Borum BBJ50TA User manual

05/20 BBJ50TA

Made in China to TQB Brands Pty Ltd specifications

Visit us at www.tqbbrands.com.au

Specifications:

Safe Working Capacity: 50,000kg

Minimum Height: 305mm

Maximum Height: 485mm

Hydraulic Stroke: 180mm

Operating Air Pressure: 110-120psi

Air Inlet Fitting: 1/4” x 18NPT

Nett Weight: 40kg

Carton: 330 x 230 x 355mm

Gross Weight: 41kg

About the Borum brand

Our “heavy duty commercial” range of Borum Industrial equipment has been manufactured to exacting standards for the past 34

years. We specify industrial quality components and design to ensure a long and durable working life in commercial transport,

mining, earthmoving and railway environments. Our Borum Industrial range of equipment is focused on achieving superior

professional standards, reliability, quality, and are covered by a 12 month trade use warranty.

50,000KG AIR ACTUATED BOTTLE JACK

05/20 BBJ50TA

Made in China to TQB Brands Pty Ltd specifications Page | 1

Visit us at www.tqbbrands.com.au

WARNING INFORMATION

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

WARNING

The instructions and warnings contained in this manual should be read and understood before using or

operating this equipment. Do not allow anyone to use or operate this equipment until they have read

this manual and have developed a thorough understanding of how this equipment works. Failure to

observe any of the instructions contained in the manual could result in severe personal injury to the user

or bystanders, or cause damage to the equipment and property. Keep this manual in a convenient and

safe place for future reference.

The warnings, cautions and instructions discussed in this instruction manual cannot cover all possible

conditions and situations that may occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be supplied by the operator.

Whilst every effort has been made to ensure accuracy of information contained in this manual, the Borum

policy of continuous improvement determines the right to make modifications without prior warning.

CONTENTS

WARNING INFORMATION ...........................................................................................................1

CONTENTS ...............................................................................................................................1

STANDARD OPERATING PROCEDURE ........................................................................................... 2

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE .................................................................3

PARTS DIAGRAM ....................................................................................................................... 7

PARTS LIST .............................................................................................................................. 8

TROUBLESHOOT........................................................................................................................9

WARRANTY............................................................................................................................. 11

05/20 BBJ50TA

Made in China to TQB Brands Pty Ltd specifications Page | 2

Visit us at www.tqbbrands.com.au

STANDARD OPERATING PROCEDURE

DO NOT use this machine unless you have been trained and assessed to a competent level in its safe use and operation, and

have been given permission to use this

PRE-OPERATIONAL SAFETY CHECKS

• Check vehicle owner's manual for correct vehicle weight and jacking points.

• Do not exceed the safe working load limit listed on the jack.

• Use only on a hard, flat, level surface that will sustain the vehicle weight.

• Apply the vehicle parking brake and securely chock wheels remaining on the

• ground.

• Inspect the jack prior to every use and do not use if parts are worn or jack is damaged.

• Lift only under an appropriate strong position on the vehicle, as specified in the vehicle

owner's manual.

• Centre the load prior to lifting and do not move or dolly the vehicle whilst on this jack.

• The jack is a lifting device only. Immediately after lifting, support the vehicle with AS

Approved jack stands.

• Do not use this jack for any purpose other than specified by this owner’s manual.

• Do not modify this jack and do not use this jack for a purpose for which it was not intended.

POTENTIAL HAZARDS

• User does not read, understand and follow the instructions and warnings in this manual prior

to operating the jack.

• Work area is not well lit or kept clean and tidy.

• Vehicle load is not immediately supported on AS Approved jack stands prior to commencing

work on or under vehicle.

• Not maintaining or servicing this jack to the manufacturer’s recommendations.

• Making unauthorised modifications to this jack.

INTENDED USE

For heavy duty truck, agriculture, construction, mining, mobile home, oil field, automotive, and marine

applications where lifting is required.

Safety glasses must be worn when

operating this equipment

Long loose hair must be contained when

operating this equipment

Safety footwear must be worn when

operating this equipment

Close fitting/protective clothing must be

worn when operating this equipment

05/20 BBJ50TA

Made in China to TQB Brands Pty Ltd specifications Page | 3

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE

1. FEATURES & MODELS

The Borum Air Actuated Hydraulic Bottle Jack is designed to operate either manually or pneumatically

for lifting and lowering, but not sustaining load. This 50,000kg Heavy-Duty Air/Hydraulic Bottle Jack

is the perfect choice for a wide variety of uses. The power of air makes it easy to lift farm vehicles,

trucks, lawn mowers, heavy equipment and other large loads.The manual function allows for normal

operation anywhere, even without an air supply.

2. BEFORE USE

Conduct a thorough visual inspection checking for any abnormal conditions, such as cracked welds,

and damaged, loose, or missing parts. Bleed any trapped air from the hydraulic system by

performing the air bleeding procedure below.

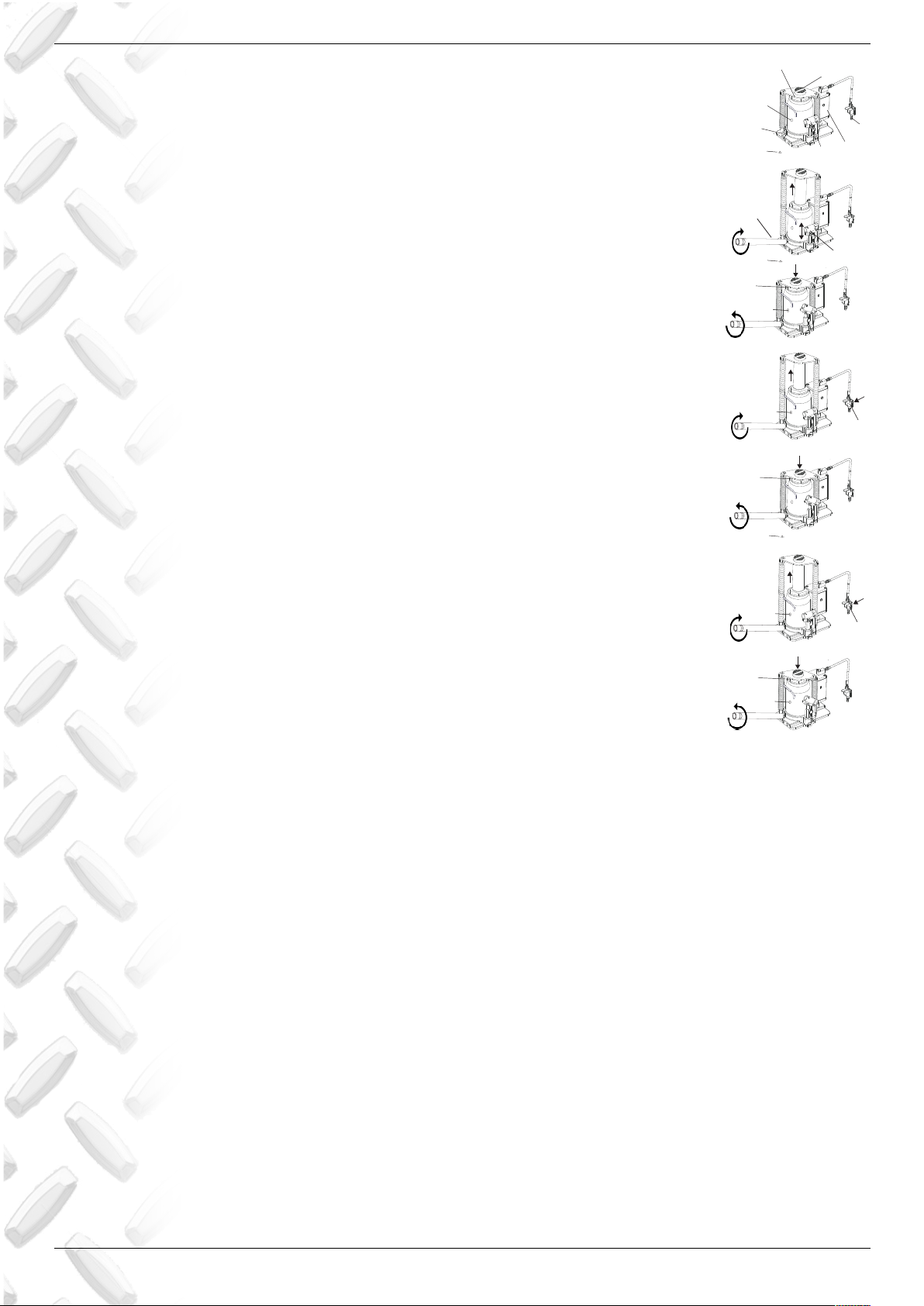

Bleed Air from Hydraulic System:

During transit the unit may become "air-bound", causing a spongy ram action.

To bleed the hydraulic system;

1. Remove the Oil Filler Bung and if required, refill with *32 Grade

hydraulic oil until the oil is lapping the bottom of the Oil Filler Hole then

replace the Oil Filler Bung.

2. Start with the Pump Socket Assembly in the horizontal position and turn

the Release Valve ‘clockwise’ to the lifting position.

3. With the Jack on its base, pull the Pump Socket upwards to the raised

position.

4. Invert the Jack and push the Pump Socket back to the horizontal

position.

5. Place the Jack back on its base to test the Pump Socket for firmness.

6. Repeat steps 4 to 6 until the Pump Socket feels firm and the Lift Ram is

extending consistently.

7. At this point the Pump Assembly should be bled of air.

8. Follow steps 8 to 9 to bleed the Lift Ram.

9. Ensure the Jack is back on its base and make sure the Release Valve is

in the ‘clockwise’ raise mode, then pump the Pump Socket until the Lift

Ram is fully extended.

10. Invert the Jack and then turn the Release Valve ‘anti-clockwise’ to the

lowering position. Carefully hold the Jack in the inverted position until

the Lift Ram is fully retracted. If necessary apply force to the bottom of

the Jack to return the Lift Ram back to fully retracted position.

At this point both the Manual Pump and Lift Ram should now be free of air and the Jack

ready for Air Motor bleeding (See Below).

Handle

(on Release Valve)

Pump

Socket

Pump

Socket

Saddle

Air

Motor

Oil Filler

Hole

Relief

Valve

Oil Filler Bung

Air

Fitting

Pump

Socket

Lift

Ram

Lift

Ram

Pump

Socket

Pump

Socket

Pump

Socket

05/20 BBJ50TA

Made in China to TQB Brands Pty Ltd specifications Page | 4

Visit us at www.tqbbrands.com.au

Bleed Air for Air Motor:

1. Remove the Oil Filler Bung and if required, refill with *32 Grade hydraulic

oil until the oil is lapping the bottom of the Oil Filler Hole.

2. Leave the Oil Filler Bung out, turn the Release Valve ‘clockwise’ to the lift

position and pump the Pump Socket ‘up and down’ to raise the Lift Ram to

full extension.

3. Replace the Oil Filler Bung, then turn the Release Valve ‘anticlockwise’ to the

lowering position until the Lift Ram returns to the fully lowered position.

(Note: Depress the Saddle where necessary)

4. Turn the Release Valve ‘clockwise’ to the raise position. Connect an air supply

to the Air Trigger assembly and depress the trigger, holding down until the

Lift Ram is fully extended.

5. Remove the Oil Filler Bung, then turn the Release Valve ‘anticlockwise’ to the

lowering position until the Lift Ram returns to the fully lowered position.

(Note: Depress the Saddle where necessary)

6. Replace the Filler Bung and turn the Release Valve ‘clockwise’ to the raise

position. Connect an air supply to the Air Trigger assembly and depress the

trigger, holding down until the Lift Ram has extended to full stroke then...

...continue to hold the trigger down for 10 seconds.

7. Turn the Release Valve ‘anticlockwise’ to the lowering position until the Lift

Ram returns to the fully lowered position. (Note: Depress the Saddle where

necessary)

At this point the Manual Pump, Air Motor Pump and Lift Ram should be free of air and

the Jack ready for Operation.

If the Jack continues to show the Symptoms as above, please refer to a Qualified

Hydraulic Technician.

3. OPERATION

Prior to each use always conduct a visual inspection checking for and any abnormal conditions, such

as cracked welds, and damaged, loose, or missing parts.

Raising the Jack:

1. Block the vehicle's wheels for lifting stability. Secure the load to prevent inadvertent shifting and

movement.

2. Position the jack near desired lift point.

3. Set the parking brake in the vehicle.

4. Refer to the vehicle manufacturer owner's manual to locate approved lifting points on the vehicle.

Position the jack so the saddle is centred and will contact the load lifting point firmly

5. Assemble the handle; ensure that spring clips align with slots.

6. Close the release valve by turning it clockwise until it is firmly closed.

Handle

(on Release Valve)

Pump

Socket

Saddle

Air

Motor

Oil Filler

Hole

Relief

Valve

Oil Filler Bung

Air

Fitting

Pump

Socket

Lift

Ram

Oil Filler Bung

Oil Filler Bung

Lift

Ram

Air

Trigger

Oil Filler Bung

Lift

Ram

Oil Filler Bung

Oil Filler Bung

Lift

Ram

Air

Trigger

Oil Filler Bung

Table of contents

Other Borum Jack manuals

Popular Jack manuals by other brands

Pittsburgh

Pittsburgh 62590 Owner's manual & safety instructions

Powerbuilt

Powerbuilt 640405 Operating and maintenance instruction manual

Clarke

Clarke STRONG-ARM CTJ3000G quick start guide

Clarke

Clarke CTJ2500QLG Operating & maintenance instructions

Omega Lift Equipment

Omega Lift Equipment 18122C Operating instructions & parts manual

Pittsburgh

Pittsburgh 58816 Owner's manual & safety instructions