ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

BOSSProductslimitedconsumerwarrantyandBOSS

Productscommercialwarrantypoliciesarelocatedat

www.bossplow.com.

Patentspending.

Introduction

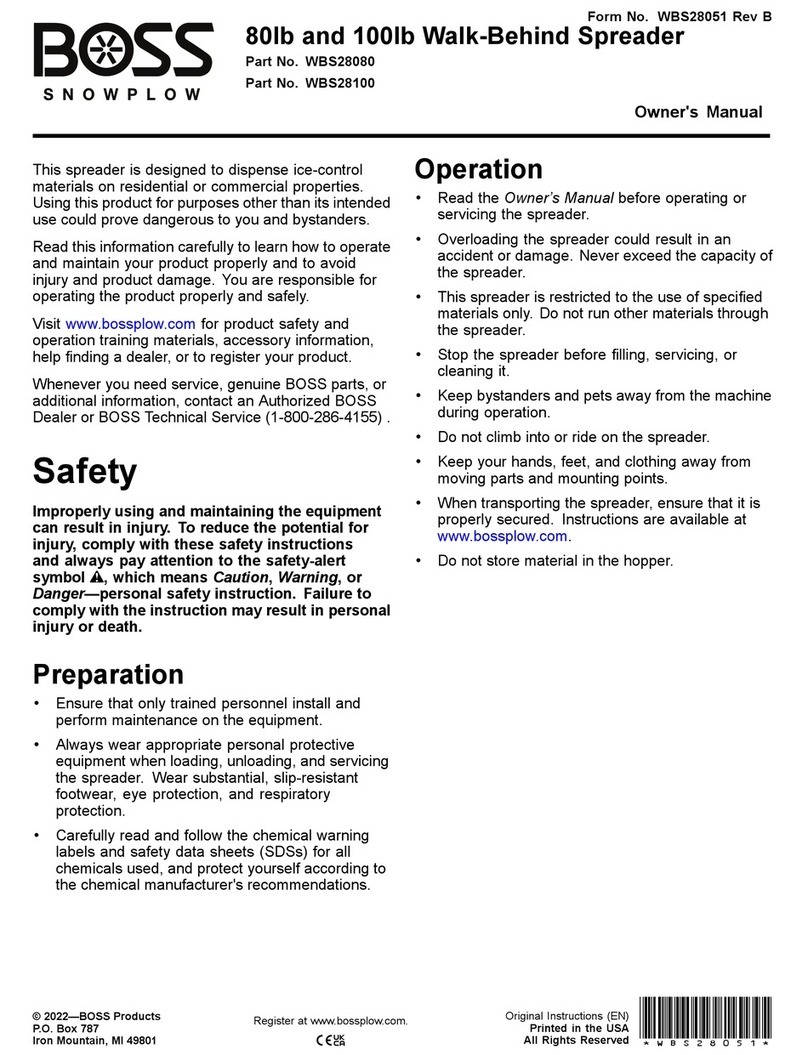

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactBOSSdirectlyatwww.bossplow.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineBOSSparts,or

additionalinformation,contactanAuthorizedBOSS

DealerorBOSSTechnicalService(1-800-286-4155)

andhavethemodelandserialnumbersofyour

productready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethe

numbersinthespaceprovided.

g029483

Figure1

1.Serialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

Preparation.........................................................3

Operation............................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................7

InstallingtheWireHarness.................................7

MountingtheSpreader.......................................9

AdjustingtheSlideStop......................................9

InstallingtheTie-DownD-Rings........................10

BuildingandInstallingtheSpacer......................11

SecuringtheSpreader.......................................11

InstallingtheSpinnerAssembly.........................11

InstallingtheSpreaderController......................12

CheckingtheInstallation...................................12

ProductOverview...................................................13

Controls...........................................................13

SpreaderController.......................................14

Specications..................................................15

Attachments/Accessories.................................15

Operation................................................................16

AdjustingtheHeightoftheSpinner

Assembly......................................................16

LoadingtheSpreader.......................................16

OperatingtheSpreader....................................16

FreeingaClog..................................................17

AdjustingtheMaterialDeectors......................17

UnloadingtheSpreader....................................18

RemovingtheSpinnerAssembly......................18

InstallingthePintle-ChainRestrictorPlate

(Optional)......................................................19

OperatingTips.................................................19

Maintenance...........................................................20

RecommendedMaintenanceSchedule(s)...........20

Lubrication..........................................................20

GreasingtheMachine.......................................20

MiscellaneousMaintenance.................................20

AdjustingthePintle-ChainConveyor

Tension.........................................................20

ControllerStatusandErrorIndicators...............22

Cleaning..............................................................24

©2018—BOSSProducts

P .O.Box787

IronMountain,MI498012

Contactusatwww.bossplow.com.

PrintedintheUSA

AllRightsReserved