DS970 Series Installation Instructions © 2011 Bosch Security Systems, Inc. Page 3

To suspend the 1-day motion monitor timer when the control panel is

armed, apply a switched voltage to Terminal 8 as shown in the

beginning of Section 6. This will prevent the motion monitor from

timing out when no movement is anticipated. When the switched

voltage is removed from Terminal 8, the motion monitor timer will

continue to count down until motion is detected.

If the time period selected has elapsed from the last detector alarm,

a supervision trouble condition will be signaled. Refer to the

Supervision Features section for more information.

NOTE: If this feature has been enabled, and you wish to use the

Memory feature, the Microwave Inhibit feature will be disabled.

6.5 Trouble Memory

Short the Trouble Memory contacts with a flathead screwdriver. The

LED will indicate the last trouble condition that occurred.

7.0 Setup and Walk Tests

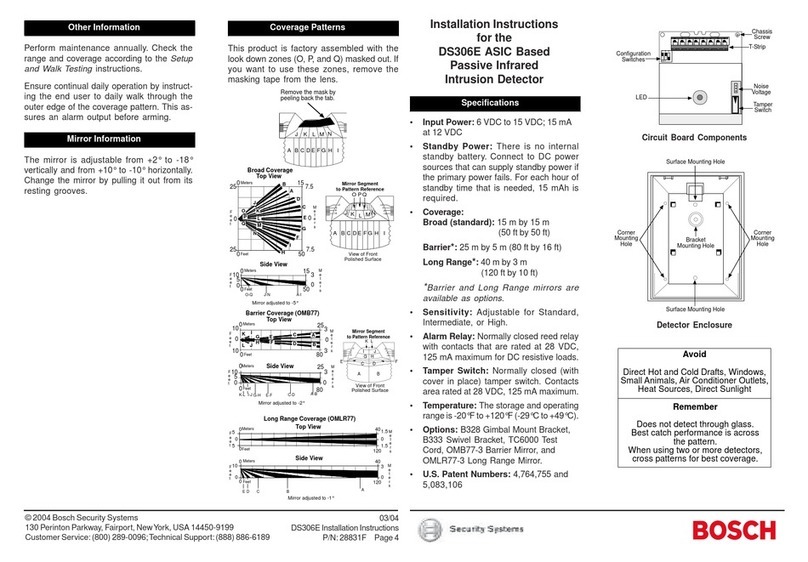

Select the vertical starting angle from this chart:

Mounting

Height Standard Broad Lens

40 ft. (12 m) 70 ft. (21 m)

Long Range Lens

80 ft. (24 m) 100 ft. (30 m)

6.5 ft. (2 m)

7.5 ft. (2.3 m)

8.0 ft. (2.4 m) -4° -3°

-8° -4°-5°

-4°-6° -2°

-3°

-3°

-8° -6°

DS970

To adjust the vertical starting angle for the desired mounting height

and range, loosen the vertical adjust screw and slide the board up, to

point the angle down. Note the settings on the vertical adjust scale.

• Place the LED plug in the ON position and replace the cover.

7.1 Establishing PIR Pattern Coverage

• Turn the Microwave range adjust to minimum.

• Replace the cover and snap it into place. This will close the

tamper switch.

•Wait two minutes minimum after applying power to start walk

tests.

NOTE: During the warm-up period, the tri-color LED will flash red

until the unit has stabilized (approximately 1 to 2 minutes)

and has seen no movement for two seconds. When the tri-

color LED stops flashing, the detector is ready to be tested.

With no motion in the protection area, the tri-color LED should

be OFF. If the LED is on, re-check the protection area for

disturbances affecting the microwave or PIR technologies.

• Walk test across the pattern at its farthest edge, then several

times closer to the detector. Start walking from outside of the

intended protection area, and observe the tri-color LED. The edge

of the pattern is determined by the first green, PIR activation of

the LED (or the first red activation if the yellow microwave LED

activates first).

• Walk test from the opposite direction to determine both

boundaries. The center of the pattern should be pointed toward

the center of the intended protection area.

NOTE: The pattern may be moved ±10° horizontally by rotating the

lens window left or right.

• Slowly bring your arm up and into the pattern to mark the lower

boundary on PIR alarm. Perform this task at 10 to 20 ft. (3 to 6 m)

from the unit. Repeat from above for the upper boundary. The

center of the pattern should not be tilted upward.

NOTE: If desired coverage cannot be achieved, try angling the

coverage pattern up or down to assure the pattern is not

aimed too high or low. The angle of the PIR pattern may be

vertically positioned between -10° and +2° by loosening the

Vertical Adjust screw and sliding the circuit board up or down.

Moving the board up will angle the pattern downward.

• Tighten the screw snug when positioning is completed.

7.2 Establishing Microwave Coverage

NOTE: It is important to wait one minute after removing/replacing

the cover so the microwave portion of the detector can settle,

and to wait at least ten seconds between the following walk

testing procedures.

• The tri-color LED should be OFF before walk testing.

• Walk test across the pattern at the intended coverage’s farthest

end. Start walking from outside the intended protection area and

observe the tri-color LED. The edge of the microwave pattern is

determined by the first yellow, microwave activation of the LED

(or the first red activation if the green PIR LED activates first).

• If adequate range can not be reached, increase the Microwave

Range Adjust slightly. Continue walk testing (waiting one minute

after removing/replacing the cover) and adjusting the range until

the farthest edge of desired coverage has been accurately placed.

NOTE: Do not adjust the microwave range higher than required.

Doing so will enable the detector to catch movement outside

of the intended coverage pattern.

• Walk test the unit from all directions to determine all the Microwave

pattern boundaries. Wait at least ten seconds between walk

tests.

7.3 Establishing Detector Coverage

• The tri-color LED should be OFF before walk testing.

• Walk test the unit from all directions to determine the detection

boundaries. A detector alarm is signaled by the first red activation

of the tri-color LED after an initial green or yellow activation.

8.0 Meter Tests

A 20,000 Ohm/Volt (or greater) analog DC VOM is recommended. Set

the meter scale for 5 VDC (Use of the TC6000 is recommended, but

is not essential for meter use. Either outside connector pin of the

TC6000 may be used for common).

8.1 PIR Meter Readings

• Connect the meter to the PIR Noise Voltage Pins.

• With no target motion in the pattern, read the voltage.

NOTE: The base reference level for PIR background noise is

approximately 1.0 VDC. Installations in quiet environments,

therefore, should result in a steady meter reading between

0.9 and 1.1 VDC.

• Walk test across the farthest edge of the coverage pattern. Make

sure the detector’s cover is on.

NOTE: Voltage changes greater than +0.75 VDC from the reference

level during walk tests are desirable. If changes are less

than 0.75 VDC, the detector may fail to respond at this far of

a distance if the temperature difference between the intruder

and the background is minimal. Try adjusting the unit up

and down to maximize the voltage change during walk tests.