BOERPLAY PB Rebo Bench model 313 User manual

Other BOERPLAY Outdoor Furnishing manuals

BOERPLAY

BOERPLAY PB Picnic Table model 321 User manual

BOERPLAY

BOERPLAY PB Picnic Set model 314 User manual

BOERPLAY

BOERPLAY PB Reboblokbank 313 User manual

BOERPLAY

BOERPLAY PKNE103.250 User manual

BOERPLAY

BOERPLAY PB Parkbank 340 User manual

BOERPLAY

BOERPLAY PKNE103.190 User manual

BOERPLAY

BOERPLAY 311 User manual

BOERPLAY

BOERPLAY PKNE040.074 User manual

BOERPLAY

BOERPLAY PKNE103.110 User manual

BOERPLAY

BOERPLAY PKNE103.240 User manual

Popular Outdoor Furnishing manuals by other brands

Belleze

Belleze 014-HG-20074 manual

Hatteras Hammocks

Hatteras Hammocks DCA1-K-HH instructions

Kozyard

Kozyard Morgan Aluminum Pergola Assembly manual

Lemeks

Lemeks Palmako PA120-5959 Assembly, installation and maintenance manual

OLT

OLT 24 Assembly manual

forest-style

forest-style HACIENDA 2354 Building instructions

Courtyard Creations

Courtyard Creations RUS0188-WM Assembly instructions

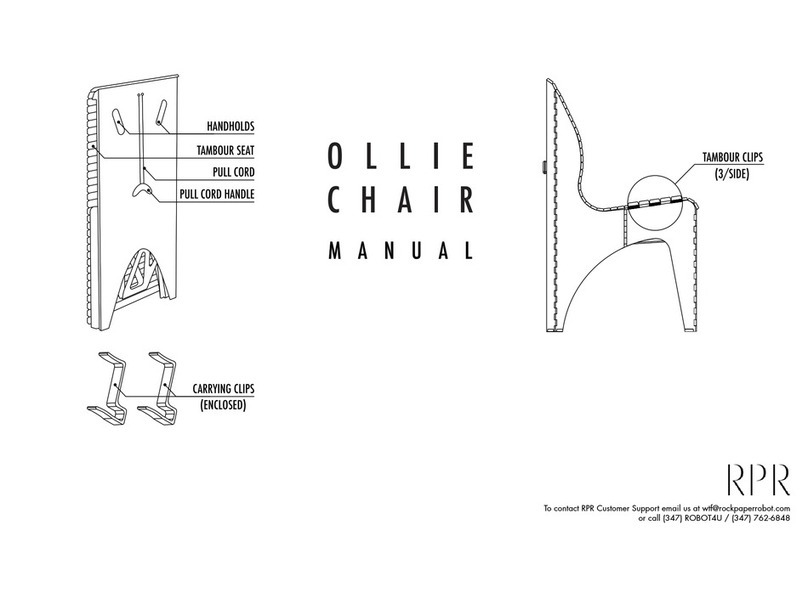

RPR

RPR OLLIE CHAIR manual

kingsley-bate

kingsley-bate MC-55 Assembly instructions

Weltevree

Weltevree Carrier product manual

Grange Fencing

Grange Fencing Elite Arch Assembly instructions

Grosfillex

Grosfillex AUVENT YR14 Assembly instructions