Borroughs Box Edge Plus User manual

- 1 -

02-50000-00C

December 2002

––––––––– IMPORTANT –––––––––

PRODUCT LIABILITY INFORMATION

Read all instructions before proceeding with installation or shelf loading.

Vital product information pertaining to proper set-up, safe loading and cau-

tions are included. Failure to follow these instructions may cause shelving

failure which may result in personal injury and/or property damage.

Box Edge Plus®Steel Shelving

Installation Instructions

RETAIN THIS MANUAL

FOR FUTURE REFERENCE

- 2 -

GENERAL INSTRUCTIONS

In preparing for multiple section installations, it is recom-

mended that a floor plan with elevations be available at the

job site. It is further recommended that the floor be marked

to indicate where the rows will be and where the aisles will

be so that the distributed material can be stacked for

minimal interference. This will also show where obstruc-

tions will occur. The sections may then be erected along

the lines so that once the row is in place, the bracing bolts

can be tightened and each section will remain square.

Rough or uneven floors should be compensated with

shims. It is required that sections not be out of plum more

than

1" in ten feet or more of height

.

+1/16"

-0"

+1/16"

-0" +1/16"

-0"

+1/32"

-0"

+1/32"

-0"

+1/32"

-0"

+1/16"

-0"

+1/16"

-0"

+1/16"

-0"

+1/16"

-0"

WIDTHS:

Nominal unit width: 24", 36", 42" or 48"

Actual beaded post unit width is the nominal width plus 1"

Actual angle post unit width is the nominal width

Actual high-rise post unit width is the nominal width plus 2"

DEPTHS:

Nominal depth: 12", 15", 18", 24", 30", 32" or 36"

Actual beaded post unit depth is the nominal depth plus 15/32"

with beaded post in front and angle post in back

Actual angle post unit depth is the nominal depth

Actual high-rise post unit depth is the nominal depth plus 15/32"

with high-rise post in front and angle post in back

Actual high-rise post unit depth is the nominal depth plus 1-15/16"

with high-rise posts in front and in back

HEIGHTS:

Nominal height: One foot increments from 3'3" to 16'3"

Actual height is the nominal height minus 1/4"

±

1/16"

NOTE: Unit anchoring is recommended when the height to depth ratio exceeds 4.

EXAMPLE:

7'3" high x 18" deep unit has a height to depth ratio of 4.873

and should be anchored to a firm restraint such as a floor, wall or tied overhead across

the aisle to an opposite upright assembly.

LENGTH OF RUN:

Actual length of beaded post shelving run in nominal unit width per unit

plus 1/2" for each row end.

Actual length of angle post shelving run in nominal unit width per unit

Actual length of high-rise post shelving run is nominal unit width per unit

plus 1" for each row end.

CLEAR SHELF OPENING:

Actual clear opening between beaded posts is the nominal width minus 1"

Actual clear opening between angle posts is the nominal width minus 2"

Actual clear opening between high-rise posts in the nominal width minus 2"

Vertical clearance between shelves is equal to center-to-center shelf spacing minus 1-7/32"

VERTICAL ADJUSTMENT:

All shelves are adjustable on 1-1/2" centers

BASIC DATA

BOX EDGE PLUS®1 BOX EDGE PLUS®2 BOX EDGE PLUS®3

Size Shelf Capacity Shelf Capacity Shelf Capacity

24" x 12" 600 lbs.

36" x 12" 600 lbs. 800 lbs. 1100 lbs.

42" x 12" 600 lbs. 1000 lbs.

48" x 12" 400 lbs. 500 lbs. 800 lbs.

36" x 15" 600 lbs. 800 lbs. 1100 lbs.

42" x 15" 600 lbs. 1000 lbs.

48" x 15" 500 lbs. 800 lbs.

24" x 18" 600 lbs.

36" x 18" 600 lbs. 800 lbs. 1200 lbs.

42" x 18" 600 lbs. 1000 lbs.

48" x 18" 400 lbs. 500 lbs. 1800 lbs.

24" x 24" 600 lbs.

36" x 24" 600 lbs. 800 lbs. 1200 lbs.

42" x 24" 600 lbs. 1000 lbs.

48" x 24" 400 lbs. 500 lbs. 800 lbs.

36" x 30" 600 lbs. 1900 lbs.

42" x 30" 600 lbs. 1000 lbs.

48" x 30" 500 lbs. 1750 lbs.

42" x 32" 300 lbs. 650 lbs. 1000 lbs.

36" x 36" 400 lbs. 1600 lbs.

42" x 36" 450 lbs. 1600 lbs.

48" x 36" 450 lbs. 1700 lbs.

IMPORTANT:

Wall, floor or top tie anchoring is recommended for units

when the height to depth ratio exceeds 4.

Example: A 7'/84" high x 18" deep unit has a height to

depth ratio of 4.67 and should be attached to a firm

restraint, such as a floor, wall or tied overhead across the

aisle to an opposite upright assembly.

SHELF CAPACITIES

NOTE:

For more specific information on each individual compo-

nent, please call our Customer Service Department at

800-748-0227 and ask for the booklet

"Box Edge Plus

®

Steel Shelving Detail Sheets".

- 3 -

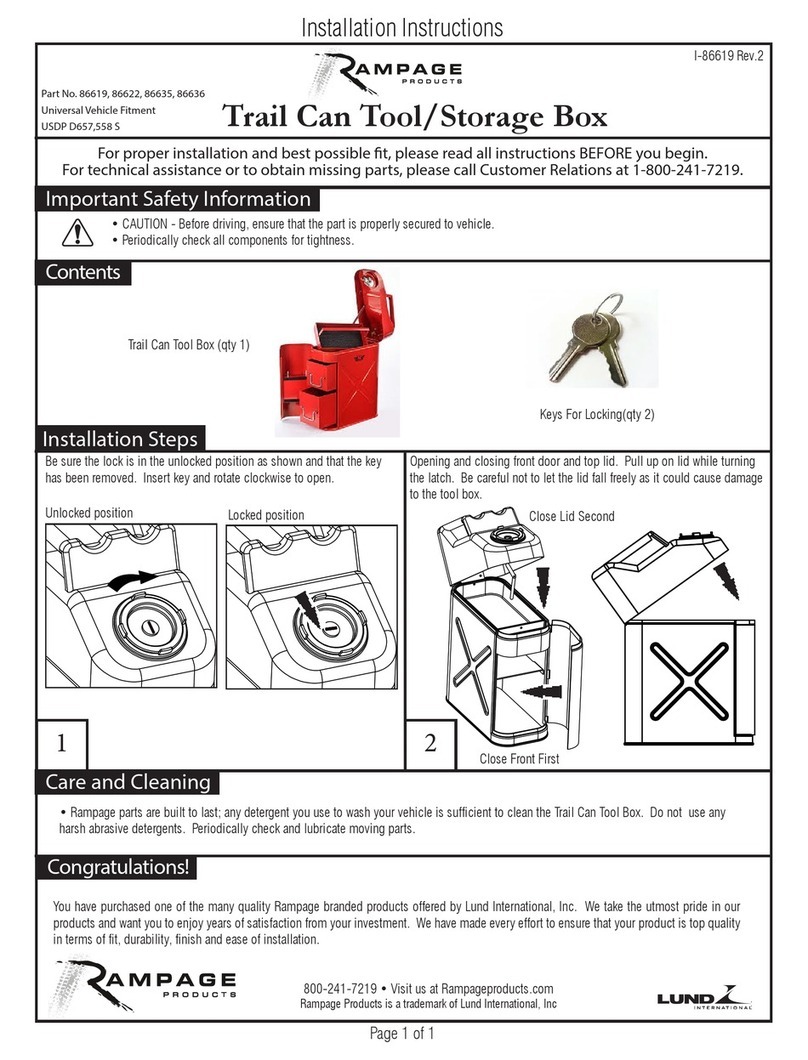

SHELVING PARTS IDENTIFICATION

7

8

910

11 12 13 17

18 19 25

26

20

21

22

16

24

23

12

34

5

6

14

15

WARRANTY

Borroughs Corporation extends to the original purchaser from the date of purchase a

5-year limited warranty against manufacturing defects in material and workmanship.

If a Borroughs product fails to perform because of a manufacturing defect,

Borroughs will examine it. If found defective, it will be repaired or replaced at our

option.

This warranty applies only to Borroughs products acquired directly from

Borroughs Corporation or from Authorized Borroughs Dealers.

This warranty does not apply to any product which has been subject to

misuse, negligence, or accident; has been damaged in shipment, storage, or

installation; has been misapplied or has been modified or repaired by unauthorized

persons or been repaired with non-standard Borroughs replacement parts. This

warranty specifically excludes claims for indirect, incidental, or consequential damages

arising in any way from a product defect. This warranty is exclusive, and exists in lieu

of all other warranties, either expressed or implied.

This warranty give you specific legal rights; you may also have other rights

which may vary from state to state.

To obtain warranty service, contact your Borroughs Selling Dealer. You must

make a written claim. Provide a copy of your purchase record and a written

description of the warranty problem with your claim. If you are unable to contact your

Dealer, contact: Borroughs Corporation, Customer Service Manager, 3002 N. Burdick

Street, Kalamazoo, MI 49004-3483.

1 ..... Angle Post

2 ..... Post Cover -Type 2

3 ..... Angle Post (2)

4 ..... Face Brace

5 ..... Box Edge Plus

®

Shelf

6 ..... Side Cross Brace

7 ..... Side Shelf Support

8 ..... Label Holder

9 ..... Back Cross Brace

10 ... Post Foot Angle

11 ... Post Cover -Type 1

12 ... Base Strip

13 ... Front Foot Plate

14 ... Bin Front

15 ... Ledge Top

16 ... Fixed Shelf Divider

17 ... Angle Post Closed Side

18 ... Shelf Box

19 ... Shelf Box Guide

20 ... Angle Shelf Divider

21 ... Shelving Back

22 ... Flush Bar

... Cornice Top

... Shelf Bracket Clip

... Angle Post Closed Side and Angle Post (2)

... Framed Swing Doors

- 4 -

STEP 3 INTERMEDIATE UPRIGHT

ASSEMBLY

Determine from the floor plan how many intermediate upright assemblies will

be required. Each intermediate consists of four angle posts and one pair of side

sway braces. Bolt two posts together (through the fourth hole from each end, in

the long flange) to form a T post. Repeat with the other two posts. The two T

posts and the side brace are now bolted together at the same level and spacing

as the row end upright assemblies (refer to Step 2). Repeat this procedure until

all intermediates are assembled.

Attach side sway braces to posts with 1/4-20 x 3/4" hex head cap screws and

hex nuts.

STEP 2 ROW ENDS UPRIGHT ASSEMBLY

Determine from the floor plan how may row end upright assemblies will be

required. For each one, attach a pair of side sway braces to two angle posts.

The brace bolts on the inside of the long flange. Refer to pages 10 and 11 for

the approximate, proper* location of the braces. Repeat this procedure until all

row ends are assembled.

*Pre-determine critical shelf location to avoid interference with the sway brace

bolts.

NOTE: ALL BACK AND SIDE SWAY BRACES ARE ATTACHED TO UP-

RIGHTS AT 30" VERTICAL SPACING.

Attach side sway braces to posts with 1/4-20 x 3/4" hex head cap screws and

hex nuts.

STEP I SWAY BRACE ASSEMBLY

After the material has been distributed to the proper location, assemble all

sway braces by loosely bolting two matched pieces together at the center.

Assemble side sway braces with 1/4-20 x 3/4" hex head cap screws and hex

nuts.

Assemble rear sway braces with 1/4-20 x 5/8" hex head cap screws and hex

nuts.

1/4-20 x 3/4" Hex Head Cap Screw

and Hex Nut

1/4-20 x 3/4" Hex Head Cap

Screw and Hex Nut

30"

1/4-20 x 3/4" Hex Head

Cap Screw and Hex Nut

Automatically Spaces

This Side

OPEN TYPE SHELVING

Bolt This Side First

Fourth Hole From Each End

- 5 -

STEP 4 SINGLE ROW - SINGLE FACE

ASSEMBLY

In assembly of a single row - single face, begin with a row end upright assem-

bly, a back sway brace and an intermediate upright assembly. The brace bolts

to the row end and the intermediate at the same level and spacing as the

previously installed side braces. (Steps 2 and 3). The brace bolts on the inside

of the short flange.

DO NOT TIGHTEN BOLTS!

Row End

Assembly

Intermediate Assembly

Back Sway Brace

Row End Assembly

Back Sway Brace

Intermediate Assembly

STEP 4A DOUBLE ROW - DOUBLE FACE

ASSEMBLY

In assembly of a double row - double face, begin with two row end upright

assemblies, a back sway brace and two intermediate upright assemblies. Bolt

the two row ends together and then bolt the two intermediates together - each

in the fourth hole from the ends. Two legs of the back brace are now bolted on

the inside of the short flanges of each upright at the same level and spacing as

the previously installed side braces. (Steps 2 and 3).

DO NOT TIGHTEN BOLTS!

STEP 5 BASE STRIP ATTACHMENT

If a base strip is used, bolt it into place behind the front of the upright assem-

blies, as shown. The four bottom shelf clips are hung and the bottom shelf is

set in place. The top shelf should now be installed using clips in the back and

bolts through the front face of the upright and shelf. If a base strip is not used,

install bottom shelf in same manner as top shelf.

NOTE: ONE FACE EDGE OF SHELF IS PLAIN (UNPUNCHED) FOR

AESTHETICS AND ONE FACE EDGE IS PUNCHED TO ACCEPT FULL-

WIDTH SHELF LABEL HOLDERS.

Base Strip

Shelf Clip

STEP 6 ROW ASSEMBLY

Continue adding intermediate upright assemblies and back sway braces until

row is complete, finishing off row with a row end upright assembly. Add the

base strips, if used, and as in Step 5, the top and bottom shelves to each

section.

Bolt

- 6 -

STEP 7 SECTION LEVELING

When required, level sections with shims to cause each upright assembly to be

plum within 1/10 inch per foot of height, up to and including 10' high units. For

units higher than 10', maximum out-of-plumbness should not exceed 1".

FAILURETO LEVEL SECTION COULD RESULT IN

SHELVING COLLAPSE, PERSONAL INJURY

AND/OR COMMODITY LOSS.

STEP 8 TIGHTEN ALL BOLTS

Tighten all bolts and add the intermediate shelves to complete the sections.

CLOSED TYPE SHELVING

STEP 1 ROW END - CLOSED UPRIGHT

ASSEMBLIES

After the material has been distributed to the proper location, determine from

the floor plan how many row end - closed upright assemblies and intermediate

- closed upright assemblies will be required. The row ends exist as received,

two angle posts welded to a side panel. Set aside the required amount.

STEP 2 INTERMEDIATE - CLOSE UPRIGHT

ASSEMBLY

Assemble the intermediate - closed upright assemblies by bolting two* angle

posts to the closed upright assemblies to form a T (bolt through the fourth hole

from each end). Repeat this procedure until all intermediates are assembled.

*One angle post is required when a beaded post - closed side is being used.

1/4-20 x 5/8

Hex Head

Cap Screw

(Grade 5)

and Hex Nut

Shims - Front and/or Rear

Fourth Hole From Each End

- 7 -

STEP 3 SINGLE ROW - SINGLE FACE

ASSEMBLY

In assembly of a single row - single face, begin with a row end - closed upright

assembly, a back and an intermediate - closed upright assembly. The back

bolts inside the angle post flanges, on both the row end and the intermediate,

at the fourth hole from each end and at two medial* points.

DO NOT TIGHTEN BOLTS!

*Pre-determine critical shelf location to avoid interference with back bolts.

STEP 4 BASE STRIP ATTACHMENT

If a base strip is used, bolt it into place behind the front flanges of the upright

assemblies, as shown. The four bottom shelf clips are hung and the bottom

shelf is set in place. The top shelf should now be installed using clips in the

back and bolts through the front face of the upright and shelf. If a base strip is

not used, bolt the bottom shelf in place.

NOTE: ONE FACE EDGE OF SHELF IS PLAIN (UNPUNCHED) FOR

AESTHETICS AND ONE FACE EDGE IS PUNCHED TO ACCEPT FULL-

WIDTH SHELF LABEL HOLDERS.

STEP 5 ROW ASSEMBLY

Continue adding intermediate - closed upright assemblies and backs until row

is complete, finishing off row with a row end - closed upright assembly. Add the

base strips, if used, and the top and bottom shelves to each section.

Row End

Intermediate

Back

Row End Intermediate

Shelf Clip

Bottom Shelf

Base Strip

Intermediate

STEP 3A DOUBLE ROW - DOUBLE FACE

ASSEMBLY

In assembly of a double row - double face, begin with two row end - closed

upright assemblies, a back and two intermediate - closed upright assemblies.

Bolt one side of the back between the angle post flanges of the row ends and

the other side between the angle post flanges of the intermediates. In both

instances, bolt through the fourth hole from each end and at two medial*

positions.

DO NOT TIGHTEN BOLTS.

*Pre-determine critical shelf locations to avoid interference with back bolts.

1/4-20 x 5/8 Hex Head

Cap Screw (Grade 5)

and Hex Nut

Row End

Back

Bolt

Top Shelf

- 8 -

Holes

Must

Align

Saddle

STEP 6 SECTION LEVELING

Where required, level sections with shims to cause each upright assembly to

be plum within 1/10" inch per foot of height.

FAILURE TO LEVEL SECTIONS COULD RESULT IN

SHELVING COLLAPSE, PERSONAL INJURY

AND/OR COMMODITY LOSS.

MAJOR ACCESSORIES

SHELF SIDE SUPPORTS

Tabs hook into front and rear posts in the same manner as shelf clips. Side

flange of shelf rests on top flange of shelf side support.

SHELF REINFORCEMENT SADDLES

Install under center of shelf, flanged side up. Turn slightly to clear shelf side

flange and then rest on side flanges. Must be used in conjunction with shelf

side supports.

Shelf Side Support

STEP 7 TIGHTEN ALL BOLTS

Tighten all bolts and add the intermediate shelves to complete the sections.

LEDGE TYPE SHELVING

Ledge sections, 3'3" high, are bolted to the front of a full height section. The

bolts are fastened through the fourth hole from each end.

Bolt Through Fourth Hole

with 1/4-20 x 5/8 Hex Head

Cap Screw (Grade 5) and

Hex Nut

Ledge Section

Full Height Section

Shims

Front and/or Rear

- 9 -

Clip or 1/4-20 x 5/8

Hex Head Cap

Screw (Grade 5) and

Hex Nut

Bin Front

Shelf

BIN FRONTS and CLIPS

Install behind front flange of posts.

1-1/2" high bin fronts are supplied with clips which slide behind beads and hook

over post flange.

3" and 6" high bin fronts are generally bolted to post front flange (hardware

furnished) or, optional bolt-on clips may be used.

SHELF DIVIDERS - FULL HEIGHT

Install beaded edge toward front. Fasten in place with a snap fastener through

hole in divider flange and hole in shelf, both top and bottom. When one divider

is installed directly above or directly below another divider, one fastener per

hole will hold both dividers.

Snap Fastener

Beaded Edge

Front

- 10 -

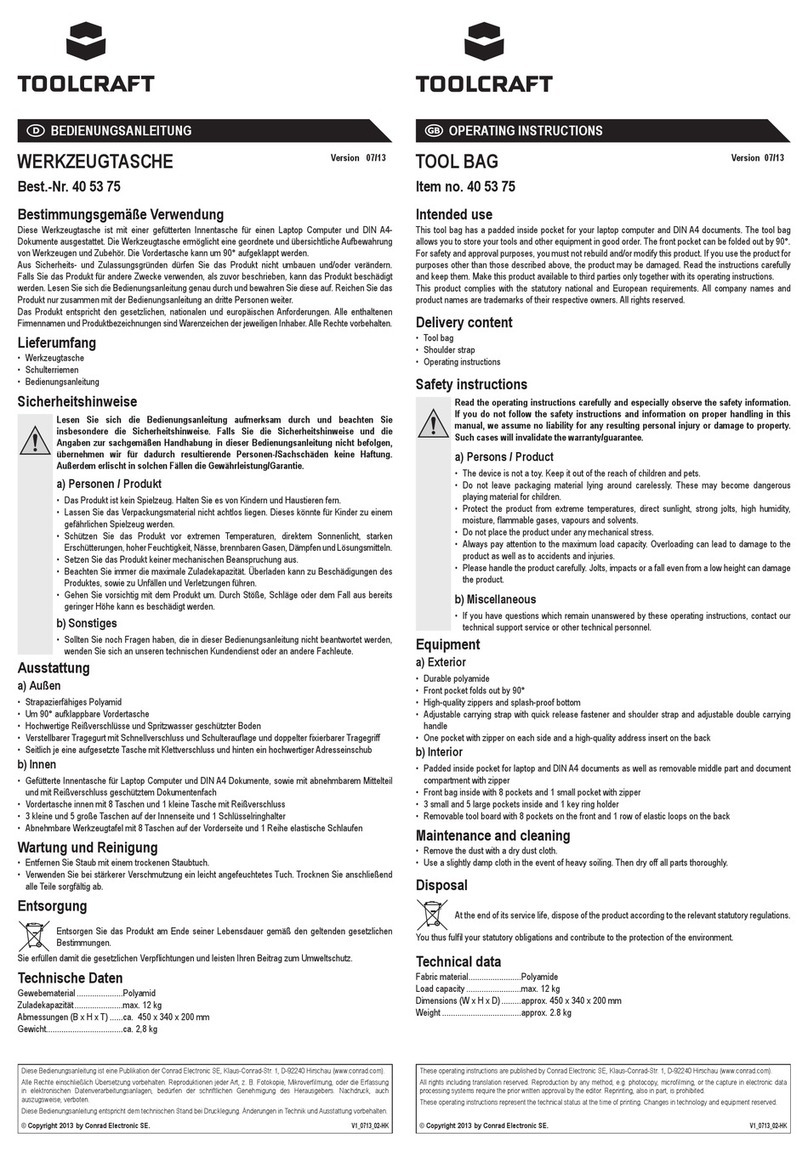

Light Loading

Both single and double rows may use sway braces as in

Figures 1 and 2. The end and back of the first and last

section of each row always contains a sway brace. Every

other intermediate and every other back should contain a

sway brace. The height location of the sway brace is

determined as in Figure 3, where the center line of the

cross is "height divider by 3" up from the bottom.

➛

➛

H

3

H

Standard Loading

For rigidity in standard duty applications, a pair of sway

braces should be put in every opening at the heights

illustrated in Figure 4. Each open end should be braced as

illustrated in Figure 4A.

Fig. 4

Back Brace

Fig. 5A

Side Brace

Fig. 5

Back Brace

Fig. 3

Back Brace

Connection point as close as possible to mezzanine level- may be either above or below level.

M = maximum distance possible - up to and including 30"

d = minimum reasonable distance (e.g. 4.5" - 6.0")

Multi-level Application

For rigidity in mezzanine applications, two sway braces

should be put in every other opening at the heights

illustrated in Figure 5. The intervening openings should be

braced with one pair of sway braces as shown. The term

"d" equals the distance for mounting the sway braces to the

post from the floor. Bolt the front of the center shelf and the

front of the top shelf and the base strip in place. The open

ends should be braced as illustrated in Figure 5A.

Light Loading

For rigidity, Borroughs recommends that one pair of sway

braces be installed in each open end and open back.

Sway brace height is as shown in Figure 6. Figure 6A and

6B are an end and an intermediate, respectively. The

bracing patterns are opposite each other and should

alternate from one end of a row down to the other end.

Pre-assembly of the two uprights is identical.

Fig. 6B

Side Brace

Fig. 6A

Side Brace

Fig. 6

Back Brace

NOTE:

FOR CRITICAL SHELF LOCATIONS, MINOR CHANGES TO THESE RECOMMENDATIONS ARE ACCEPTABLE.

Fig. 7B

Side Brace

Fig. 7A

Side Brace

Fig. 7

Back Brace

Connection point as close as possible to mezzanine level-

may be either above or below level.

M = maximum distance possible - up to and including 30"

d = minimum reasonable distance (e.g. 4.5" - 6.0")

Standard Loading and Multi-level

For rigidity, Borroughs recommends that sway braces be

used in open backs as illustrated in Figure 7. Sway brace

height is as shown in Figure 7. Bolt the front of the center

shelf and the front of the top shelf and the base strip in

place. Sway bracing for the ends of sections should be

installed as shown in Figure 7A for heavy-duty and Figure

7B for multi-level applications.

➛

60

➛

30

➛

➛

➛

➛

d

➛

60

➛

➛

➛

➛

d

➛

30

➛

➛

➛

➛

d

➛

30

➛

M

➛

➛

30

➛

➛

➛

d

➛

30

➛

➛

➛

➛

M

30

Fig. 4A

Side Brace

SWAY BRACING RECOMMENDATIONS

Double Row

No. Units 16 14 12 10 8642

No. Braces 16 14 13 11 10 8 6 3

Single Row

No. Units 8765 4321

No. Braces 10 9 8 7 6543

Fig. 2

Fig. 1

NOTE:

FOR CRITICAL SHELF LOCATIONS, MINOR CHANGES

TO THESE RECOMMENDATIONS ARE ACCEPTABLE.

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖✖

✖✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖

✖✖

FOR UNITS 99" HIGH and LESS

FOR UNITS OVER 99" HIGH

PLEASE NOTE: FAILURE TO FOLLOWTHESE SWAY BRACING RECOMMENDATIONS COULD RESULT IN AN IMPROPER INSTALLATION, SHELVING COLLAPSE, PERSONAL INJURY AND/OR COMMODITY LOSS.

- 11 -

HARDWARE REQUIREMENTS

Pieces

Part Name Hardware Included Req'd.

Sliding Door Hardware Pack #48 includes:

Door Pulls (Plated) 2

Furniture Lock (Plated) 1

Lock Catch (Painted) 1

Ball Bearing Sheave 4

10-24 Hex Nut 8

1/4-20 Hex Nut 14

10-24 x 3/8 Phillips THMS 8

#8 x 3/8 Slotted Oval Head

Screw 4

1/4" Lock Washer Fin. P. 14

1/4-20 x 5/8 THMS 14

Instructions 1

Mezzanine Beam None -

Mezzanine Bracket 1/4-20 x 1 HHMS Gr. 5 5

Angle & Beaded 1/4-20 Keps Nut 5

Catwalk Beams 1/4-20 Keps Nut 4

Angle & Beaded 1/4-20 x 1 HHMS Gr. 5 4

Face Aisle 1/4-20 Keps Nut 2

Cap Beam 1/4-20 x 3" Hex Head Cap

Screw 2

Cross Aisle None -

Cap Beam

Outside Aisle 1/4-20 Keps Nut 2

Cap Beam 1/4-20 x 3" Hex Head Cap

Screw 2

Single Face 1/4-20 Keps Nut 1

Back Cap 1/4-20 x 3" Hex Head Cap

Screw 1

Back-to-Back Cap 1/4-20 Keps Nut 2

1/4-20 x 3" Hex Head Cap

Screw 2

Single Face 1/4-20 Keps Nut 2

Attachment Bracket 1/4-20 x 5/8 Hex Head Cap

Screw 2

Row End Corner 1/4-20 Keps Nut 3

Splice Channel 1/4-20 x 1-1/4" HHMS Gr. 5 3

Row End 1/4-20 Keps Nut 4

Kick Plate 1/4-20 x 1-1/2" Hex Head Cap

Screw 4

Row End 1/4-20 Keps Nut 3

Hand Rail 1/4-20 x 3/4" THMS 3

Citation 0612 Hardware Pack #251 includes:

1/4-20 Hex Nut 21

Shelf Brackets 12

1/4-20 x 5/8 PHMS 21

Citation 0618 Same as Citation 0612

Pieces

Part Name Hardware Included Req'd.

Shelf Divider Divider Clip (nylon) 2

Angle (14761-000)

Shelf Divider Divider Clip (nylon) 4

Fixed (14761-000) Up to 24" deep

36" deep 6

Shelf Divider None -

Support

Label Holder Divider Clip (nylon) 3

Full Length (14761-000)

Long Parts Frame Hardware Pack #334 includes:

1/4-20 x 1 Slotted THMS 4

1/4-20 Hex Nut 4

5/15-18 x 5/8 Hex Head

Cap Screw 4

5/16-18 Square Nut 4

5/16 Shakeproof Washers 4

Spacer Rods None -

Boltless Hang Rods None -

Shelf Box None -

Box Guide 1/4-20 x 5/8 HHMS Gr. 5 2

1/4-20 Hex Nut 2

Bin Front Bin Front Clip Plated 2

1-1/2" Angle Post 1/4-20 x 5/8 HHMS Gr. 5 2

1/4-20 Hex Nut 2

Bin Front 1/4-20 x 1 Slotted THMS 2

3" & 6" Angle Post 1/4-20 Hex Nut 2

Bin Front 1/4-20 x 5/8 HHMS Gr. 5 2

1-1/2", 3" & 6" 1/4-20 Hex Nut 2

Beaded Post

Bin Front Clip 1/4-20 x 5/8 HHMS Gr. 5 2

3" & 6" 1/4-20 Hex Nut 2

Counter Top None -

Ledge Top None -

Counter Back 1/4-20 x 5/8 HHMS 8

1/4-20 Hex Nut 8

Tape Reel Hanger Hardware Pack #342 includes:

Kit 10-24 Keps Nut 2

10-24 x 3/8 Phillips THMS 2

Print-out Hanger Hardware Pack #342 includes:

10-24 Keps Nut 2

10-24 x 3/8 Phillips THMS 2

Single Point Hanger None -

Framed Swing Hardware Pack #414 includes:

Door Handle with Lock and 2 Keys 1

Push Clip (11914-028) 1

Handle Reinforcement 1

Cam Ind. Double Door 1

1/4-20 x 5/8 HHMS 6

1/4-20 Hex Nut 6

Saddle Reinforcement 1

#8-32 x 5/16 Sems Screw 2

Pieces

Part Name Hardware Included Req'd.

Angle Post 1/4-20 x 5/8 HHMS Gr. 5 2

Std. & Commercial 1/4-20 Hex Nut 2

Beaded Post None -

Closed Side 1/4-20 x 5/8 HHMS Gr. 5 4

Angle Post 1/4-20 Hex Nut 4

Closed Side None -

Beaded Post

Post Splicer 1/4-20 x 3/4 HHMS Gr. 5 4

1/4-20 x 5/8 HHMS Gr. 5 4

1/4-20 Hex Nut 8

Post Splicer Bar 1/4-20 x 5/8 HHMS Gr. 5 6

1/4-20 Keps Nut 6

Post Splicer Plate 1/4-20 x 5/8 HHMS Gr. 5 8

1/4-20 Keps Nut 8

Beaded Post 1/4-20 Keps Nut 4

Splice Kit 1/4-20 x 5/8 HHMS Gr. 5 4

10-24 x 1/2 Rolok Screw 8

Splicer Bar 1

Beaded Post Splicer 1

Foot Plate Kits

Front Foot 1/4-20 Keps Nut 1

and Back-to-Back 1/4-20 x 5/8 HHMS Gr. 5 1

Plate

Shim Plates

Front None -

Back None -

Post Foot Plate None -

Post Foot Angle 1/4-20 x 5/8 HHMS Gr. 5 2

1/4-20 Hex Nut 2

Post Cover 10-24 Hex Nut 6

Back Back Clip (05088-824-330) .25

1/4-20 x 5/8 Gr. 5 HHMS 10

1/4-20 Hex Nut 10

Back Brace (pair) 1/4-20 x 5/8 HHMS 5

1/4-20 Hex Nut 5

Side Brace (pair) 1/4-20 x 3/4 HHMS Gr. 5 5

1/4-20 Hex Nut 5

Face Brace 1/4-20 x 5/8 HHMS Gr. 5 6

Angle & Beaded Post 1/4-20 x 3/8" Self-Drilling MS 6

(pair) 1/4-20 Keps Nut 6

Double Face Tape .075 ft.

Base Strip 1/4-20 x 5/8 HHMS Gr. 5 2

Angle & Beaded 1/4-20 Hex Nut 2

Box Edge Shelves Shelf Brackets 4

(09531-099-330)

Shelf Saddle None -

Shelf Saddle None -

Support - Boltless

(pair)

Shelf Divider None -

Sliding

- 12 -

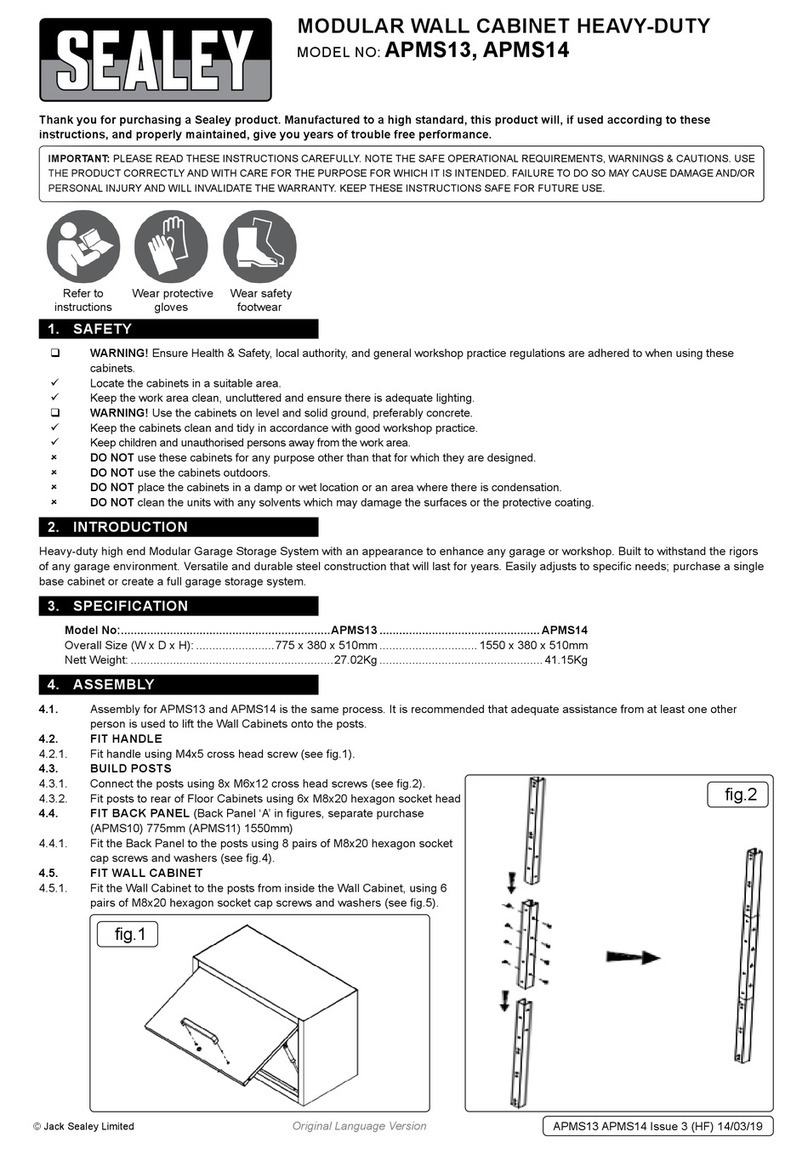

SEISMIC RISK MAP

All areas of the United States have been zoned seismically. Each zone indicates the anticipated intensity or severity of a seismic occurrence within

that region. Zones range from 0 (least likely) to 4 (most likely) to experience damage.

NOTE: Special care should be taken when specifying any system in a highly seismic area.

Reproduced from the 1997 edition of the Uniform Building Code™, copyright© 1997, with the permission of the publisher, the International Conference of Building Officials.

ICBO and Borroughs assume no responsibility for the accuracy or the completion of summaries provided herein.

2B 32B 10

4

3

3

4

4

3

2B

3

2B

3

4

2A 2B 1

1

1

101

2A

2A

3

2A

0

0

1

0

0

2A

1

2A

1

2A

ALASKA

01

2B

3

4

1

2B

1

ALEUTIAN

ISLANDS

34

3

2B

PUERTO RICO

34

GUAM

TUTUILA

33

HAWAII

MAUI

OAHU

KAUAI 1

2B

3

MILES

0100

MILES

0 100 200 300

MILES

025 50 MILES

0100 200 300

3002 N. BURDICK STREET KALAMAZOO, MI 49004-3483

800-748-0227 FAX: 269-342-4 6 www.borroughs.com

Table of contents

Other Borroughs Tools Storage manuals