BRAHMA EG25 Series User manual

2708_r04 1/6

EG25* ... EG30* ... SERIES

SOLENOID GAS VALVES WITH 3/4” AND

1” CONNECTIONS AND OPERATING

PRESSURE UP TO 500 mbar

GENERAL DESCRIPTION

This series of solenoid valves are of normally closed type,

suitable for civil and industrial applications, supplied with

alternate or direct current and inclusive of inside rectification

circuit which permitted to make actions as silent as possible;

a wire-net filter on the inlet avoids the entrance of dirt

of > 1 mm.

There is the possibility to have a fast opening or a slow

opening valve (obtained by special hydraulic shock-

absorber), with flow adjustment and fast opening initial flow

adjustment.

All versions can be connected with suitable fixing brackets,

provided with by-pass solenoid valves and pressure plugs

upstream and downstream.

Gas valves of this series, conforming to EN161, have a CE

type Certificate (CE Reg. N° 63AQ0626) in accordance to

European Directives 90/396 and 93/68.

−EC- type certification in accordance with the new

European Gas Appliances Regulation (EU) 2016/426

(GAR);

−conformity to EC Low-voltage directive 2014/35/EU

TECHNICAL FEATURES

Class: A

Group: 2

Supply voltage (1): 230 Vac / 50-60 Hz

110 Vac / 50-60 Hz

Operating temperature: -10°C / +60°C

Closing time: 1s

Opening time: 1s (quick opening

versions only)

Protection degree: GMO IP54

GFD IP54

Mounting: vertical and horizontal

Body: die-cast aluminium

Core hitch: PG9

(1) Versions with different supply voltages are available.

2/6 2708_r04

DIRECTIONS FOR INSTALLATION AND MAINTENANCE

•This valve is a safety appliance and should not be

modified. The manufacturer's responsibility and guarantee

are invalidated in case the device is tampered with by the

user.

•The applicable national regulation and European

standards (Ex. EN 60335-1 and EN 60335-2-102) related

to the electrical safety must be respected;

•Assemble the valve to the installation so that the arrow

on the valve body has the same direction as the fuel flow.

•During the assembly of the valve to the installation

piping, avoid twisting on the sheath and always use an

hexagonal wrench to be fitted to the valve body.

•Make sure that no foreign matters have entered the

valve body.

•Make sure that the max. fuel input pressure never

exceeds the value appearing on the label.

•All operations (installation, maintenance, etc.) must be

carried out by a qualified technician.

•Before any connection operation, completely isolate the

system from power supply (multi-pole disconnection).

Place the system safely to avoid accidental switch-on and

make sure there is no voltage. If the system is not

switched off, there is a risk of electric shock.

•During and after any operation (installation,

maintenance, etc.), make sure that the type and code are

the ones provided, check the correct functioning and the

internal and external thickness of the valve.

•In the event of a fall or impact, the valves must not be

started, as safety functions may be compromised even if

no damage is visible to the outside.

•Faulty valves or damaged must be unplugged from power

supply and cannot be used.

•The valve has a designed lifetime* based on the

endurance tests in the standard EN 161. A summary of

the conditions has been published by the European

Control Manufacturers Association (Afecor)

(www.afecor.org). The designed lifetime is based on use

of the valve according to the manufacturer’s technical

notes. After reaching the designed lifetime in terms of the

number of burner startup cycles, or the respective time of

usage, the valve has to be replaced by authorized

personnel.

* The designed lifetime is not the warranty time specified

in the Terms of Delivery.

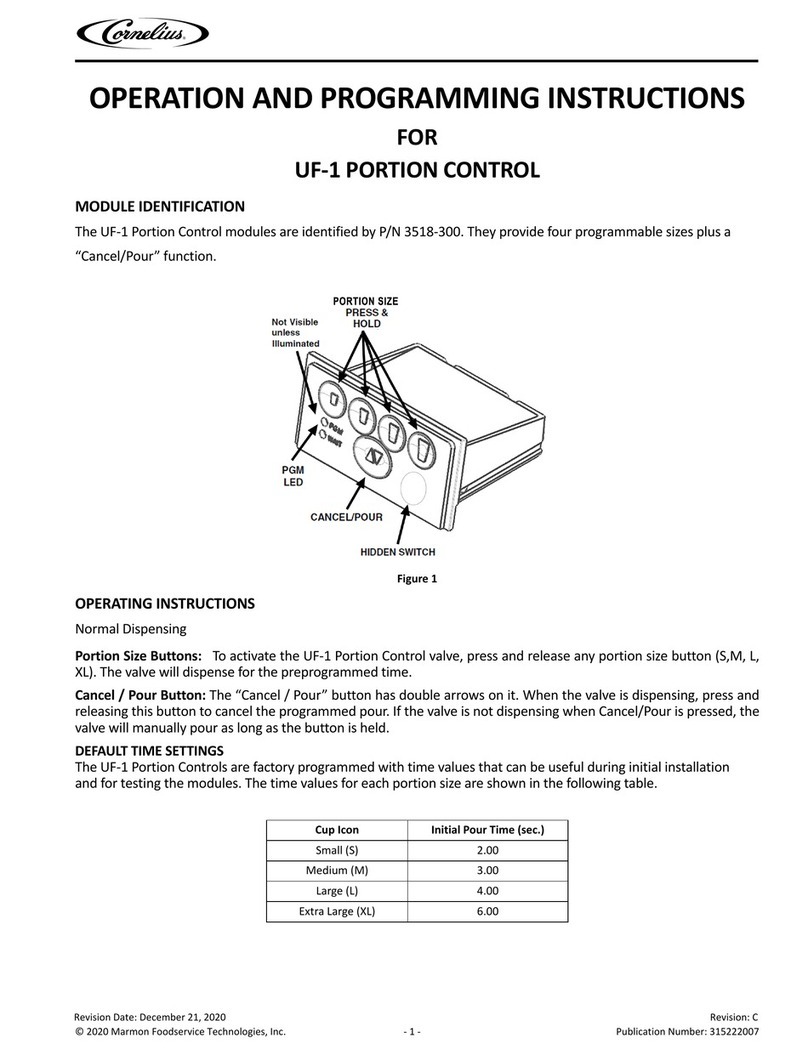

SOLENOID VALVES CONNECTIONS

It is possible to connect two valves with two fixing brackets

and an O-ring to guarantee the sealing. The whole system is

blocked by two screws, as shown in Fig. 1. This method

permits to avoid the onerous use of threaded junctions.

Fig. 1

2708_r04 3/6

DIRECTIONS FOR EG25*L... AND EG30*L... VALVES

ADJUSTMENT

Flow adjustment

To adjust the gas flow, you have to remove one of the two

screws used to fasten the lag group (the not enamelled one,

marked with 4 in Fig. 2) and rotate clockwise the whole group

to reduce the flow or in the opposite direction to increase it.

Opening time adjustment

After removing the top protection, by rotating it

counterclockwise, you have to act on the adjustment screw,

marked with 1 in Fig. 2; by rotating clockwise, the opening

time becomes longer, by rotating in the opposite direction, the

opening time becomes shorter.

Quick release initial flow adjustment

After removing the top protection by rotating it

counterclockwise, if you rotate clockwise the nut marked with

2 in Fig. 2, the initial release will be reduced; if you rotate the

same nut counterclockwise, the initial release will be

increased.

1

2

3

4

Fig. 2

DIRECTIONS FOR EG25*SR... AND EG30*SR... VALVES

ADJUSTMENT

Flow adjustment

After removing the top protection by rotating it

counterclockwise, rotate clockwise the screw marked with 1

in Fig. 3 to reduce the flow, rotate in the opposite direction to

increase the same.

1

Fig. 3

SOLENOID VALVES WITH BY-PASS

All versions of EG25*... and EG30*... valves can be equipped

with a by-pass valve (with orifice diameter 11 mm) directly

fitted on the body. In this way it is avoided the installation of a

separated by-pass valve.

Both to the main valve and to the by-pass one, flow is given

from the same inlet gas pipe, even if they have different

electrical controls.

By-pass valve can have fast or slow opening, and can be with

or without flow adjuster, but anyway inclusive of an inside

rectification circuit, which permitted to use suitable

attenuators, to make its actions as silent as possible.

EG25 BY-PASS

EG30 BY-PASS

4/6 2708_r04

OVERALL DIMENSIONS

EG25*S.3*GMO

EG25*SR.3*GMO

EG25*L.3*GMO

EG25*L.1*GMO

EG25*SR.1*GMO

EG25*S.1*GMO

EG25*.1*GFD

See note

below

EG25*.3*GFD

See note

below

EG30*S.5*GMO

EG30*SR.5*GMO

EG30*L.5*GMO

EG30*L.2*GMO

EG30*SR.2*GMO

EG30*S.2*GMO

EG30*GFD

See note

below

Note:

“GFD” and “GMO” connections don’t affect the gas valve’s overall dimensions, which remain the same.

2708_r04 5/6

DIAGRAM

PRESSURE DROP

mbar

FLOW RATE

m3/h

A : Standard flow rate m3/h of NATURAL GAS relative density 0.554

B : Standard flow rate m3/h of LPG relative density 1.54

C : Standard flow rate m3/h of TOWN GAS relative density 0.411

D : Standard flow rate m3/h of AIR relative density 1

EG25*S.3 EG25*SR.3 EG25*L.3

EG25*L.1EG25*SR.1EG25*S.1

NOTES FOR PRODUCT DISPOSAL

The device contains electronic components and cannot therefore be disposed of as normal household waste. For the disposal

procedure, please refer to the local rules in force for special waste.

BRAHMA S.p.A.

Via del Pontiere, 31

37045 Legnago (VR) - ITALY

Tel. +39 0442 635211 - Fax +39 0442 25683 03/11/20 Subject to amendments without notice

http://www.brahma.it

E-mail : brahma@brahma.it

6/6 2708_r04

ATTENTION --> Company Brahma S.p.A. declines any responsibility for any damage resulting from Customer tampering with the device.

TYPE REFERENCES

EG30 * S R P 2 * S R S 15* G FD 8 P D 230/50-60

Supply voltage

Type

Description

110/50-60

110 Vac / 50-60 Hz

230/50-60

230 Vac / 50-60 Hz

Opening type (fast/slow)

Type

Description

S

Fast opening valve.

L

Slow opening valve (this

version is inclusive of flow

adjuster).

Flow adjustment

Valve fitted with equipment for flow

adjustment.

Pressure plug

Valve inclusive of pressure plug with

G1/4” connections.

Valve fitted with BY-PASS

By-pass valve supply voltage and connections

are the same of the main gas valve; therefore

both “GMO” or both “GFD”.

By-pass type

Type

Description

S

Fast opening.

SR

Fast opening with flow

adjustment.

L

Slow opening with flow

adjustment.

Gas pressure switch type

Type

Description

P

Fixed setting

PR

adjustable setting

Gas pressure switch position

Type

Description

D

Right

S

Left

Connection type

Type

Description

FD

Connection with fast-on DIN

MO

Connection with terminal

board.

Type

Type

Description

EG25

G3/4” inlet-outlet Ø25

orifice.

EG30

G1” inlet-outlet Ø30

orifice.

Winding type

Type

Descrizione

C

Supply in direct current.

G

Supply in alternate current, but

valve operates in direct current

thanks to an embodied

rectification bridge.

(“MO” and “FD” connection

versions only)

By-pass model (EG30 only version)

Type

Description

Standard By-pass

15

By-pass made up EG15 valve

By-pass position

Type

Description

D

Right

S

Left

Test pressure point position

Type

Description

5

Outlet left

6

Outlet right

7

Inlet left

8

Inlet right

SUMMARY TABLE

Type

DN

Operating

pressure

(mbar)

Orifice

diameter

(mm)

Connection

Weight

(g)

Coil

Consumption

(W)

230Vac

Consumption

(W)

110Vac

Flow

(m³/h gas with

P2.5mbar)

EG25S.1

EG25*S.3

EG25*SR.1

EG25*SR.3

EG25*L.1

EG25*L.3

20

20

20

20

20

20

0 ÷ 100

0 ÷ 500

0 ÷ 100

0 ÷ 500

0 ÷ 50

0 ÷ 350

25

25

25

25

25

25

G3/4"

G3/4"

G3/4"

G3/4"

G3/4"

G3/4"

1280

2170

1275

2180

1390

2415

BE10*G..

BE8*G..

BE10*G..

BE8*G..

BE10*G..

BE8*G..

20VA

33W

20VA

33W

25VA

33W

18VA

34W

18VA

34W

in progress

34W

15

15

15

15

15

15

EG30*S.2

EG30*S.5

EG30*SR.2

EG30*SR.5

EG30*L.2

EG30*L.5

25

25

25

25

25

25

0 ÷ 350 (1)

0 ÷ 500 (1)

0 ÷ 350 (1)

0 ÷ 500 (1)

0 ÷ 200

0 ÷ 350 (1)

30

30

30

30

30

30

G1"

G1"

G1"

G1"

G1"

G1"

2350

2780

2360

2800

2600

3050

BE8*G..

BE9*G..

BE8*G..

BE9*G..

BE8*G..

BE9*G..

33W

35W

33W

35W

33W

35W

34W

33W

34W

33W

34W

33W

23

23

23

23

23

23

Operating pressure range

See summary table

(1) In the versions equipped with by-pass valve type “L” the standard operating pressure range is 0÷250 mbar

This manual suits for next models

18

Table of contents

Other BRAHMA Control Unit manuals

Popular Control Unit manuals by other brands

Metso

Metso Mapag BAR Series Installation maintenance and operating instructions

Quectel

Quectel BC95 Hardware design

Swegon

Swegon Parasol evo II ma quick start guide

OHM

OHM PATCH PANEL PP-1 user manual

H3C

H3C SecPath NSQM2AC1400 user manual

Cornelius

Cornelius UF-1 Portion Control Operation and Programming Instructions