M3452 Complete

4

1. INTRODUCTION............................................................................................................. 7

1.1. Who Should Use...........................................................................................................7

1.2. Purpose and Scope......................................................................................................7

1.3. Manual Version an d Change Record...........................................................................7

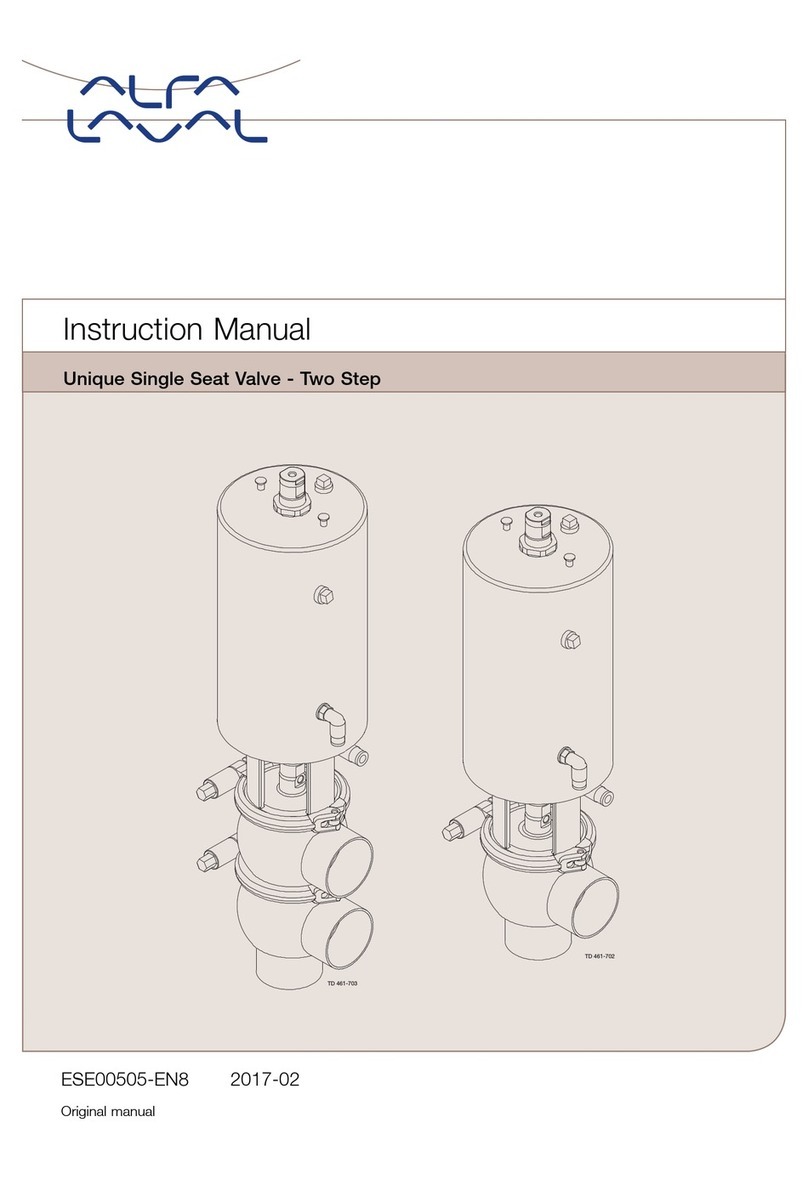

Figure 1-1: Typical M3452 Complete Module...............................................................................7

1.4. Symbol Conventions Used in this Manual and on Equipment.......................................8

2. PRODUCT DESCRIPTION /FEATURES ............................................................................. 9

2.1. Related Products..........................................................................................................9

2.2. Part Number Breakdown ..............................................................................................9

Table 2-1: Part Number Breakdown.............................................................................................9

Table 2-2: AC Voltage Rating.......................................................................................................9

Table 2-3: Resistors....................................................................................................................10

Table 2-4: Chassis Codes ..........................................................................................................10

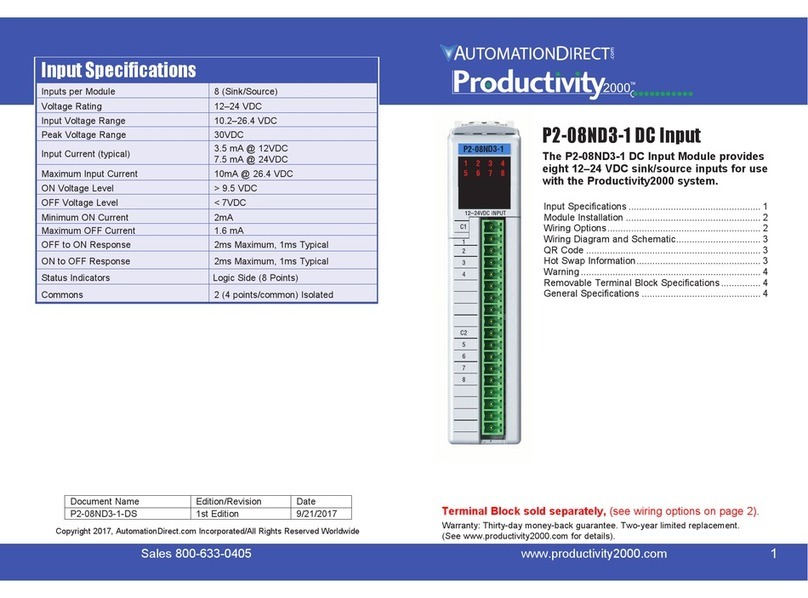

2.3. General Specifications................................................................................................10

Table 2-5: Specifications ............................................................................................................10

2.4. General Precautions and Safety Warnings.................................................................11

3. INSTALLATION INSTRUCTIONS...................................................................................... 13

3.1. Environment...............................................................................................................13

3.2. Unpacking ..................................................................................................................13

3.3. Mounting.....................................................................................................................13

3.3.1. Mounting the M3452 ...........................................................................................................13

Figure 3-2: Recommended Placement and Required Minimum Mounting Clearances .............14

3.4. Wiring and Customer Connections.............................................................................15

3.4.1. Power Wiring.......................................................................................................................15

Figure 3-3: Power Termination Information................................................................................15

Table 3-1: Power Wiring Specifications......................................................................................15

Table 3-2: DC Bus Wiring Specifications....................................................................................16

3.4.2. Control Interface Wiring ......................................................................................................16

Figure 3-4: Control Termination Information...............................................................................16

Table 3-3: Control Wiring Specifications ....................................................................................17

3.5. Typical Configurations................................................................................................18

Figure 3-4: Field Connections.....................................................................................................18

4. OPERATION ............................................................................................................... 20

4.1. Functional Description................................................................................................20

4.2. Features.....................................................................................................................20

4.2.1. Indicators.............................................................................................................................20

4.3. Startup........................................................................................................................20

4.3.1. Pre-Power Checks ..............................................................................................................20

4.3.2. Startup Procedure and Checks...........................................................................................21

4.4. Operational Adjustments ............................................................................................21

5. MAINTENANCE AND TROUBLESHOOTING ...................................................................... 22

5.1. Periodic Testing..........................................................................................................22

5.2. Maintenance Items.....................................................................................................22

5.3. Troubleshooting..........................................................................................................22

5.3.1. Control power light not illuminated......................................................................................22

5.3.2. DC bus light not illuminated ................................................................................................22

5.3.3. Blown DC bus fuse..............................................................................................................23

5.3.4. Fan runs constantly.............................................................................................................23

5.3.5. Fan doesn’t run ...................................................................................................................23