bonitron M3528M4 User manual

Model M3528M4

Battery Voltage Monitor Module

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has over many competitors is combined

on-site engineering labs and manufacturing facilities, which allows the engineering team to have

immediate access to testing and manufacturing. This not only saves time during prototype

development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3528M4

4

This page intentionally left blank

Table of Contents

5

1. INTRODUCTION..........................................................................................................................7

1.1. Who Should Use...........................................................................................................................7

1.2. Purpose and Scope........................................................................................................................7

1.3. Manual Version and Change Record............................................................................................7

Figure 1-1: Model M3528M4......................................................................................................................7

2. PRODUCT DESCRIPTION............................................................................................................9

2.1. Related Products........................................................................................................................... 9

2.2. Part Number Breakdown ..............................................................................................................9

2.3. General Specifications..................................................................................................................9

Table 2-1: General Specifications Table......................................................................................................9

2.4. General Precautions and Safety Warnings .................................................................................10

3. INSTALLATION INSTRUCTIONS................................................................................................11

3.1. Environment ...............................................................................................................................11

3.2. Unpacking................................................................................................................................... 11

3.3. Wiring and Customer Connections.............................................................................................11

Figure 3-1: Typical Interconnection ..........................................................................................................12

3.3.1. Power Wiring....................................................................................................................13

3.3.2. I/O Wiring.........................................................................................................................13

Table 3-1: Wiring Specifications TB1.......................................................................................................13

Table 3-2: Wiring Specifications TB2.......................................................................................................13

Table 3-3: Wiring Specifications TB3.......................................................................................................14

Table 3-4: Wiring Specifications TB4.......................................................................................................14

4. OPERATION..............................................................................................................................15

4.1. Functional Description ...............................................................................................................15

4.2. Features....................................................................................................................................... 15

4.2.1. Operation ..........................................................................................................................15

4.2.2. Connectors........................................................................................................................ 16

4.2.3. Jumpers............................................................................................................................. 17

Figure 4-1: JP1...........................................................................................................................................17

Figure 4-2: JP2...........................................................................................................................................17

4.2.4. Ribbon Connector.............................................................................................................18

Table 4-1: Blink Patterns...........................................................................................................................18

5. TROUBLESHOOTING ................................................................................................................19

5.1. Status Relays won’t close ...........................................................................................................19

5.2. Status LED remains blinking after changing the blown fuse .....................................................19

5.3. Battery Overvoltage....................................................................................................................19

5.4. Battery Undervoltage..................................................................................................................19

5.5. Over Temperature.......................................................................................................................19

6. ENGINEERING DATA................................................................................................................21

6.1. Ratings........................................................................................................................................21

6.2. Dimensions and Mechanical Drawings ......................................................................................21

Figure 6-1: M3528M4 Dimensional Outline Drawing ..............................................................................21

Figure 6-2: M3528D4 Battery Monitoring Panel Mounting Information..................................................21

M3528M4

6

This page intentionally left blank

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intended for use by anyone who is responsible for integrating, installing,

maintaining, troubleshooting, or using this equipment with any DC energy storage system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the Model M3528M4 Battery Voltage Monitor Module. It

will provide the user with the necessary information to successfully install, integrate, and

use the M3528M4.

In the event of any conflict between this document and any publication and/or

documentation related to the DC storage system, the latter shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Rev 00 is the initial release of this manual.

About Bonitron Section was updated in Rev 00a.

The manual template was updated in Rev 00b.

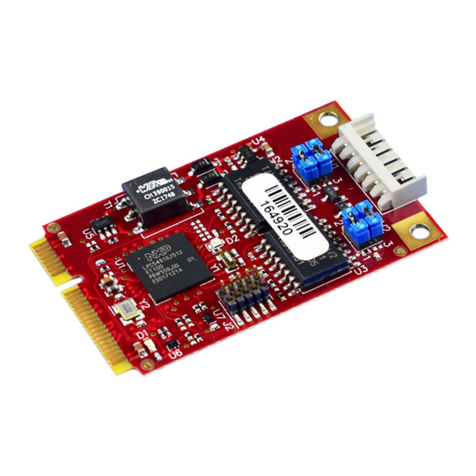

Figure 1-1: Model M3528M4

M3528M4

8

This page intentionally left blank

User’s Manual

9

2. Product Description

DC voltage monitoring is required for battery storage systems to ensure individual battery

voltages are within safe tolerances. If a battery discharges too far, individual cells may change

polarity, causing permanent damage to the batteryand reducing its lifetime. A battery subjected

to an overvoltage can produce harmful or explosive gases and lead to dangerous conditions

and severe battery damage. Batteries, capacitors, and any other system can be damaged by

the voltage across them rising too high. The M3528M4 voltage monitor is designed to monitor

DC voltage levels and signal the user if the voltage departs a set range.

The M3528M4 monitors a series of 12V batteries and signals the user if:

One or more of the battery’s voltages fall below the undervoltage set point

One or more of the battery’s voltages exceeds the overvoltage set point

A fuse is blown

Over-temperatures exist

2.1. RELATED PRODUCTS

This product is designed for use with battery strings connected in series to attain a higher

terminal voltage, such as the Bonitron M3528B Battery Storage Modules.

The M3528D4 Local Display is used with this monitor board to allow for a visual indication

of the storage system status for mounting in a door or access cover of the storage system.

Contact your distributor for more information.

2.2. PART NUMBER BREAKDOWN

The Base Model Number, M3528, indicates that the unit is related to storage system

components. ‘M’ specifies a monitor board, and ‘4’ specifies this particular unit.

There are no options at this time.

2.3. GENERAL SPECIFICATIONS

Table 2-1: General Specifications Table

PARAMETER

SPECIFICATION

Power

24 VDC ± 10%, 200mA

Monitor Voltages

10 batteries (0-15VDC) each

Outputs

(10) Good Battery Open Collector (24VDC, 150mA Max)

(11) LED driver outputs for remote LED display

(1) Not Undervoltage - Open Collector (24VDC, 150mA Max)

(1) Not Overvoltage- Open Collector (24VDC, 150mA Max)

(1) Not Overtemp - Open Collector (24VDC, 150mA Max)

(1) Not Blown fuse - Open Collector (24VDC, 150mA Max)

(2) Status - Relay output (250VDC, 230VAC, 3A MAX.)

(1) Not Under Voltage Relay output (250VDC, 230VAC, 3A MAX.)

Inputs

(1) Reset –Active Low, Open Base (24VDC)

Local Indicators

Power, Status

Storage Temp

-20 to +65ºC

Operation Temp

0 to +40ºC

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and conductive dust

M3528M4

10

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

HIGH VOLTAGES MAY BE PRESENT !

FAILURE TO HEED THESE WARNINGS MAY

RESULT IN SERIOUS BODILY INJURY OR DEATH!

CAUTION!

NO USER-SERVICEABLE PARTS ARE CONTAINED WITHIN

THIS PRODUCT.INOPERABLE UNITS SHOULD BE

REPLACED OR RETURNED FOR EVALUATION AND/OR

REPAIR BY QUALIFIED TECHNICIANS.

BEFORE ATTEMPTING INSTALLATION OR REMOVAL OF

THIS PRODUCT ,BE SURE TO REVIEW ALL DRIVE AND/OR

RESISTIVE LOAD DOCUM ENTATION FOR PERTINENT

SAFETY PRECAUTIONS.

INSTALLATION AND /OR REM OVAL OF THIS PROD UCT

SHOULD ONLY BE ACCOMPLISHED BY A QUALIFIED

ELECTRICIAN IN ACCOR DANCE WITH NATIONAL

ELECTRICAL CODE OR EQUIVALENT REGULATIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

User’s Manual

11

3. INSTALLATION INSTRUCTIONS

CAUTION!

Installation and/or removal of this product should only be performed by a

qualified electrician in accordance with National Electrical Code or local codes

and regulations.

Proper installation of the Model M3528M4 Battery Voltage Monitor Module should be

accomplished following the steps outlined below. Please direct all installation and start up

inquiries regarding this product to your supplier or system integrator.

3.1. ENVIRONMENT

The installation site should be dry and clean without extreme temperatures.

3.2. UNPACKING

Upon receipt of this product, please verify that the product received matches the product

that was ordered and that there is no obvious physical damage to the unit. If the wrong

product was received or the product is damaged in any way, please contact the supplier

from which the product was purchased.

3.3. WIRING AND CUSTOMER CONNECTIONS

This sectionprovides information about thefield connection of the batteries and signal inputs

to the M3528M4 Voltage Monitor Module.

Be sure to review all pertinent system documentation as well as the power wiring information

in Section 3.4.1 before proceeding.

Refer to Table 3-1 for the maximum wire size accepted by the individual field connection

terminals. Wire types and sizes should be chosen in accordance with national and local

electrical codes to meet the voltage and current levels present for your application.

Figure 3-1 shows a typical interconnection of the M3528M4 with a DC voltage source and

I/O signals.

M3528M4

12

Figure 3-1: Typical Interconnection

Dwg: 090113 Rev: 20090417

User’s Manual

13

CAUTION!

Only qualified electricians should perform and maintain the interconnection

wiring of this product. All wiring should be done in accordance with National

Electrical Code or equivalent regulations.

3.3.1. POWER WIRING

Internal or external 24V 200mA.

3.3.2. I/O WIRING

The I/O connectors connect the unit to the internal batteries to be monitored and to

external signals used to indicate the state of the monitor voltage.

Table 3-1: Wiring Specifications TB1

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

TB1-1

Fuse terminal note(1)

12VDC to TB1-2 1mA

24

12

.5 Nm

TB1-2

Battery 10 (+)

12VDC to TB1-3 1mA

24

12

.5 Nm

TB1-3

Battery 10 (-)

Battery 9 (+)

12VDC to TB1-4 1mA

24

12

.5 Nm

TB1-4

Battery 9 (-)

Battery 8 (+)

12VDC to TB1-5 1mA

24

12

.5 Nm

TB1-5

Battery 8 (-)

Battery 7 (+)

12VDC to TB1-6 1mA

24

12

.5 Nm

TB1-6

Battery 7 (-)

Battery 6 (+)

12VDC to TB1-7 1mA

24

12

.5 Nm

TB1-7

Battery 6 (-)

Battery 5 (+)

12VDC to TB1-8 1mA

24

12

.5 Nm

TB1-8

Battery 5 (-)

Battery 4 (+)

12VDC to TB1-9 1mA

24

12

.5 Nm

TB1-9

Battery 4 (-)

Battery 3 (+)

12VDC to TB1-10 1mA

24

12

.5 Nm

TB1-10

Battery 3 (-)

Battery 2 (+)

12VDC to TB1-11 1mA

24

12

.5 Nm

TB1-11

Battery 2 (-)

Battery 1 (+)

12VDC to TB1-12 1mA

24

12

.5 Nm

TB1-12

Battery 1 (-)

12VDC to TB1-11 1mA

24

12

.5 Nm

Note (1): Fuse must be connected to the negative terminal of the batteries series.

Table 3-2: Wiring Specifications TB2

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

TB2-1

+24V

24VDC 200mA

24

12

.5 Nm

TB2-2

0V

24VDC 200mA

24

12

.5 Nm

M3528M4

14

Table 3-3: Wiring Specifications TB3

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

TB3-1

Battery 1 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-2

Battery 2 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-3

Battery 3 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-4

Battery 4 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-5

Battery 5 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-6

Battery 6 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-7

Battery 7 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-8

Battery 8 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-9

Battery 9 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-10

Battery 10 status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-11

Over Temperature

status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-12

Fuse status signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-13

Undervoltage status

signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-14

Overvoltage status

signal

Open Collector 24V 150mA (2)

24

12

.5 Nm

TB3-15

External Reset signal

Dry Contact 24V, 10mA

24

12

.5 Nm

TB3-16

24V com

24VDC 200mA

24

12

.5 Nm

Note (2): Outputs have an internal 4.7k pull up resistor to the 24V+ power supply.

Table 3-4: Wiring Specifications TB4

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

TORQUE

TB4-1

Thermostat Input -1

Dry contact 24VDC 20mA

24

12

.5 Nm

TB4-2

NC

24

12

.5 Nm

TB4-3

Thermostat Input -2

Dry contact 24VDC 20mA

24

12

.5 Nm

TB5-1

Status Output 1

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-2

Status Output 1

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-3

Status Output 2

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-4

Status Output 2

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-5

Undervoltage Output

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-6

Undervoltage Output

pole

Relay Output

250VDC, 230VAC, 3A MAX.

24

12

.5 Nm

TB5-7

No Connection

TB5-8

No Connection

User’s Manual

15

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3528M4 Module monitors nine or ten (0-15VDC batteries) voltages connected to the

input terminals TB2 (2 - 12). The module monitors each battery’s voltage, and indicates if

the voltage is outside a predefined voltage range. Individual batteries are indicated, along

with the specificfault. There are remote monitoring outputsfor connection to a PLC or other

supervisory system, as well as relay outputs to allow for control functions of ancillary

equipment. The unit has a ribbon connector that can be used to drive the Bonitron M3528D4

display panel for remote mounting of indicators.

4.2. FEATURES

4.2.1. OPERATION

4.2.1.1. UNDERVOLTAGE

When one or more of the batteries voltages fall below the undervoltage set

point for 12 seconds, undervoltage output relay opens and the status LED

blinks (see Blink Pattern Table 4-1), theundervoltage signal goes lowand one

or more of the display LEDs turn on indicating which battery falls under the

undervoltage setpoint. The fault will latch until the batteries voltages rise

above the undervoltage set point and the user pushes the reset button on the

front panel. Then the undervoltage output relay closes and the status LED

turns on. An undervoltage is indicated by an individual battery terminal

voltage of 9V.

4.2.1.2. OVERVOLTAGE

When one or more of the batteries voltages rise above the overvoltage

setpoint, the status output relays open, the Status LED blinks (see Blink

Pattern Table 4-1), the Overvoltage signal goes low, and one or more of the

display LEDs turn on indicating which battery hasrisen above the overvoltage

setpoint. The Fault will latch until the batteries voltages fall under the

undervoltage set point and the user pushes the reset button onthe front panel.

Then the status output relay closes and the status LED turns on. An

Overvoltage is indicated by an individual battery terminal voltage of 15.2V

±0.1V.

4.2.1.3. OVERVOLTAGE AND UNDERVOLTAGE

When one of the battery string voltages rises above the 15.2V ±0.1V and

another battery voltage falls below 9V, status relays and the undervoltage

relay open. The Status LED blinks as an Overvoltage Fault (see Table 4-1).

4.2.1.4. BLOWN FUSE DETECTION

When the fuse is blown the Status LED blinks (see Blink Pattern Table 4-1),

the blown fuse signal will go low and the status output relays open. The status

LED will keep blinking until the user changes the fuse and pushes the reset

button on the front panel.

4.2.1.5. OVER TEMPERATURE

When temperature sensor reaches a setpoint the status LED blinks (see Blink

Pattern Table 4-1), the Over Temperature signal will go low and the Status

M3528M4

16

Output relays open. The Fault will latch until the unit cools down and the user

pushes the reset button on the front panel.

4.2.2. CONNECTORS

4.2.2.1. TB1 -1 (FUSE)

This terminal connects the input side of the fuse for monitoring. A voltage

higher than 10VDC on this pin between TB1-1 andTB1-12 will indicate a good

fuse.

4.2.2.2. TB1 -2THRU 12 (BATTERY MONITOR)

These terminals measurethe voltage across each individualcell. The nominal

voltage is 12VDC. If the voltage between adjacent pins is not between 9 volts

and 15.1 volts, a fault will be indicated.

4.2.2.3. TB2 -1&2 (POWER CONNECTOR)

This is the control power input for the board. This can be from a separate

24VDC power supply; or the first two batteries of the string can be used as a

local supply by connecting to Terminals TB5-7 & 8. Be aware that this can

cause unbalanced battery voltages if the batteries are not being constantly

charged.

4.2.2.4. TB3 -1THRU 10 -BATTERY CELL GOOD

Each of these outputs indicates that each individual battery’s voltage is within

range. When the voltage falls outside the range, the input will go low.

4.2.2.5. TB3 -11 NOT OVER TEMPERATURE

This output indicates that there is not an overtemperature alarm. It is

controlled by the temperature input at TB4-1 & 3.

4.2.2.6. TB3 -12 NOT BLOWN FUSE

This output indicates that there is no blown fuse.

4.2.2.7. TB3 -13 NOT UNDERVOLTAGE

This output is normally high, and indicates that there is no undervoltage fault

on any battery.

4.2.2.8. TB3 -14 NOT OVERVOLTAGE

This output is normally high, and indicates that there is no overvoltage fault

on any battery.

4.2.2.9. TB3 -15 (RESET SIGNAL)

Closing a contact between TB3-15 and TB3-16 will reset any faults. The input

is open base pulled up internally to 24VDC.

4.2.2.10. TB3 -16 (24V COM)

Signal common for all outputs on TB3.

4.2.2.11. TB4 -1&3 (THERMOSTAT INPUT)

Accepts normally closed thermostat terminals.

4.2.2.12. TB5 -1&2 (STATUS SIGNAL OUTPUT)

The isolated overvoltage signal output connector is connected to a normally

open held closed relay.

User’s Manual

17

This relay opens when any battery has an Overvoltage, a Blown Fuse, or

Overtemperature. The relay is rated for 250 VDC, 230VAC, 3A maximum.

4.2.2.13. TB5-3&4 (STATUS SIGNAL OUTPUT)

Same as TB5-1&2.

4.2.2.14. TB5 -5&6 (UNDERVOLTAGE SIGNAL OUTPUT)

The isolated undervoltage signal output connector is connected to a normally

open held closed relay.

This relay opens when any battery has an Undervoltage fault.

The relay is rated for 250VDC, 230VAC, 3A maximum.

4.2.2.15. TB5 -&8 (NOT USED)

4.2.3. JUMPERS

4.2.3.1. JP1

This jumper is indicates the number of batteries in the string.

For a 9 cell string, the position should be to the left or “9” position.

For a 10 cell string, the position should be to the right or “10” position.

Figure 4-1: JP1

4.2.3.2. JP2

If the Over Temperature option is not used, the user needs to install JP2.

Figure 4-2: JP2

JP1

JP2

M3528M4

18

4.2.4. RIBBON CONNECTOR

The unit has a ribbon connector that can be used with the Bonitron M3528D4 display

panel. The indicators on the front panel that will show basic status information for the

supply.

4.2.4.1. BATTERY STATUS

The Battery Status LEDs are 10 LEDs indicate which battery reaches an

Overvoltage or Undervoltage limit.

4.2.4.2. STATUS INDICATOR

The Status Indicator illuminates when there is a fault active in the unit. The

blink sequence will indicate the specific fault.

Table 4-1: Blink Patterns

BLINK PATTERN

STATUS

On

No Fault

On –Off

Blown fuse

On –On –Off

Over Temperature

On –On –On –Off

Over Temperature

On –On –On –On - Off

Undervoltage

User’s Manual

19

5. TROUBLESHOOTING

If a problem occurs on start-up or during normal operation, refer to the solutions described

below. If a problem persists after following the steps below, contact the product supplier or your

system integrator for assistance.

Repairs or modifications to this equipment are to be performed by Bonitron approved personnel

only. Any repair or modification to this equipment by personnel not approved by Bonitron will

void any warranty remaining on this unit.

5.1. STATUS RELAYS WON’T CLOSE

Make sure there is 24VDC between terminals TB4-1 & 2. Check to see if the other outputs

are on, and if so, continue troubleshooting below.

5.2. STATUS LED REMAINS BLINKING AFTER CHANGING THE BLOWN FUSE

Try to reset the fault with the reset input on terminals TB3-15 & 16. If the fault will not reset,

check the voltage between terminals TB1-1 and TB1-12. It should be between 0V and 10V.

If this does not solve the issue, contact Bonitron for assistance.

5.3. BATTERY OVERVOLTAGE

Try to reset the fault with the reset input on terminals TB3-15 & 16. If the fault will not reset,

check the voltage between each battery terminals from TB1-1 to TB1-11. None of the

voltages should be more than 15.2V ±0.1V.

5.4. BATTERY UNDERVOLTAGE

Try to reset the fault with the reset input on terminals TB3-15 & 16. If the fault will not reset,

check the voltage between each battery terminals from TB1-1 to TB1-11. None of the

voltages should be less 9 V.

5.5. OVER TEMPERATURE

Try to reset the fault with the reset input on terminals TB3-15 & 16. If the fault will not reset,

check the voltage between terminals TB4-1 to TB4-3. It should be 0V.

M3528M4

20

This page intentionally left blank

Table of contents

Other bonitron Control Unit manuals

bonitron

bonitron M3699 User manual

bonitron

bonitron M3528M2 User manual

bonitron

bonitron M3575R User manual

bonitron

bonitron M3460RD User manual

bonitron

bonitron M3628PUD User manual

bonitron

bonitron M3452 EIP User manual

bonitron

bonitron M3452 User manual

bonitron

bonitron M3460D User manual

bonitron

bonitron M3452 User manual

bonitron

bonitron M3345D User manual

Popular Control Unit manuals by other brands

Satel

Satel GSM-X manual

Entron

Entron EN1000 series instruction manual

Santec

Santec ESTATE Series manual

Hays Fluid Controls

Hays Fluid Controls HVAC Series technical information

NXP Semiconductors

NXP Semiconductors TWR-RF-SNAP user manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FMM-A-S Series Installation and maintenance instructions