Product description

2018/02 993203x3x-mub-en – V10 7

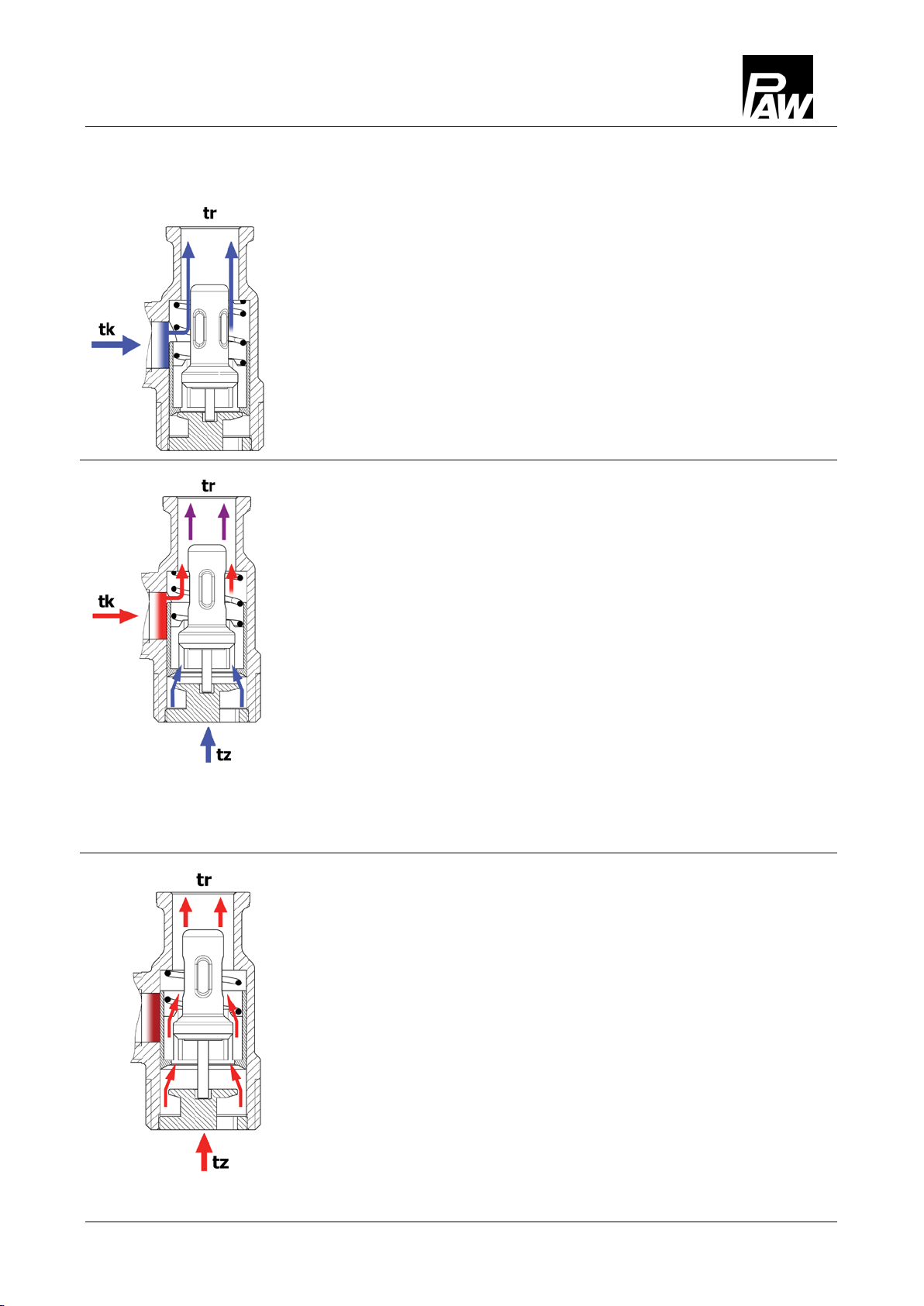

The thermal valve shuts off the connection to the tank, as long

as the water in the boiler circuit [tk] is colder than the opening

temperature of the thermal control valve. The pump in the K36

circulates the water in the boiler circuit through the automatic

bypass which is completely open.

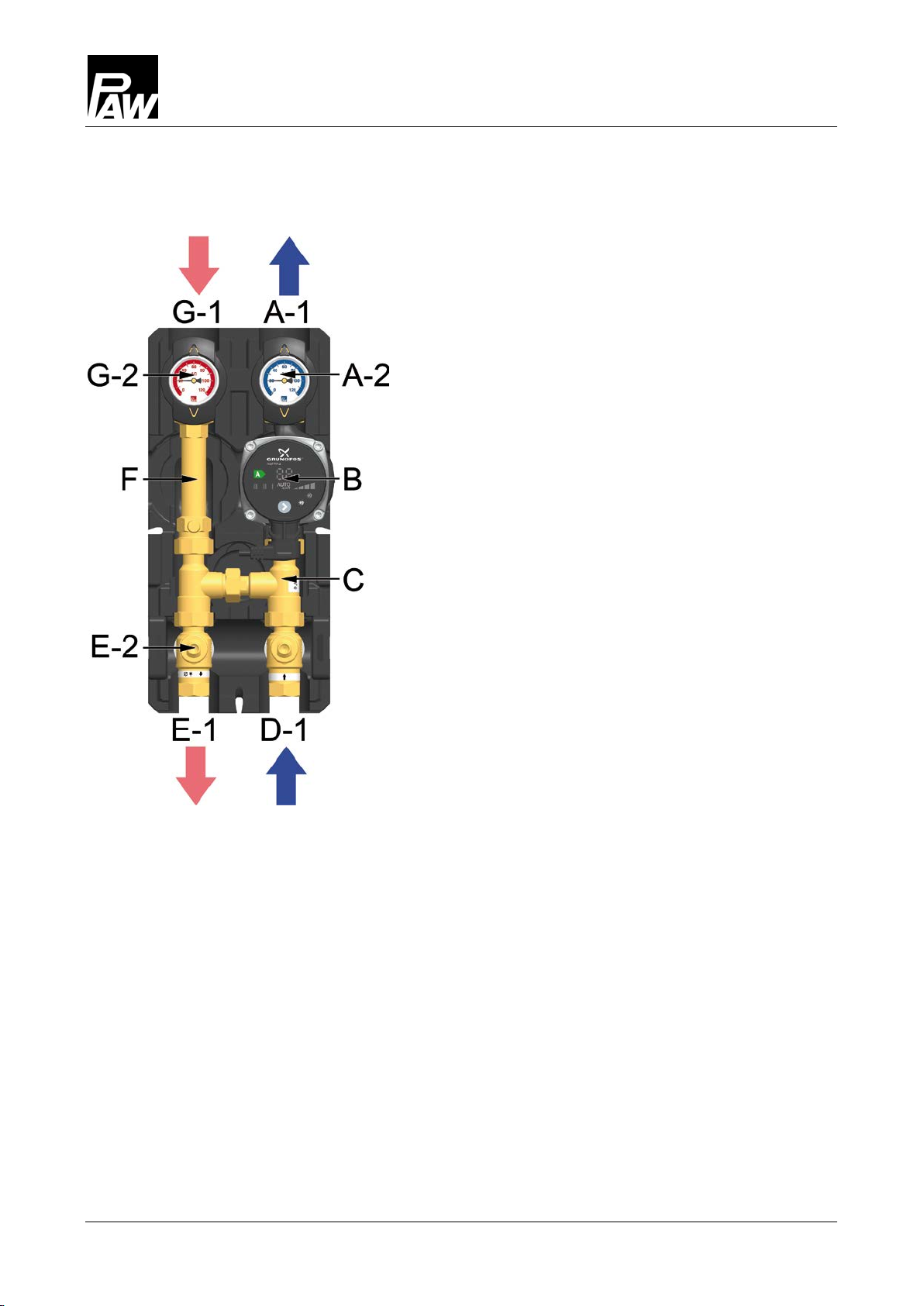

When the water in the boiler circuit [tk] has obtained the opening

temperature (+/- 3 K) of the thermal control valve, the valve opens

the connection from/to the tank. The bypass shuts off to the same

extent as the connection to the tank is opened. The control valve

opens the return line from the tank and thus enables the water to

circulate in the tank circuit. The cold water from the tank return line

is mixed in the control valve with the hot water from the bypass.

Depending on the temperature and the flow rate of the water from

the return line the thermal control valve shuts off or opens the line

to the tank. Thus the return line which leads to the boiler [tr] always

remains at a certain temperature level.

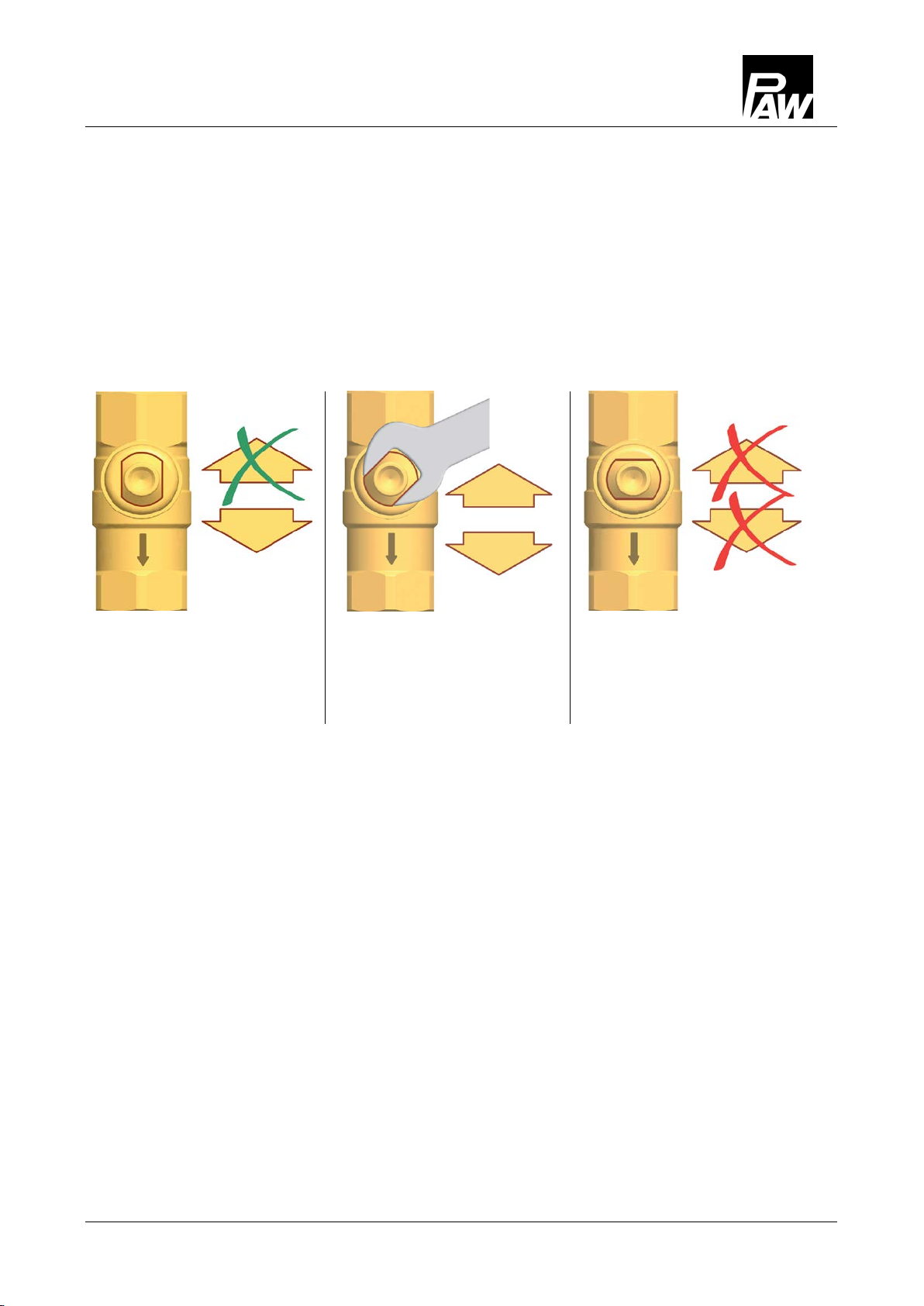

With rising temperature in the flow line of the boiler or with rising

temperature from the return line of the tank [tz] the thermal control

valve opens the connection to the tank. The temperature of the

return line of the boiler remains nearly constant (+/- 3 K).

Please note:

When the boiler output is controlled by the boiler temperature the

boiler must heat up 20 K above the opening temperature of the

K36. Otherwise there will not be enough power available (the

boiler output may be reduced before the thermal control valve

opens completely).