7Cutter CU4

Cut Position

The "Cut position" parameter allows to adjust the distance between the cut

position and the rear edge of the label. Cut position with the initial offset

value of "0" causes to cut in the middle of the gap between two labels. If

the real cut position deviates from the middle of the gap, the amount of the

cut offset can be altered in the range from -9.9mm to +9.9mm. If the cut

position value is positive, the media will be advanced before it is cut, that

means the distance between the cut edge and the rear edge of the label

increases.

The setting should be made when first operating the printer and cutter, or

when changes that will effect all print jobs sent to the printer.

NOTICE!

Changes to individual print jobs can be accomplished by changing

the software settings.

The offset values from „Cut position“ and from software are added together

for execution. The software value does not replace the „Cut position“ value,

but temporariliy adjusts it for the current print job.

Label Sensor

For recognizing the start of label the printer offers besides the two

standard methods ( Gap sensor / Bottom reflect) the setting ’’Endless

media’’. This setting should be used when operating with continuous

material in cut mode. That way it is possible to realize the movement

forward and the cut after loading the media and then pressing the key

(see section ’’Modes of Operation’’).

Backfeed

In cut mode, the media will be stopped in a position where the leading

edge of the following label has already been moved beyond the printhead.

The printer can backfeed the label material from its cut position to the

printhead. Therefore, the next label can be printed completely.

A backfeed will always be performed if the parameter is set to "always". If

the setting is set to "smart", the backfeed will only be performed if the front

label is in its cut position and the printer has not yet received all of the data

for printing the following label. Otherwise, the print of the second label will

be started, but it will only be completed after the first label has been cut.

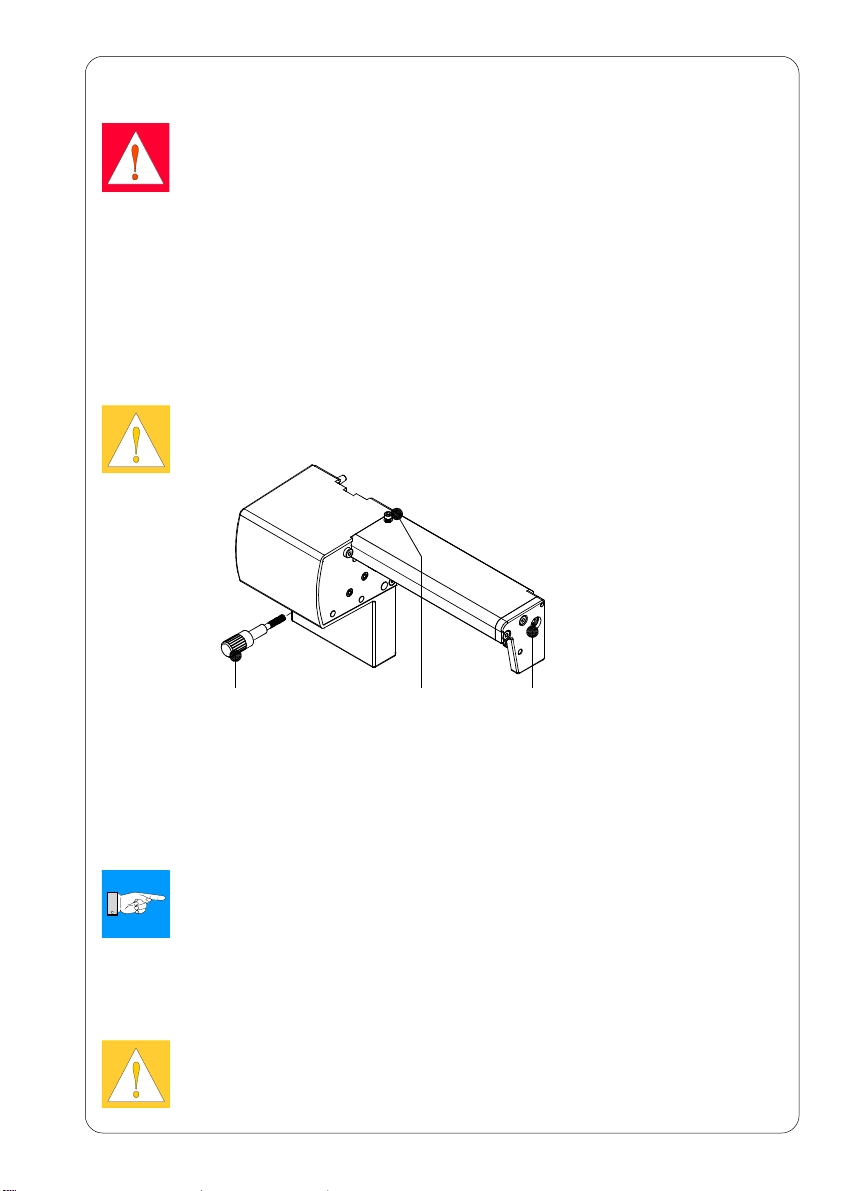

Media Loading

Load the transfer ribbon as described in the Printer’s Operators Manual.

Load the label media for cut mode similar to the way it would be loaded for

tear-off mode.

Place the media strip between the printhead and the drive roller, so that

the beginning of the strip reaches into the cutter.