Table of Contents

5

1. INTRODUCTION..........................................................................................................................7

1.1. Who Should Use...........................................................................................................................7

1.2. Purpose and Scope........................................................................................................................ 7

1.3. Manual Version and Change Record............................................................................................7

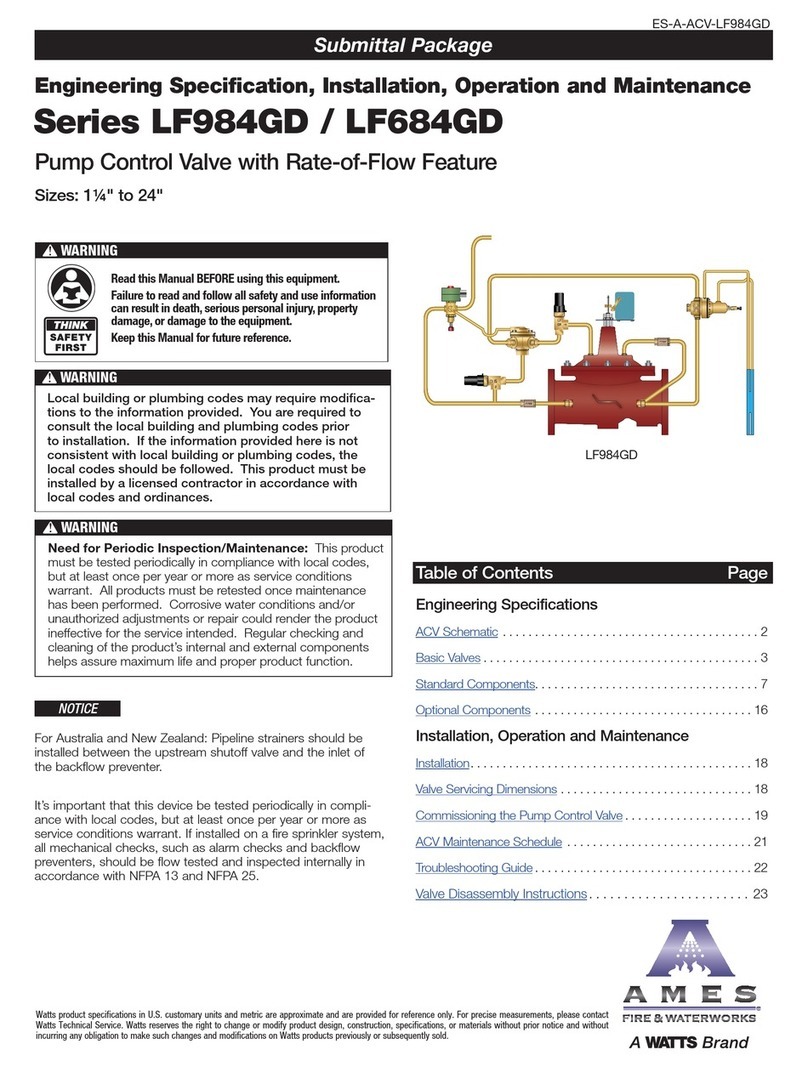

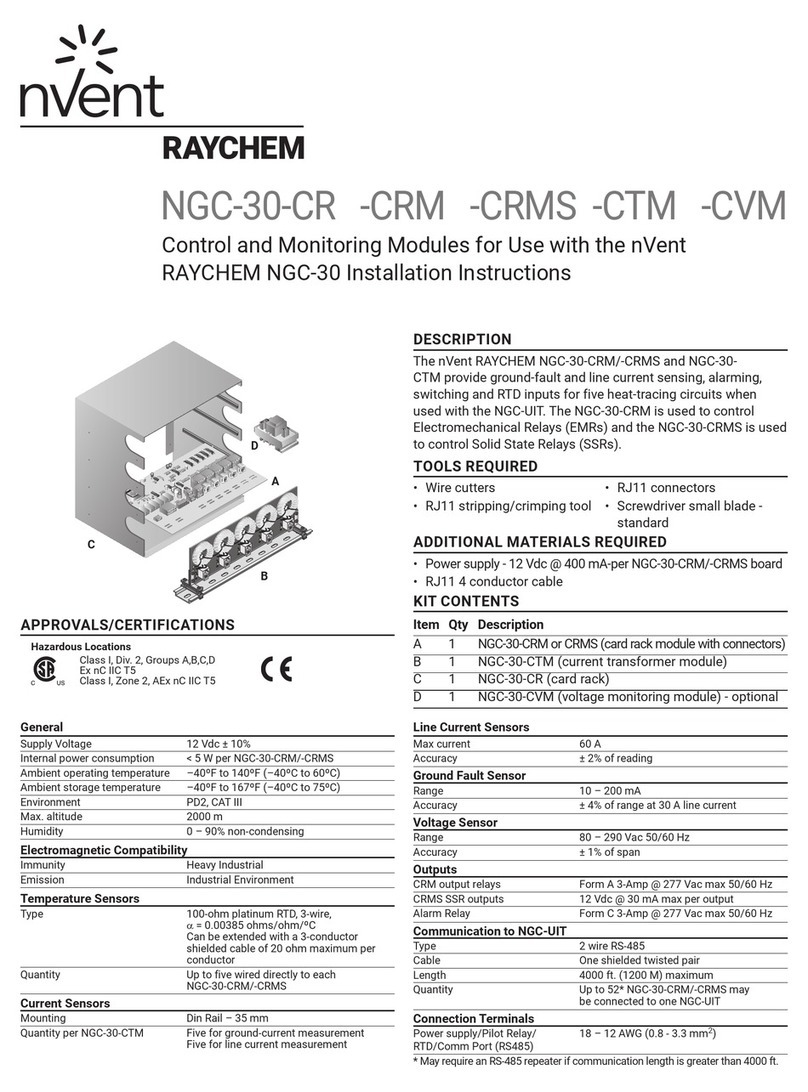

Figure 1-1: Typical M3460D.......................................................................................................................7

1.1. Symbol Conventions Used in this Manual and on Equipment.....................................................8

2. PRODUCT DESCRIPTION /FEATURES........................................................................................9

2.1. Related Products...........................................................................................................................9

2.2. Part Number Breakdown ..............................................................................................................9

Figure 2-1: Example of M3460D Part Number Breakdown........................................................................9

Table 2-1: Chassis Codes.............................................................................................................................9

2.3. General Specifications................................................................................................................10

Table 2-2: General Specifications Chart....................................................................................................10

2.4. General Precautions and Safety Warnings .................................................................................11

3. INSTALLATION INSTRUCTIONS................................................................................................13

3.1. Product Inspection......................................................................................................................13

3.2. Site Selection.............................................................................................................................. 13

3.3. Mounting ....................................................................................................................................13

3.4. Wiring and Customer Connections.............................................................................................13

3.4.1. Power Wiring......................................................................................................................................13

Table 3-1: Power Wiring Specifications....................................................................................................13

3.5. Typical Configurations...............................................................................................................14

Figure 3-1: Typical Field Wiring for M3460 Booster System...................................................................14

4. OPERATION..............................................................................................................................15

4.1. Functional Description ...............................................................................................................15

4.2. Features....................................................................................................................................... 15

4.3. Startup......................................................................................................................................... 15

4.3.1. Pre-Power Checks...............................................................................................................................15

4.3.2. Startup Procedure And Checks...........................................................................................................15

4.4. Operational Adjustments............................................................................................................15

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................17

5.1. Troubleshooting.......................................................................................................................... 17

5.1.1. Circulating currents between drives ...................................................................................................17

5.1.2. Heatsink gets excessively hot or drives do not behave properly during normal operating conditions17

5.1.3. Ground Faults.....................................................................................................................................17

5.2. Technical Help –before you call................................................................................................17

6. ENGINEERING DATA................................................................................................................19

6.1. Ratings Charts.............................................................................................................................19

Table 6-1: M3460D Diode Ratings............................................................................................................19

6.2. Watt Loss....................................................................................................................................19

Table 6-2: M3460D Watt Loss..................................................................................................................19

6.3. Dimensions and Mechanical Drawings ......................................................................................20

Figure 6-1: Typical “H” Chassis................................................................................................................20

Figure 6-2: Typical “J” Chassis .................................................................................................................21

Figure 6-3: Typical “L” Chassis ................................................................................................................21

Figure 6-4: Typical “N” Chassis................................................................................................................22

Figure 6-5: Typical “P4” Chassis ..............................................................................................................23

Figure 6-6: Typical “P6” Chassis ..............................................................................................................24

Figure 6-7: Typical “P2” Chassis ..............................................................................................................26

Figure 6-8: Block Diagram Example of a Ride-Thru / Diode Application................................................27