12.3. CYCLE BREAKING ........................................................................................................33

12.4. SPEED ADJUSTING OF THE ARM LOWERING......................................................................33

13. AUTOMATIC MODE ..........................................................................................................34

13.1. SAFETY NOTES ...........................................................................................................34

13.2. CYCLE PRESET ...........................................................................................................34

13.2.1. Preset............................................................................................................................. 34

13.2.2. Program storing ............................................................................................................. 35

13.2.3. Program selection........................................................................................................... 35

13.2.4. Editing ........................................................................................................................... 36

13.2.5. New Preselection inserting .............................................................................................. 37

13.2.6. Clearing memory ............................................................................................................ 38

13.3. AUTOMATIC CYCLE WITH MATERIAL CUTTING ...................................................................39

13.4. AUTOMATIC CYCLE WITHOUT MATERIAL CUTTING..............................................................39

13.5. CYCLE BREAKING ........................................................................................................40

13.6. SETTING THE SPEED OF THE SAW ARM LOWERING ............................................................40

14. SERVICE MENU................................................................................................................41

14.1. ENTRANCE TO SERVICE MENU .......................................................................................41

14.2. VICE PARAMETERS ......................................................................................................41

14.3. COOLING PARAMETERS ................................................................................................41

14.3.1. Cooling type ................................................................................................................... 41

14.3.2. Cooling mode ................................................................................................................. 42

14.4. CUTTING PARAMETERS.................................................................................................42

14.5. SWARF CONVEYOR OPERATION .....................................................................................43

14.6. MACHINE PARAMETERS ................................................................................................43

14.7. LANGUAGE .................................................................................................................44

14.8. LENGTH UNITS SELECTION ............................................................................................44

14.9. REGULATOR ...............................................................................................................44

14.10. LENGTH CORRECT .......................................................................................................44

14.11. SERVICE MENU CLOSING ..............................................................................................45

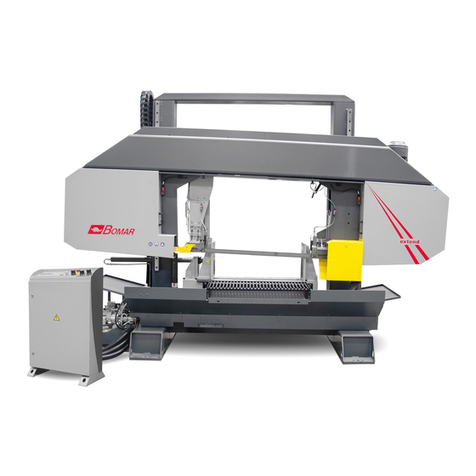

15. BLANKS REMOVING FROM THE BAND SAW...................................................................46

15.1. SAFETY NOTES ...........................................................................................................46

15.2. HANDLING AGENT SELECTION........................................................................................46

15.3. BLANKS REMOVING ......................................................................................................46

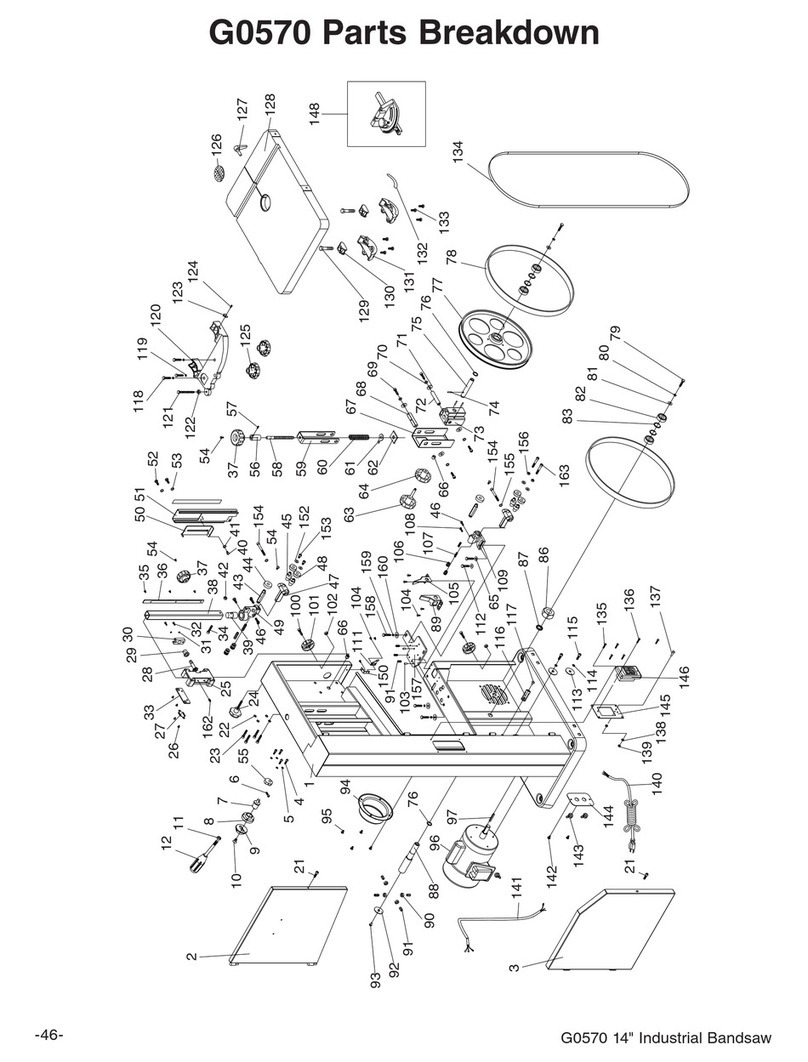

16. SELECTION AND REPLACEMENT OF THE SAW BAND ...................................................47

16.1. SAFETY NOTES ...........................................................................................................47

16.2. SAW BAND SIZE...........................................................................................................47

16.3. SELECTION OF THE SAW BAND TOOTH SYSTEM:................................................................47

16.4. SAW BAND RUNNING -IN...............................................................................................49

16.5. SAW BAND DISMANTLING ..............................................................................................50

16.6. SAW BAND INSTALLATION .............................................................................................51

16.7. SAW BAND STRETCHING AND INSPECTION .......................................................................52

16.7.1. Saw band stretching........................................................................................................ 52

16.7.2. Saw band inspection ....................................................................................................... 52

17. COOLING AGENTS AND CHIPS DISPOSAL .....................................................................53

17.1. SAFETY NOTES ...........................................................................................................53

17.2. COOLING LIQUID PREPARATION .....................................................................................53

17.3. COOLANT DEVICE INSPECTION.......................................................................................54

17.4. CHIPS DISPOSAL .........................................................................................................55

18. GREASES AND OILS........................................................................................................56