Table of Contents

5

4.2.6. Network Configuration............................................................................................................35

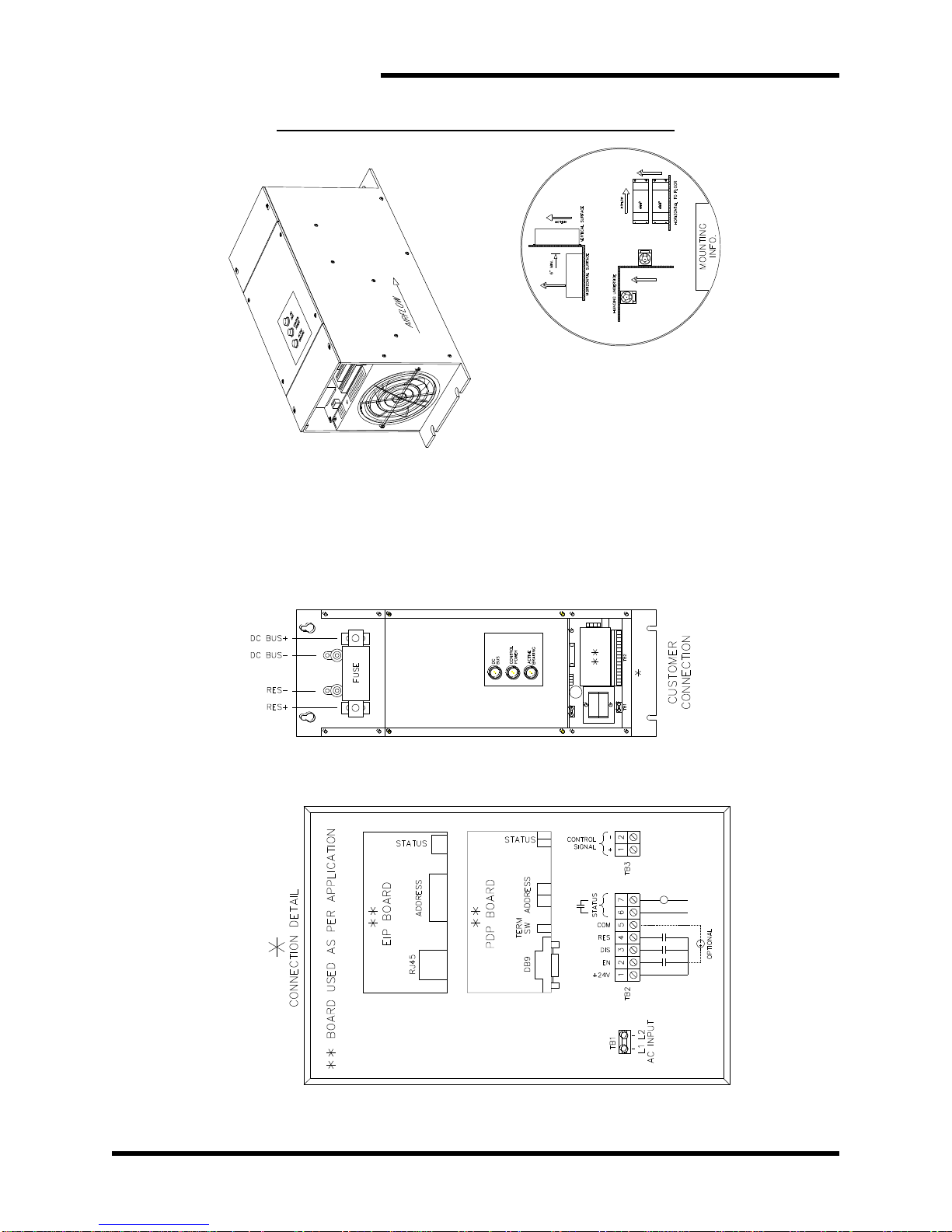

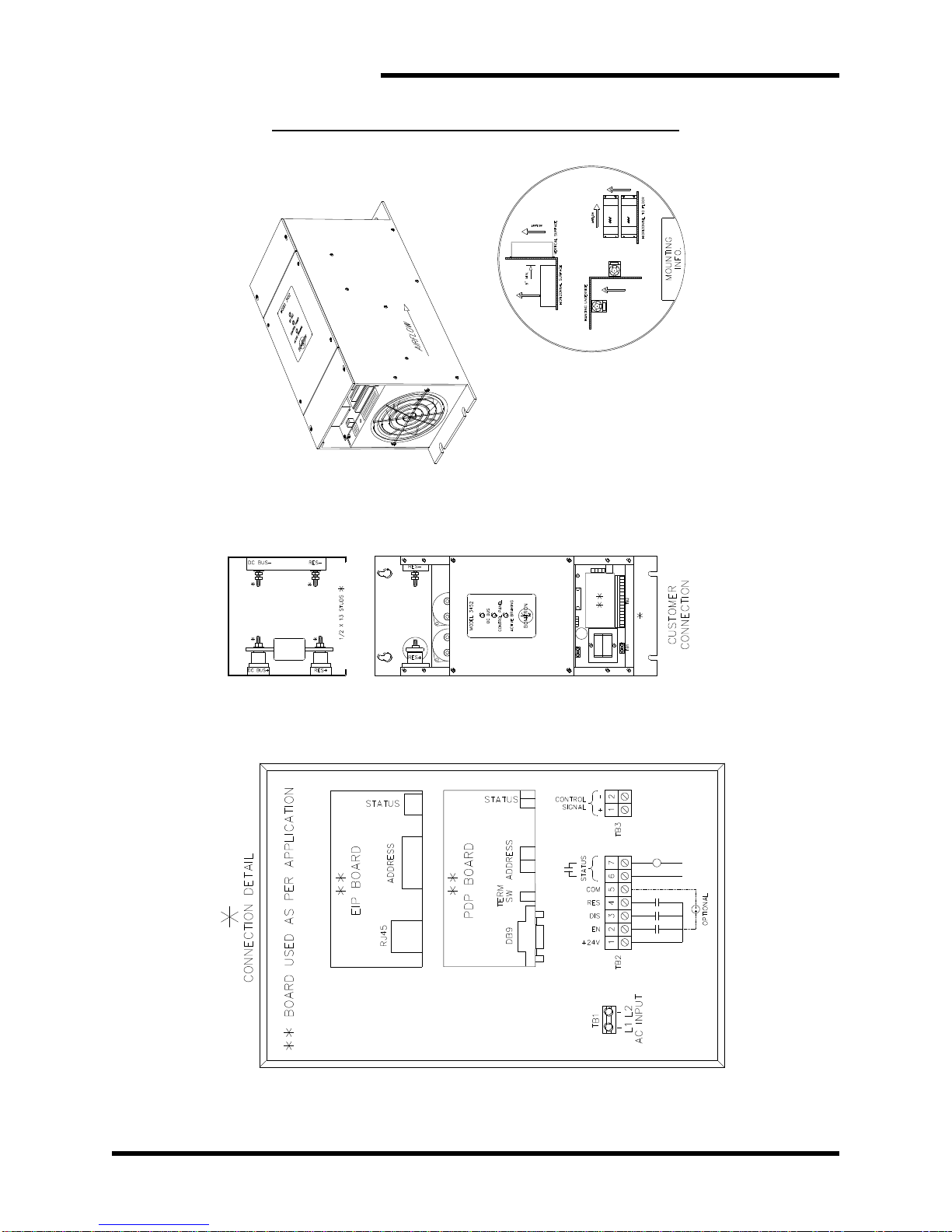

Figure 4-3: EtherNet / IP Module Features................................................................................................38

Table 4-2: Ethernet Status Indicators.........................................................................................................38

Figure 4-4: PROFIBUS Module Features..................................................................................................39

Table 4-3: PROFIBUS Status Indicators ...................................................................................................39

4.3. Startup......................................................................................................................................... 40

4.3.1. Pre-Power Checks ...................................................................................................................40

4.3.2. Startup Procedure and Checks.................................................................................................41

4.4. Operational Adjustments............................................................................................................41

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................43

5.1. Periodic Testing..........................................................................................................................43

5.2. Maintenance Items......................................................................................................................43

5.3. Troubleshooting.......................................................................................................................... 43

5.3.1. Green Control power light not illuminated..............................................................................43

5.3.2. Amber DC bus light not on......................................................................................................44

5.3.3. Blown DC bus fuse..................................................................................................................44

5.3.4. Fan runs constantly..................................................................................................................44

5.3.5. Fan doesn’t run ........................................................................................................................44

5.3.6. Status contact won’t close .......................................................................................................45

5.3.7. Module over-temp, or module seems too hot..........................................................................45

5.3.8. Drive trips on Overvoltage......................................................................................................46

5.3.9. Braking light flickers...............................................................................................................46

5.3.10. Red Braking light stays on all the time....................................................................................47

5.3.11. Master unit appears to function properly, but slave units do not seem to follow the master...47

5.3.12. EtherNet/IP Link Sensed light does not turn on......................................................................47

5.3.13. EtherNet/IP Module Status LED is solid red, flashing red, or flashing green.........................47

5.3.14. EtherNet/IP Network Status LED is solid red.........................................................................47

5.3.15. PROFIBUS Fieldbus Offline light is red.................................................................................48

5.3.16. PROFIBUS Fieldbus Diagnostics light is blinking .................................................................48

5.3.17. Attached Drive Will Not Precharge.........................................................................................48

5.4. Technical Help –Before You Call .............................................................................................48

6. ENGINEERING DATA................................................................................................................49

6.1. Ratings Charts.............................................................................................................................49

Table 6-1: Module Ratings: 230 –240 VAC Drives (375 VDC Setpoint) ................................................49

Table 6-2: Module Ratings: 380 –415 VAC Drives (620 VDC Setpoint) ................................................50

Table 6-3: Module Ratings: 460 –480 VAC Drives (750 VDC Setpoint) ................................................51

Table 6-4: Module Ratings: 575 –600 VAC Drives (940 VDC Setpoint) ................................................52

Table 6-5: Module Ratings: 690VAC Drives (1090 VDC Setpoint).........................................................53

6.2. Watt loss..................................................................................................................................... 53

Table 6-6: Watt Loss .................................................................................................................................53

6.3. UL 508A Short Circuit Current Rating ...................................................................................... 53

6.4. Fuse/Circuit Breaker Sizing and Rating .....................................................................................53

6.5. DC Bus Link Length Limits....................................................................................................... 54

Table 6-7: Maximum Inductance for DC Link Cable................................................................................54

Figure 6-1: DC Link ..................................................................................................................................54

6.6. Resistor Link Length Limits.......................................................................................................54

6.7. Dimensions and Mechanical Drawings ...................................................................................... 55

Figure 6-2: M3452 K6 Chassis Dimensional Outline Drawing.................................................................55

Figure 6-3: M3452 K9 Chassis Dimensional Outline Drawing.................................................................56

Figure 6-4: M3452 K10 Chassis Dimensional Outline Drawing...............................................................57

Figure 6-5: M3452 M14 Chassis Dimensional Outline Drawing ..............................................................58

Figure 6-6: M3452 T10 Chassis Dimensional Outline Drawing ...............................................................59