BOOCAX BKS-ST-180A User manual

BooCax Terminal Disinfection Robot

BKS-ST-180A

Product Manual

V 1.0.0

BOOCAX ROBOTICS

400 -161- 8661

Better Robot, Better Life.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 1/ 24 www.boocax.com

Safety and Use Precautions

Please follow the operation instructions of the product when using the robot. It

is forbidden to use beyond the scope!The company will not assume any responsibility

for the loss caused by improper operation beyond the standard.

01/ Instructions on safety matters in use of robots

1) Behaviors below are prohibited,

①Stay in the space where the robot is disinfecting;

②Robots are used in flammable gases and similar hazardous environments;

③Add any disinfectant not suitable for this product to the tank;

④Cleaning, wiping and other non-necessary operations when the robot is on;

⑤Unauthorized disassembly of the robot for repair or debugging;

⑥Touch the circuit terminal while the robot is charging;

⑦Replace any parts without authorization (If necessary, please do so under the company's

approval and guidance);

⑧To transport the robot while its tank is still with hydrogen peroxide disinfectant

2) Safety instructions for use

①The robot should be parked and run as far as possible in a flat, solid, normal

temperature condition;

②When adding hydrogen peroxide, do not splash to other parts of the robot;

③If abnormal sound is found during the disinfection work, please immediately turn off the

power of the robot and report to the after-sales service for treatment;

④Before starting the robot, please check whether the safety device (sensor, emergency

stop switch, etc.) is normal;

⑤If discover the road with water and greasy, please clean the road, to remove greasy;

⑥When to maintain the robot, it must be carried out by trained professionals;

⑦If the robot is not to use for a long time, it must keep the tank out of any liquid and

promote it to a cool and dry place for preservation。

02/ Safety instructions for using hydrogen peroxide

Please strictly comply with all requirements of hydrogen peroxide.

03/ Daily maintenance instructions

When cleaning the tank, please use the matching cleaning detergent, make sure the robot is

power off and unplugged or away from the charging pile!Otherwise, electric shock or serious

failure may occur.

It is strictly prohibited to flush the robot and charging pile directly with tap water, which may

lead to the accumulation of water vapor or water inside the equipment and cause serious

irreparable failure.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 2/ 24 www.boocax.com

1) Cleaning

① Please refer to the use method and attention of detergent for cleaning the tank;

② Regularly brush the surface of the driving wheel and universal wheel;

③Use neutral detergent and dust-free cloth to gently wipe the outer surface of the

robot regularly

④Regularly contact after-sales for maintenance services such as lubrication, dust-

cleaning at the damping spring and universal wheel bearing;

⑤Lidar sensor, as the expensive precision component in robot, should be wiped

regularly with a non-dust cloth. Do not wipe with force or other detergent, which may

be easy to cause functional damage.

⑥If the robot will not be used for a long time, store it in a dry and cool place.。

2) Check whether the screw is loose

Shake the components gently on a regular basis to observe whether they are loose. If

there is any abnormal sound, please check the screws at the installation position of relevant

components. All the screws of the robot have undergone anti-loosening treatment. However,

for the sake of safety, please contact "BooCax After-sales" if any screw is found loose。

04/Disclaimer

BooCax company owns multiple patents related to this robot product. No organization or

individual may use these patents without authorization.

The robot has precise internal structure. For the sake of safety, no one is allowed to

disassemble the robot without permission except the authorized personnel of BooCax,

otherwise the warranty will be invalid. BooCax will not assume any responsibility for any

damage, breakdown and property/personal injury caused by unauthorized disassembly. The

identification of unauthorized disassembly will be subject to the anti-disassembly mark on the

robot body.

05/ After-sales

If you have any questions about maintenance, safety and other issues during use of BooCax

robot, please contact us by phone or email provided on the back of this manual. We are very

willing to provide you with product-related services.

06/About “Terminal Disinfection”

Refer to Article

"11.2.1.5"

in the

"Health Industry Standards of the People's Republic of

China" -WS/T 367-2012

Technical Specifications for Disinfection in Medical Institutions,

Terminal disinfection is performed after surgery, patient discharge, transfer, or death.

The

terminal disinfection can be fumigated with 3% hydrogen peroxide or peracetic acid,to aerosol

spray by 3% hydrogen peroxide per 20mL/m³,to heat and fumigate by Peracetic acid at 1g/

m³,humidity70%-90%,make it airtight for 24H. Or to aerosol spray by 5% peracetic acid per

2.5mL/ m³, humidity20%-40%.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 3/ 24 www.boocax.com

目录

1. Introduction to Terminal Disinfection Robot............................................................... 4

1.1. Product Features.....................................................................................................................................4

1.2. Product Specification.............................................................................................................................5

1.3. Appearance Size......................................................................................................................................6

1.4. Function Modules...................................................................................................................................7

2. Assembly................................................................................................................................ 8

3. Install the charging pile ...................................................................................................11

4. QR code deployment........................................................................................................12

5. Clean up barriers................................................................................................................13

6. Download mobile App .....................................................................................................14

7. Turn on, connect the robot.............................................................................................14

8. Build map........................................................................................................................................................ 16

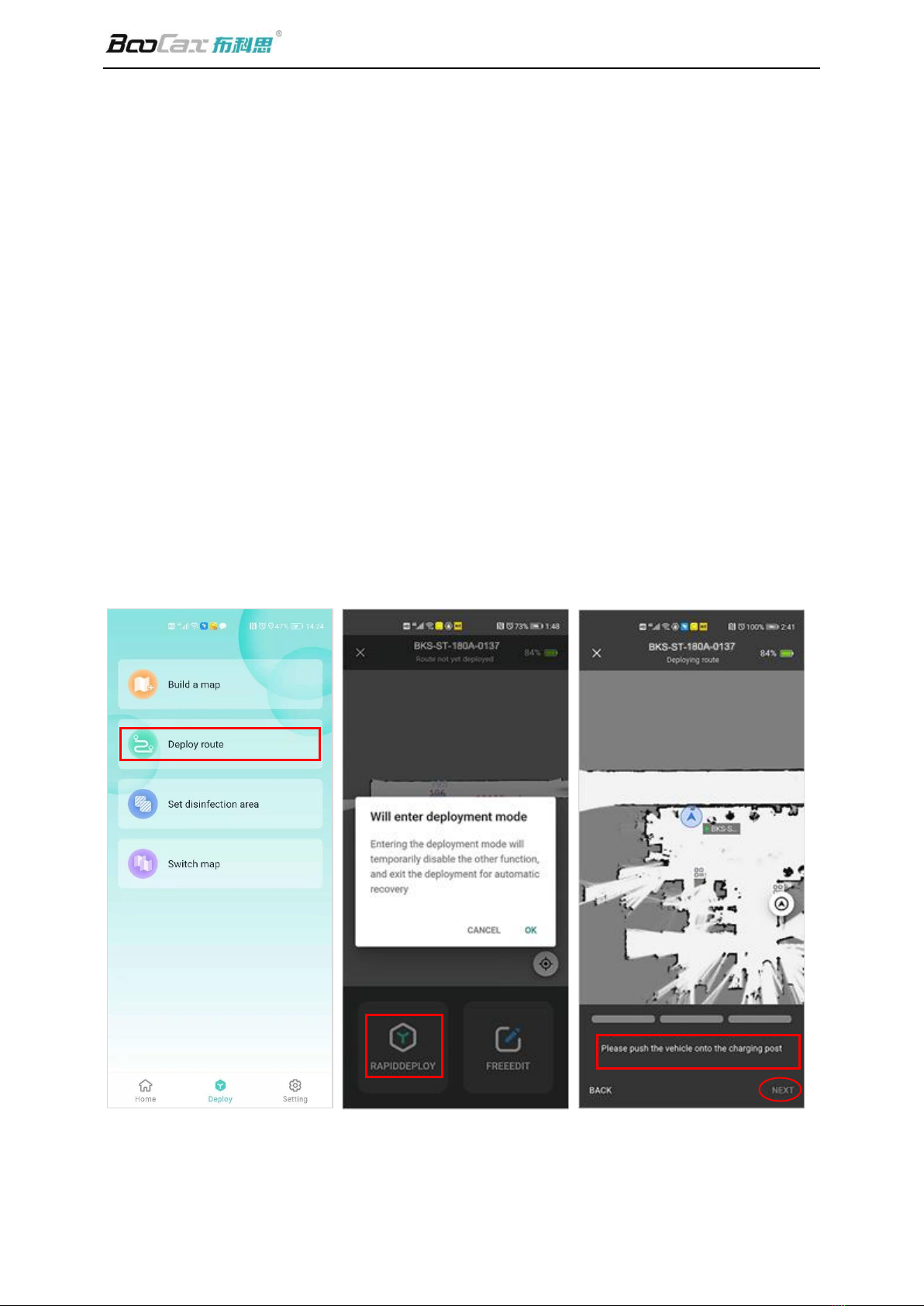

9. Deploy Route/Area setting ....................................................................................................................... 17

9.1 Deploy route setting................................................................................................................................. 17

10 Schedule setting............................................................................................................................................ 21

11. Other settings.......................................................................................................................................... 21

12. Start to work ...............................................................................................................22

12.1 Add liquid............................................................................................................................................... 22

12.2 Start spraying ........................................................................................................................................... 22

Attachment: Upgrade.................................................................................................................23

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 4/ 24 www.boocax.com

1. Introduction to Terminal Disinfection Robot

1.1. Product Features

①Atomizing the disinfectant into dry mist, the atomized particle is as small as 5μmin diameter.

②Atomizing rate reaches 3200ml/hour,

③The spray diameter is 5~6 m(maximum), leaving no dead corners in the spraying area,

④16 L ultra large-capacity tank,

⑤By mobile App control and supports two spraying modes: regular spraying, immediate

spraying, and record the disinfection log automatically,

⑥With functions of autonomous navigation, disinfection route(area) setting and schedule

setting,

⑦Applicable to multi-area (room), layout complex environment, ensure the uniformity and

consistency of disinfection,

⑧Automatic obstacle-detect function with APP and voice prompt function,

⑨Support auto-charging, free users from the cable trouble,

⑩When the liquid is lower than the warning level, the robot will automatically close the spray

device and returns to the charging pile.

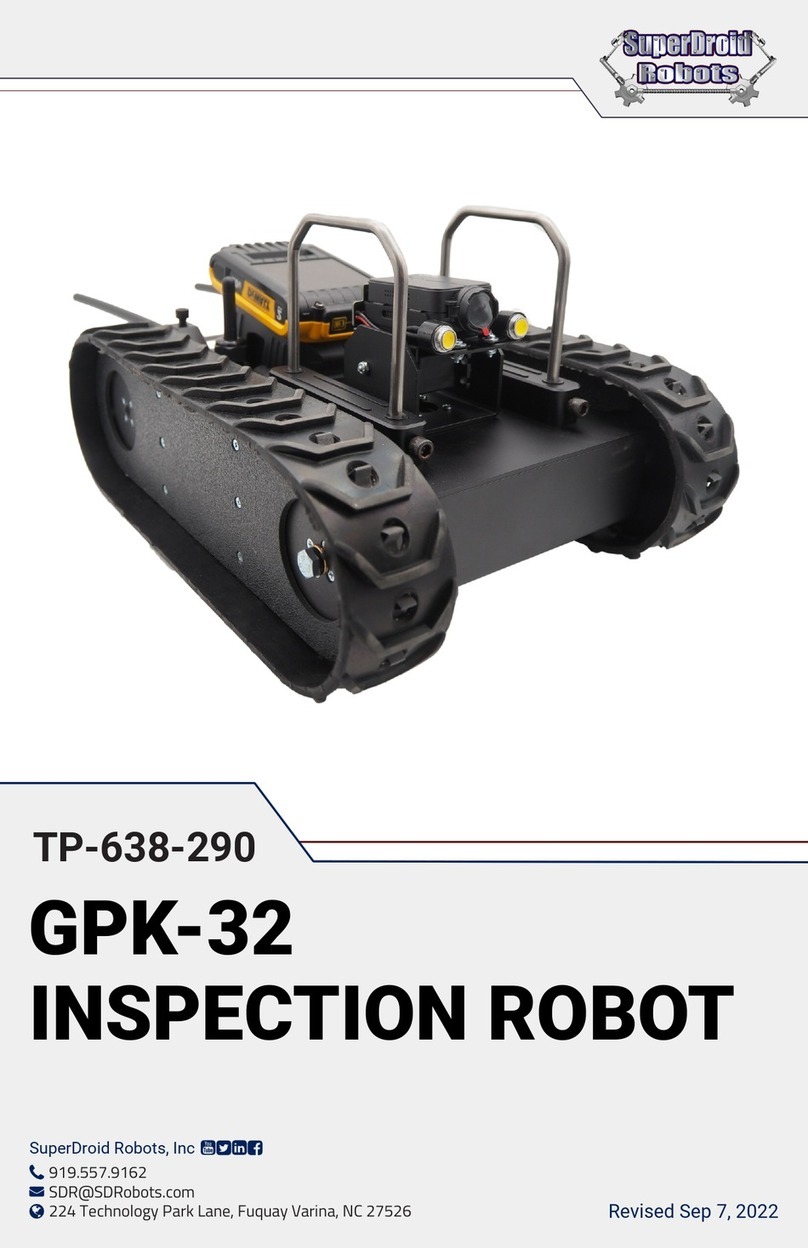

BooCax BKS-ST-180A terminal disinfection robot is

designed to purify the air by rapidly atomizing the

Hydrogen peroxide or similar terminal disinfectant and

automatically spraying the indoor area.

This robot can automatically navigate to the area for

full-coverage spraying, and supports mobile App control to

achieve man-machine separation and minimize personnel

exposure, so that the use safety is greatly improved. With

simple structure, it is easy to maintain and manage

This robot is applicable to the indoor area where need

Hydrogen peroxide or similar terminal disinfectant for

terminal disinfection.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 5/ 24 www.boocax.com

1.2. Product Specification

Item

Name

BooCax Terminal Disinfection Robot

Model No.

BKS-ST-180A

Basic data

Application

Auto terminal disinfection by hydrogen peroxide and similar

disinfectant solution

External Size

Diameter 600mm, Height 1660mm(with 500mm spray tube)

Net weight

52.5kg(exclude disinfectant)

Spray

Function

Spray rate

Maximum 3200 ml/h

Tank Volume

18L maximum

Spray diameter

≤ 6 m

disinfectant

Hydrogen peroxide and similar disinfectants for terminal

atomization disinfection

Spray mode

Multiple directions(single-nozzle/dual-nozzle for choice)

Motion

Performance

Movement mode

Can plan route and set area,with auto-navigation

Moving speed

0.3 m/s

Driving

Differential drive

Obstacle surmounting

≤10 mm

Gradeability

≤8°

Gradeability

Travel lane width

≥750 mm

Endurance

Endurance

≥3小时(by max spray rate continuously)

Battery

28Ah(The full battery voltage is 29.4V)

Charging Way

Auto-charging、10-90% by 3 hours

Charging pile

Support 110V ~ 240V wide voltage input

Rated output: voltage 29.4V, current 8.0A

Safety

Safety protection

low water alarm

Emergency stop

yes

Bumper Strip

yes

Noise

≤60dB

Working temperature

10℃~40℃

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 6/ 24 www.boocax.com

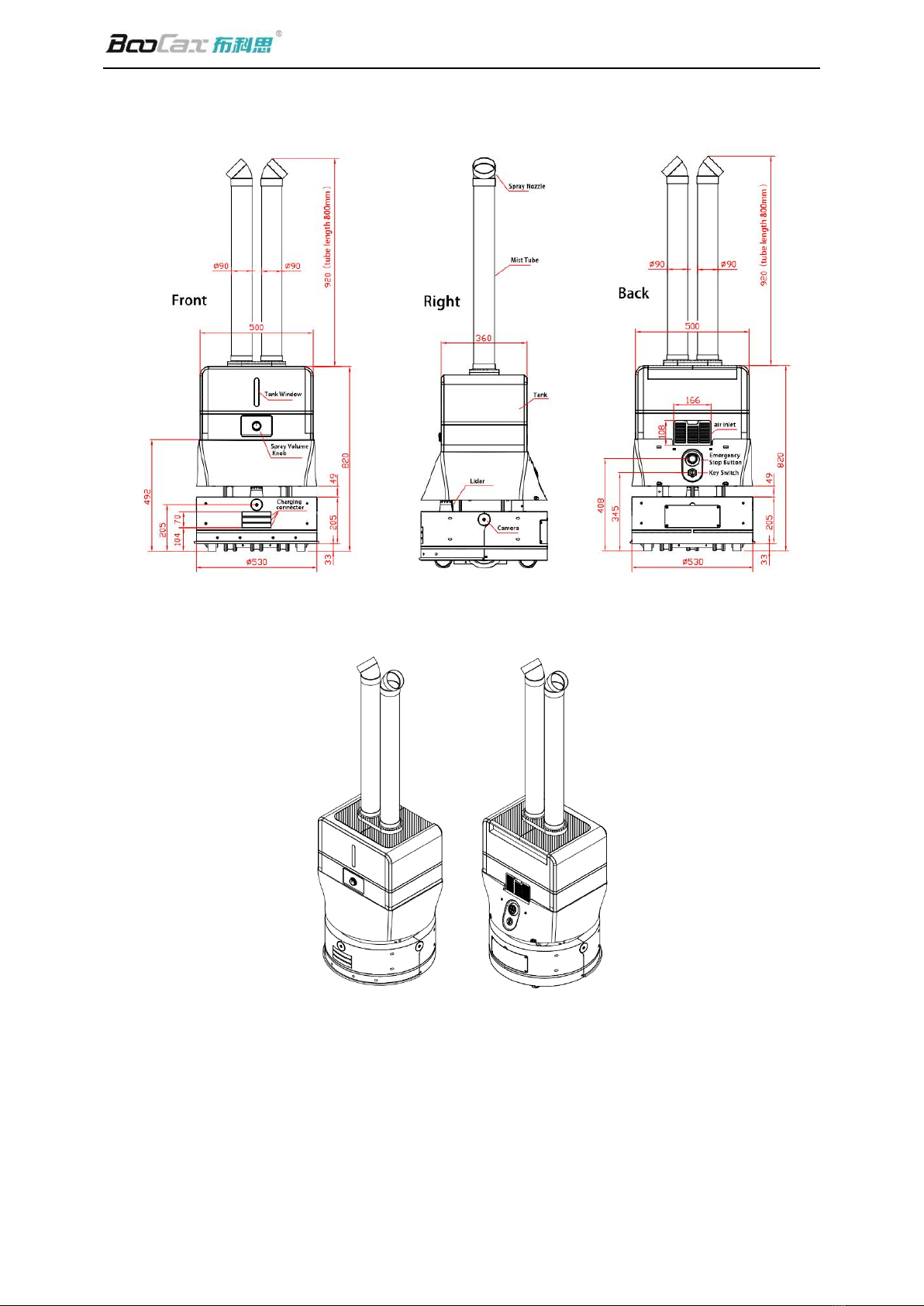

1.3. Appearance Size

前

后

Back

Front

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 7/ 24 www.boocax.com

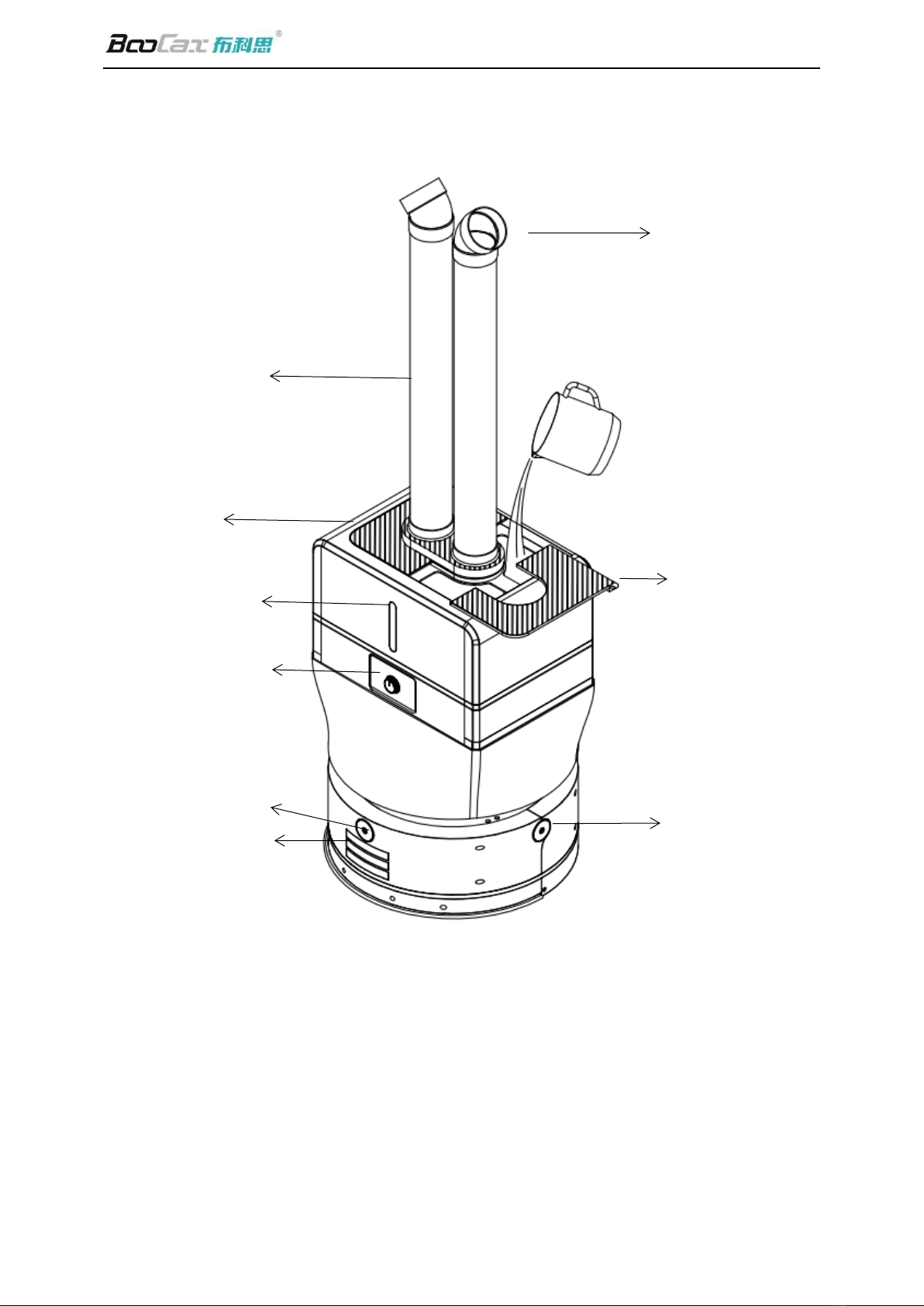

1.4. Function Modules

nozzle

Mist tube

Tank

Tank window

Spray volume knob

Charging interdace

Vision sensor

(Camera)

Laser Radar

Tank lid

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 8/ 24 www.boocax.com

2. Assembly

Step 1:Unpack and check materials

The packaging of this product consists of two boxes, with the larger box for the chassis

and charging pile (①-③), and the smaller box for the robot body(④-⑧). After unpacking,

check the materials and accessories against the Nos.1-8 in the figure below for any missing or

damage (Package concludes two one-way nozzles, and two mist tubes).

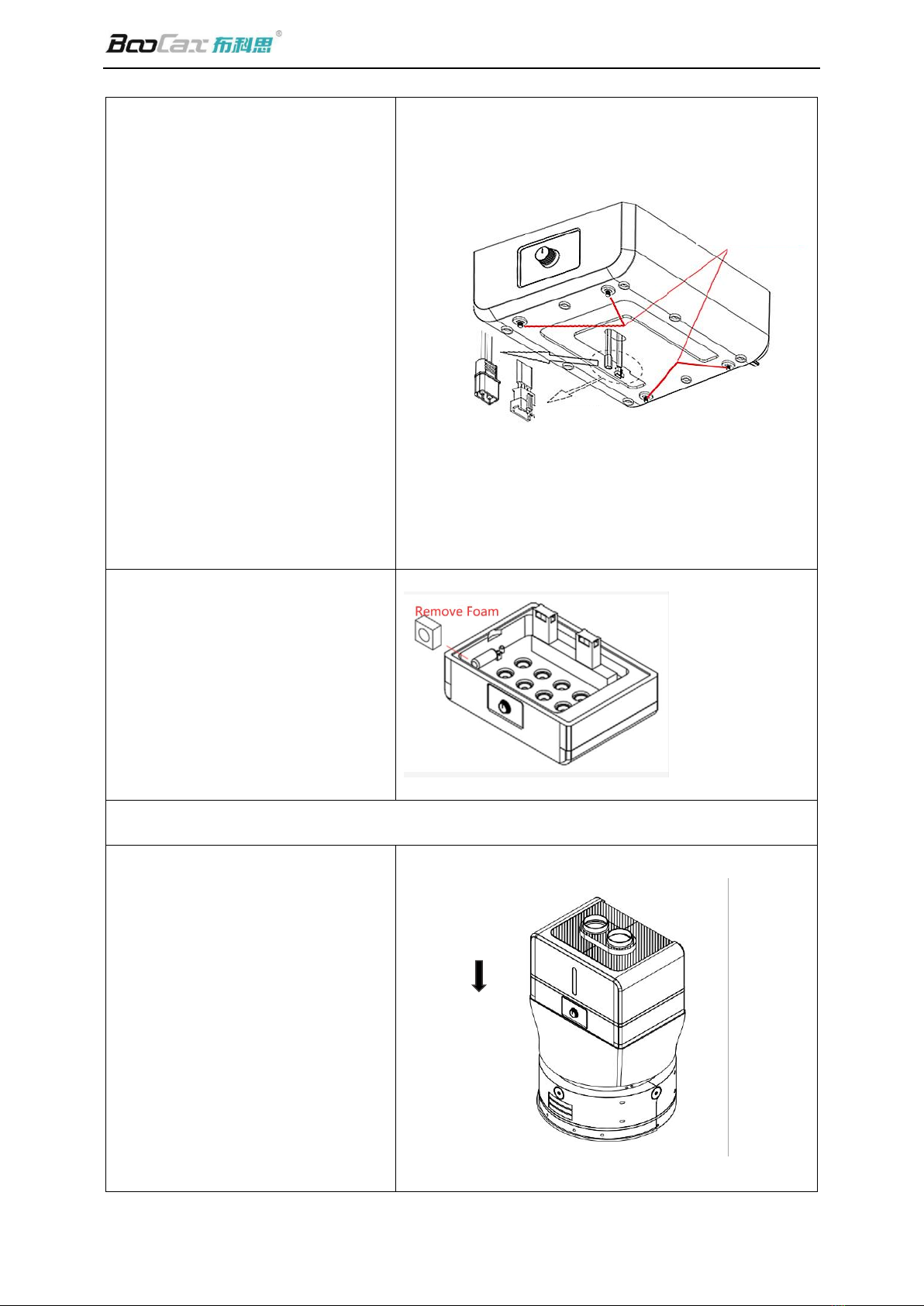

Step 2:Install the Sprayer

①Take out the chassis and place it

on the floor stably, make sure

that the lower charging mouth is

facing forward, pull out the two

connectors (Terminal 1: signal

wire, Terminal 2: power wire),

and visually find the four

positioning holes on the iron

plate →

Terminal 2

Power Wire

Terminal 1

Signal Wire

①

Chassis

Charging Pile

Adapter, power cord

Sprayer base

Tank lid

Mist Tube

Tank

One-way nozzle

②

③

④

⑧

⑦

⑥

⑤

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 9/ 24 www.boocax.com

②Turn the direction of knob on

the sprayer base forward, and

then pull out the two connectors

(Terminal 1, Terminal 2 as

shown) at the bottom to match

the male and female connectors

on the chassis. Four dowels are

aligned with the four positioning

holes on the chassis (attention

that the lower charging mouth

of the chassis is also facing

forward).Make it fall smoothly,

buckle in place →

③Remove the protective foam

from the water control valve on

the sprayer base to ensure that

the next step of placing tank is

not hindered

Step 3:Dock the tank and robot Chassis

Lift the water tank stably,

stack it on top of the

sprayer base. Relying on the

positioning steps that sink

around, it can be freely in

place from top to bottom

under the action of gravity

→

Terminal 2

Power wire

Terminal 1

Signal wire

Four dowels

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 10 / 24 www.boocax.com

Step 4: Install mist tube and nozzle

Take out the mist tube, insert one end

into the circular outlet at the center

of the water tank,and then connect

the other end on the top with nozzles

(for tight connection, it is

recommended to wrap it with

waterproof tape before putting it

in, single-tube mode or dual-tube

mode is optional to switch) →

Note:To reach the maximum

spray rate, you may select the

single-tube mode with one-way

nozzle.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 11 / 24 www.boocax.com

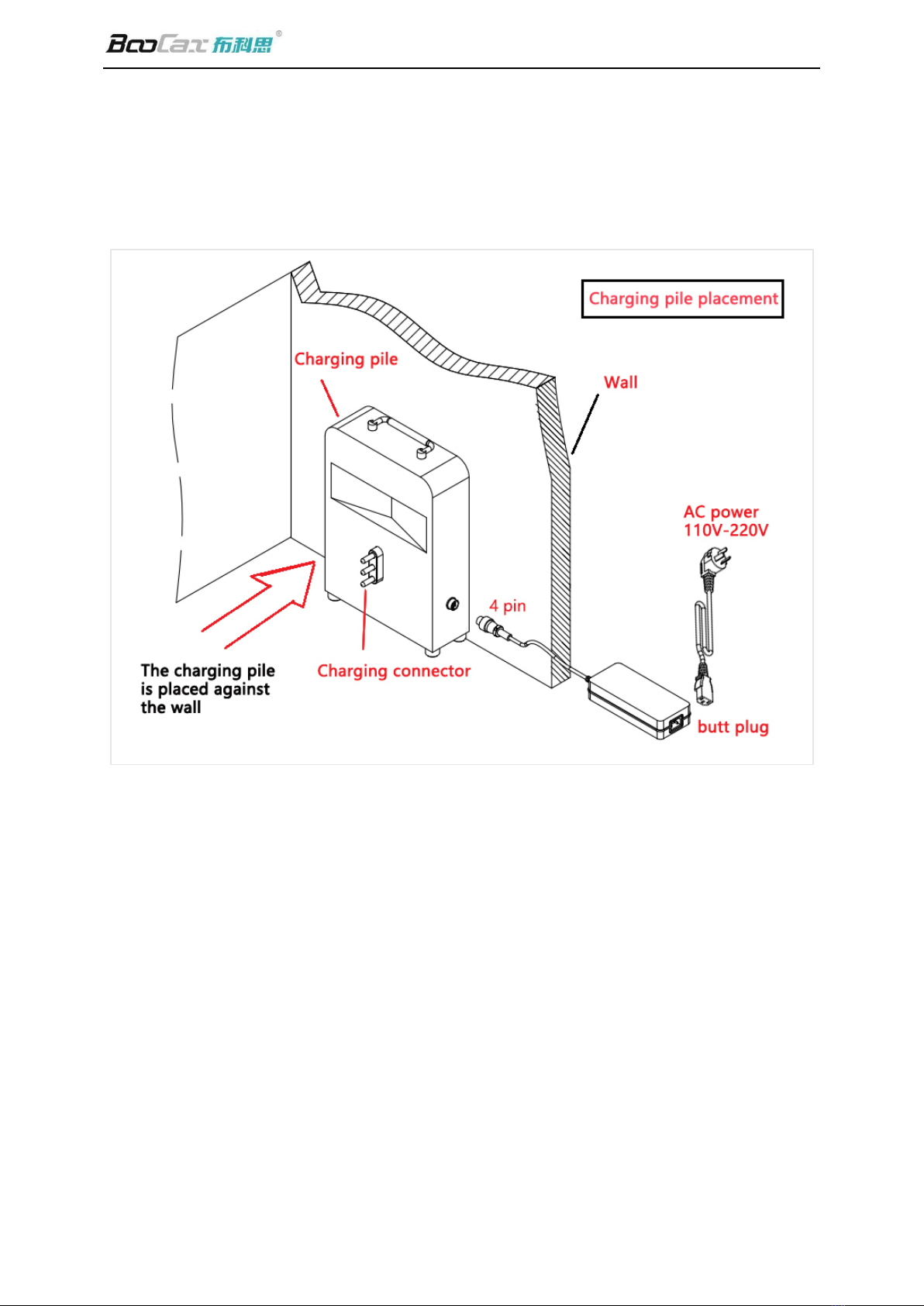

3. Install the charging pile

The charging pile of the spray robot should be placed in a safe and tidy place. It should

be on the flat ground with its back against the flat wall。As shown in the below figure:

①Place the back of the charging pile against the wall, and then turn the foot pads at the

bottom to adjust the charging pile.

②Connect the power cord, adapter, and charging pile as shown above, and finally connect the

end of the power cord to the 110V / 220V AC socket to formally complete the boot preparation.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 12 / 24 www.boocax.com

4. QR code deployment

In order to enhance the positioning accuracy of the robot, we designed a QR code scheme

to ensure that the robot's long-term running position is not lost.

The QR code is generally used where the robot positioning is prone to deviation, for example, the

two ends of a long corridor, for example, the two ends of a long corridor, in which case, a QR code

can be pasted at a distance of 15m from the two ends to assist positioning.

Also, In relatively empty scenes, QR Code is also need to assist positioning.

1) Standard of QR code pasting

•Avoid deploying at a place with strong light, incase the strong light will affect the camera

to capture the QR code image;

•The QR code should be pasted at the same level as the camera;

•Paste the QR code per the direction of the arrow pointed (marked in below picture)

•Replace the QR Code once it is damaged.

Referenced to below:

2) Precautions for QR code

a) Two same QR codes are not accepted in same environment,

b) When mapping, the robot stops at the QR code board for 1-2 seconds to ensure that the

QR code is saved,

Same level

Parrel to the

ground

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 13 / 24 www.boocax.com

c) The QR code of the charging pile should be identified by the robot’s front-facing camera,

whereas the QR code of a corridor can be identified by the lateral cameras of the robot.

d) When incrementally mapping, it is necessary to ensure that the robot's positioning is

accurate before identifying and saving the QR code。

5. Clean up barriers

1) Before using the spray robot, remove the barriers in the aisle to avoid affecting the working

and charging of the robot,

The minimum walking width of the robot is 750mm

2) Make sure that there is no vertical step over 10mm within the spraying area,and no objects

(books, boards, stones, etc.) over 10mm in height on the working path;

3) Make sure that there is no large slope on site

The maximum gradeability of the robot is 8°.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 14 / 24 www.boocax.com

6. Download mobile App

Android 8.0 and above mobile phone Scan the QR code below download the corresponding App

and install:

Android mobile browser scan to download the App

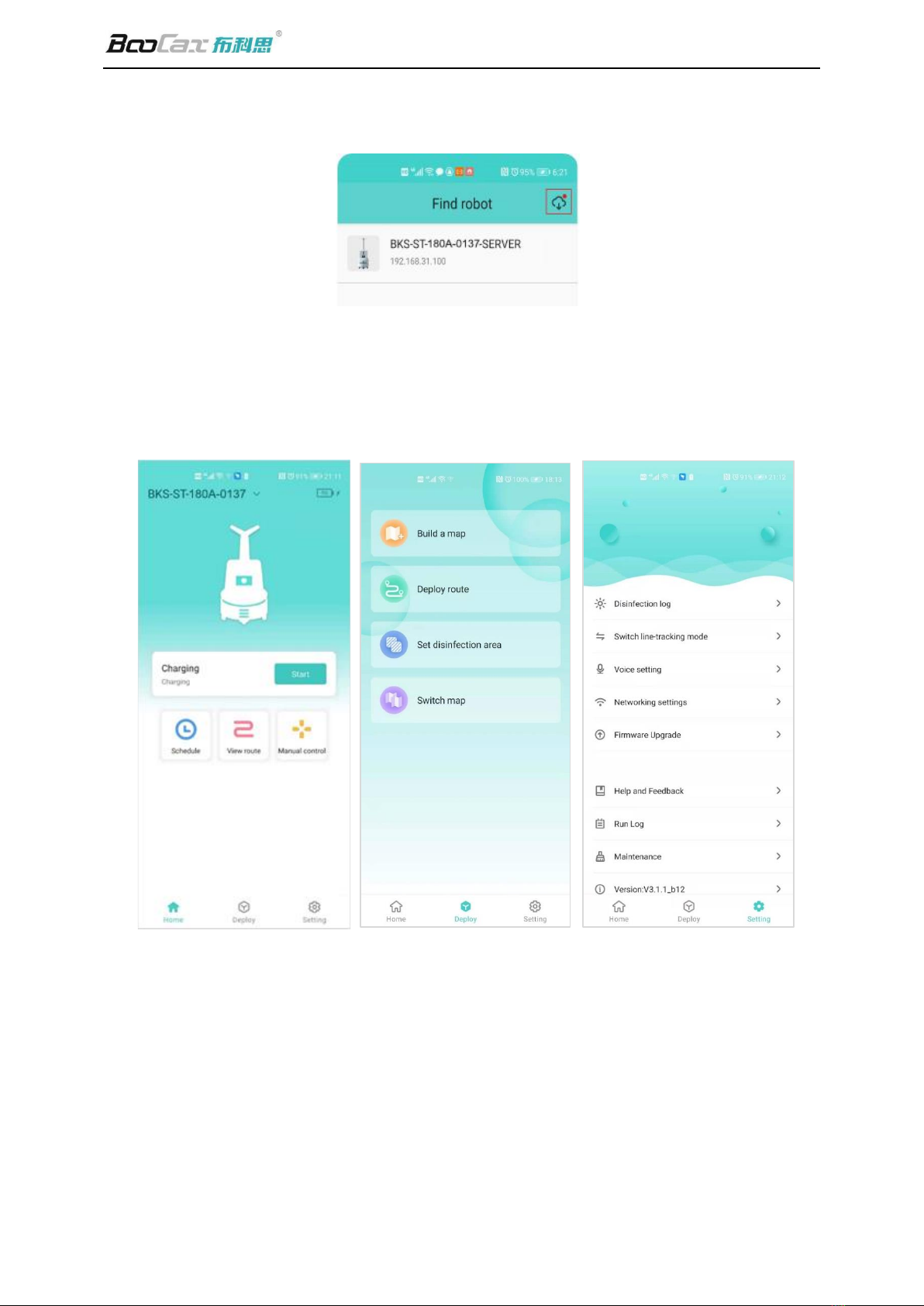

7. Turn on, connect the robot

1) Turn on the switch to initiate the working mode of the robot;

2) Turn on the phone wifi, search the wifi network beginning with "BKS-ST-180A", and enter the

assigned password “robot123”to connect the robot

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 15 / 24 www.boocax.com

3) Click into the App, you will find the robot beginning with "BKS-ST-180A" (as shown in the

following figure), click login;

4) Open the App, which shows the interface as below then forward to deploy map,

Screenshots of App interface and function buttons:

App homepage:

•Robot name and

battery

•Robot status

•Scheduled

disinfection

View route

Manual control

App deployment:

•Build map

•Deploy route

•Set disinfection

area

Switch map

App setting:

•Disinfection log

•Switch loop mode

•Volume

•Networking setting

•Firmware update

•Help and feedback

•Run log

•Maintenance

•App version information

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 16 / 24 www.boocax.com

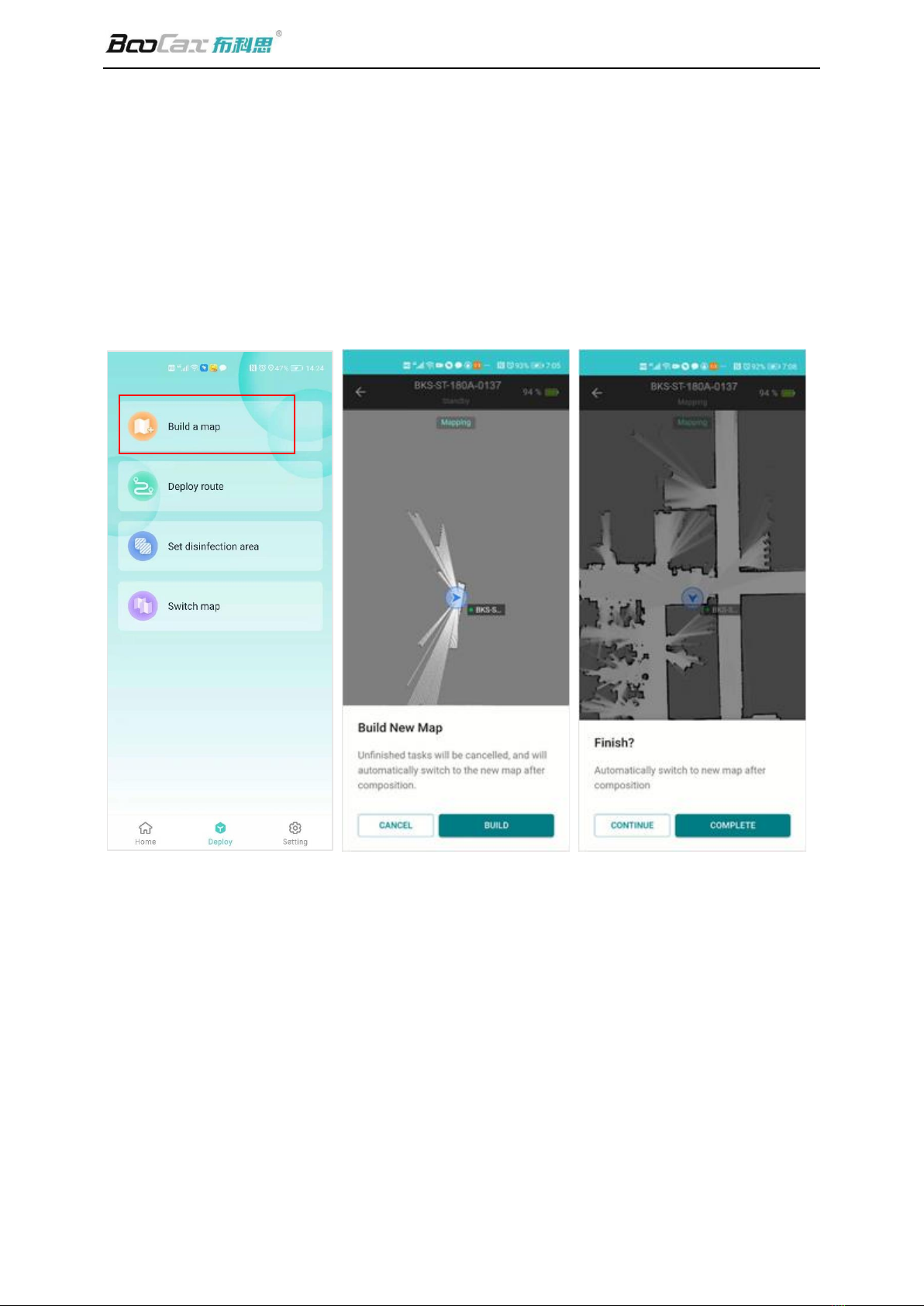

8. Build map

1) Preparation before building the map

·Push the robot 0.5-1m in front of the charging pile

·Robot power >50%

2) Start building the map

Click "Deploy" on the homepage of App to show the "Build Map" button. Click the button to

build a two-dimensional spraying map, as shown in the following figure (Push the robot by

hand to build the map):

Notifications:

•White radius—the range scanned by the laser;

•Black thick line—the scanned obstacles (special objects such as transparent glass may not be

identified)

•Gray area: Area that has not been scanned.

⚠Attention:

①When mapping by hand, push the robot forward slowly in the scene from the charging

pile as the starting point, and finally return to the charging pile to form a large circle;;

②When mapping, don't be too close to the wall and keep a distance of at least 0.5m;;

③The operator must stand behind the robot to avoid leaving noise on the map;

④When turning, walk slowly so that the robot can collect as much characteristic point data

as possible;

⑤As laser radar does not recognize accurately in abnormal environment (glass, mirror, pure

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 17 / 24 www.boocax.com

black object, grid, etc.), it is recommended to carry out appropriate treatment, such as

pasting frosted sticker, gray adhesive tape, etc.;

⑥If the working scene is too large/noise, you can use "Incremental composition" to

enlarge/repair the map;

⑦When passing the QR code, stay in front for more than 1 second, and there will be a voice

prompt after the entry is successful.

9. Deploy Route/Area setting

9.1 Deploy route setting

The working path of robot consists of the starting point, path points and the disinfection points in

series.

Specific setting procedures follow the instructions of App, as shown below:

1) Rapid deployment

➢Charging point: The position of the robot docking the charging pile 。

Click "Deploy route" to enter the route setting mode; push the robot to the charging pile for

docking as guided, and click Next to complete the setting.

➢Path points and disinfection points: deploy the points by pushing robot /dragging map

Mark the required location on the map, and then set the corresponding path

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 18 / 24 www.boocax.com

point/disinfection point ( The small blue icon is the corresponding location point)

Path points need to be set for the route that the robot passes through, such as turns and

gates, which must be marked (as shown in Figure 2 below: gray points are path

points).

Disinfection points are set as required for the environmental site (as shown in Figure 3 below:

purple icons are disinfection points).

Button “Change“ and ”Connect" function:Mainly used to connect button "nearby points" in

series.

Change “is to switch point, that is, changing the current point of the robot to the selected

nearby point. After this operation, you can click "Connect " to connect the robot's previous

path point or disinfection point with the current point.

“Change” and “Connection”, these two functions are mainly designed to facilitate route editing.

2)Free editing-adjust path

➢If the route by rapid deployment is not applicable, click "Free Edit" to adjust the route. The

robot supports adding/deleting/moving points, changing running route, changing disinfection

points, etc.

BKS Terminal Disinfection Robot Product Manual v1.0

BooCax Robotics 19 / 24 www.boocax.com

⚠ Attention:

When mapping,the turning should be deployed with waypoints which cannot pass through the

wall, as shown in the figure below:

As shown in the figure above, when the robot has to move from A to C, but is obstructed by a

wall or an unmovable obstacle in between, the correct path deployment should be A-B-C. B

must be set as it is the key node of the turning. The figure on the right shows the wrong

deployment, in which the path will go through the wall directly, causing the robot unable to walk.

Table of contents

Other BOOCAX Robotics manuals