3

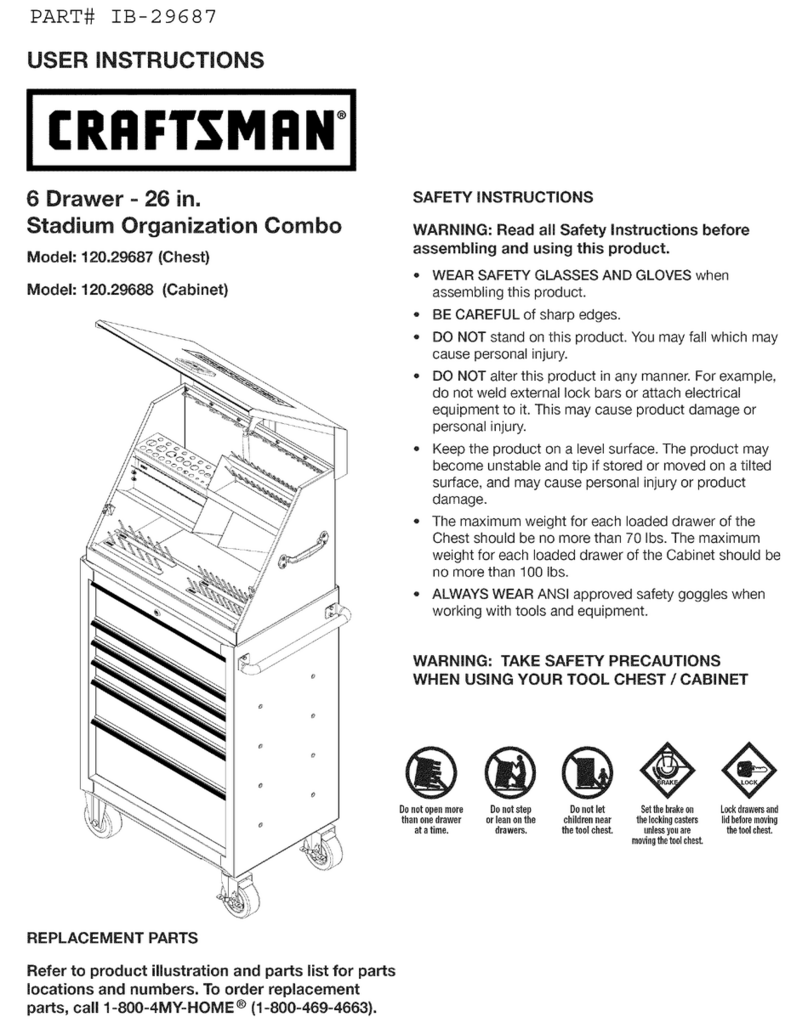

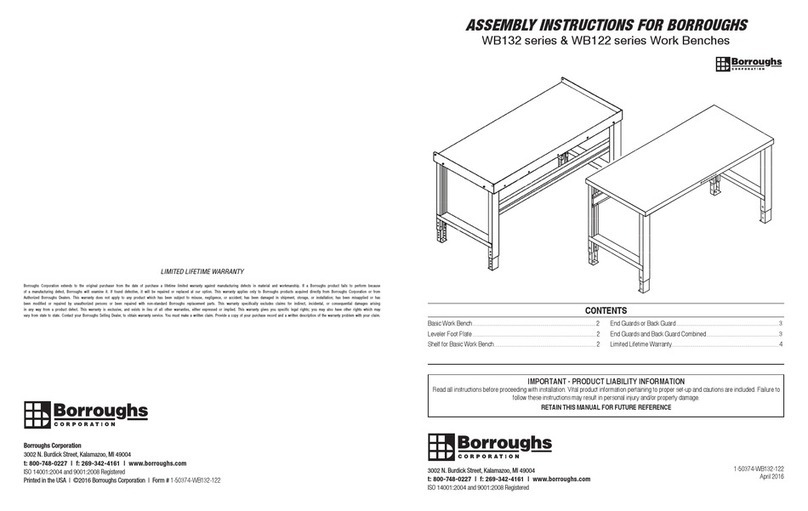

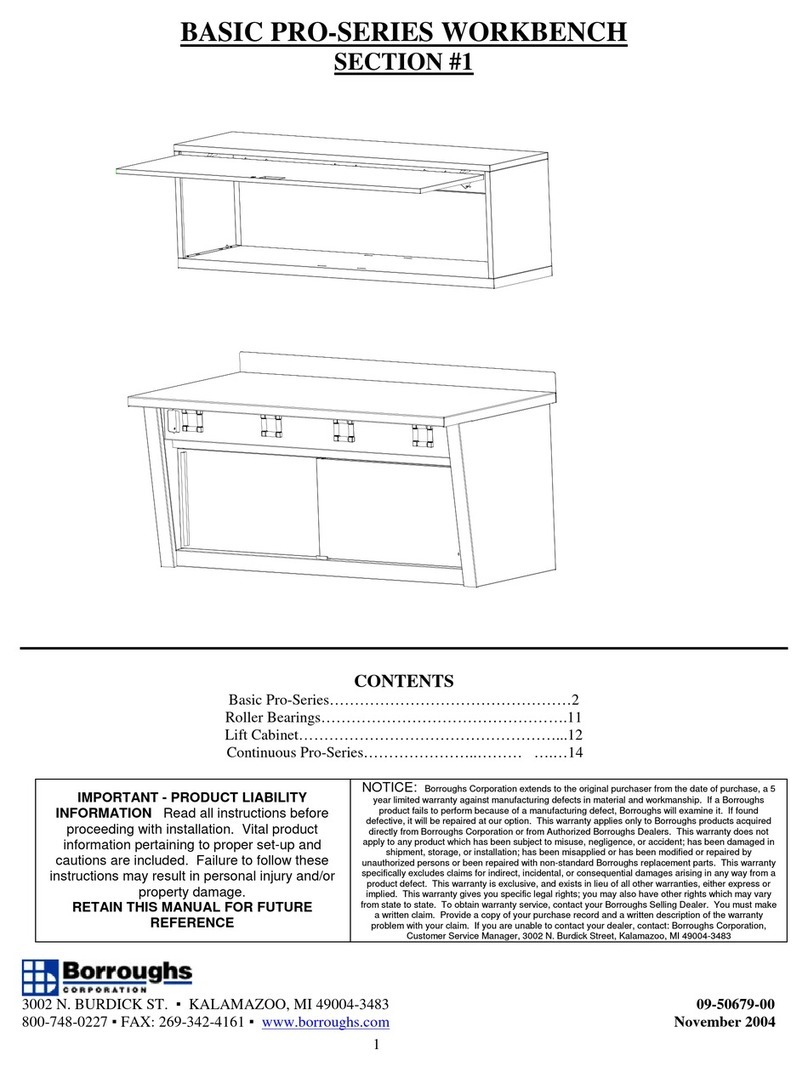

Work Bench with an All-Wood Top

Parts List "A"

Item Description Req'd.

1 Bench Top 1

2 Stringer 1

3 Leg Attachment Channel 2

4 Leg Weldment 2

5 Adjustable Foot 4

6 .312 (5/16) - 18 x .500 (1/2) Phillips T.H.M.S. 40

7 .312 (5/16) - 18 Keps Nut 32

8 .312 (5/16) - 18 Weldnut 8

Basic Work Bench

1

2

3

4

5

Parts List "B"

Item Description Req'd.

1 Maple Wood Top 1

2 Multi-Duty Wood Top 1

3 Stringer 1

4 Leg Weldment 2

5 Adjustable Foot 4

6 .312 (5/16) - 18 x .500 (1/2) Phillips T.H.M.S. 24

7 .312 (5/16) - 18 Keps Nut 16

8 .312 (5/16) - 18 Weldnut 8

3

4

5

12

1. Lay bench top (Item 1) upside down

on a at surface.

2. Insert leg attachment channel (Item

3) into bench top with the open area

of channel facing upward. Position

attachment channel so that the

holes in the end anges are in line

with the oval and rst hole in the

front and back anges of the bench

top. Fasten channel to bench top

with (4) screws and nuts (Items 6

& 7) as provided in the 00293-00

hardware pack. See Figure 1. Repeat

procedure at the other end.

3. Stand leg weldment (Item 4) in

place. (Leg fits inside attachment

channel). Position leg so that holes

in the sides of the leg weldment are

in line with the holes in the sides of

the attachment channel. Loosely

fasten leg and channel together with

(4) screws and nuts (Items 6 & 7) as

provided in 00293-00. See Figure 2.

Repeat procedure at the other end.

4. The stringer (Item 2) is to be attached

so the legs along the back edges of

bench. (BORROUGHS is stamped on

the front edge of Bench). Position

stringer so that the holes in the end

of the stringer are in line with the

holes in the leg. Fasten stringer to leg

with (4) screws and weldnuts (Items

6 & 8) as provided in 00664-00. See

Figure 3. Repeat procedure at the

other end. Tighten screws holding

leg weldments and attachment

channels together.

5. Insert adjustable foot (Item 5) into

leg so that the holes in the sides

of the foot are aligned with the

holes in the sides of the leg. At the

desired height, fasten foot to leg

with (4) screws and nuts (Items 6 &

7) as provided. See Figure 4. Repeat

procedure for the other legs.

5

FIGURE 4

2

FIGURE 3

4

5

FIGURE 7

21

3

8

11-

1. The stringer (Item 3) is to be attached

to the leg weldment (Item 4). Posi-

tion the stringer so that the holes

in the end of the stringer are in line

with the holes in the legs; located

approximately 11-5/8" down from

the top of the leg weldment. Fasten

the stringer to the leg with (4) screws

and weldnuts (Items 6 & 8) as provid-

ed. See Figure 5. Repeat procedure

at the other end.

2. Lay bench top (Item 1 or 2) upside

down on a at surface.

3. Place the leg weldment and stringer

assembly upside down on the bench

top. The stringer should be placed

toward the back edge of the bench

top. Position the leg weldment and

stringer assembly so it is centered

on the bench top and the legs are

parallel to the ends of the bench.

Use the leg weldments as templates

and drill (8) 1/4" pilot holes x 1" deep

for the lag screws at each end of the

bench top. Fasten the leg weldment

and stringer assembly to the bench

top with (8) .312 (5/16") x 1" lag

screws. See Figure 6. Lag screws are

not furnished by manufacturer.

4. Insert adjustable foot (item 5) into

leg so that the holes in the sides

of the foot are aligned with the

holes in the sides of the leg. At the

desired height, fasten foot to leg

with (4) screws and nuts (Items 6 &

7) as provided. See Figure 7. Repeat

procedure for the other three legs.

This completes assembly of the Work

Bench with an All-Wood Top. Put bench

in upright position.

~

FIGURE 1

FIGURE 2

FIGURE 6

FIGURE 5

Tools Required: 1. Phillips Screwdriver

2. 1/2" Open End or Box Type Wrench

Tools Required: 1. Drill with 1/4" Drill Bit

2. Phillips Screwdriver

3. 1/2" Open End or Box Type Wrench

4

6

67

67