Bradford White FT Series User manual

800.900.9276 •Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 •603.335.6300 •Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 •905.238.0100 •Fax 905.366.0130

www.Laars.com

Document 4288D

The FT Series, Wall Combi, Gas Conversion Kit

pg 1 of 4

The FT Series, wall combi, condensing boiler is

congured for Natural Gas (NG) from the factory.

A Natural Gas to Propane Conversion Kit is included

with every FT. The gas conversion kit will show you

how to convert your FT boiler to propane gas. If your

FT does not have the bag containing the conversion

kit, a replacement kit can be obtained. Contact the

manufacturer and request a replacement conversion kit.

NOTICE

If your installation altitude is greater than 2000 ft, check

that the ‘High Altitude’ Installer Setting has been adjusted

to suit your installation altitude. Refer to Section 4.12 of the

Installation and Operation Instructions (Document 1318).

WARNING

This gas conversion kit shall be installed by a qualied

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements of

the authority having jurisdiction. The information in these

instructions must be followed to minimize the risk of re or

explosion or to prevent property damage, personal injury

or death. The qualied service agency is responsible for

the proper installation of this kit. The installation is not

proper and complete until the operation of the converted

appliance is checked as specied in the manufacturer’s

instructions supplied with the kit.Installation must conform

to local codes and the latest edition of the National Fuel

Gas Code, ANSI Z223.1 and CAN-B149.1. Failure to

follow instructions could result in serious injury or property

damage. The qualied agency performing this work

assumes responsibility for gas conversion.

CAUTION

This combination boiler has already been set to burn natural

gas, but can be converted to burn LP gas. Before placing the

combination boiler into operation, verify that the type of gas

supplied to your combination boiler.

Steps 1 thru 25

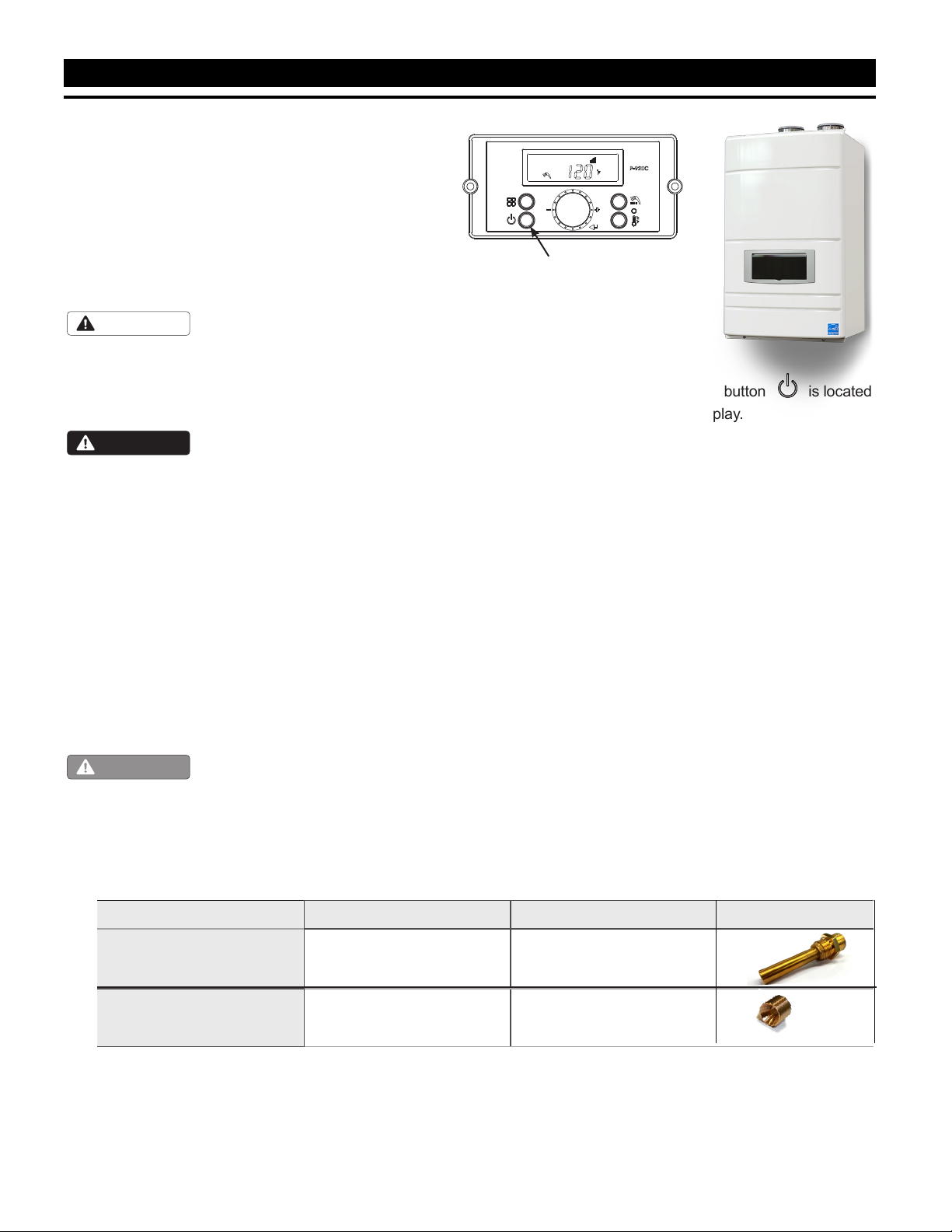

1.

Turn OFF the FT. The ON / OFF button is located at

the bottom left of the Control Display.

2.

Turn OFF the GAS and WATER supply to the FT (valves

are located on the plumbing pipes.)

3.

Using a Phillips screwdriver, remove the 4 screws on the

front cover. See Figure A.

4. Locate the Gas Inlet Pipe at the top left of the unit as

shown in Figure A, and loosen the Brass Fittings at both

ends of the Gas Inlet Pipe.

5. Completely unthread the brass tting on the blower end of

the Gas Inlet Pipe and then carefully swing the Gas Inlet

Pipe to the left or right, just enough so that it is out of the

way. See Figure B.

6. Remove the existing natural gas nozzle or orice. If your

unit is a 199, note that the at side of the orice is towards

the blower. Save the packing for re-use. See Figure C.

7. Install the new LP (propane) nozzle or orice. Re-use the

packing from previous.

8. Return the Gas Inlet Pipe to its original position and tighten

both of the brass ttings.

ON / OFF

H2373800D

Model Natural Gas (NG) part # Propane Gas (LP) part #

FTCW140

FT1412N

FT1412P

FTCW199 FT1780 FT1802

Nozzle

Orice

Kit # R20770

Table A. Gas Conversion Parts

800.900.9276 •Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 •603.335.6300 •Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 •905.238.0100 •Fax 905.366.0130

www.Laars.com

Document 4288D

The FT Series, Wall Combi, Gas Conversion Kit

pg 2 of 4

WARNING

This conversion shall be installed by a qualied

service agency in accordance with the manufacturer's

instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information

in these instructions is not followed exactly, a re,

an explosion or production of carbon

monoxide may result causing property

damage, personal injury or loss of

life. The qualied service agency is

responsible for the proper and complete

installation of this kit. The installation is

not proper and complete until the operation of the

converted appliance is checked as specied in the

manufacturer's instruction supplied with the kit.

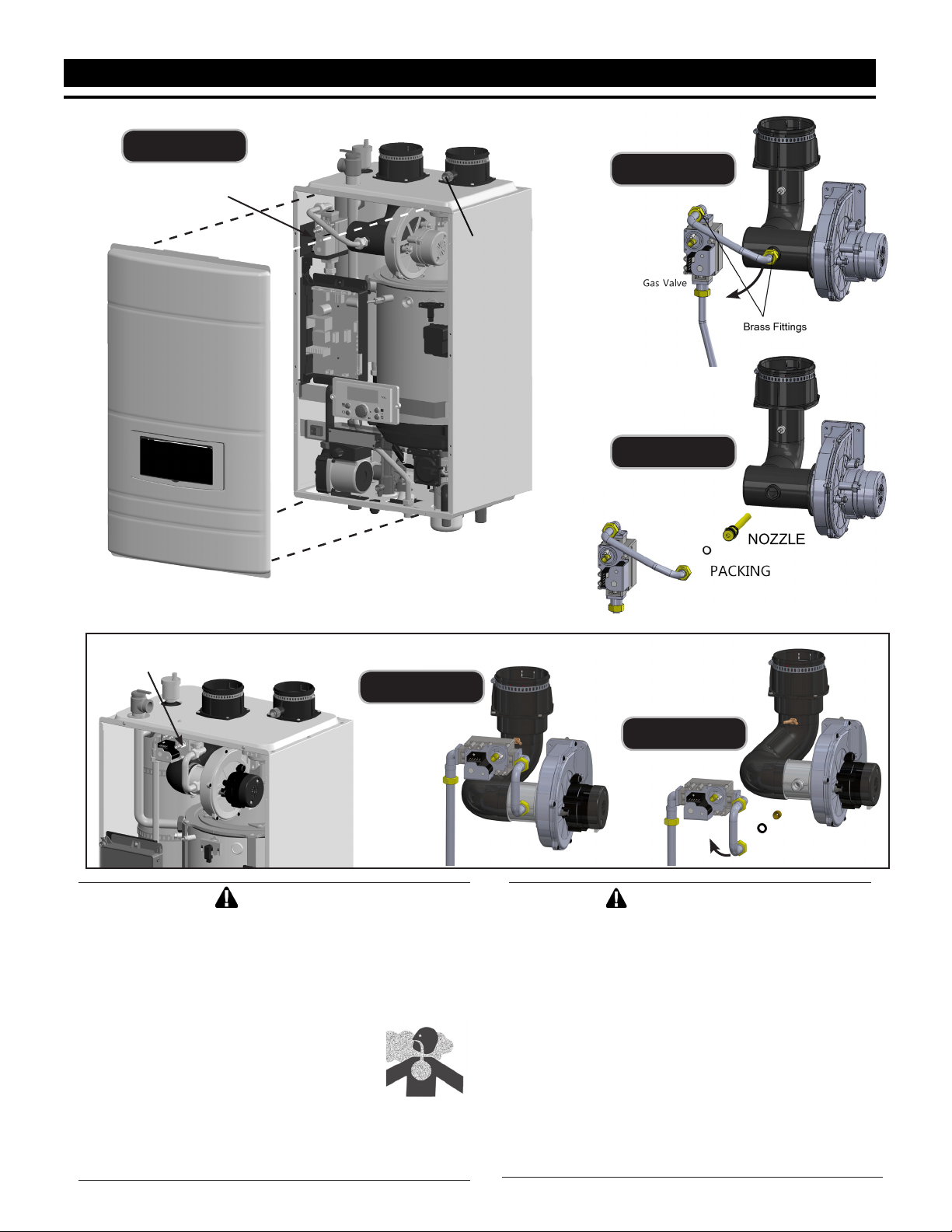

Figure C

Figure A

AVERTISSEMENT

Ce conversion doit être installé par un organisme de

service conformément aux instructions du fabricant

et tous les codes et les exigences de l’autorité

compétente. Si les informations contenues dans ces

instructions n’est pas suivi à la lettre, un incendie,

une explosion ou de la production de monoxyde

de carbone mais résultat causant des dommages

matériels, des blessures ou des pertes de vie. Le

service est responsable pour la bonne et complète

l’installation de ce kit. L’installation n’est pas correcte

et complète jusqu’à ce que le fonctionnement de

l’appareil converti est vériée comme spécié dans

le manuel d’instruction fourni avec le kit.

Figure B

Gas Valve

Gas Valve

ORIFICE

PACKING

FTCW140

FTCW199

Figure C

Figure B

Gas Valve

Combustion

Test Port

800.900.9276 •Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 •603.335.6300 •Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 •905.238.0100 •Fax 905.366.0130

www.Laars.com

Document 4288D

The FT Series, Wall Combi, Gas Conversion Kit

pg 3 of 4

Gas Valve

Adjustment Port

+

+

-

-

Gas Valve

Adjustment Port

Figure D

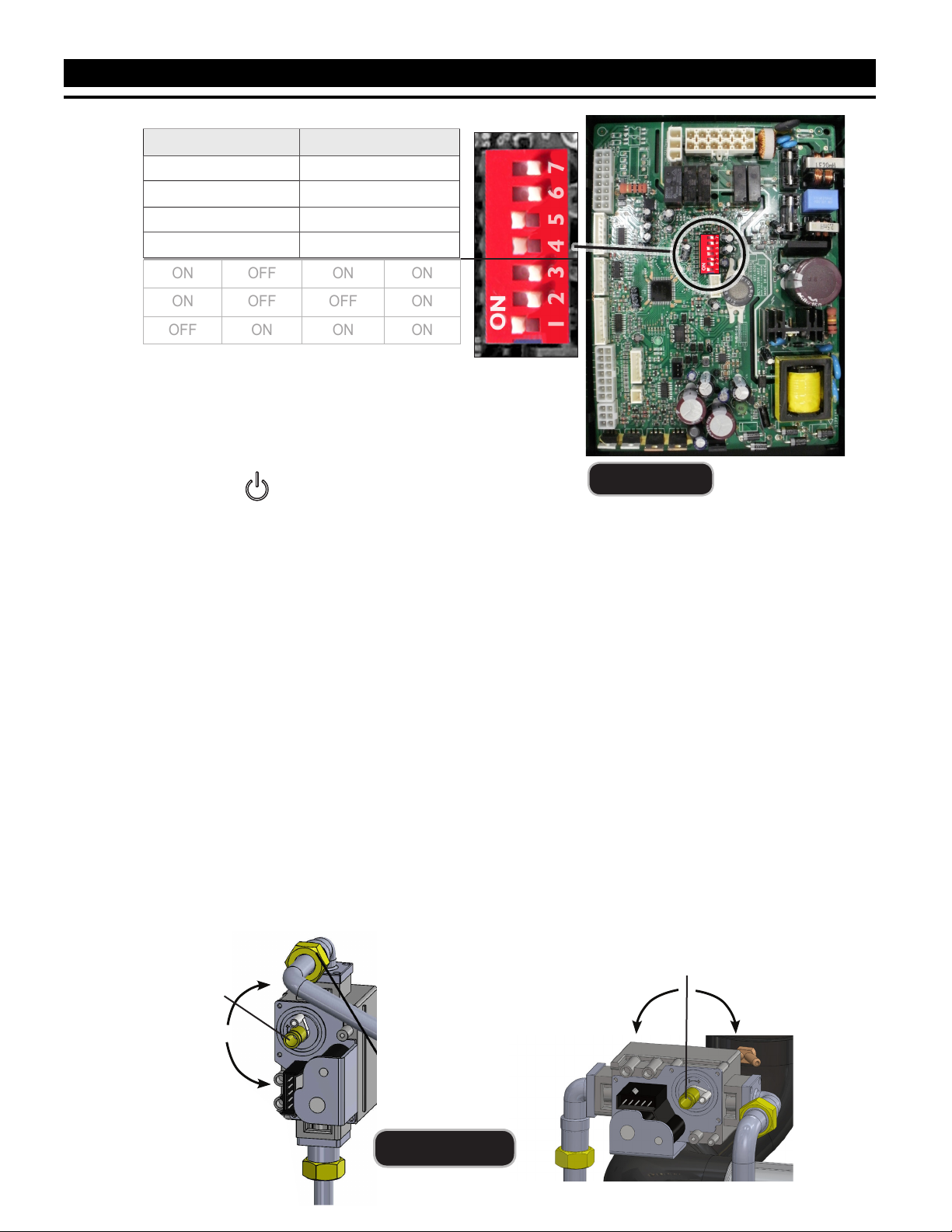

Table B DIP Switch Settings

9.

Per Table B, set DIP Switch 5 to OFF for LP Propane.

10. Turn ON the GAS and WATER supply to the FT.

11. Turn ON the FT.

12.

Connect a manometer to the manifold pressure port. For dual port manometers, use the positive pressure

side. Check for proper manifold gas pressure. Refer to Table D.

13.

Establish a call for heat. You may need to disconnect the outdoor reset if you are making this gas conversion

during warm weather.

14. Setup your combustion analyser and place the sensor into the combustion test port

15.

Per Table B for Max Fire, change dip switch 6 to ON and 7 to OFF. The unit will cycle up to MAX re.

16.

WAIT for your combustion analyser to stabilize. This may take up to 3 minutes depending on your

combustion analyser. Then check the CO2 measurement for MAX re. Refer to Table C for acceptable MAX

re combustion readings Do NOT attempt to adjust CO2 at MAX Fire. ONLY in MIN Fire,

so...

17.

Per Table B for MIN Fire, change dip switch 6 to OFF and 7 to ON. The unit will cycle down to MIN Fire.

18.

WAIT for your combustion analyser to stabilize. Then check the CO2 measurement for MIN re. Refer to

Table C for acceptable MIN re combustion readings

19.

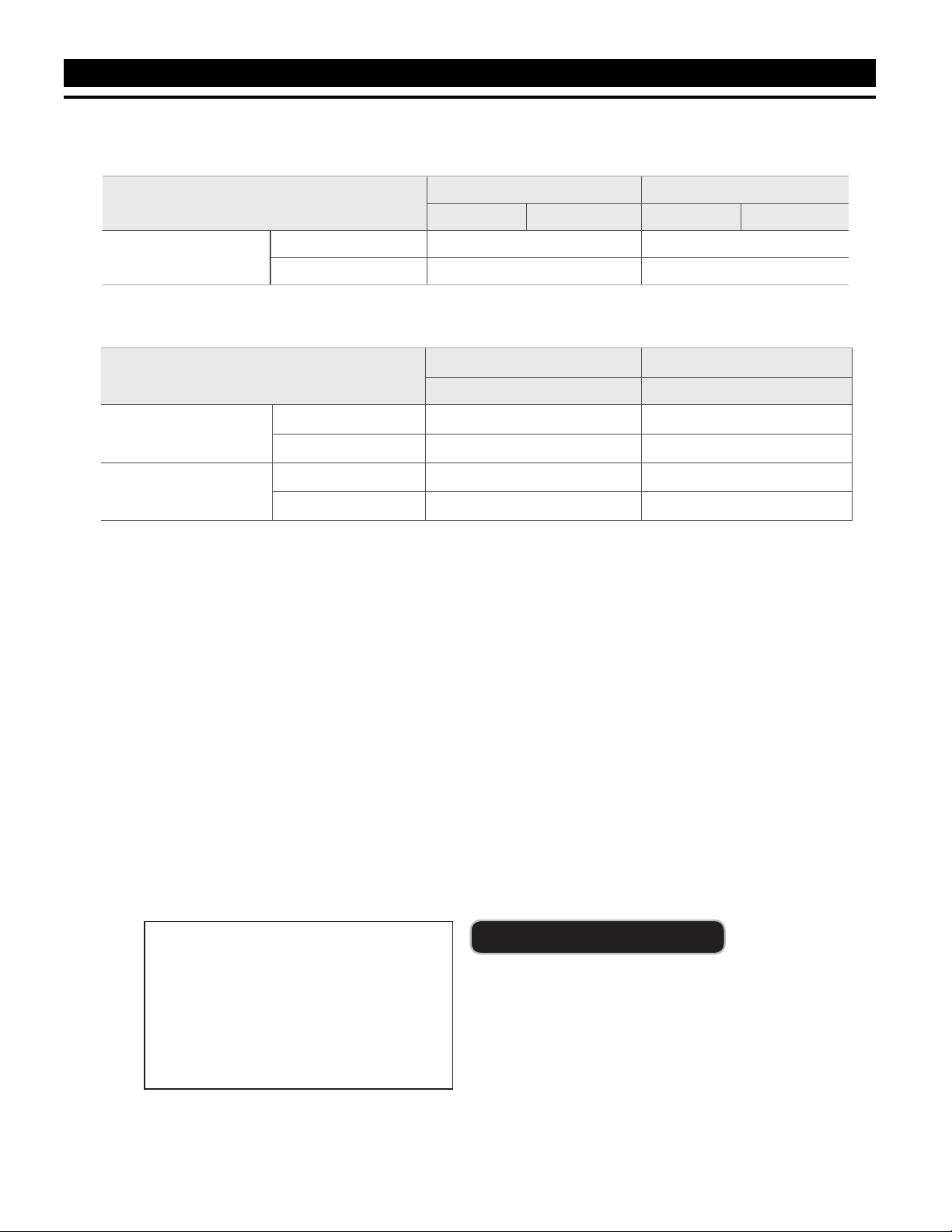

Open the Gas Valve Adjustment Port by removing the cap screw with a 4mm Allen wrench.

20.

Then use the 4 mm Allen wrench to make a minor adjustment (1/8 turn) to either increase or decrease CO2.

Figure E

MBH N/A 140 N/A 199

ON OFF

MIN Fire Normal Operation

MAX Fire Normal Operation

NG Natural LP Propane

3” Vent Size 2” Vent Size

ON OFF ON ON

ON OFF OFF ON

OFF ON ON ON

DO

NOT

CHANGE

REFERENCE

ONLY.

FTCW140 FTCW199

800.900.9276 •Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 •603.335.6300 •Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 •905.238.0100 •Fax 905.366.0130

www.Laars.com

Document 4288D

The FT Series, Wall Combi, Gas Conversion Kit

pg 4 of 4

Figure F (Conversion label)

This unit was converted on ____/____/___to _____gas

with kit #____________by______________________

(name and company __________________________

accountable)_________________________________

___________________________________________

Cette unité a été converti ____/____/____ten ______gaz

en utilisant le kit numéro _____ par______________

(nom et société_________________________________

responsable)___________________________________

_____________________________________________

CO2value

Natural Gas (NG) Propane Gas (LP)

2˝ VENT 3˝ VENT 2˝ VENT 3˝ VENT

FTCW (ALL Sizes) MAX FIRE 8.5 - 10.5% 9.5 - 11%

MIN FIRE 8 - 10% 9 - 10.5 %

NOTE: Installer is required to verify combustion settings as part of the installation process.

CO should not exceed 200 ppm.

H2373800D

Manifold pressure ‘NG’ type combustibility ‘LP’ type combustibility

2"/3" VENT 2"/3" VENT

FTCW140

MAX FIRE -0.216

"

WC -0.216

"

WC

MIN FIRE 0.002

"

WC 0.079

"

WC

FTCW199

MAX FIRE -0.314

"

WC -0.173

"

WC

MIN FIRE -0.015

"

WC -0.015

"

WC

21. It may be necessary to go back and forth between HI Fire and LOW Fire several times (and making

adjustments only at LOW Fire), before CO2 at both are within acceptable levels. Be sure to put the

adjustment port cap screw back onto the valve when done.

22. Once the CO2 and manifold pressure measurements for both MIN and MAX Fire are acceptable per

Table C, set DIP switches 6 and 7 to the OFF position for Nominal Fire (normal operation).

23. Write in the correct Conversion Date and the Technicians Name to the included gas conversion

sticker. See Figure F. Then apply that sticker adjacent to the rating plate.

24. Remove your combustion analyser from the Test Port and be sure to thread the Test Port plug back

into position.

25. Re-connect outdoor reset if it was disconnected, put the boiler cover back on and assemble/tighten

the 4 screws that hold the cover in place.

Table C

Table D

Other manuals for FT Series

3

This manual suits for next models

2