Borglocks BL2400 Series User manual

BL2400

Series Instruction

Manual

Helpline: 0800 44 88 377

Contents

Problem Solving Guide

After Installation Problems

Guarantee: If your lock should develop a fault within 1 year from date of purchase, due to inferior

materials or workmanship the goods will be repaired or replaced free of charge.

Please call our helpline for spares, repairs and technical advice - UK: 0800 44 88 377

- International: +44 (0) 1708 225700

Disclaimer: Under no circumstances should the lock be dismantled, this will invalidate our warranty.

Problem Cause Solution

The latch cannot be withdrawn

when entering and turning the

knob.

The unit has been tted to a left hand

hung door.

All units are set to suit a right hand hung

door. The unit needs to be removed and

reversed. See `determing the hand of the

door’.

Both inside and outside knobs

retract when turned towards the

door frame.

The spindle has been set for the wrong

hand of door.

Remove the unit from the door and reposi-

tion the spindle. See ‘tting & positioning

the spindle’ (page no.4).

The latchbolt does not move

smoothly in and out.

The lock has not been installed

correctly.

Check the the hole for the spindle in the

back of the keypad and inside handle are in

alignment with the hole in the latch. Check

that the latch is positioned horizontally and

the forend of the latch is parallel to the door

edge. Also check the spindle length, it may

be too long and binding against the inside

handle or keypad spindle holes.

The keypad knob turns after enter-

ing a correct code but does not

retract the latch.

The knob will not turn after the

code has been changed.

One or more of the buttons in the code

have been programmed incorrectly.

Re-read ‘how to change your code number’

on (page no.7) and ensure that all of the

dials in the code are facing towards the

number down the centre.

The spindle has been cut too short or

has been positioned incorrectly.

If the spindle is too short it will not engage

with the keypad knob or inside handle. If

the spindle has been placed incorrectly

please refer to ‘tting & positioning the

spindle’ (page no.4).

Problem Cause Solution

The keypad knob turns freely with-

out having to enter any code.

The knob has been forcibly turned with-

out the correct code being entered.

Please call the Borg Locks helpline or return

the unit to Borg Locks or your distributor.

The inside handle lever does not

return to the upright position after

turning.

The handle return spring has broken. Please call the Borg Locks helpline or visit

our website for a replacment.

The latch does not engage with

the strike and the door remains in

the open position.

The latch is to entering the hole in the

strike plate.

Your door or frame may have warped since

the lock was installled. Check that the latch-

bolt is inline with the hole in the strike plate.

Re-align position of the stike if necessary.

Make sure the anti-thrust pin on the latch

does not enter the hole in the strike plate.

V2

Code Card

C####

Borglocks

3

4

6

7

8

9

10

11 12 13

14

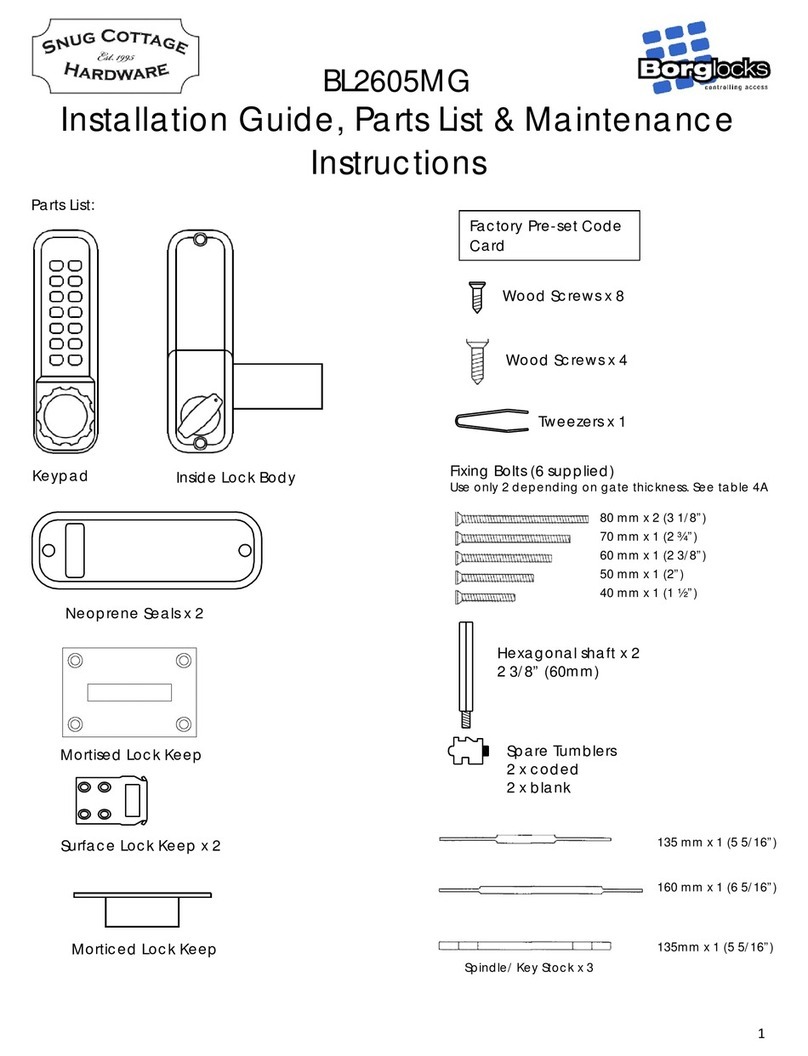

1. Keypad

2. Inside handle

3. Gaskets (x2)

4. Tubular Latch

5. Strike Plate & Box Keep

6. Holdback Snib Blank (Holdback Models Only)

7. Latch Support Post

8. Hexagon Support Posts

9. Spindle (100mm)

10. Spindle (85mm)

11. Machine Screws (50mm)

12. Machine Screws (35mm)

13. Wood Screws (15mm)

Installation Problems

www.borglocks.com

5

8

14. Code Card

1

borglocks.com

1 6

2 7

3 8

4 9

5 0

Y C

2

15. Allen Key

15

16. Code Change Tool

16

2

Please check that all parts are working correctly. Enter the factory preset code as on the code card (part no.14), ro-

tate the turn on the keypad one turn clockwise, re-enter the code and turn the knob anti-clockwise ensuring that the

follower on the back of the keypad rotates each time. The knob should return easily under its spring pressure. If you

intend to change the code please refer to ‘how to change your code number’ instructions (page no.7) prior to tting.

Make sure that the Inside handle device rotates freely and returns under its spring pressure.

Check that the latch bolt on the tubular latch (part no. 4) moves freely by pressing the bolt head at the end, and

also turning the spindle (part no. 9 or 10) in the hour glassed shaped follower on the locking device.

Determining the hand of the door

Many of the installation instructions refer to the handing

of the door. The hand of the door is determined with the

door in its closed position from the exterior or keypad

side of the door.

A) Right hand door – door opens inward (push), hinged

on the right side.

B) Left hand door – door opens inward (push), hinged

on the left side.

C) Right hand inward opening – door opens outward

(pull), hinged on the right side.

D) Left hand inward opening – door opens outward

(pull), hinged on the left side

Inside

Outside

A B

CD

V2

Preparation

Fitting the Latch Support Post

Fit the latch support post (part no.7) in hole A for a right hand hung door or

Bfor a left hand hung door. Please refer to the ‘determining the hand of the

door’ if you are unsure what hand of door you have.

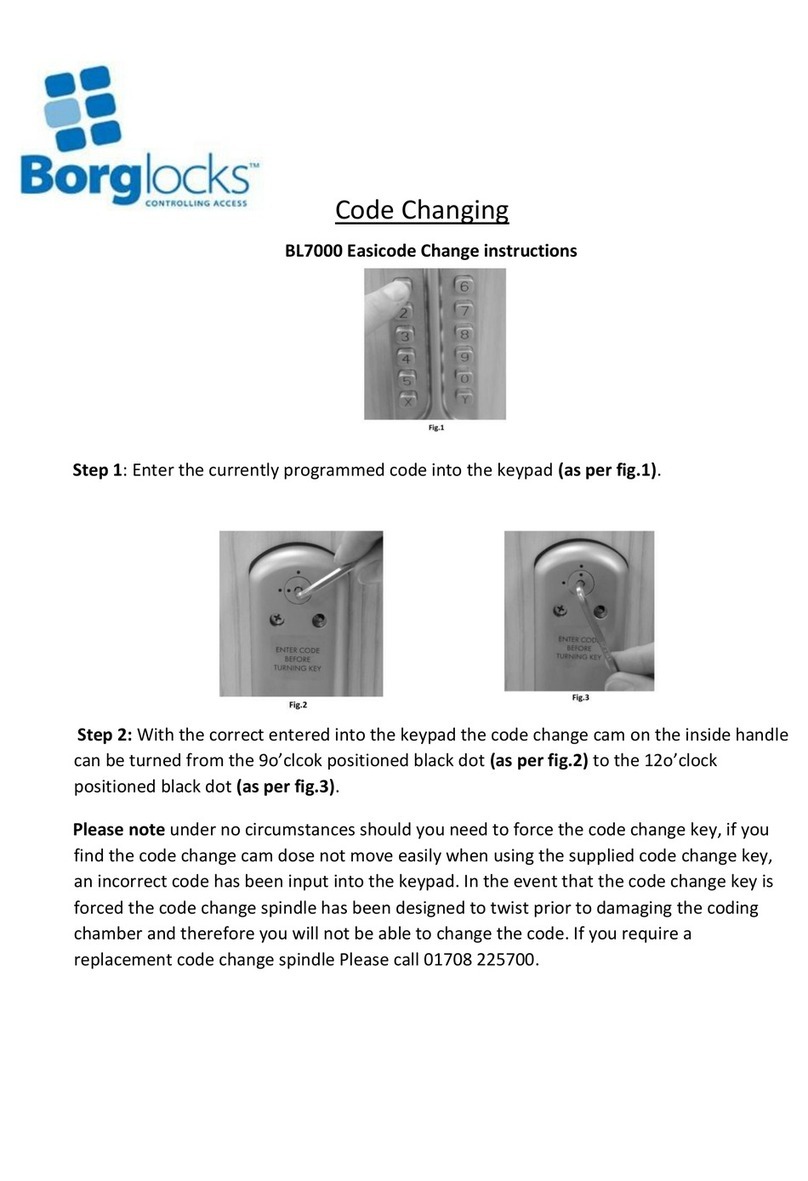

How To Change Your Code Number

Changing the Handing of the Unit

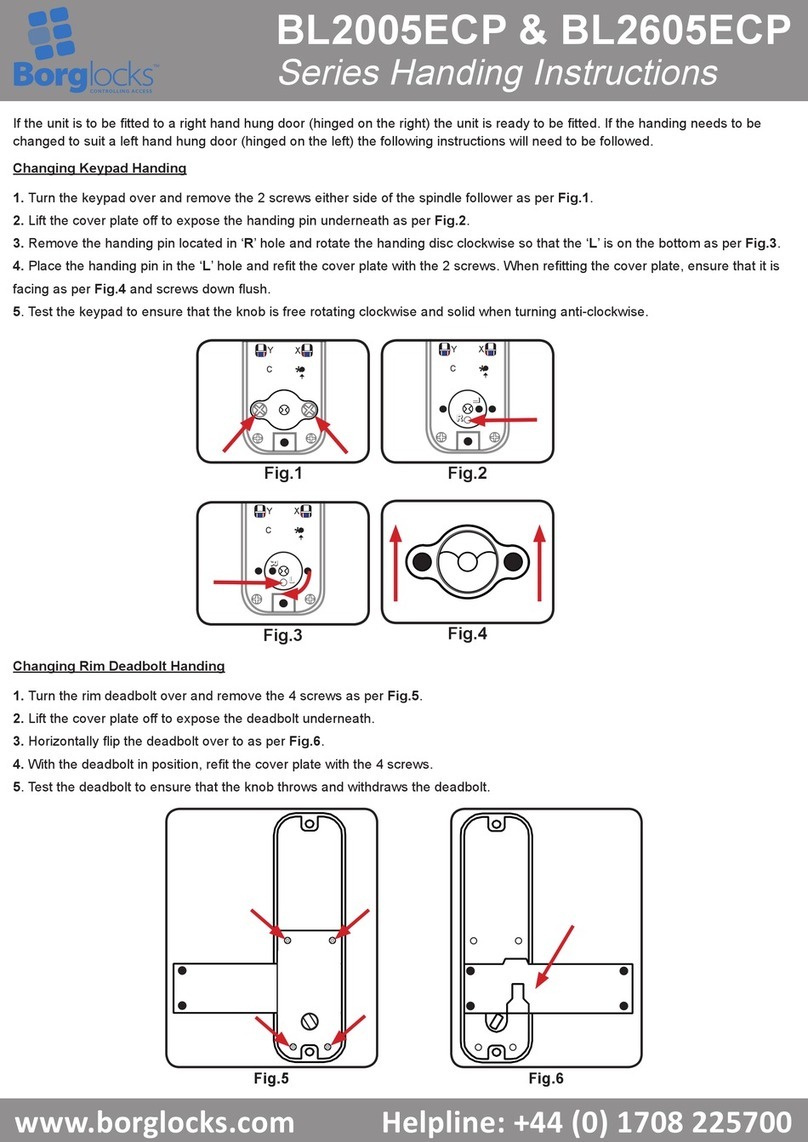

If the unit is being tted to a right hand hung door as per the ‘determining

the hand of the door’ nothing will need to be changed on the unit.

If the unit is being tted to a left hand hung door there are three parts

that would need to be changed. Firstly the blue handing screw on the

back of the inside handle will need to be moved from point Ato point B

as per the diagram.

Finally both handles will need to be swapped around so that they are fac-

ing the opposite way. This is done by removing the rubber grommet from

the stem of the handle to reveal the grub screw. Using the allen key (part

no.15) remove the grub screw, this will allow the handle to come off from

its holder and be rotated the opposite way. Once the handles are facing

the correct way reinsert the grub screw and replace the rubber grommet.

AB

1. Remove the lock from the door, which is done by removing the two screws at the very top and bottom of the inside handle.

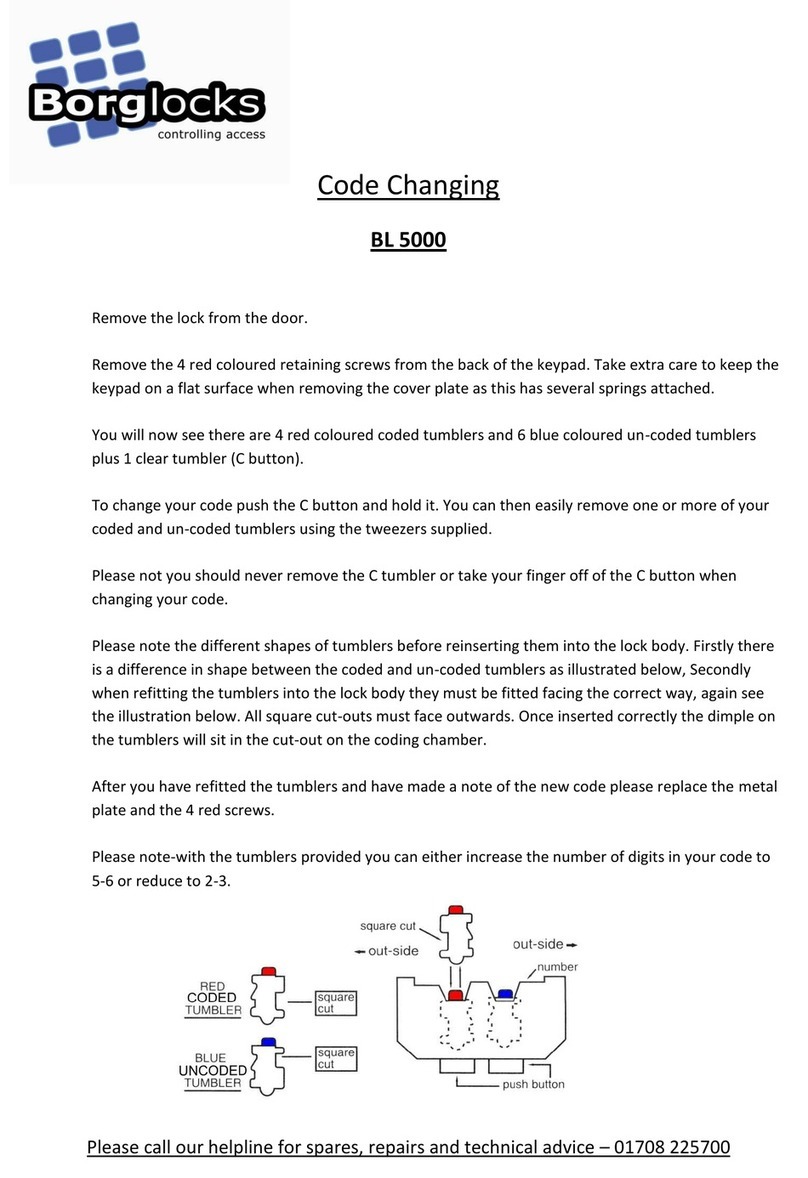

2. Turn the keypad over so that you are able to see the code change dials on the reverse (as shown in the diagram below).

3. Press the ‘C’ button to ensure that no digits have been pressed.

4. Using the code change tool (part no.16) press and turn all of the code change dials outwards so that all of the red markers

on all of the code change dials are facing outwards.

Under no circumstances should any tool other than the code change tool (part no.16) to be used to turn the code

change dials.

5. To ensure that no digits have been entered, press the ‘C’ button and turn the knob on the keypad.

If the knob does not turn freely without having to enter any code, turn the keypad over and check that all of the red

markers on the code change dials are facing outwards.

6. To set a button as a coded digit the code change dial will need to be pressed and rotated using the code change tool (part

no.15) so that the red marker is facing towards the number or letter down the centre of the lock.

As you will see in the diagram below it has been coded to 1, 2, 3, 4, 5 as all of the red markers on the code change

dials are facing towards the numbers down the centre of the keypad and the remaining non coded digits are facing

outwards.

7. Ensure that all the remaining digits that are not in the code are facing outwards. As you will see from the diagram below the

digits that are not in the code 6, 7, 8, 9, 0 and Y have the red marker facing outwards and all of the coded digits red markers

are facing inwards towards the number down the centre of the keypad.

Please note that the code is not sequential and if for instance the unit was coded to 1, 2, 3, 4, 5 the code can be en-

tered 5, 4, 3, 2, 1 or any sequence as long as all of the digits in the code have been pressed. It is recommended that

the ‘C’ button is pressed before each use to clear the coding chamber of any buttons that may have been pressed.

8. With the lock coded and a note made of the new code; enter the code and rotate the knob 3 - 4 times to check that the unit

has been recoded successfully before retting it to the door. Once tted to the door check the code once more before closing.

7

A B

6

7

8

9

0

C

1

2

3

4

5

Y

OutwardsOutwards

Code

Change Dial

V2

Fitting the Hexagonal Support Posts

Fit both of the hexagonal support posts (part no.8) into the top and bottom

threaded holes of the keypad, as shown in the diagram.

Do not over tighten the hexagonal support posts as this may strip the

thread on either the post itself or the thread in the back of the keypad.

V2 3

Removing the Holdback Function

If you do not require the holdback function on the inside handle (holback

models model only) this feature can be removed.

On the back of the inside handle (part no. 2), unscrew all of the screws as

shown on points A, B, Cand Don the diagram.

With the 4 screws removed the plate can now be lifted out of position, this

will reveal the holdback snib, which has a spring and ball bearing attached.

Remove the holdback snib, spring and ball bearing and place the hold back

snib blank (part no. 6) in the hole.

AB

C D

V2

PreparationInstallation

6

Fitting the Strike Plate & Box Keep

Anti-Thrust Pin

Latchbolt

Push the door to the closed position and mark the area on the frame of the door where the strike plate would need

to be tted.

Open the door and now mark the inner and outer edges of the strike plate. Using a sharp chisel remove 1mm of

material from the frame of the door until the strike plate can sit ush.

With the material for the strike plate removed from the frame of the door, the material for the box keep will need to

be removed. Place the box keep in the cut-out made for the strike plate and draw around the box keep. You will

need to remove 36mm high, 23mm wide and 13mm deep of material to accommodate the box keep, alternatively a

20mm diameter by 15mm deep hole can be drilled in the frame to allow the latchbolt to fully protrude when the door

is in its closed position.

To secure the strike plate and box keep in place use two of the wood screws (part no. 13). Now that the strike and

the box keep have been secured in place the door can be closed. Ensure that the keypad and inside handle with-

draw the latch when the door is in its closed position.

If the operation of the lock is excessively stiff when turning the keypad or inside handle, the strike plate

and box keep position will need to be adjusted.

Please note the anti-thrust beside the latchbolt (as

per the diagram), this deadlocks the latchbolt and

protects it against manipulation. It must not enter

the hole made for the latchbolt when the door is

closed.

If the anti-thrust pin does go into hole for the

latchbolt, adjust the position of the strike plate

until the anti-thrust pin sits on the face of the

strike plate.

Operating the Holdback Function

To operate the holdback function the handle will need be

turned a full 90° to the left or right (depending on the handing

of the door.

If the unit is tted to a left hand hung door the handle will need

to turned to the right (clockwise) and the snib will need to be

pushed to the left. When the snib has been pushed across the

handle will stay in the rotated position and the latchbolt in the

door will be withdrawn.

If the unit is tted to a right hand hung door the handle will

need to turned to the left (anticlockwise) and the snib will need

to be pushed to the right. When the snib has been pushed

across the handle will stay in the rotated position and the

latchbolt in the door will be withdrawn.

To release the holdback function a small amount of pressure

will need to be applied to the handle to allow you to push

the snib across. With the snib pushed across the handle will

spring back to its vertical position and the latchbolt in the door

will now be visible.

Holdback

Snib

A

B

6

7

8

9

0

C

1

2

3

4

5

Y

4V2

Drilling the Door & Fixing the Latch

With all the drilling points marked out on the door, the holes can be drilled.

All of the 6 x 8mm holes will need to be drilled through the door. The remaining material which will be around the 4 x

8mm horizontal holes will need to be removed with a sharp chisel.

Where the ‘centre line of latch’ is marked on the template, drill a 25mm wide and 85mm deep hole in the edge of the

door to accommodate the barrel of the latch.

Insert the barrel of the latch into the hole in the edge of the door and draw around the rectangular face plate latch.

With the face plate marked, remove the latch from the hole in the door. Now remove 3mm of material from the door

so that the face plate of the latch sits ush with the door edge. With the latch positioned in the door it can now be

secured using two of the woods screws (part no. 13) via the two screw holes in the face plate of the latch.

Apply the Drilling Template

Tape the template to the door and ensure that the dotted line on the template is

aligned to the edge of the door.

Mark all six of the 8mm holes as shown on the drilling template.

Mark on the door ‘centre line of latch’ ensuring that the centre line for the latch is in

the centre on the edge of the door.

Installation

Fitting & Positioning the Spindle

Select one of the two spindles (part no.9 - 100mm spindle) or

(part no. 10 - 85mm spindle) supplied in the accesory pack. Use

the longest spindle possible. Cutting the spindle down may be re-

quired, but this would depend entirely on the thickness of the door.

Please note if the spindle is cut too short this may cause the

spindle to slip out of possition if the door is slammed and

result in users being locked out.

Fitting the Keypad & Inside Handle

Place the larger of the two rubber gaskets (part no.3) around the back of the

keypad, ensuring that the gasket is the correct way up and that the spindle fol-

lower is still visible. As per the image.

The xing posts at the top and bottom on the reverse of the keypad will sit in

the very top and bottom 8mm holes drilled in the face of the door. When in

place ensure that the spindle is located into the spindle follower on back of the

keypad. Continued of page no.5.

5V2

Place the smaller remaining rubber gasket (part no. 3) around the back of the inside handle and as with the key-

pad side the spindle follower on the back of the inside handle will need to be visible.

With the keypad in place on the door and the inside handle having the rubber gasket in place the inside handle

can be offered up to the door and secured in place using one pair of the machine screws (part no. 11 or 12). The

length of machine screw used would depend entirely on the thickness of the door.

Once the unit has been secured onto the door the unit can be tested on the set code. Check that both the keypad

and inside handle retract the latch fully.

Please note if the latch does not retract, the spindle has been put in the incorrect way. Please refer to ‘tting and

positioning the spindle’ on page no.4 as how to insert the spindle into the latch.

If the spindle is too short for the thickness of door, you will nd that you will only be able to retract the latch from

one side of the door and therefore you will need to remove and replace with a longer spindle.

If you nd the operation of the unit is very stiff when you are testing, either the unit has been over tightened on the

door and would need to be loosened or not enough material has been removed when drilling out the hole for the

barrell of the latch and therfore the unit will need to be taken off of the door and more material removed.

Installation

Fitting Illustration

Right Hand Left Hand

As viewed from the outside

of the door

Gaskets

(part no.3)

Keypad

(part no.1)

Inside Handle

(part no.2)

Machine Screws

(part no.11/12)

Hexagon Support

Posts (part no.8)

Spindle

(part no.9/10)

Tubular Latch (part no.4)

Secured in place with 2 wood screws (part no.13)

Other Borglocks Lock manuals

Borglocks

Borglocks BL2615MG Configuration guide

Borglocks

Borglocks BL2701 Quick guide

Borglocks

Borglocks BL7000 Easicode User manual

Borglocks

Borglocks BL4409 User manual

Borglocks

Borglocks BL 2605 MG Pro Configuration guide

Borglocks

Borglocks BL 5000 User manual

Borglocks

Borglocks BL2605MG User manual

Borglocks

Borglocks BL2615MG Configuration guide

Borglocks

Borglocks BL2005ECP Series User manual

Borglocks

Borglocks BL2605MG Configuration guide