1 General 4

1.1 About these instructions 4

1.2 Safety information 4

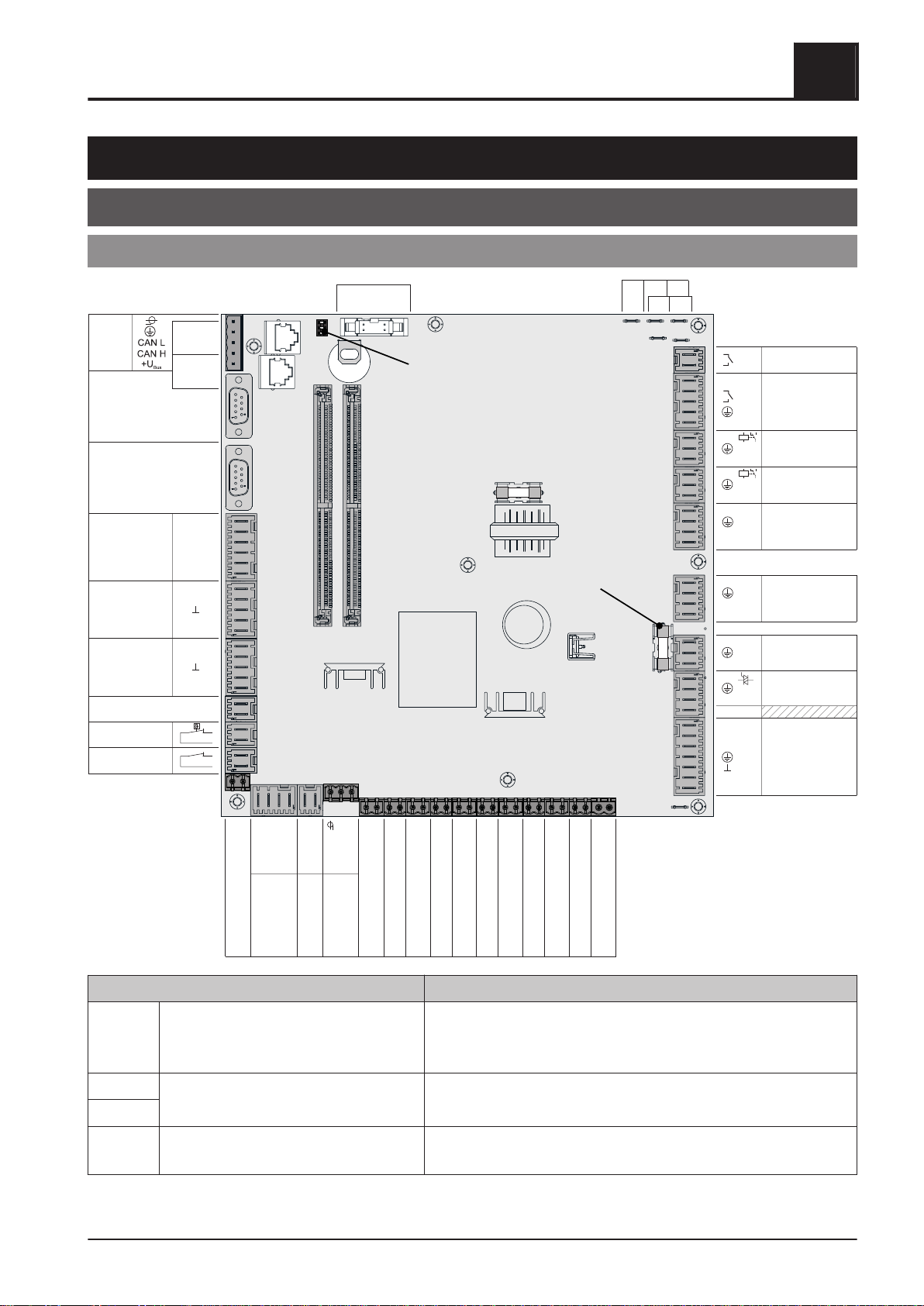

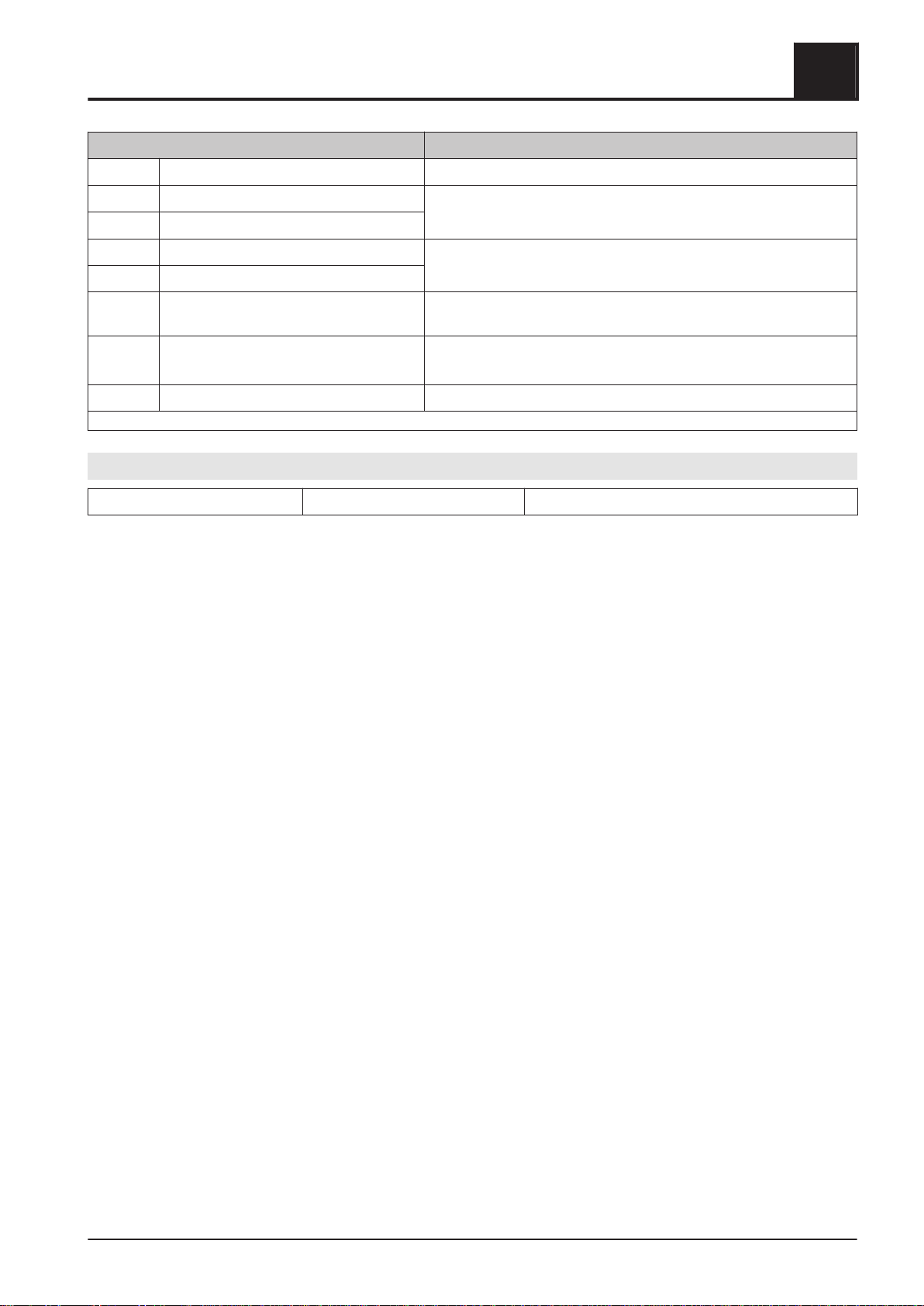

2 Power connection and wiring 5

2.1 Core module and connection options 5

2.1.1 Board view - core module 5

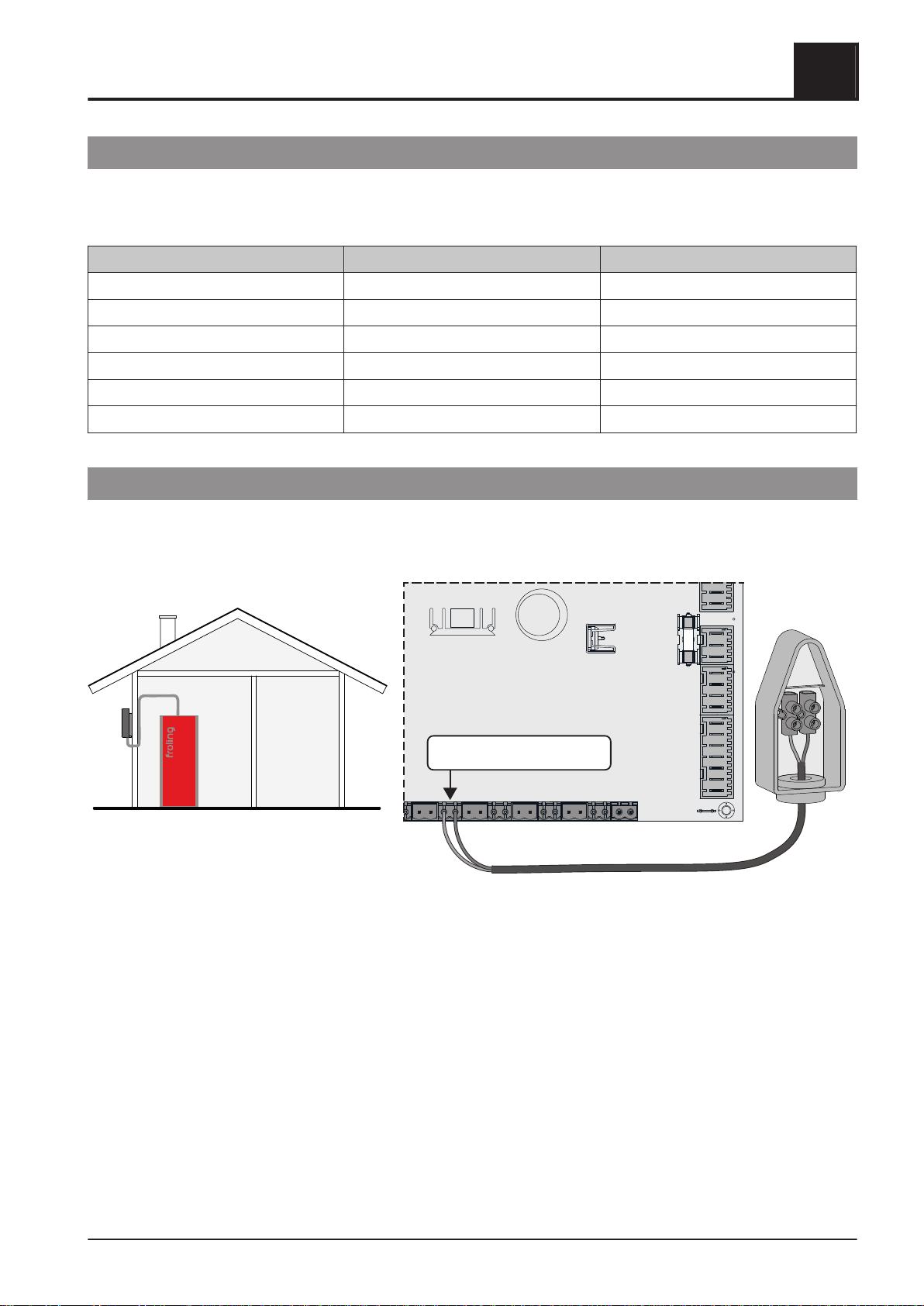

2.1.2 Mains connection 9

2.1.3 Connecting the outside temperature

sensor

9

2.1.4 FRA room temperature sensor 10

2.1.5 Connecting a circulating pump to the core

module

11

2.1.6 Connecting an isolating valve to the core

module

13

2.1.7 Heating circuit pump 0 / burner relay 14

2.1.8 Operating signal 14

2.2 Expansion modules 15

2.2.1 Heating circuit module 15

2.2.2 Hydraulic module 16

Connecting a circulating pump to the hydraulic

module

18

Connecting an isolating valve to the hydraulic

module

21

2.2.3 Return mixer module 22

2.2.4 Ignition expansion 23

2.2.5 Analogue module 25

External power demand

26

24 V power supply

26

2.3 BUS connection 27

2.3.1 Connecting the bus cable 28

2.3.2 Setting end jumpers 28

2.3.3 Setting the module address 29

2.3.4 Potential equalisation / potential

separation

30

2.4 Connection information according to

pump types

31

3 Initial start-up with settings wizards 32

3.1 Before switching on for the first time 32

3.1.1 Controller check 32

3.1.2 Check on the connected units 32

3.1.3 System check 32

3.2 General information about the settings

wizard

33

3.3 Switching on for the first time 34

3.4 Starting the setting wizard 35

4 Parameters overview 37

4.1 Heating 37

4.1.1 Heating - Status 37

4.1.2 Heating – Temperatures 38

4.1.3 Heating - Times 39

4.1.4 Heating - Service 39

4.1.5 Heating - Heating up program 40

Heating up programs

41

Configure program 8

41

Heating circuits used

41

4.1.6 Heating - General settings 42

4.2 Water 43

4.2.1 Water - Status 43

4.2.2 Water - Temperatures 43

4.2.3 Water - Times 44

4.2.4 Water - Service 44

4.3 Solar 45

4.3.1 Solar - Status 45

4.3.2 Solar - Temperatures 46

4.3.3 Solar - Times 47

4.3.4 Solar - Service 47

4.3.5 Solar - Heat meter 49

4.4 Buffer tank 50

4.4.1 Buffer tank - Status 50

4.4.2 Buffer tank - Temperatures 51

4.4.3 Buffer tank - Service 52

4.5 Boiler 53

4.5.1 Boiler - Status 53

4.5.2 Boiler - Temperatures 54

4.5.3 Boiler - Service 54

4.5.4 Boiler - General settings 55

Boiler - General settings - MODBUS settings

56

Boiler - General settings - Operator data

57

4.6 Boiler 2 57

4.6.1 Boiler 2 - Status 57

4.6.2 Boiler 2 - Temperatures 58

4.6.3 Boiler 2 - Service 59

4.7 Ignition 60

4.8 Fuel 61

4.9 Network pump 62

4.9.1 Network pump - Status 62

4.9.2 Network pump - Temperatures 62

4.9.3 Network pump - Service 63

4.10 Difference regulator 64

Table of contents

2 Froling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com