Document No.: EN-MN-006-01-iii

Page 4 of 21

Table of Contents

1. Precautions Regarding Installation.....................................................................................................5

2. Specifications ........................................................................................................................................6

2.1. Introduction.......................................................................................................................................6

2.2. Specifications ...................................................................................................................................7

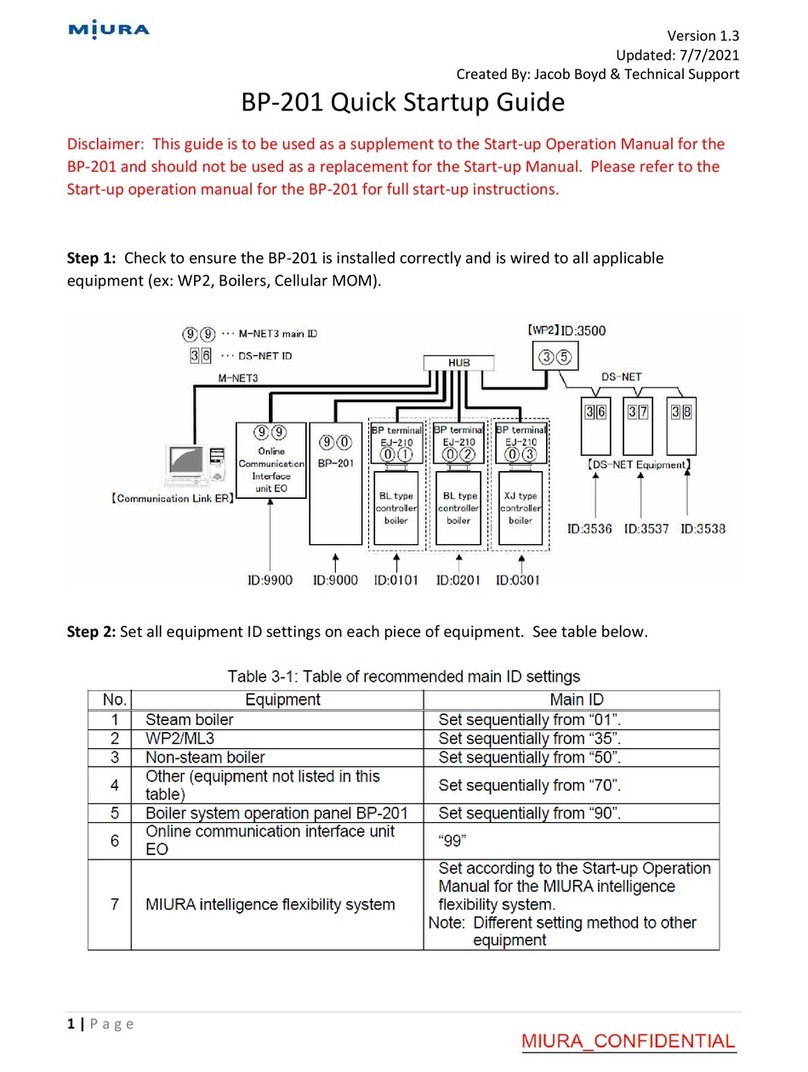

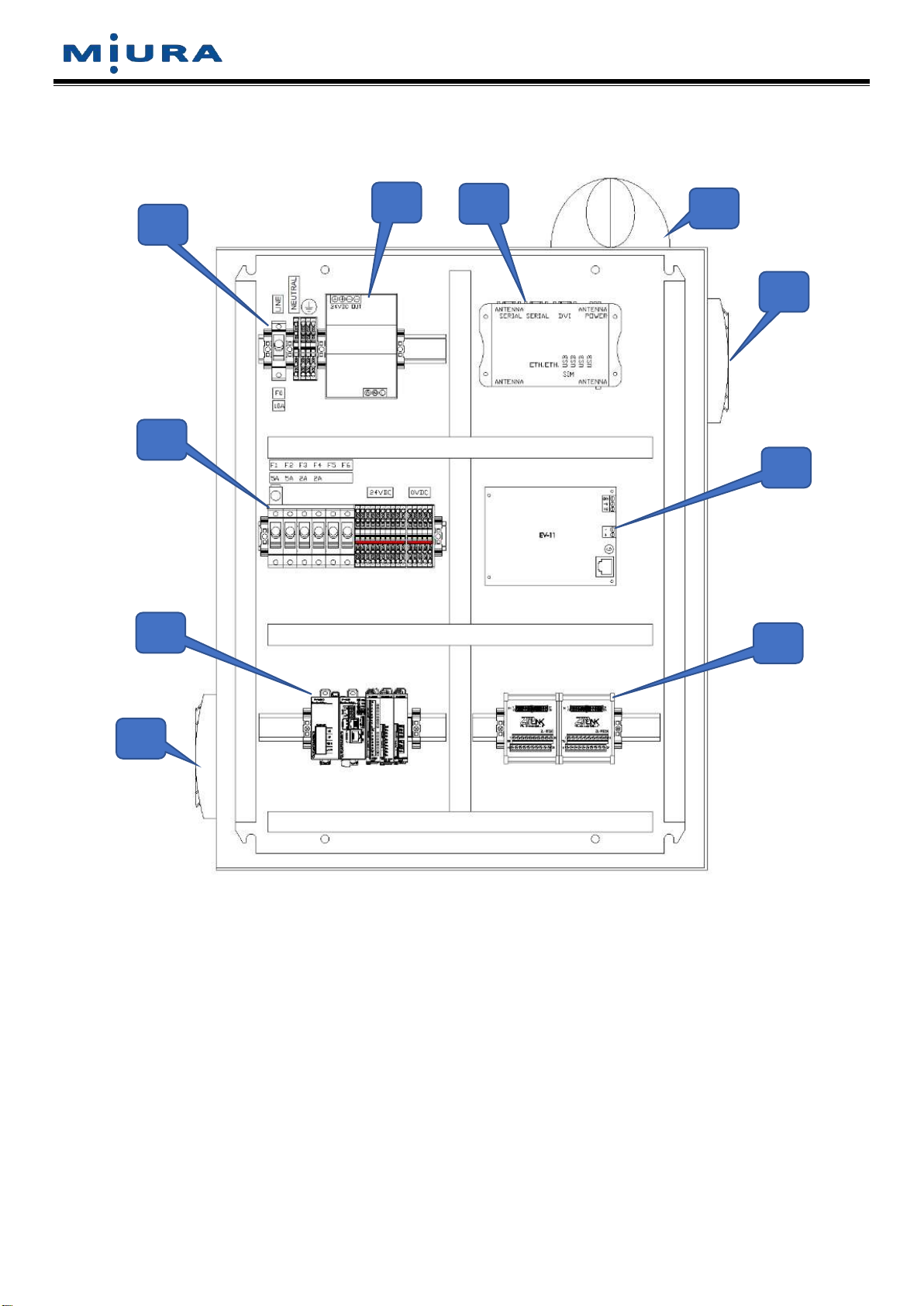

2.3. Internal System Configuration..........................................................................................................8

3. Mounting the Panel ...............................................................................................................................9

3.1. Precautions when Installing the Main Unit.......................................................................................9

3.2. Installation Procedures...................................................................................................................10

4. Field Wiring ..........................................................................................................................................10

4.1. Wiring Power Supply and Installing Ground Fault Circuit Breaker ................................................10

4.2. Wiring Communication Lines .........................................................................................................10

4.3. Antenna .......................................................................................................................................... 11

4.4. (Optional) PLC – Thermocouples ..................................................................................................12

4.5. (Optional) PLC – Discrete Inputs (dry contacts) ............................................................................12

4.6. (Optional) PLC – Analog Inputs (see next section for pressure transducer wiring) ......................13

4.7. (Optional) PLC – Analog Input – Yokogawa Pressure Transducer Input.......................................14

4.8. (Optional) PLC – Analog Input – Johnson Controls Pressure Transducer Input...........................15

5. Device Settings ....................................................................................................................................16

5.1. EV-11 COM Settings (board inside Miura Connect panel) ............................................................16

5.2. EJ-210 Settings (communication board inside each boiler control panel) ....................................16

6. Modbus TCP Output (Optional)..........................................................................................................17

7. Startup ..................................................................................................................................................17

7.1. Boiler Room Setup on www.Miura-Connect.com...........................................................................17

7.2. SIM Card Installation......................................................................................................................17

7.3. Change Modbus IP Address at Startup..........................................................................................18

7.4. Connect to a Wi-Fi Network at Startup ..........................................................................................18

7.5. Change the PLC Program at Startup.............................................................................................19

8. Serial Number Explanations...............................................................................................................20

9. Spare Parts...........................................................................................................................................21