6

6. To stop engine, turn key OFF (counterclockwise)

and place gear shift lever in NEUTRAL, setting

brake if necessary. Remove ignition key when trac-

tor is not in use.

EMERGENCY STARTING

In the event of electrical failure, remove the genera-

tor belt and proceed as follows:

1. Check PTO safety clutch (should be in OFF posi-

tion) and gear shift (should be in NEUTRAL). Turn

ignition key clockwise.

2. Pull choke knob all the way out (to fully close

choke). Experience will indicate need for more or

less choking due to variations in temperature, grade

of fuel, etc.

3. Turn throttle knob counterclockwise, if necessary,

to unlock it. Pull throttle knob out about half-way

until after engine has started, then adjust to desired

RPM and lock at this setting, if desired, by turning

knob clockwise.

4. Wind the starter rope around the starter pulley.

Give a quick, steady pull on starter rope. Repeat,

if necessary, until engine starts.

5. Choke should be partially opened (knob pushed

forward) as soon as engine starts and then gradually

pushed all the way forward as the engine warms up.

In normal operation, choke knob should be in OPEN

(forward) position for best engine efficiency and fuel

economy.

6. To stop engine, turn key OFF (counterclockwise)

and place gear shift lever in NEUTRAL, setting brake

if necessary. Remove ignition key when tractor is

not in use.

7. If engine fails to start, recharge or replace bat-

tery.

STOPPING THE ENGINE

1. If the engine has been operating under a heavy

load and is hot, do not stop it suddenly. Allow the

engine to idle for approximately three to five min-

utes. This will reduce the engine temperature more

quickly and evenly than stopping the engine.

2. Turn ignition switch off.

RUN – IN PERIOD

Before operating the tractor at full load, it should

be operated at one-half throttle for approximately one-

half hour with no load applied. After the first half

hour of operation, run the tractor at full throttle with

no load applied for an additional one-half hour.

Attach a light load to the tractor. Operate the trac-

tor with light load for a period of three hours at full

throttle. The tractor is now ready for maximum

load operation.

NOTE

Always operate the tractor at full throttle

when heavy and light work loads are applied.

Use gear ratios to obtain safe and desirable

ground speeds. The governor will control

for any increase or decrease in power re-

quirement.

PREVENTATIVE MAINTENANCE

Operational maintenance and preventative mainte-

nance are synonymous. When neglected, unneces-

sary down time and costly repairs can result. A

little time spent each day by the operator on pre-

ventative maintenance will lead to longer operating

life of the HUSKY.

The removal of debris, dirt and grease accumula-

tions are considered normal maintenance practices

and can help discover minor difficulties before they

become troublesome.

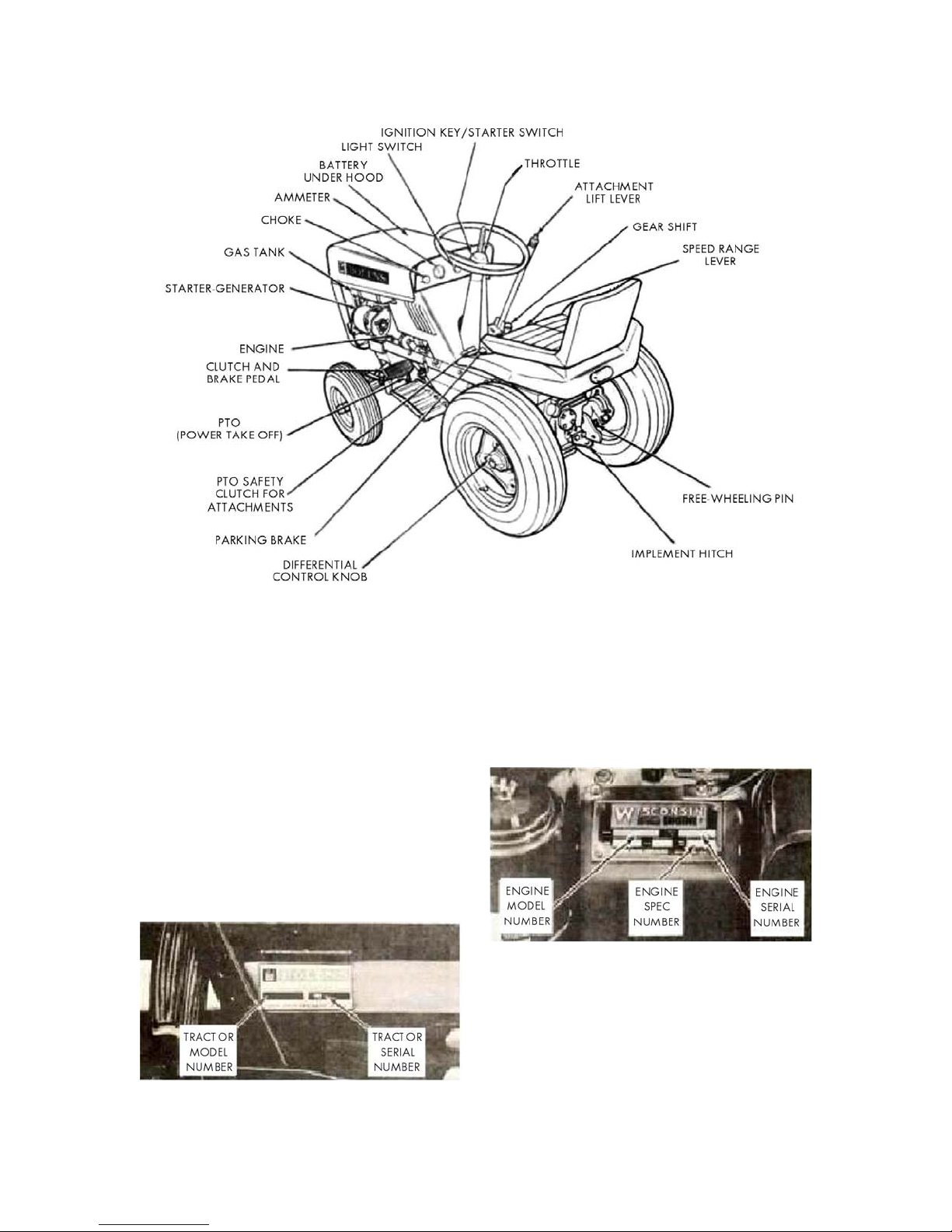

BATTERY (Fig. 7) - Keep cables and terminals clean

and apply a light coat of vaseline or oil for protec-

tion. Check battery bracket for corrosion and keep

clean. Check water for proper level. Never loosen

hold down clamps until you have removed battery

cables from the battery post. Always remove ground

(-) cable first.

FUEL TANK (Fig. 8) - Fill with clean, fresh gaso-

line of regular grade. DO NOT MIX OIL WITH GAS-

OLINE! Check to see that vent hole in fuel tank cap

is not plugged.

AIR CLEANER (Fig. 9) - Dry Type - Refer to en-

closed Engine booklet for instructions.

SPARK PLUG - Clean area around spark plug

before removing plug. The correct gap setting is .025 inch.

Figure 7