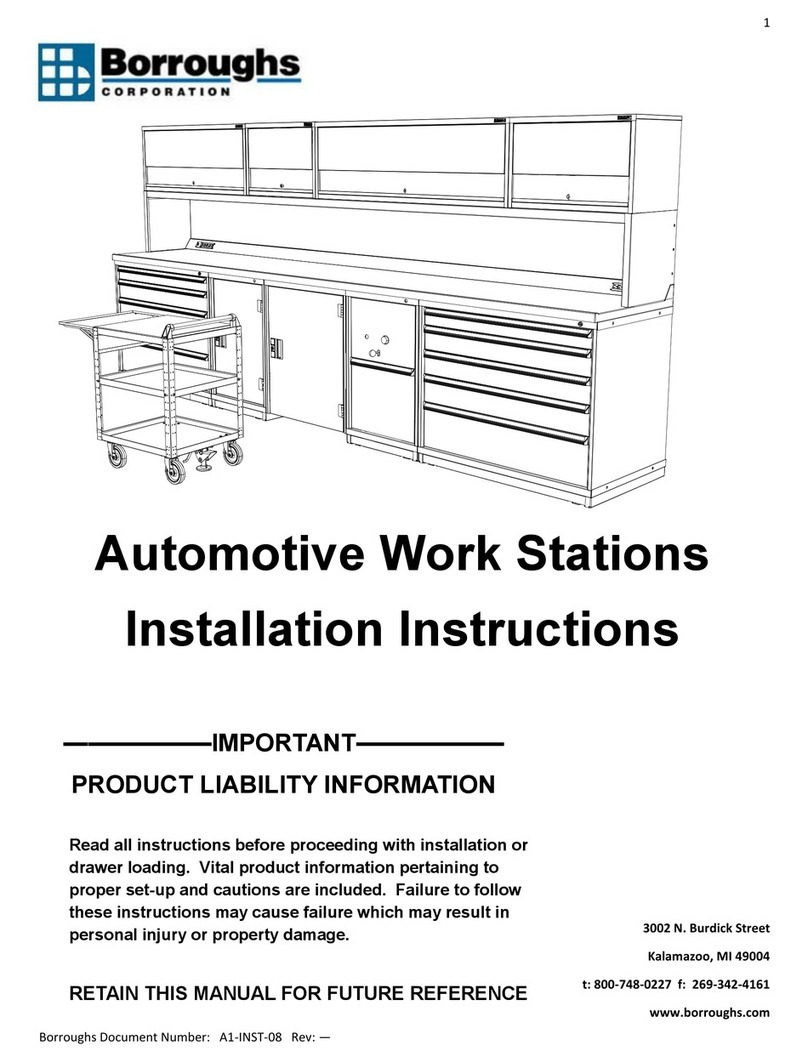

Borroughs BASIC PRO SERIES User manual

1

BASIC PRO-SERIES WORKBENCH

SECTION #1

CONTENTS

Basic Pro-Series…………………………………………2

Roller Bearings………………………………………….11

Lift Cabinet……………………………………………...12

Continuous Pro-Series…………………..……… ….…14

IMPORTANT - PRODUCT LIABILITY

INFORMATION Read all instructions before

proceeding with installation. Vital product

information pertaining to proper set-up and

cautions are included. Failure to follow these

instructions may result in personal injury and/or

property damage.

RETAIN THIS MANUAL FOR FUTURE

REFERENCE

NOTICE:

Borroughs Corporation extends to the original purchaser from the date of purchase, a 5

year limited warranty against manufacturing defects in material and workmanship. If a Borroughs

product fails to perform because of a manufacturing defect, Borroughs will examine it. If found

defective, it will be repaired at our option. This warranty applies only to Borroughs products acquired

directly from Borroughs Corporation or from Authorized Borroughs Dealers. This warranty does not

apply to any product which has been subject to misuse, negligence, or accident; has been damaged in

shipment, storage, or installation; has been misapplied or has been modified or repaired by

unauthorized persons or been repaired with non-standard Borroughs replacement parts. This warranty

specifically excludes claims for indirect, incidental, or consequential damages arising in any way from a

product defect. This warranty is exclusive, and exists in lieu of all other warranties, either express or

implied. This warranty gives you specific legal rights; you may also have other rights which may vary

from state to state. To obtain warranty service, contact your Borroughs Selling Dealer. You must make

a written claim. Provide a copy of your purchase record and a written description of the warranty

problem with your claim. If you are unable to contact your dealer, contact: Borroughs Corporation,

Customer Service Manager, 3002 N. Burdick Street, Kalamazoo, MI 49004-3483

3002 N. BURDICK ST. ▪KALAMAZOO, MI 49004-3483 09-50679-00

800-748-0227 ▪FAX: 269-342-4161 ▪www.borroughs.com November 2004

2

FOR STEPS 1-3, HARDWARE NEED ONLY BE FINGERTIGHTENED

TOOLS REQUIRED: PHILLIPS HEAD SCREWDRIVER, ADJ WRENCH, FLAT HEAD SCREWDRIVER, CORDLESS

DRIVER WITH PHILLIPS ATTACHMENT, TAPE MEASURE

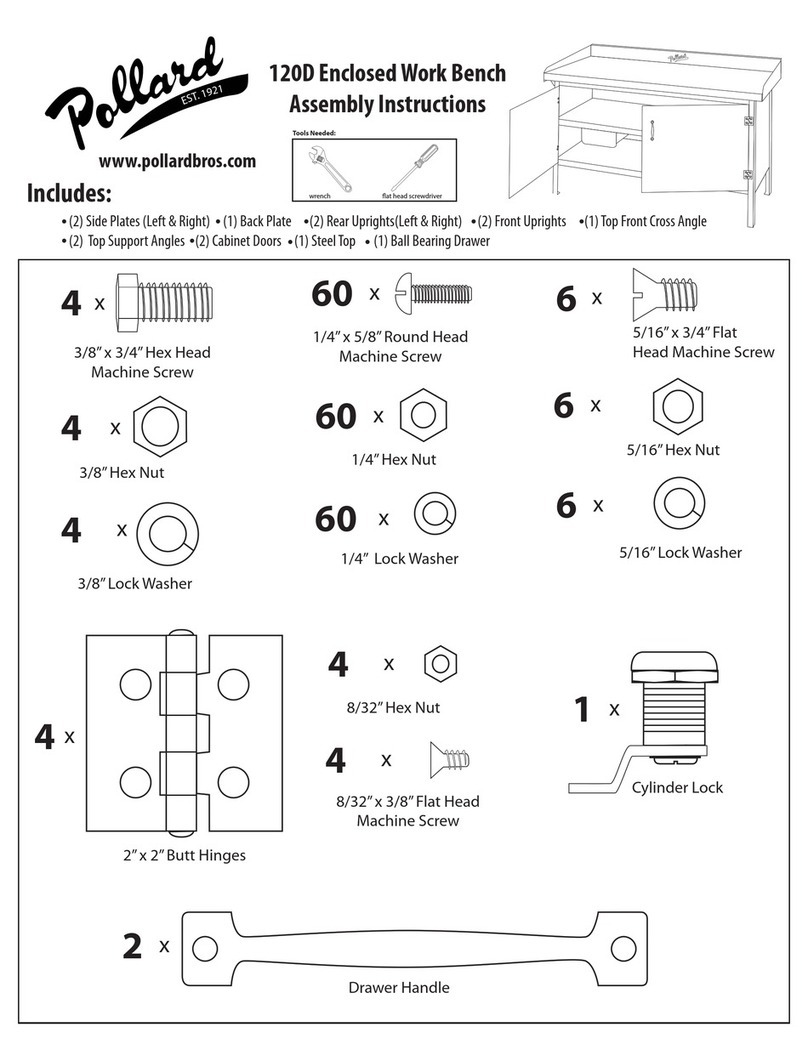

*REMOVE ALL ITEMS FROM CARTON AND CHECK AGAINST THE FOLLOWING LIST:

*PARTS LIST – BASIC UNIT*

ITEM DESCRIPTION REQ’D

1 BENCH TOP 1

2 LH LEG NO HOLES 1

3 RH LEG NO HOLES 1

4 LH LEG FILLER 1

5 RH LEG FILLER 1

6 BASE SHELF 1

7 BACK STOP CHNLS 1

8 BENCH DOORS 2

9 DOOR TRACK 1

10 TRACK COVER 1

11 BACKSPLASHES 1

12 FRONT FACE BRKT 1

*REMOVE ALL ITEMS FROM THE HARDWARE PACK AND CHECK AGAINST THE FOLLOWING LIST:

ITEM 13 ITEM 14 ITEM 15 ITEM 16 ITEM 17

10-24 KEPS NUT PNHD TH 10-24 x 3/8 ¼ FLAT WASHER ¼-20 KEPS NUT ¼-20X5/8 GD5 HX HD

SCREW

(3) REQ’D (3) REQ’D (24) REQ’D (12) REQ’D (12) REQ’D

ITEM 18 ITEM 19 ITEM 20 ITEM 21 ITEM 22

DBLE CHNL DOOR GUIDE 8-32 x ¾ FLHD MS KEPS NUT 8-32 1-5/8 X 1-5/8 SQ WASHER 3/8-16 X1-1/4 BOLT

(1) REQ’D (2) REQ’D (2) REQ’D (4) REQ’D (4) REQ’D

3

ITEM 23 ITEM 24 ITEM 25 ITEM 26 ITEM 27

5/16-18 KEPS NUT 5/16-18 X 5/8 HXHD BOLT DOOR HANDLE 15IN ROLLER WHEEL 10-24 ROLOK

(12) REQ’D (12) REQ’D (2) REQ’D (4) REQ’D (12) REQ’D

ITEM 28 ITEM 29 ITEM 30 ITEM 31

5/8 OFFSET WHEEL BRKT STRAIGHT WHEEL BRKT M4-.7 X 8MM TRHD 8-32 X 5/16 PNHD PHIL

(2) REQ’D (2) REQ’D (4) REQ’D (4) REQ’D

ITEM 32 ITEM 33

¼-20 x ¾ Hes Head SFS #14 x ¾ Hex Head SDS

(4) REQ’D (1) REQ’D

4

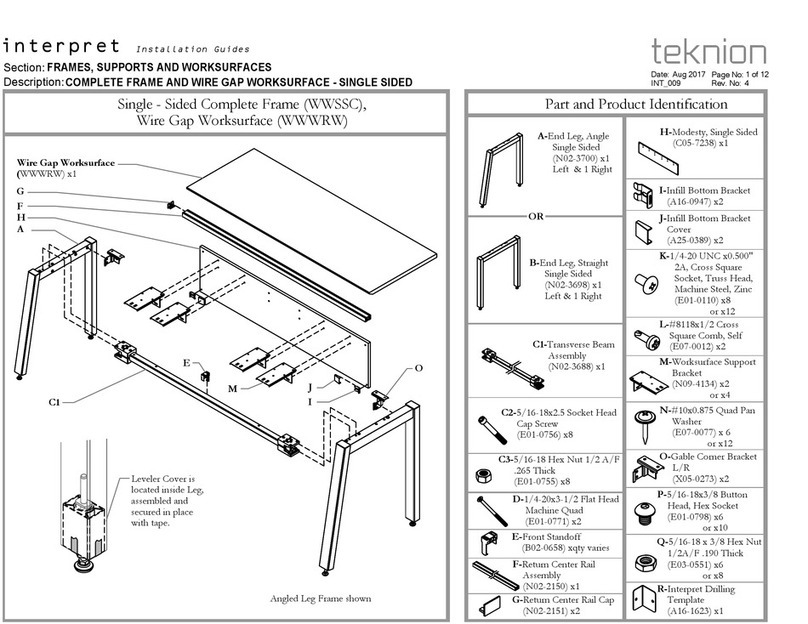

STEP 1: LEG ASSEMBLY

Place a bench top (Item 1) on a flat surface with the four support angles facing up. Fasten LH and RH legs (Items 2 & 3) to

the outside angles using (10) 5/16-18 x 5/8 hex head bolts (Item 24) and (10) 5/16-18 keps nut (Item 23). If your bench has

an overhang then move the leg with holes in 12” to the inside support angle. Do not place bolt in hole closest to front of

bench until leg fillers are in place. Next, place LH and RH leg fillers (Items 4 & 5) to the inside of the legs as shown in

(Figure 1.). Use (1) 5/16-18 x 5/8 cap screw (Item 24) and (1) 5/16-18 keps nut (Item 23) per filler. Do not tighten fasteners.

Figure 1.

5

STEP 2: BASE SHELF ASSEMBLY

Place the base shelf (Item 6) between the leg fillers and the leg (Figure 2.) on both sides. Fasten base shelf to legs

and fillers by using (8) ¼-20 x 5/8 cap screws (Item 17), (16) ¼ flat washers (Item 15), & (8) ¼-20 keps nuts (Item

16). Next, position and fasten back stop chnl into place with (4) ¼-20 x 5/8 cap screws (Item 17), (8) ¼ flat washers

(Item 15), & (4) ¼-20 keps nuts (Item 16). Do not tighten

fasteners at this point.

Figure 2.

6

IF INSTALLING ROLLER BEARINGS THEN SKIP TO SECTION 2 BEFORE GOING TO STEP 3

STEP 3: FRONT FACE / DOOR TRACK

Place the front face (Item 12) in-between the leg fillers as is shown in (Figure 3). Line up the holes in the leg fillers with the

holes on the ends of the front face and fasten tight with (4) ¼-20 x ¾ hex head TFS (Item 32). Next, fasten the front edge of

the front face to the top using (1) #14x3/4 hex head SDS (Item 33) through the hole in the front face. Place the track cover

(Item 10) on the front face lining up the three holes, then place the track (Item 9) on top of the track cover keeping the three

holes lined up. Using (3) #10-24 x 3/8 Truss Hd Phil (Item 14) and (3) #10-24 keps nut (Item 13) fasten track & track cover

to front face.

Figure 3.

7

STEP 4: SQUARE AND TIGHTEN

Measure the distance from the back of the leg to the edge of the top. This distance needs to be 1/8” smaller than the depth of

the uni-strut being used to mount unit to the wall (Ex. Set distance to 1-1/2” if using 1-5/8” uni-strut). Next measure the

distance from the outside of the leg to the side edge of the top and make sure they are equal to ensure a square unit. NOTE:

IF BUILDING A 10FT BENCH WITH 24” CENTER SHELF SET DISTANCE FROM OUTSIDE OF LEG TO SIDE

EDGE OF BENCH TO 12-1/16”. Once both legs have been measured and set for square then tighten the (12) 5/16-18 x 5/8

cap screws (Item 24) that attach the top to the legs. Once those have been tightened everything else may be tightened at this

time. See (Figure 4).

Figure 4.

IF INSTALLING LIFT CABINET THEN SKIP TO SECTION 3 BEFORE GOING TO STEP 5

8

STEP 5: ATTACH BACKSPLASH

Remove protective film from backsplash and fasten to back of bench top using (4) 10-24 rolok screws (Item 27). See (Figure

5).

Figure 5.

9

STEP 6: MOUNT TO WALL

Set bench upright on floor. Cut (2) pieces of uni-strut to nominal length of bench. Attach first piece of uni-strut to wall 12”

above the floor. Attach second piece of uni-strut to wall 30” above floor. For proper alignment it’s very important that the

two pieces of uni-strut are mounted 18” center to center. Make sure uni-strut is parallel to floor and parallel to each other.

Place (2) spring loaded uni-strut nuts in the top and bottom uni-strut that will line up with the holes in the legs for mounting.

Using (4) 1-5/8 x 1-5/8 sq washers (Item 21) and (4) 3/8-16 x 1-1/4” cap screws (Item 22) attach unit to wall. Keep fasteners

loose until bench is in desired location and then tighten. See (Figure 6)

Figure 6.

NOTE: IF A BENCH TOP HEIGHT OF 36” IS NOT WANTED THEN ADJUST BOTTOM UNI-STRUT

ACCORDLYING BUT KEEP 18” DISTANCE BETWEEN THE TWO UNI-STRUTS

10

IF YOU’RE ASSEMBLING A 2

nd

PART 10FT WORK BENCH GO TO SECTION #4 BEFORE STARTING STEP

#7

STEP 7: DOOR ASSEMBLY

Attach the handles (Item 25) to the doors using (2) M4-.7 x 8mm phil truss hd screws (Item 30) per door. Fasten (2) 5/8

offset wheel brackets (Item 28) to the front door using (4) 10-24 rolok screws (Item 27), make sure handle is on the right

hand side. Then fasten (2) straight wheel brackets (Item 29) to the back door using (4) 10-24 rolok screws (Item 27), make

sure when brackets are attached that handle is on the left hand side. Assemble (2) roller wheels (Item 26) to each door using

(2) 8-32 x 5/16” pnhd phil screw (Item 31). See (Figure 7).

Figure 7.

STEP 8: MOUNT DOORS

Hang back door first by tilting door outward at bottom and setting on the back track. Then hang the front door by tilting door

outward at the bottom and setting on the front track. Once both doors are hung then push both doors to one side and slide in

(1) double channel door guide (Item 18). Use (2) 8-32 x ¾ flat hd screw (Item 19) and (2) 8-32 keps nut (Item 20) to fasten

door guide. See (Figure 8).

Figure 8.

11

ROLLER BEARING ASSEMBLY

SECTION #2

FOR STEP 1, HARDWARE NEED ONLY BE FINGERTIGHTENED

TOOLS REQUIRED: PHILLIPS HEAD SCREWDRIVER

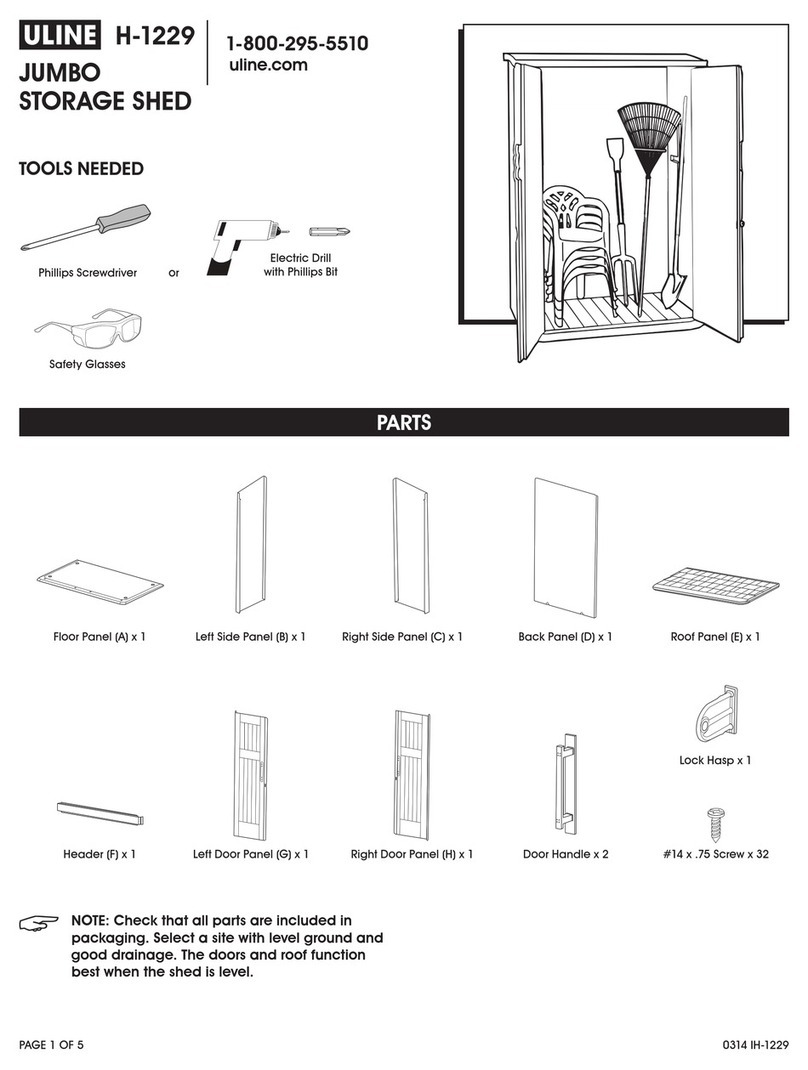

*REMOVE ALL ITEMS FROM CARTON AND CHECK AGAINST THE FOLLOWING LIST:

*PARTS LIST – ROLLER BEARING*

*REMOVE ALL ITEMS FROM THE HARDWARE PACK AND CHECK AGAINST THE FOLLOWING LIST:

ITEM 1 ITEM 2 ITEM 3 ITEM 4

PNHD TH 10-24 x 1/4 NYLON ROLLER ROLLER GUIDE MTG BLOCK 2-9/16” ROD

(4) REQ’D (4) REQ’D (4) REQ’D (4) REQ’D

STEP 1: ROLLER BEARING ASSEMBLY

Prior to Step 3 in the first section, attach the (4) roller guide mtg blocks (Item 3) to the front face. Use (4) 10-24x1/4 pnhd

screws to attach the mounting blocks, DO NOT TIGHTEN. Slide (1) rod (Item 4) into (1) nylon roller (Item 2) and then

slide the rod into hole in mounting block then slide the other end into the corresponding hole in opposite mounting block.

Make sure that the tabs on the mounting blocks are facing towards the opening. Repeat for all four rollers. See (Figure 9).

Figure 9.

STEP 2: TIGHTEN ROLLER ASSEMBLY

Once all four roller bearings are installed then tighten all four screws.

12

LIFT CABINET ASSEMBLY

SECTION #3

FOR STEP 1, HARDWARE NEED ONLY BE FINGERTIGHTENED

TOOLS REQUIRED: PHILLIPS HEAD SCREWDRIVER, ADJ WRENCH

*REMOVE ALL ITEMS FROM CARTON AND CHECK AGAINST THE FOLLOWING LIST:

*PARTS LIST – LIFT CABINET*

ITEM DESCRIPTION REQ’D

1 BOTTOM ANGLE LATCH

1

2 LIFT SIDE PAN W/HOLES 1

3 LIFT SIDE PAN NO HOLES

1

4 LIFT CABINET FACE 1

*REMOVE ALL ITEMS FROM THE HARDWARE PACK AND CHECK AGAINST THE FOLLOWING LIST:

ITEM 5 ITEM 6 ITEM 7 ITEM 8 ITEM 9

¼ FLAT WASHER ¼-20 KEPS NUT ¼-20X5/8 GD5 HX HD SCREW 10-24 ROLOK SNAP IN MAGNET

(12) REQ’D (6) REQ’D (6) REQ’D (2) REQ’D (8) REQ’D

STEP 1: ATTACH LEGS TO TOP

Prior to Step 5 in the first section, attach (1) lift side panel w/holes (Item 2) to the leg on the side where the over hang is. The

edge of panel with rectangular holes goes to the front. Use (4) 1/4-20x5/8 hex head screws (Item 7), (4) ¼-20 keps nuts (Item

6) & (8) ¼ flat washers (Item 5) to attach the panel, DO NOT TIGHTEN. Set (1) lift side panel with no holes (Item 3) on the

top support at the edge of the bench top with rectangular holes towards the front. Use (2) 1/4-20x5/8 hex head screws (Item

7), (2) ¼-20 keps nuts (Item 6) & (4) ¼ flat washers (Item 5) to attach the panel, DO NOT TIGHTEN. Measure the distance

from back edge of the bench top to the back of leg. Use that dimension to set lift side panels flush with the legs on the back

side. Also, make sure outer panel with no holes is flush with the side edge of bench top. See (Figure 10). Once panels are

located flush with the legs tighten hardware.

13

Figure 10.

STEP 2: ASSEMBLE BOTTOM LATCH ANGLE

Once both side panels are tightened then attach (1) bottom angle latch (Item 1) to the underside of the side panels shown in

Figure 2. Use (2) 10-24 rolok screws (Item 8) to fasten bottom angle. If door fits too tight than loosen 10-24 rolok screws

and pull side panels apart to widen distance and then re-tighten.

14

10 FEET PRO-SERIES ASSEMBLY

SECTION #4

FOR STEPS 1&2, HARDWARE NEED ONLY BE FINGERTIGHTENED

TOOLS REQUIRED: PHILLIPS HEAD SCREWDRIVER, ADJ WRENCH, FLAT HEAD SCREWDRIVER, CORDLESS

DRIVER WITH PHILLIPS ATTACHMENT, TAPE MEASURE

*REMOVE ALL ITEMS FROM CARTON AND CHECK AGAINST THE FOLLOWING LIST:

*PARTS LIST – 10FT W/CENTER SHELF UNIT*

ITEM DESCRIPTION REQ’D

1 CENTER DOOR 1

2 CENTER BASE SHELF 1

3 BACK STOP CHNL 1

4 24” FRONT FACE BRKT 1

*REMOVE ALL ITEMS FROM THE HARDWARE PACK AND CHECK AGAINST THE FOLLOWING LIST:

ITEM 5 ITEM 6 ITEM 7 ITEM 8

¼ FLAT WASHER ¼-20 KEPS NUT ¼-20X5/8 GD5 HX HD SCREW ¼-20 x ¾ Hes Head SFS

(8) REQ’D (4) REQ’D (4) REQ’D (4) REQ’D

ITEM 9 ITEM 10 ITEM 11

#14 x ¾ Hex Head SDS ¼ TURN SPRING LOADED ¼ TURN RETAINER

(1) REQ’D (2) R EQ’D (2) REQ’D

STEP 1: HANG BENCHES ON UNI-STRUT

Once both benches are hanging on the uni-strut slide the two together until the tops touch. NOTE: IF YOU DO NOT HAVE

A CENTER BASE SHELF THEN GO TO STEP 3. Bolt the center base shelf (Item 2) into position using (4) ¼-20 x 5/8 hx

hd screw (Item 7), (8) ¼ flat washer (Item 5), & (4) ¼-20 keps nuts (Item 6). DO NOT TIGHTEN.

15

STEP 2: 24” FRONT FACE BRACKET

Insert the (2) ¼ turn retainers (Item 11) into the square holes in the 24” front face bracket. See (Figure 11). Next fasten 24”

front face brkt using (4) ¼-20 x ¾ hex head SFS (Item 8) into position, DO NOT TIGHTEN.

Figure 11.

STEP 3: TIGHTEN BENCHES

Tighten the (4) 3/8-16 x 1-1/4 hex head bolts that go to the uni-strut on both units. STOP HERE IF YOU DO NOT HAVE A

CENTER BASE SHELF. Then tighten the (4) ¼-20 x 5/8 hex head bolts (Item 7) that go to the center base shelf. Also

tighten the (4) ¼-20 x ¾ hex head SFS (Item 8) that hold the 24” front face. Lastly install (1) #14-3/4 Hex Head SDS (Item

9), in the front face going up through hole in front flange.

STEP 4: INSTALL CENTER DOOR

To install center door drop taps of door into slots in the shelf. Line up the holes in the door with the ¼ turn retainers (Item

11) and then install (2) ¼ turn spring loaded fasteners (Item 10) to hold door. See (Figure 12)

16

Figure 12.

GO TO SECTION #1, STEP #7

*NOTICE*

The following is the only warranty applicable to the products: the manufacturer warrants that the products are free from

defects in material or workmanship when installed, used and serviced in accordance with the manufacturer’s

recommendations. The manufacturer’s only obligation under this warranty shall be to replace any product, which is defective

in materials within one year or defective in workmanship within ninety days, from the date of installation. THE

FOREGOING WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PURPOSE. The manufacturer shall not

be liable for any loss or damage, direct of indirect, resulting from the use or loss of use of the product. This warranty may

not be changed except by a written agreement signed by an officer of the manufacturer.

17

Table of contents

Other Borroughs Tools Storage manuals