Deutsch | 7

Bosch Power Tools 1 609 92A 172 | (16.4.15)

Bewahren Sie unbenutzte Elektrowerkzeuge außer-

halb der Reichweite von Kindern auf. Lassen Sie Perso-

nen das Gerät nicht benutzen, die mit diesem nicht ver-

traut sind oder diese Anweisungen nicht gelesen

haben. Elektrowerkzeuge sind gefährlich, wenn sie von

unerfahrenen Personen benutzt werden.

Pflegen Sie Elektrowerkzeuge mit Sorgfalt. Kontrollie-

renSie,ob bewegliche Teile einwandfreifunktionieren

und nicht klemmen, ob Teile gebrochen oder so be-

schädigt sind, dass die Funktion des Elektrowerkzeu-

gesbeeinträchtigtist. LassenSie beschädigte Teile vor

demEinsatzdesGerätesreparieren. Viele Unfälle haben

ihre Ursache in schlecht gewarteten Elektrowerkzeugen.

Halten Sie Schneidwerkzeuge scharf und sauber. Sorg-

fältig gepflegte Schneidwerkzeuge mit scharfen Schneid-

kantenverklemmensich weniger und sind leichter zu führen.

Verwenden Sie Elektrowerkzeug, Zubehör, Einsatz-

werkzeuge usw. entsprechend diesen Anweisungen.

BerücksichtigenSiedabeidieArbeitsbedingungenund

die auszuführende Tätigkeit. Der Gebrauch von Elektro-

werkzeugen für andere als die vorgesehenen Anwendun-

gen kann zu gefährlichen Situationen führen.

Verwendung und Behandlung des Akkuwerkzeuges

Laden Sie die Akkus nur mit Ladegeräten auf, die vom

Hersteller empfohlen werden. Durch ein Ladegerät, das

für eine bestimmte Art von Akkus geeignet ist, besteht

Brandgefahr, wenn es mit anderen Akkus verwendet wird.

Verwenden Sie nur die dafür vorgesehenen Akkus in

den Elektrowerkzeugen. Der Gebrauch von anderen

Akkus kann zu Verletzungen und Brandgefahr führen.

Halten Sie den nicht benutzten Akku fern von Büro-

klammern, Münzen, Schlüsseln, Nägeln, Schrauben

oder anderen kleinen Metallgegenständen, die eine

Überbrückung der Kontakte verursachen könnten. Ein

Kurzschluss zwischen den Akkukontakten kann Verbren-

nungen oder Feuer zur Folge haben.

Bei falscher Anwendung kann Flüssigkeit aus dem

Akku austreten. Vermeiden Sie den Kontakt damit. Bei

zufälligem Kontakt mit Wasser abspülen. Wenn die

Flüssigkeitin die Augen kommt, nehmen Sie zusätzlich

ärztliche Hilfe in Anspruch. Austretende Akkuflüssigkeit

kann zu Hautreizungen oder Verbrennungen führen.

Service

Lassen Sie Ihr Elektrowerkzeug nur von qualifiziertem

Fachpersonal und nur mit Original-Ersatzteilen repa-

rieren. Damit wird sichergestellt, dass die Sicherheit des

Elektrowerkzeuges erhalten bleibt.

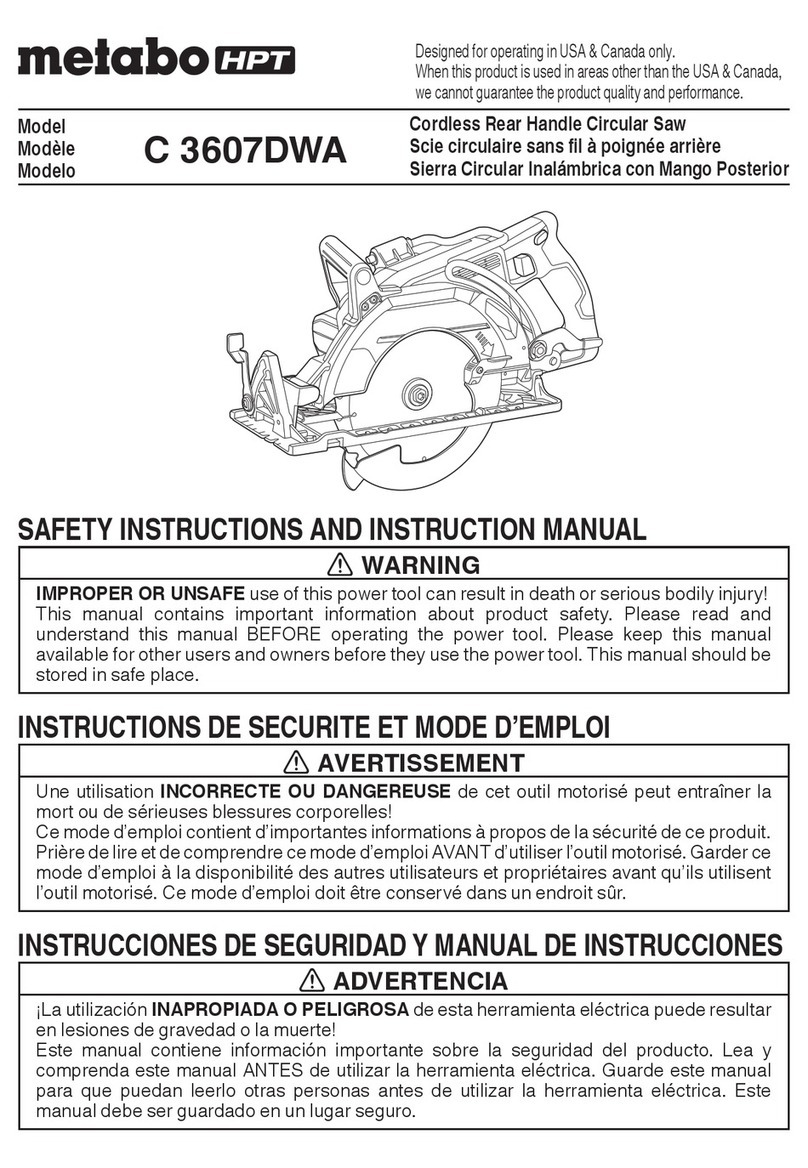

Sicherheitshinweise für Kreissägen

Sägeverfahren

GEFAHR: Kommen Sie mit Ihren Händen nicht in den

Sägebereich und an das Sägeblatt.

GreifenSienichtunter dasWerkstück.DieSchutzhaube

kann Sie unter dem Werkstück nicht vor dem Sägeblatt

schützen.

Passen Sie die Schnitttiefe an die Dicke des Werk-

stücks an. Es sollte weniger als eine volle Zahnhöhe unter

dem Werkstück sichtbar sein.

Halten Sie das zu sägende Werkstück niemals in der

Hand oder über dem Bein fest. Sichern Sie das Werk-

stück an einer stabilen Aufnahme. Es ist wichtig, das

Werkstück gut zu befestigen, um die Gefahr von Körper-

kontakt, Klemmen des Sägeblattes oder Verlust der Kon-

trolle zu minimieren.

Fassen Sie das Elektrowerkzeug nur an den isolierten

Griffflächen an, wenn Sie Arbeiten ausführen, bei de-

nen das Einsatzwerkzeug verborgene Stromleitungen

treffen kann. Kontakt mit einer spannungsführenden Lei-

tung setzt auch die Metallteile des Elektrowerkzeugs unter

Spannung und führt zu einem elektrischen Schlag.

Verwenden Sie beim Längsschneiden immer einen

Anschlagodereine gerade Kantenführung. Diesverbes-

sert die Schnittgenauigkeit und verringert die Möglichkeit,

dass das Sägeblatt klemmt.

Verwenden Sie immer Sägeblätter in der richtigen Grö-

ße und mit passender Aufnahmebohrung (z.B. rauten-

förmigoder rund). Sägeblätter, dienicht zu den Montage-

teilen der Säge passen, laufen unrund und führen zum

Verlust der Kontrolle.

Verwenden Sie niemals beschädigte oder falsche

Sägeblatt-Unterlegscheiben oder -Schrauben. Die

Sägeblatt-Unterlegscheiben und -Schrauben wurden

speziell für Ihre Säge konstruiert, für optimale Leistung

und Betriebssicherheit.

Rückschlag – Ursachen und entsprechende Sicher-

heitshinweise

– ein Rückschlag ist die plötzliche Reaktion infolge eines

hakenden,klemmenden oder falsch ausgerichtetenSäge-

blattes, die dazu führt, dass eine unkontrollierte Säge

abhebt und sich aus dem Werkstück heraus in Richtung

der Bedienperson bewegt;

– wenn sich das Sägeblatt in dem sich schließenden

Sägespalt verhakt oder verklemmt, blockiert es, und die

MotorkraftschlägtdieSägeinRichtungderBedienperson

zurück;

– wird das Sägeblatt im Sägeschnitt verdreht oder falsch

ausgerichtet, können sich die Zähne der hinteren Säge-

blattkante in der Oberfläche des Werkstücks verhaken,

wodurch sich das Sägeblatt aus dem Sägespalt herausbe-

wegt und die Säge in Richtung der Bedienperson zurück-

springt.

EinRückschlag ist die Folgeeines falschen oder fehlerhaf-

ten Gebrauchs der Säge. Er kann durch geeignete Vor-

sichtsmaßnahmen,wie nachfolgend beschrieben, verhin-

dert werden.

Halten Sie die Säge fest und bringen Sie Ihre Arme in

eine Stellung, in der Sie die Rückschlagkräfte abfan-

gen können. Halten Sie sich immer seitlich des Säge-

blattes, nie das Sägeblatt in eine Linie mit Ihrem Kör-

per bringen. Bei einem Rückschlag kann die Säge

rückwärts springen, jedoch kann die Bedienperson durch

geeignete Vorsichtsmaßnahmen die Rückschlagkräfte

beherrschen.

OBJ_BUCH-2459-001.book Page 7 Thursday, April 16, 2015 2:33 PM