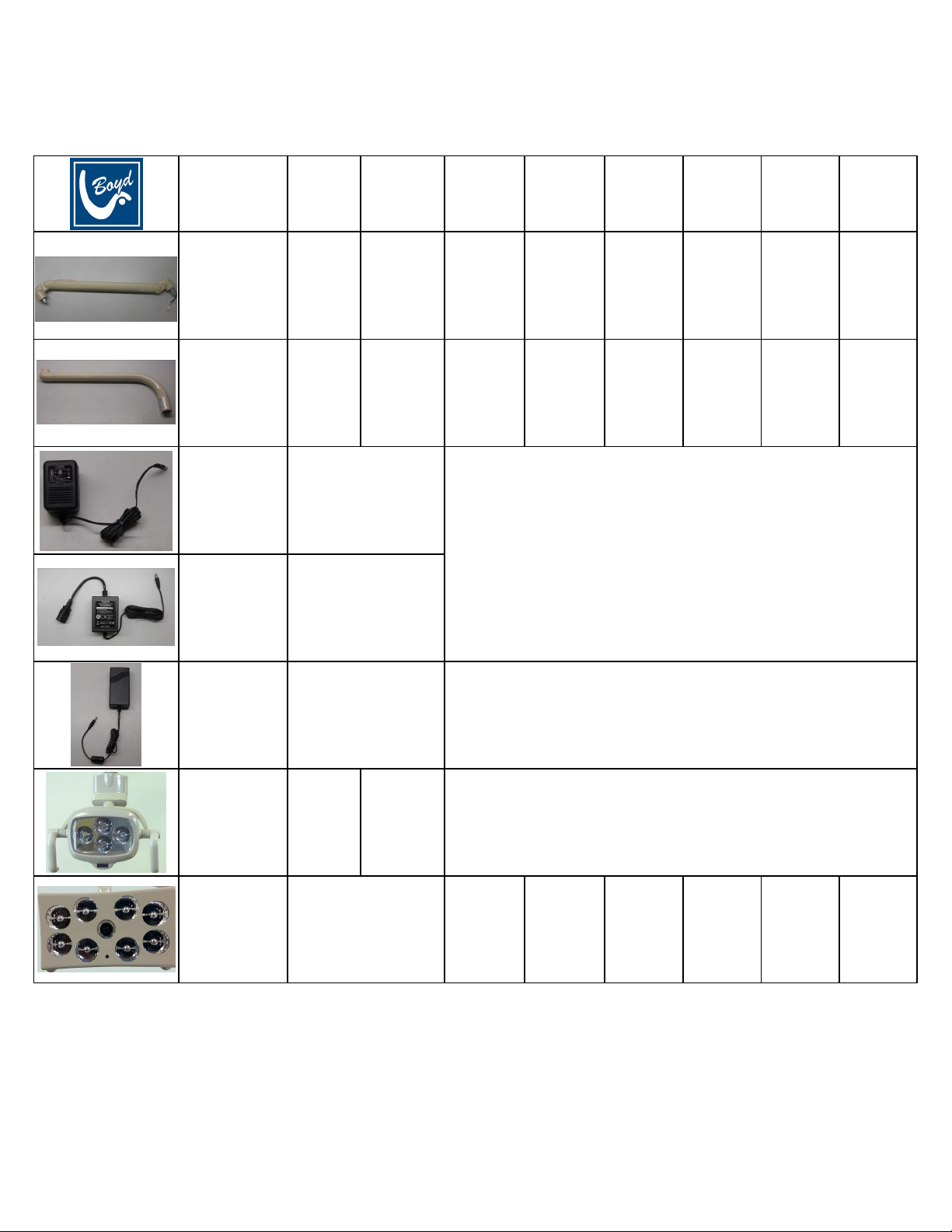

4

IG-001

Rev 1

1. The Boyd LED Exam Light has been designed to be safe and eecve when used for paent dental examinaon when properly

installed, used, monitored and maintained.

2. Prior to installation, visually examine the light head, lens, arms, power cords, video cables, transformer and plugs for any sign of

damage or deterioration.

3. Disable, disconnect or de-energize the power circuit that the light will be installed on prior to installation and throughout the

installation process. This should be accomplished by turning off the power at the breaker box or by unplugging the chair that the light

is attached to. The chair should be unplugged or otherwise de-energized to prevent accidental movement while working under or

around the chair.

4. Please use caution when using illumination of Boyd LED exam lights to avoid unnecessary glare into the patient’s eyes. Prolonged

exposure of LED light may cause eye irritation or permanent eye injury.

5. Regular disinfection / sterilization is required in order to prevent contamination.

6. Avoid use of cleaning agents including benzene, bleach, thinners or other harsh chemicals as they may cause discoloration and other

hazards.

7. Instruments and other items should not be attached or hung from the light or arms.

8. Gloves should be worn when handling the Boyd light in order to prevent inadvertent scratching or damage.

9. Do not store near unsafe chemicals or flammable materials. Lights are not rated or suitable for use in explosive environments.

Note: This installaon guide depicts the Boyd C300 and C500 LED Exam Lights. The processes of installation, operation and

maintenance are the same for both units. Refer to the Service & Repair Manual for any issues beyond the scope of this document.

Safety Tips and Precauons

Please read the installaon guide before use.

Warnings & Cauons

Unplug before performing maintenance procedures on this product.

Do not use bleach for cleaning on this product.

Handle this product and internal parts with care during maintenance procedures.