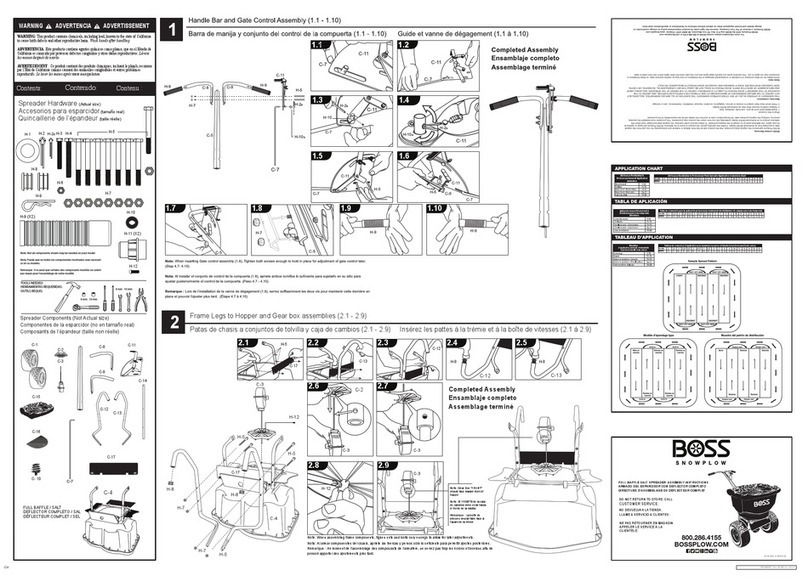

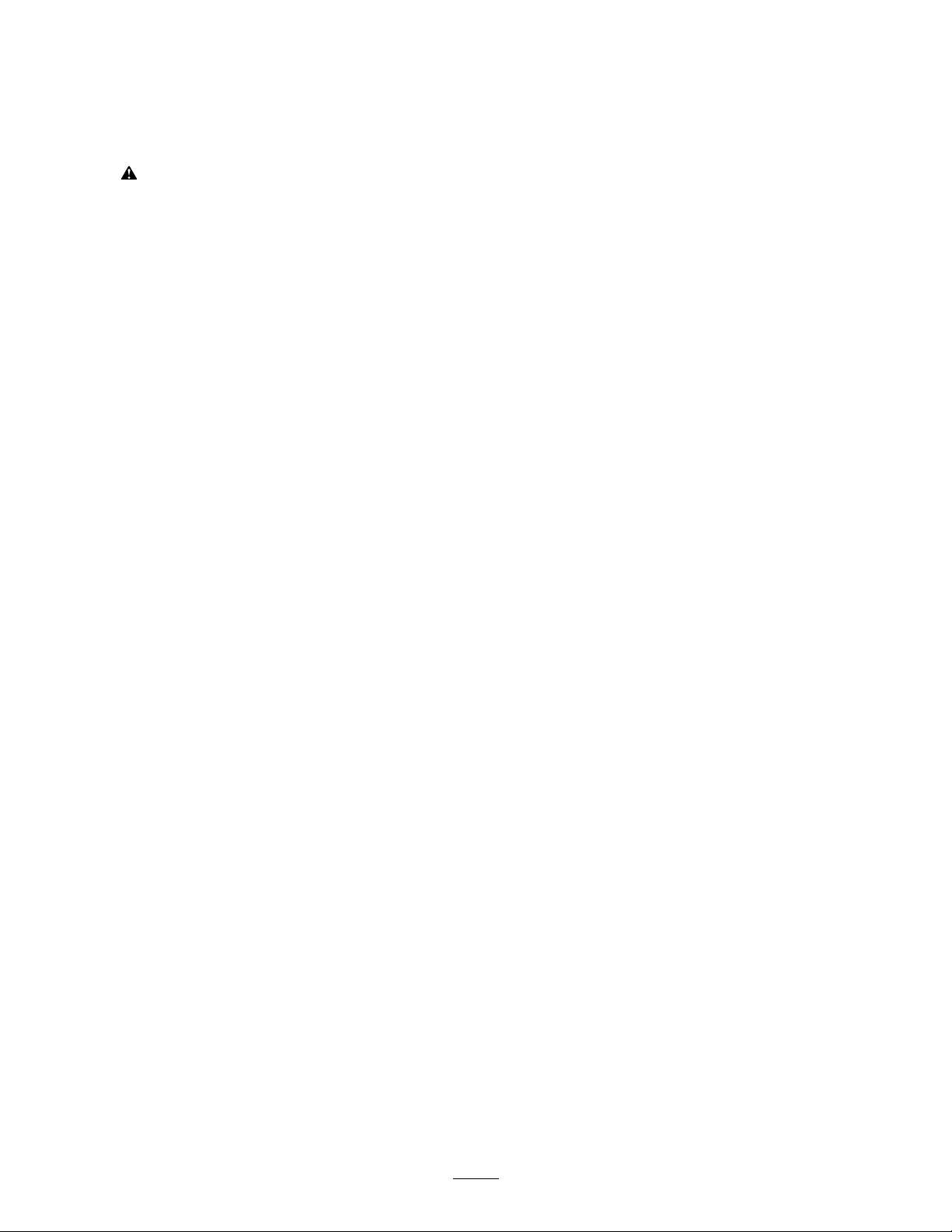

Safety

Improperlyusingandmaintainingtheequipment

canresultininjury.Toreducethepotentialfor

injury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol,whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Preparation

•ReadtheOwner’sManualbeforeoperatingor

servicingthespreader.

•Ensurethatonlytrainedpersonnelinstallsand

performsmaintenanceontheequipment.

•Alwayswearappropriatepersonalprotective

equipmentwhenloading,unloading,andservicing

thespreader.Wearsubstantial,slip-resistant

footwear,cold-weatherclothing,hardhat,safety

glasses,anddustprotection.

•Manynewertrucksareequippedwithairbags.

Neverdisable,remove,orrelocateanysensorsor

othercomponentsrelatedtotheoperationofthe

airbags.

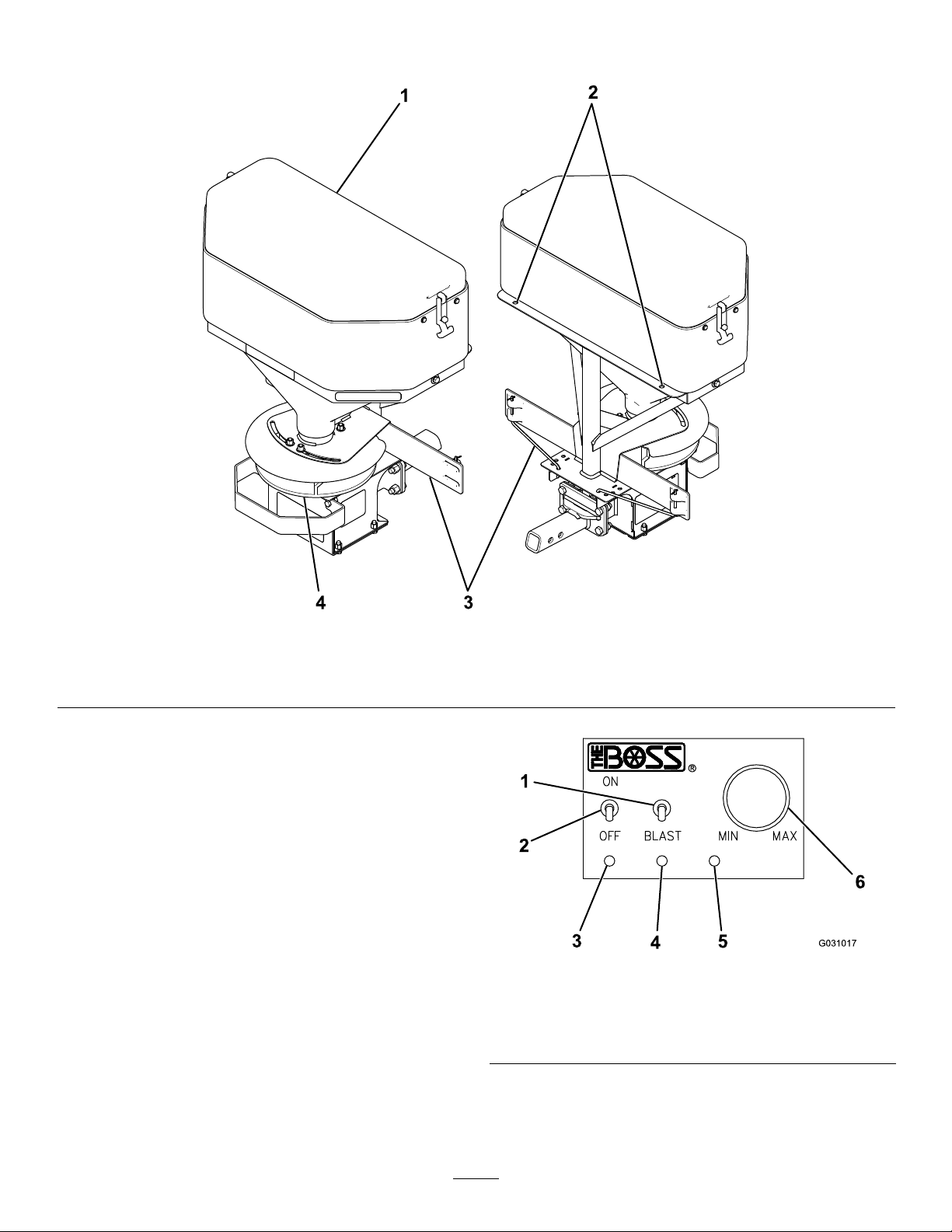

•TGS300spreadersmustonlybeusedwitha

minimumClassIIreceiverhitch.Donotexceed

thevehiclehitchrating.

•TheTGS300canholdamaximumweightof91

kg(200lb)ofsalt.Donotexceedthisweight.

Operation

•ReadtheOwner’sManualbeforeoperatingor

servicingthespreader.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Forvehicle-mountedspreaders,alwaysfollow

themanufacturer’srecommendationsforproper

parkingprocedures.

•Alwayswearyourseatbeltwhileoperatingamotor

vehicle.

•Donotexceed22.5km/h(14mph)while

spreading.

•Thisspreaderhasanoperatingsoundlevelbelow

70dBA.

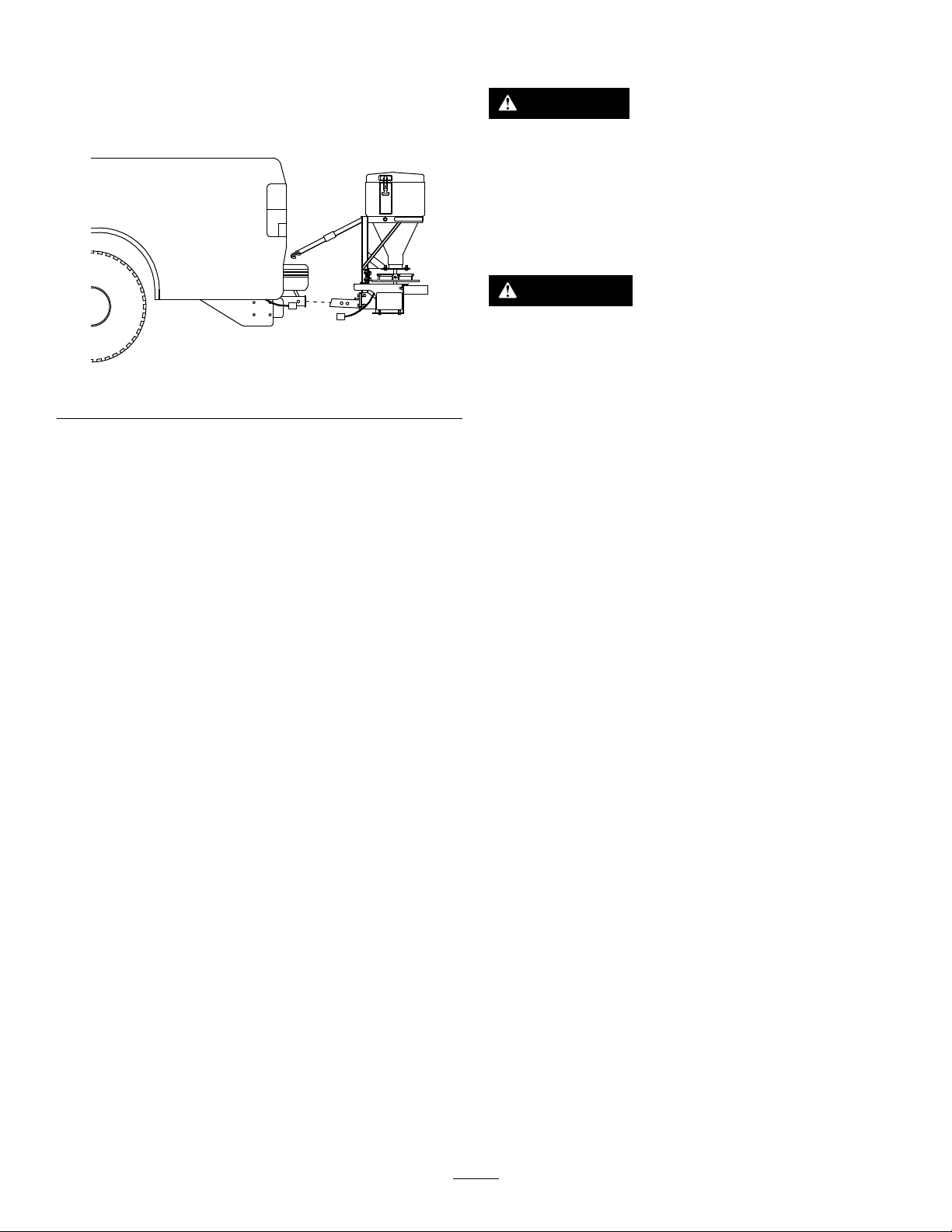

•Neverputanypartofyourbodybetweenthe

spreaderandthevehicle.

•Overloadingthespreadercouldresultin

anaccidentordamage.Neverexceedthe

gross-vehicle-weightrating(GVWR)orthefront

orreargross-axle-weightratings(FGAWRor

RGAWR)forthevehicle.

•Thisspreaderisrestrictedtotheuseofsaltonly.

Donotrunothermaterialsthroughthespreader.

•Donotattempttomountorremovethespreader

withmaterialinit.

•Turnthespreaderoffbeforelling,mounting,

removing,servicing,orcleaningit.

•Neveroperatethespreaderwithin7.6m(25ft)

ofbystanders.

•Donotclimbintoorrideonthespreader.

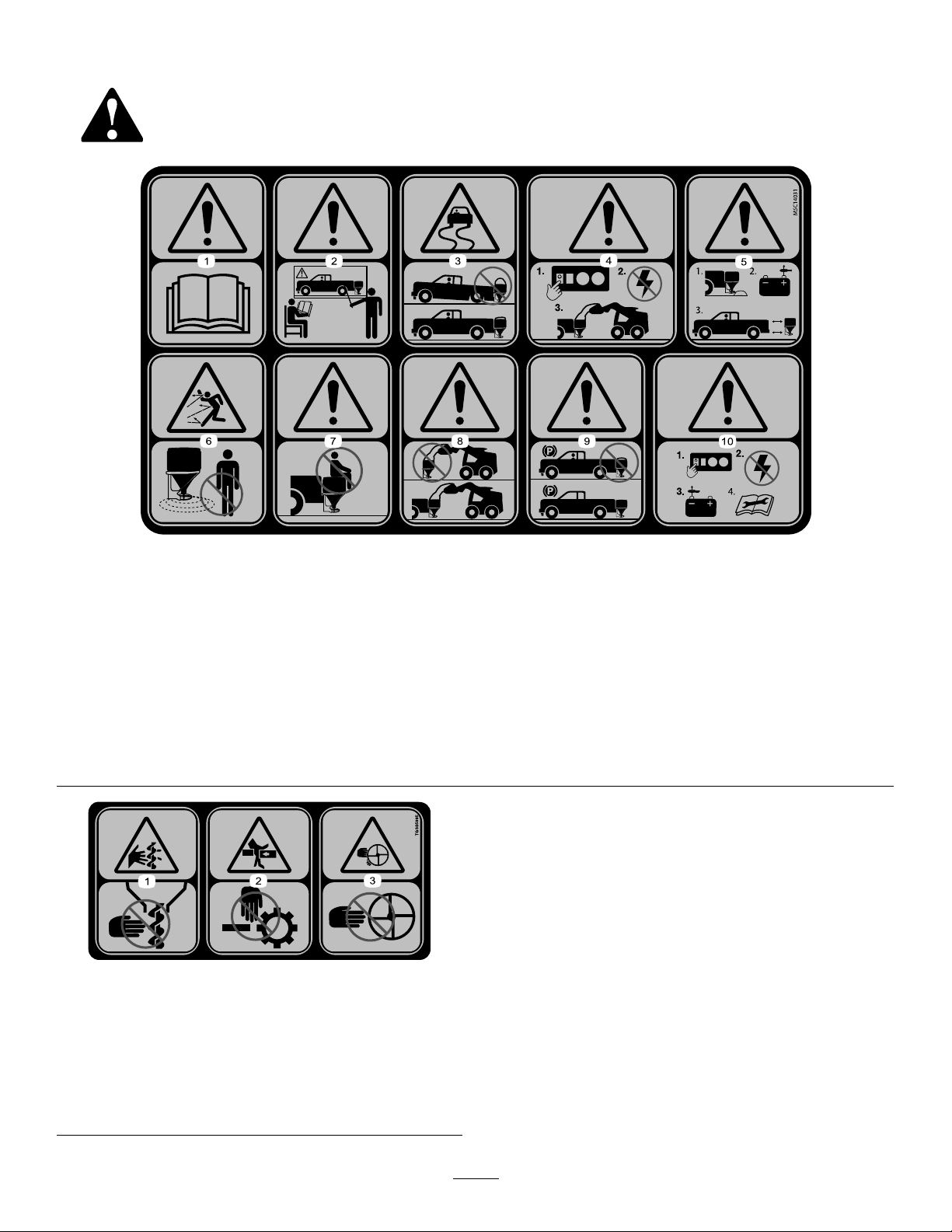

•Keepyourhands,feet,andclothingawayfrom

movingpartsandmountingpoints.

•Mountthespreadertoavehiclebeforeloading

material.

•Installratchetstrapsandkeepthemproperly

tightenedwiththeslide-inattachment.

•Whentransportingthespreader,ensurethatitis

properlysecured.Instructionsareavailableat

www.bossplow.com.

•Theslide-inattachmentmustbefullyengagedand

pinnedintothevehicle’s3cm(1-1/4inch)or5cm

(2inch)receiverhitch.

•Materialsafetydatasheets(MSDS)areavailable

atwww.bossplow.com.

•Usea1/2tonminimumliftingdevicetomove

heavyspreadercomponents.

•Donotstorematerialinthehopper.

3