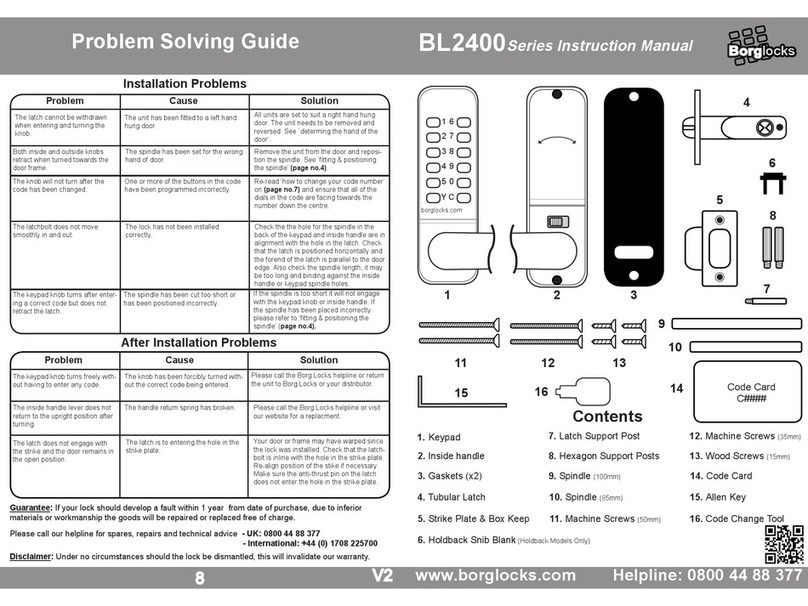

5. Fixing the Lock How to change your code number

6. Fitting the Strike Plate

7. The Snib Function

Cut the fixing bolts to suit the door thickness,

allowing at least one threaded section to screw

into the keypad.

Hold the keypad and the inside handle, with the

seals, onto the door with the spindle in position.

Using the fixing bolts, screw everything together

through the top and bottom holes of the inside

handle. Before final tightening, make sure the lock

is vertical, and test the mechanism to ensure that

it is all moving easily.

DO NOT CLOSE THE DOOR UNTIL YOU'RE SURE THAT

THE CODE WORKS.

DO NOT over tighten the fixing bolts. This may cause

distortion and poor operation.

Position the strike plate on the door so that it lines up

with the flat of the latcholt, NOT THE PLUNGER.

Mark the inner and outer edges of the strike plate and

cut a 1mm rebate so that it fits flush with the surface

of the door frame.

Drill or cut a recess for the latchbolt.

Fit the strike plate using only wood screw to ensure

it's positioned accurately. The latch bolt, and not the

plunger, should enter the aperature easily and be held

without too much 'play'. When satisfied, secure the

strike with the second screw.

The 'Hold-open' model is equipped with a snib on the

inside handle. This enables the latchbolt to be held

open when required.

If the snib function is not required, you can remove it by

unscrewing the 4 screws, one from each corner, (2 long & 2

short) from inside the backplate. This will enable the metal

plate, the snib, a small spring & a ball bearing to be removed.

Please note that the metal plate, only needs to be replaced

plus the enclosed plastic clip to cover the aperture.

it is all moving easily.

DO NOT CLOSE THE DOOR UNTIL YOU'RE

SURE THAT THE CODE WORKS.

DO NOT over tighten the fixing bolts. This may

cause distortion and poor operation.

Position the strike plate on the door so that it lines up with

the flat of the latchbolt, NOT THE PLUNGER.

Mark the inner and outer edges of the strike place and cut

a 1mm rebate so that it fits flush with the surface of the

door frame.

Drill or cut a recess for the latchbolt

Fit the strike plate using only wood screw to ensure it's

positioned accurately. The latch bolt, and not the plunger,

should enter the aperature easily and be held without too

much 'play'. When satisfied, secure the strike with the

second screw.

N.B The plunger beside the

latchbolt deadlocks the latchbolt

and protects against manipulation.

It must not enter the strike plate

aperture when the door is closed.

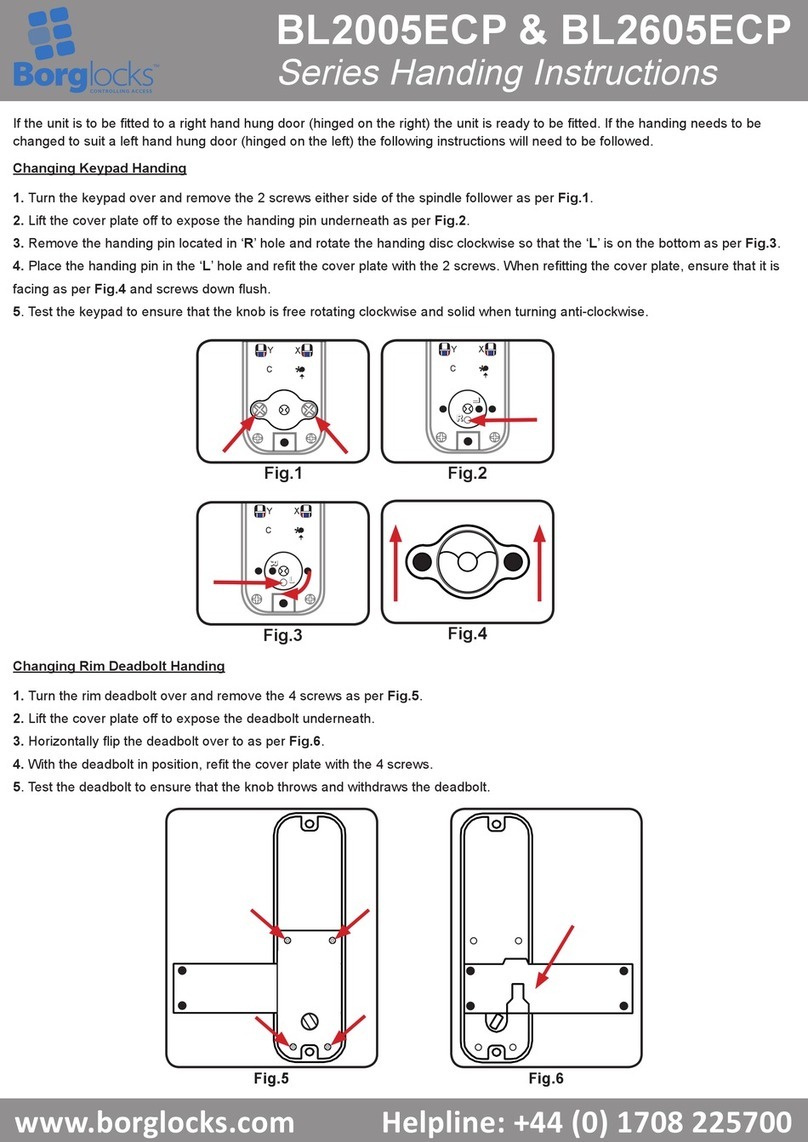

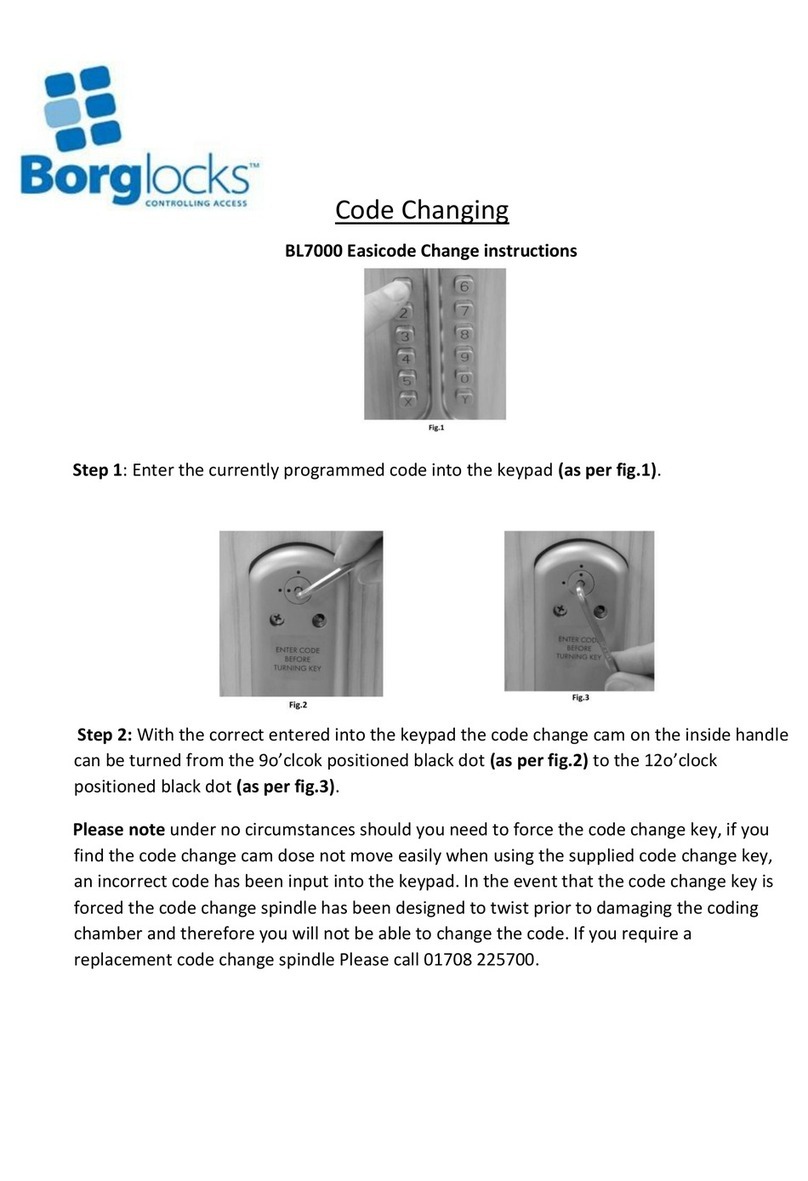

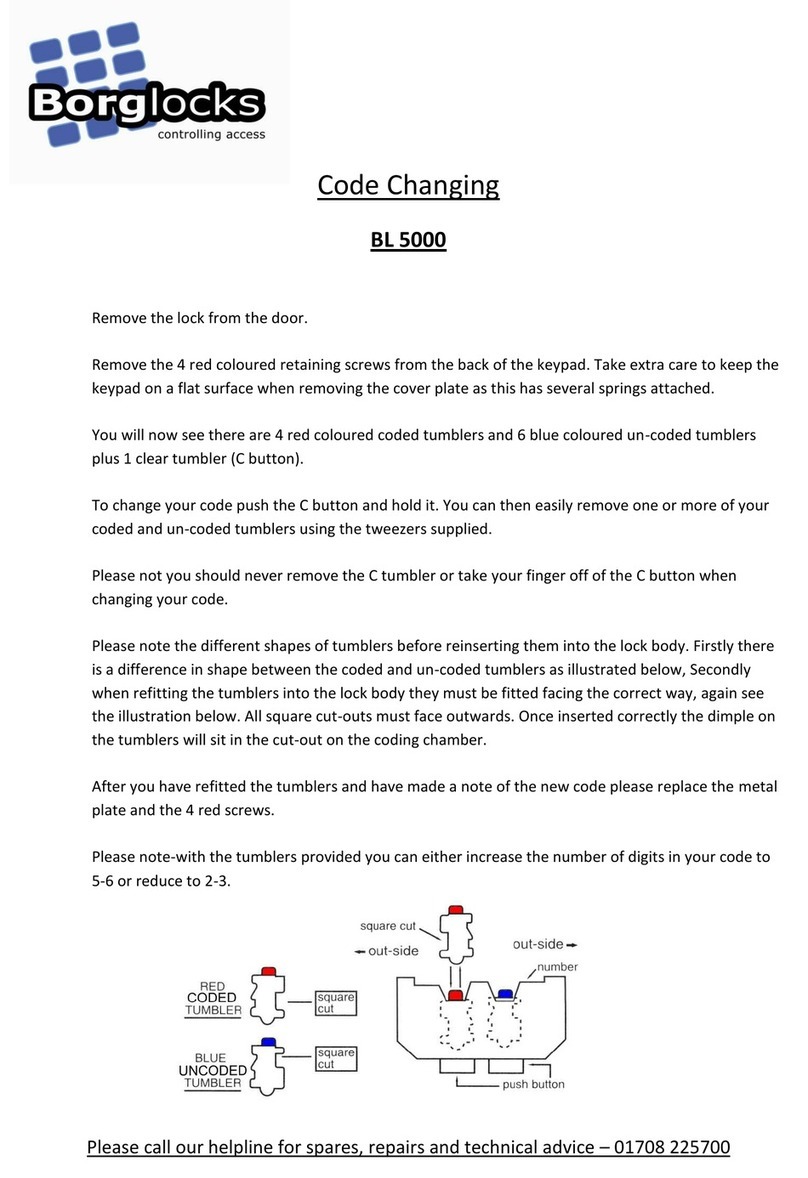

Remove the lock from the door.

Remove the 4 retaining screws from the back of

the keypad. Take extra care to keep the keypad on

a flat surface, when you are removing the plate

due to all of the small components inside.

You will now see that there are 5 red coloured

coded tumblers & 8 blue coloured, uncoded

tumblers plus 1 clear tumbler ('C' button).

To change your code, push the 'C' button down

and hold it. You can then easily remove one or

more of your coded & uncoded tumblers, using the

tweezers supplied.

Please note you should never remove the 'C' tumbler.

Please note the different shapes of tumblers,

before reinsterting them into the lock body. Firstly,

there is a difference in shape between the coded &

uncoded tumblers into the lock body, they must be

fitted facing the right way.

After you have refitted the tumblers and made a note

of the new code, please replace the metal plate with

the 4 screws.

Please note, with the spare tumblers provided, you

can either increase the number of digits in your

code to 6 or 8 or reduce to 4.

1)

2)

3)

4)

5)

6)

7)

8)