................................................................................23-26

Assembly step 5...........................................................................................................27-29

Assembly step 6...........................................................................................................30-32

Assembly step 7...........................................................................................................33-34

Assembly step 8...........................................................................................................35-36

Assembly step 9...........................................................................................................37-39

Assembly step 10...........................................................................................................40-42

Assembly step 11...........................................................................................................43-50

Spare Parts List

5

No. Serial No Descripon Note Qty

1 BK-3059-001 connecon tube 1

2 BK-3059-002 upright frame le1

3 BK-3059-003 upright frame right 1

4 BK-3059-004 bending tube le1

5 BK-3059-005 bending tube right 1

6 BK-3059-006 upper connecon tube 1

7 BK-3059-007 upper bending tube right 1

8 BK-3059-008 upper bending tube le1

9 BK-3059-009 hexagon bolt M10*75 50

10 BK-3059-010 lock nut M10 99

11 BK-3059-011 washer 10 207

12 BK-3059-012 chin up bar 1

13 BK-3059-013 upper plate 4

14 BK-3059-014 oval mat 5

15 BK-3059-015 plug 76*1.5 2

16 BK-3059-016 upright tube 2

17 BK-3059-017 tube with hole right 1

18 BK-3059-018 tube with hole le1

19 BK-3059-019 lower plate 4

20 BK-3059-020 sliding tube right 1

21 BK-3059-021 sliding tube le1

22 BK-3059-022 foot tube cover 2

23 BK-3059-023 end tube 2

24 BK-3059-024 hexagon bolt M10*80 14

25 BK-3059-025 lower base 2

26 BK-3059-026 upper base 2

27 BK-3059-027 guide rod 25*1850 2

28 BK-3059-028 lock sleeve 2

29 BK-3059-029 sliding sleeve 2

30 BK-3059-030 rubber pad with groove 60*26*45 2

31 BK-3059-031 safety hook right 1

32 BK-3059-032 safety hook le1

33 BK-3059-033 hexagon bolt M10*90 8

34 BK-3059-034 headless socket hexagon bolt M8*10 4

35 BK-3059-035 end cap 51*42.5*36.6L 2

36 BK-3059-036 check ring 60*48.5*27L 2

37 BK-3059-037 pipe 50*310*T0.5 2

6

Spare Parts List

No. Serial No Descripon Note Qty

38 BK-3059-038 buon head socket screw M12*40 4

39 BK-3059-039 spring washer 12 8

40 BK-3059-040 washer 12 16

41 BK-3059-041 barbell rod 1

42 BK-3059-042 inner pipe 48*298*2.5 2

43 BK-3059-043 rubber pad 60*26*25 2

44 BK-3059-044 upper connecon tube short 1

45 BK-3059-045 lower connecon tube 1

46 BK-3059-046 hang frame 1

47 BK-3059-047 guide rod hollow 2

48 BK-3059-048 rubber pad 2

49 BK-3059-049 hexagon bolt M10*25 13

50 BK-3059-050 hexagon bolt M10*95 3

51 BK-3059-051 hexagon bolt M10*55 2

52 BK-3059-052 hexagon bolt M12*30 5

53 BK-3059-053 double pulley bracket 1

54 BK-3059-054 hexagon socket buon head screws M8*16 2

55 BK-3059-055 back barbell plate holder 2

56 BK-3059-056 nut M8 12

57 BK-3059-057 pulley 95 22

58 BK-3059-058 rivet nut M10 2

59 BK-3059-059 hexagon bolt M10*45 17

60 BK-3059-060 pipe plug 50*50*T2.0 10

61 BK-3059-061 sleeve 25*160 2

62 BK-3059-062 wire 5x4130mm 1

63 BK-3059-063 ”-“ shape pulley frame 3

64 BK-3059-064 short bar 1

65 BK-3059-065 footplate 1

66 BK-3059-066 chain + 2 snap hook 5

67 BK-3059-067 wire 5*4185 1

68 BK-3059-068 pulley spacer sleeve 20*10.5*L20.5 16

69 BK-3059-069 pulley frame 1

70 BK-3059-070 wire 5*1705mm 1

71 BK-3059-071 hexagon socket buon head screws M10*20 1

72 BK-3059-072 wire 5*9715mm 1

73 BK-3059-073 pulley 50*310*T0.5 5

74 BK-3059-074 shield 1

75 BK-3059-075 barbell plate holder 6

7

Spare Parts List

No. Serial No Descripon Note Qty

76 BK-3059-076 hexagon bolt M8*20 16

77 BK-3059-077 washer 8 26

78 BK-3059-078 lock nut M8 7

79 BK-3059-079 core trainer 1

80 BK-3059-080 powder metallurgy sleeve 33.2*29*20*18 6

81 BK-3059-081 barbell rod cup 1

82 BK-3059-082 big washer 25*10*2.0 1

83 BK-3059-083 dip bar le1

84 BK-3059-084 dip bar right 1

85 BK-3059-085 barbell rod holder right 1

86 BK-3059-086 barbell rod holder le1

87 BK-3059-087 barbell rod holder short le1

88 BK-3059-088 barbell rod holder short right 1

89 BK-3059-089 barbell clamp collar 2

90 BK-3059-090 long bar 1

91 BK-3059-091 ship rod 1

92 BK-3059-092 hand belt 2

93 BK-3059-093 pull lidevice 1

94 BK-3059-094 T shape pin 10*100 1

95 BK-3059-095 leg curl tube 1

96 BK-3059-096 cover 25 6

97 BK-3059-097 bolt M4*5 6

98 BK-3059-098 hanging ring 1

99 BK-3059-099 socket head pipe plug 25*1.5 8

100 BK-3059-100 sleeve 60-50 4

101 BK-3059-101 T shape play pin 10 2

102 BK-3059-102 pulley rotaon frame 2

103 BK-3059-103 rotaon bearing 20*M10*67 2

104 BK-3059-104 spring washer 10 4

105 BK-3059-105 lock cap 25*M12*35 24

106 BK-3059-106 hang lever sha 25*M12*98 24

107 BK-3059-107 thumbstall 21*15*35 2

108 BK-3059-108 straight line bearing LM25UU 6

109 BK-3059-109 bearing 6005 4

110 BK-3059-110 spring collar 40 8

111 BK-3059-111 hook-le1

112 BK-3059-112 hexagon socket cap screws M6*16 4

113 BK-3059-113 hook-right 1

8

Spare Parts List

No. Serial No Descripon Note Qty

114 BK-3059-114 solid rod 25 1

115 BK-3059-115 spring washer 6 4

116 BK-3059-116 50-70 inner plug 50*70*2.0 2

117 BK-3059-117 inner tube 25*2*295 2

118 BK-3059-118 stainless steel tube-310 50*0.8*310 2

119 BK-3059-119 barbell bar plug 51*42.5*36.6L 2

120 BK-3059-120 inner cap 60*48.5*27L 2

121 BK-3059-121 spring washer 8 2

122 BK-3059-122 rubber gasket 70*50*10 2

123 BK-3059-123 buery clip 50 8

124 BK-3059-124 lining 50-25 4

125 BK-3059-125 wire-ball head 3

126 BK-3059-126 wire-ball head part 3

127 BK-3059-127 hexagon socket cap screws M5*25 3

128 BK-3059-128 handle cover 32*180 4

129 BK-3059-129 handlebar grip 8*100 4

130 BK-3059-130 stainless steel tube 50*0.8*200 6

131 BK-3059-131 barbell bar tube 48*1.5*198 6

132 BK-3059-132 inner support cap 70*44.8*25.5*30 6

133 BK-3059-133 outside support cap 50*44.8*25.5 6

134 BK-3059-134 hexagon socket buon head screws M8*20 6

135 BK-3059-135 nut M8 8

136 BK-3059-136 rotaon welidng 1

137 BK-3059-137 powder metallurgy sleeve 50*25*15 2

138 BK-3059-138 out hexagon bolt M12*25 2

139 BK-3059-139 rotaon bearing 25*M12*77 1

140 BK-3059-140 pull sleeve 1

141 BK-3059-141 locking spring knob M10 1

142 BK-3059-142 straight tube 25*150 2

143 BK-3059-143 straight tube-2 25*130 2

144 BK-3059-144 lock nut M12 1

145 BK-3059-145 sponge end cap-inner 2

146 BK-3059-146 100 sponge 100*180 2

147 BK-3059-147 sponge end cap-outsidse 2

148 BK-3059-148 hexagon socket buon head M8*25 2

149 BK-3059-149 pull pin 10 1

150 BK-3059-150 handle cover 32*130 2

Spare Parts List

9

0 1 6 7 8 9 10 11 12 13 14 152 3 4 5

cm

No. Serial No Descripon Note Qty

151 handle cover 25*150 4

152 hexagon socket plain head bolt M12*25 6

153 stainless steel bushing 25*57 6

154 tube plug 48*2 2

155 short safety catch outside rubber-open 85mm 1

156 short safety catch outside rubber 85mm 1

157 long safety catch outside rubber 387mm 2

158 spring collar 28 2

159 inner pipe 1

160 inner sha2

161 washer 33*12*3 2

162 bearing 6001-2RS 2

163 bearing sleeve 2

164 T shape bolt 6.3*50.5 2

165 Tshape bush 13*6.4*10.5 4

166 U shape fastener 2

167 check ring 5 2

168 powder metallurgy sleeve 20*10.5*L15 4

169 1

170 hexagon bolt M10*70 2

BK-3059-151

BK-3059-152

BK-3059-153

BK-3059-154

BK-3059-155

BK-3059-156

BK-3059-157

BK-3059-158

BK-3059-159

BK-3059-160

BK-3059-161

BK-3059-162

BK-3059-163

BK-3059-164

BK-3059-165

BK-3059-166

BK-3059-167

BK-3059-168

BK-3059-169 hexagon bolt M8*60

BK-3059-170

33*22*35

Assembly Step-1Drawing

10

1 Fix bending tube le-4 fastening on upright frame le-2 using M10x75 hexagon bolt-9, 10

washer-11 and M10 lock nut-10.

2 Fix bending tube right-5 fastening on upright frame right-3 using M10x75 hexagon bolt-9, 10

washer-11 and M10 lock nut-10.

3 Connect connecon tube-1,upright frame le-2 and upright frame right-3 using M10x75 hexagon

bolt-9, 10 washer-11 and M10 lock nut-10.

4 Fix upper connecon tube-6 fastening on upright frame using M10x75 hexagon bolt-9, 10

washer-11 and M10 lock nut-10.

5 Fix upper bending tube le-8 fastening on upright frame le-2 using M10x75 hexagon bolt- 9, 10

washer-11 and M10 lock nut-10.

6 Fix upper bending tube right-7 fastening on upright frame right-3 using M10x75 hexagon bolt-9,

10 washer-11 and M10 lock nut-10.

11

8

2

6

4

1

5

3

7

9

10

11

9

9

9

10

9

10

9

9

9

No.

Descripon

Note

Qty.

1

connecon tube

1

2

upright frame le

1

3

upright frame right

1

4

bending tube le

1

5

bending tube right

1

6

upper connecon tube

1

7

upper bending tube right

1

8

upper bending tube le

1

9

hexagon bolt

M10*75

16

10

lock nut

M10

16

11

washer

10

32

12

1

58

60

upright frame right

QTY: 1PCS/SET

upright frame left

QTY: 1PCS/SET

connection tube

QTY: 1PCS/SET

No.

Descripon

Note

Qty.

3

upright frame right

1

14

oval mat

1

15

plug

76*1.5

1

56

nut

M8

6

No.

Descripon

Note

Qty.

2

upright frame le

1

14

oval mat

1

15

plug

76*1.5

1

56

nut

M8

6

No.

Descripon

Note

Qty.

1

connecon tube

1

58

rivet nut

M10

2

60

pipe plug

50*50*t2.0

2

Strawing

13

1

Fix sliding tube le-21 on tube with hole le-18.

2

Fix sliding tube right-20 on tube with hole right-17.

3 Fix upright tube-16 and tube with hole le-18 tube with hole right-17 fastening on assembly

step-1 using M10x75 hexagon bolt-9, 10 washer-11, M10 lock nut-10, upper plate-13 and lower

plate-19.

4 Fix end tube-23 fastening on upper plate-13 using M10x75 hexagon bolt-9, 10 washer-11 and

M10 lock nut-10.

5 Fix foot tube cover-22 fastening on lower plate-19 using M10x75 hexagon bolt-9, 10 washer-11

and M10 lock nut-10.

6 Fix chin up bar-12 fastening on upper plate-13 using M10x80 hexagon bolt-24, 10 washer- 11

and M10 lock nut-10.

,

14

12

13

16

18

17

19

21

20

22

9

24

11

10

11

9

9

24 24

24

9

24

24

23

23

11 10

11

11

9

9

No.

Descripon

Note

Qty.

No.

Descripon

Note

Qty.

9

hexagon bolt

M10*75

34

18

tube with hole le

1

10

lock nut

M10

40

19

lower plate

4

11

washer

10

80

20

sliding tube right

1

12

chin up bar

1

21

sliding tube le

1

13

upper plate

4

22

foot tube cover

2

16

upright tube

2

23

end tube

2

17

tube with hole right

1

24

hexagon bolt

M10*80

6

Assembly Step - 2 Enlarged Drawing

15

9

9

10

22

19

19

17

11

60

18

17

14

22

60

16

tube with hole left

QTY: 1PCS/SET

tube with hole right

QTY: 1PCS/SET

foot tube cover

QTY: 2PCS/SET

use glue to glue foot tube cover

No.

Descripon

Note

Qty.

22

foot tube cover

1

14

oval mat

1

No.

Descripon

Note

Qty.

17

tube with hole right

1

60

pipe plug

50*50*t2.0

2

No.

Descripon

Note

Qty.

18

tube with hole le

1

60

pipe plug

50*50*t2.0

2

12

61

99

96

97

98

78

77

21

100

101

11

59

10

102

57

80

103

49

104

17

QTY: 1PCS/SET

chin up bar

No.

Descripon

Note

Qty.

12

chin up bar

1

61

sleeve

25*160

2

96

cover

25

2

97

bolt

M4*5

2

98

hanging ring

1

77

washer

8

2

78

lock nut

M8

2

99

socket head pipe plug

25*1.5

4

No.

Descripon

Note

Qty.

21

sliding tube le

1

100

sleeve

60-50

2

101

T shape play pin

10

1

11

washer

10

6

59

hexagon bolt

M10*45

2

10

lock nut

M10

2

102

pulley rotaon frame

1

57

pulley

95

2

80

powder metallurgy sleeve

33.2*29*20*18

2

103

rotaon bearing

20*M10*67

1

49

hexagon bolt

M10*25

2

104

springwasher

10

2

sliding tube left

QTY: 1PCS/SET

20

49

16

105

100

101

104

11

11

59

100

80

80

103

102

57

11 10

106

60

18

sliding tube right

QTY: 1PCS/SET

upright tube

QTY: 2 PCS/SET

No.

Descripon

Note

Qty.

20

sliding tube right

1

100

sleeve

50-60

2

101

T shape play pin

10

1

11

washer

10

6

59

hexagon bolt

M10*45

2

10

lock nut

M10

2

57

pulley

95

2

103

rotaon bearing

20*M10*67

1

102

pulley rotaon frame

1

80

powder metallurgy sleeve

33.2*29*20*18

2

49

hexagon bolt

M10*25

2

104

spring washer

10

2

No.

Descripon

Note

Qty.

16

upright tube

1

105

lock cap

25*M12*35

12

106

hang lever sha

25*M12*98

12

60

pipe plug

50*50*t2.0

2

Assembly Step-3Drawing

19

1 Fix lower base-25 fastening on lower plate using M10x90 hexagon bolt-33, 10 washer-11 and

M10 lock nut-10.

2 Fix upper base-26 fastening on upper plate using M10x90 hexagon bolt-33, 10 washer-11 and

M10 lock nut-10.

3 Guide rod-27 in turn through lock sleeve-28, sliding sleeve-29, rubber pad-43, safety hook le- 32

and rubber pad with groove-30 fastening on base using M8x10 socket set screw-34

4 Barbell rod-41 in turn through sliding sleeve-29, check ring-36, inner pipe-42, pipe-37 and end cap-

35 fastening using M12x40 buon head socket screw-38, 12 spring washer-39 and 12 washer-

40, then t on barbell clamp collar-89.

5 Guide rod -27 in turn through lock sleeve-28, sliding sleeve-29, rubber pad-43, safety hook right-

31 and rubber pad with groove-30 fastening on base using M8x10 socket set screw-34.

20

33 11

26

34

10

36

42

37

35 40

39 38

25

25

27

29

28

30

31

32

29

41

33

10

33

10

11

28

33

26

30

38

89

43

No.

Descripon

Note

Qty.

No.

Descripon

Note

Qty.

10

lock nut

M10

8

34

headless socket hexagon bolt

M8*10

2

11

washer

10

16

35

end cap

51*42.5*36.6L

2

25

lower base

2

36

check ring

60*48.5*27L

2

26

upper base

2

37

pipe

50*310*T0.5

2

27

guide rod

25*1850

2

38

buon head socket screw

M12*40

2

28

lock sleeve

2

39

spring washer

12

2

29

sliding sleeve

2

40

washer

12

2

30

60*26*45

2

41

barbell rod

1

31

safety hook right

1

42

inner pipe

48*298*2.5T

2

32

safety hook le

1

43

rubber pad

60*26*25

2

33

hexagon bolt

M10*90

8

89

barbell clamp collar

2

rubber pad with groove

Other manuals for BPMFSRD

1

Table of contents

Other body Power Fitness Equipment manuals

body Power

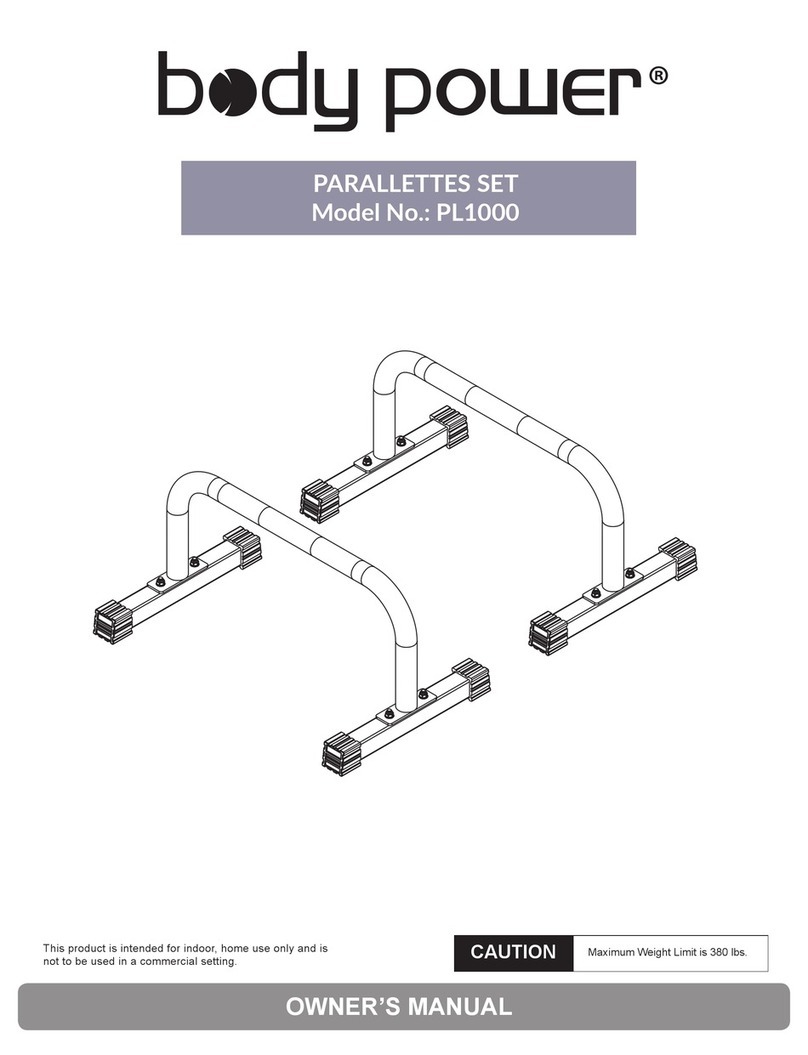

body Power PARALLETTES SET PL1000 User manual

body Power

body Power BK-4006 User manual

body Power

body Power PT728 User manual

body Power

body Power BR2998 User manual

body Power

body Power IT 6000 User manual

body Power

body Power BPMFSRD User manual

body Power

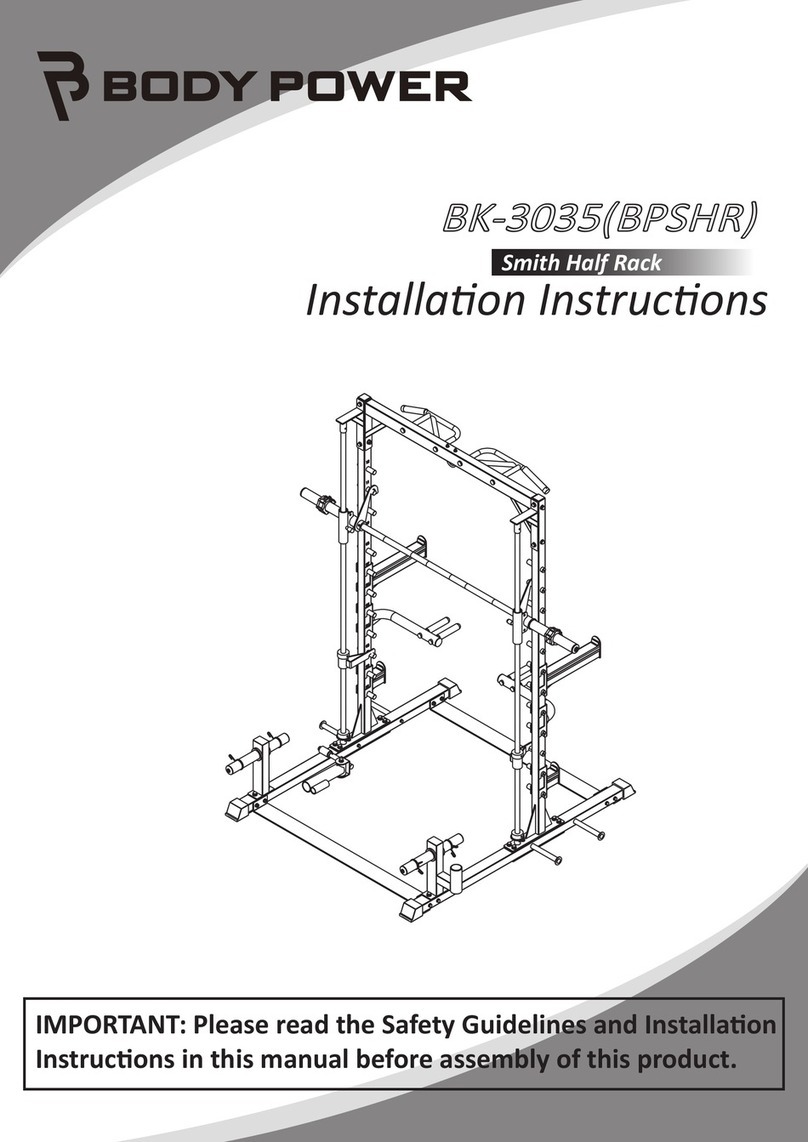

body Power BK-3035(BPSHR) User manual

body Power

body Power BK-3018 User manual

body Power

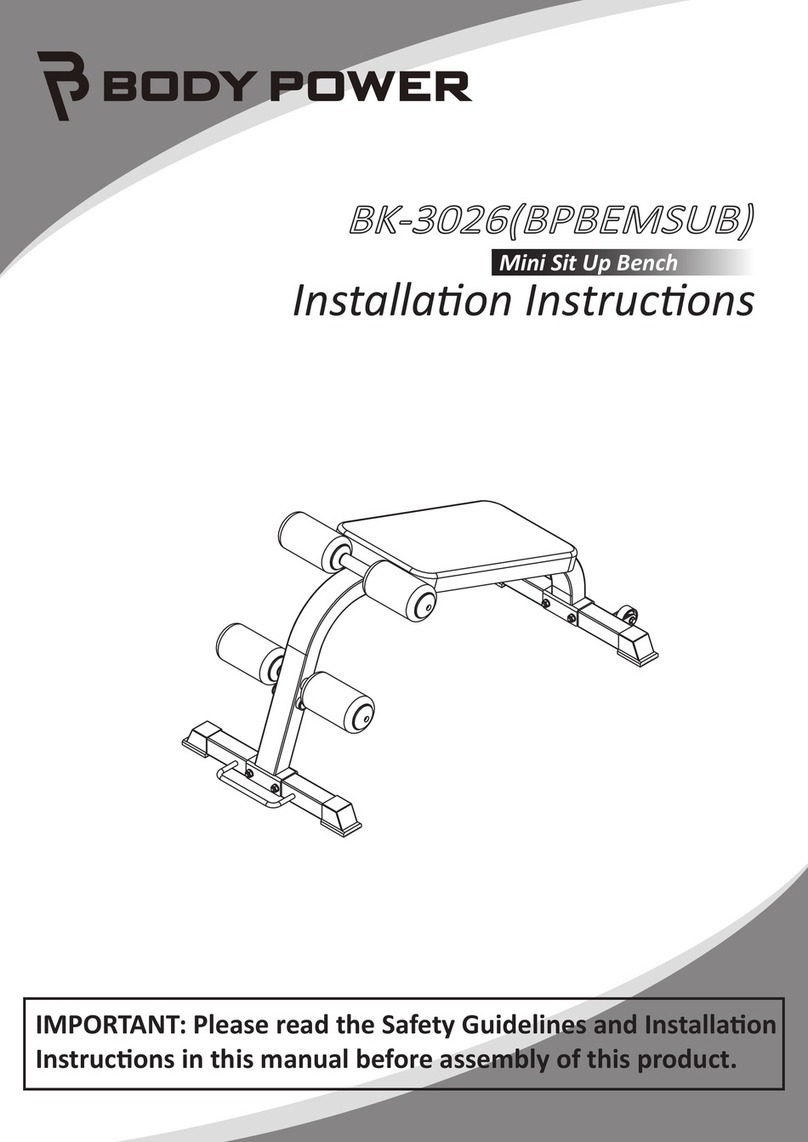

body Power BK-3026 User manual

body Power

body Power BCB5280 User manual