Model Congurations

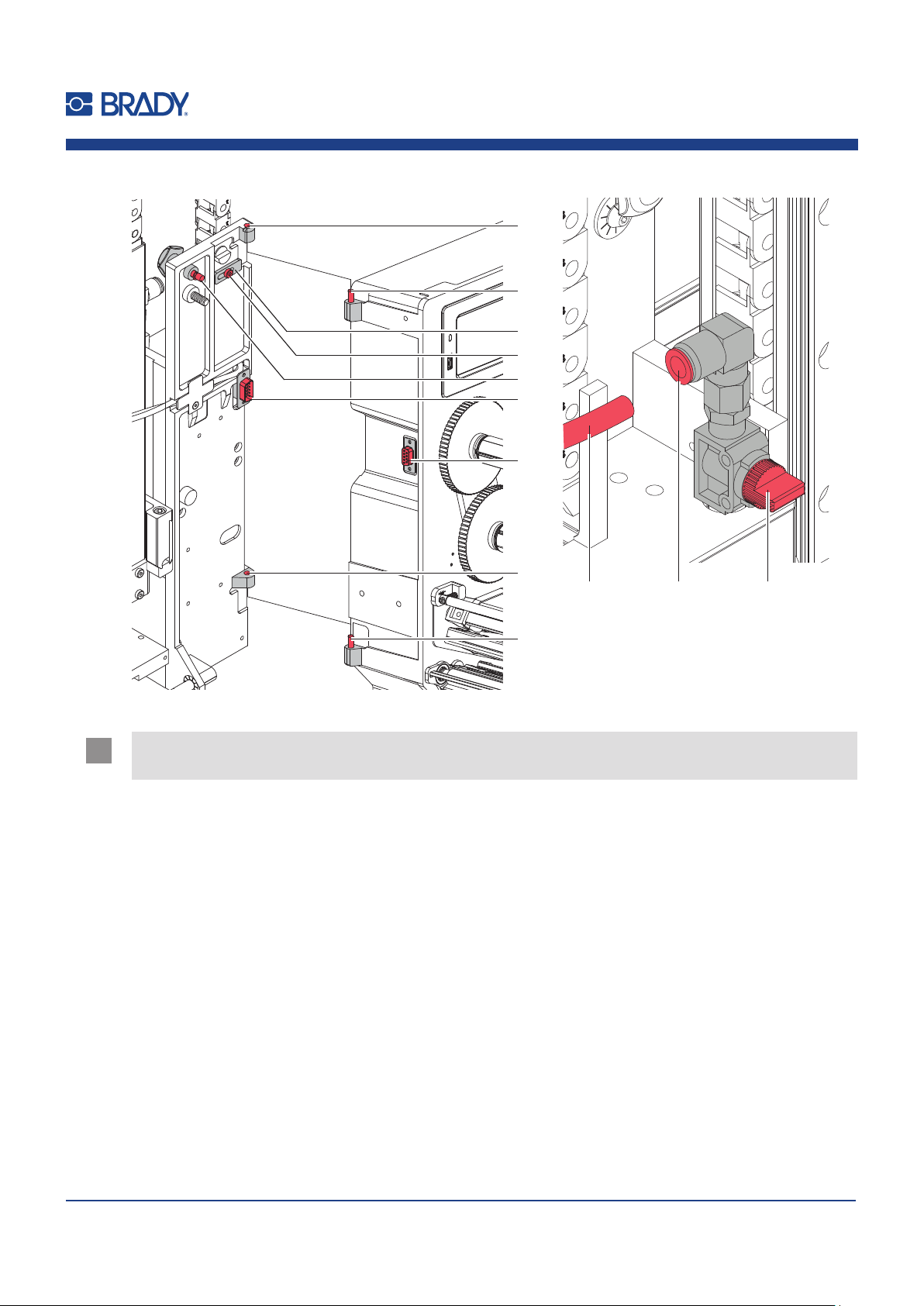

4114 Stroke Applicator 4114L-300

Stroke Applicator 4114R-300

Assembly Instructions for the following products

Disclaimer

This manual is proprietary to Brady Worldwide, Inc. (hereafter "Brady"), and may be revised from time to time without notice.

Brady disclaims any understanding to provide you with such revisions, if any. This manual is copyrighted with all rights reserved.

No portion of this manual may be copied or reproduced by any means without the prior written consent of Brady.

While every precaution has been taken in the preparation of this document, Brady assumes no liability to any party for any

loss or damage caused by errors or omissions or by statements resulting from negligence, accident, or any other cause. Brady

further assumes no liability arising out of the application or use of any product or system described, herein; nor any liability for

incidental or consequential damages arising from the use of this document. Brady disclaims all warranties of merchantability of

tness for a particular purpose.

Brady reserves the right to make changes without further notice to any product or system described herein to improve reliability,

function, or design.

Trademark

Windows, Microsoft and Internet Explorer are registered trademarks of the Microsoft Corporation.

Bluetooth is a registered trademark of Bluetooth SIG, Inc.

Firefox is a registered trademark of Mozilla Foundation.

ZPL and Zebra logo are registered trademarks of ZIH Corporation.

BradyPrinter™ is a trademark of Brady Worldwide, Inc. All brand or product names referenced in this manual are trademarks

(™) or registered trademarks (®) of their respective companies or organizations. ©2018 Brady Corporation. All rights reserved.

Editor

Regarding questions or comments please contact Brady Technical Support.

Topicality

Due to the constant further development of products discrepancies between documentation and product can occur. Please

check BradyID.com for the latest update.

Terms and conditions

Deliveries and performances are effected under the General conditions of sale of BradyPrinter A8500.

Brady Warranty

Our products are sold with the understanding that the buyer will test them in actual use and determine for him or herself

their adaptability to his/her intended uses. Brady warrants to the buyer that its products are free from defects in material and

workmanship, but limits its obligation under this warranty to replacement of the product shown to Brady’s satisfaction to have

been defective at the time Brady sold it. This warranty does not extend to any persons obtaining the product from the buyer.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY OTHER

OBLIGATIONS OR LIABILITY ON BRADY’S PART. UNDER NO CIRCUMSTANCES WILL BRADY BE LIABLE FOR ANY LOSS,

DAMAGE, EXPENSE OR CONSEQUENTIAL DAMAGES OF ANY KIND ARISING IN CONNECTION WITH THE USE, OR

INABILITY TO USE, BRADY’S PRODUCTS.

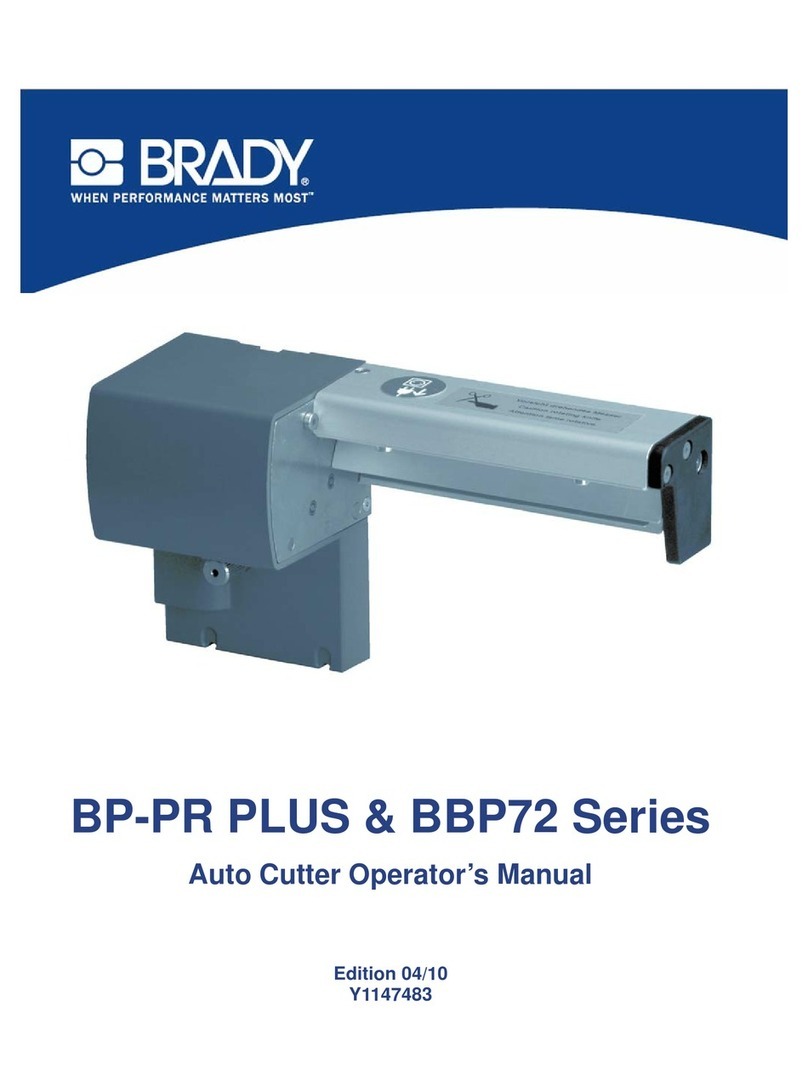

Stroke Applicator

4114

A8500L

LABEL PRINTER APPLICATOR

™

2User Manual