BrandMotion 9002-8722 User manual

INSTALLATION(INSTRUCTIONS(

8722 Instructions 2-9-15.doc Page 1 of 6

OEM Lip Mount Camera with Harness and OnStar Mirror for GM

Vehicles with 16-pin Mirror Connector

(Kit part number 9002-8722)

Please read thoroughly before starting installation

and check that kit contents are complete.

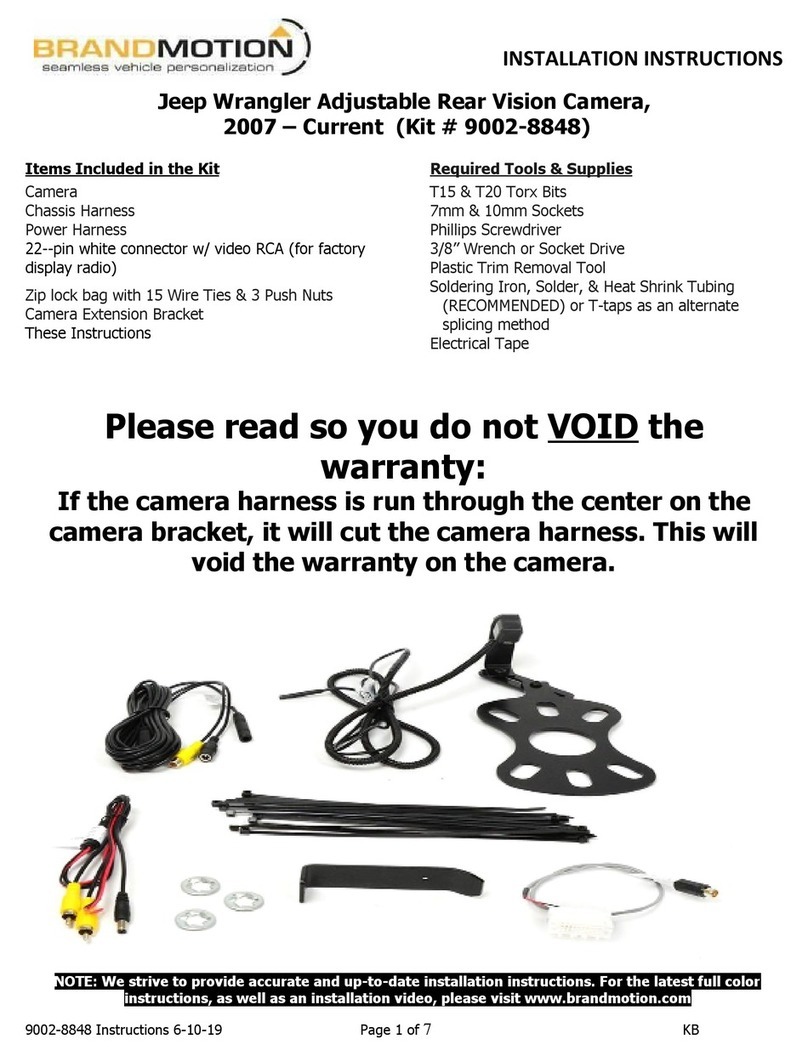

Items Included in the Kit:

Tools & Supplies Needed:

Bubble bag containing:

Camera with Mount

Mirror

Mirror Harness

Chassis Harness

Zip lock bag containing:

12 Zip Ties

2 Rubber Well Nuts

2 Bolts

2 sets of T-taps

Zip lock bag containing:

These Instructions

Self-adhesive Template

Phillips Screwdriver

5/16” Drill Bits

7/8” or 22mm Center Hole Saw

Power Drill

Deburring Tool or Round File

Multi-meter or computer safe test light

Wire Crimper

Rust Inhibitor (Recommended)

Soldering Iron (Recommended)

Solder (Recommended)

Plastic Trim Removal Tool

Safety Precautions:

•Work in a well ventilated area that is clear of obstructions.

•Secure vehicle with tire chucks in both front and rear of tires.

•Turn vehicle accessories OFF and ensure ignition key is in OFF position.

•Wear safety goggles and snug fitting clothes.

•Use tools only for their intended purpose and which are in good repair.

•Only perform this task if confidence, skill, and physical ability permit.

NOTE: We strive to provide accurate and up-to-date installation instructions.

For the latest full color instructions, please visit www.brandmotion.com

ATTENTION: 16 Pin Mirror Connector required - This kit only works on

vehicles that are equipped with the 16-pin Mirror Connector illustrated on Page 4. Some

GM vehicles with OnStar are equipped with a 10-pin connector. For these applications,

purchase a 10-pin mirror kit BrandMotion part number 9002-8723

For a current list of GM vehicles equipped with a 10 pin connector,

download the latest application guide at www.brandmotion.com/docs2/rvsappguide.pdf

INSTALLATION(INSTRUCTIONS(

8722 Instructions 2-9-15.doc Page 2 of 6

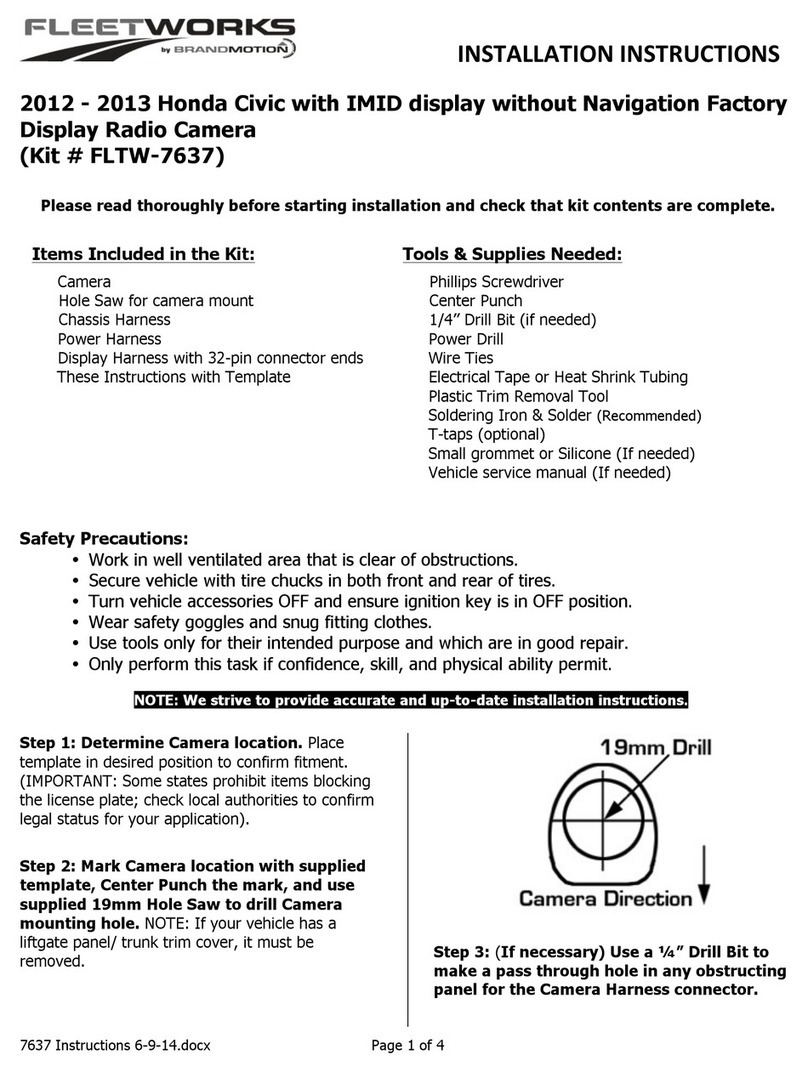

Step 1: Place Camera Mount in desired position to

confirm fitment. (IMPORTANT: Some states

prohibit items blocking the vehicle license plate;

check local authorities to confirm legal status for

your specific application).

Note: the rear trim of several GM vehicles such as

the Chevy Equinox and Cadillac CTS have slight

depressions (indicated by the arrow below) where

factory installed rear view cameras are mounted.

These positions are ideal camera locations.

Step 2: Peel adhesive backing from supplied

Camera Mount Template and apply to the desired

location making sure that the camera direction is

correct.

Step 3: Use a Center Punch to mark the centers of

the required three holes and drill three pilot holes

using a 1/8” drill bit. NOTE: If your vehicle has a

liftgate panel/trunk trim cover, it must be removed.

Step 4: Drill two 5/16” holes for the camera

mounting bolts and one 7/8” hole for the camera

harness. Use a Deburring Tool or Round File to

smooth edges.

Step 5 (if necessary): Using a 7/8” drill bit, drill an

opening in the trunk or liftgate for the head of the

Camera Harness to pass through. Insert Camera

Harness head through the backside of the hole so

that the gray connector end of the Camera Harness

is inside the trunk or liftgate. (RECOMMENDED:

Protect Camera Harness with a rubber grommet or

by applying a small amount of silicone caulk to the

area that comes into contact with the edges of the

hole. Additional recommendation: If drilling

through sheet metal, apply a Corrosion Inhibitor.)

Step 6: Mount the Camera using the supplied

hardware. Insert the two Rubber Well Nuts into the

outer 5/16” camera mount holes.

Step 7: Thread the two supplied bolts through the

Camera Mount and into the Well Nuts using a

Phillips Screwdriver but do not tighten the Bolts all

the way down just yet.

Step 8: Determine location of vehicle power and

reverse from the chart on Page 6.

NOTE: If self-adhesive Template is missing or

damaged, cut out the image above and affix

with Masking Tape.

INSTALLATION(INSTRUCTIONS(

8722 Instructions 2-9-15.doc Page 3 of 6

Step 9: Route Camera Harness towards the side of

the vehicle that supplies power. It may be

necessary to remove sill plates, pillar covers, seat

bottoms, side panels, etc. In some cases even the

seatbelt bolts at the bottom of the pillars must be

removed.

CAUTION: Any bolts removed for safety devices

must be retightened to manufacturer’s specified

torque specifications). Use a plastic trim

removal tool to avoid damage to trim pieces.

Step 10: Connect Camera Harness to supplied

Chassis Harness.

The optimal location for this junction may occur at

the top of the liftgate or the inner edge of the

trunk. (Note: Most vehicles have existing wires

passing through this area; use this route if at all

possible).

Step 11: Route Chassis Harness forward. It may

be necessary to remove sill plates, pillar covers,

seat bases, side panels, etc. using a Plastic Trim

Removal Tool. In some cases, seatbelt bolts must

be removed. (CAUTION: Any bolts removed for

safety devices must be retightened to

manufacturer’s torque specifications).

Step 12: Secure Camera Harness to existing

vehicle wiring with supplied Wire Ties. This will

minimize chance of binding or otherwise damaging

the harness.

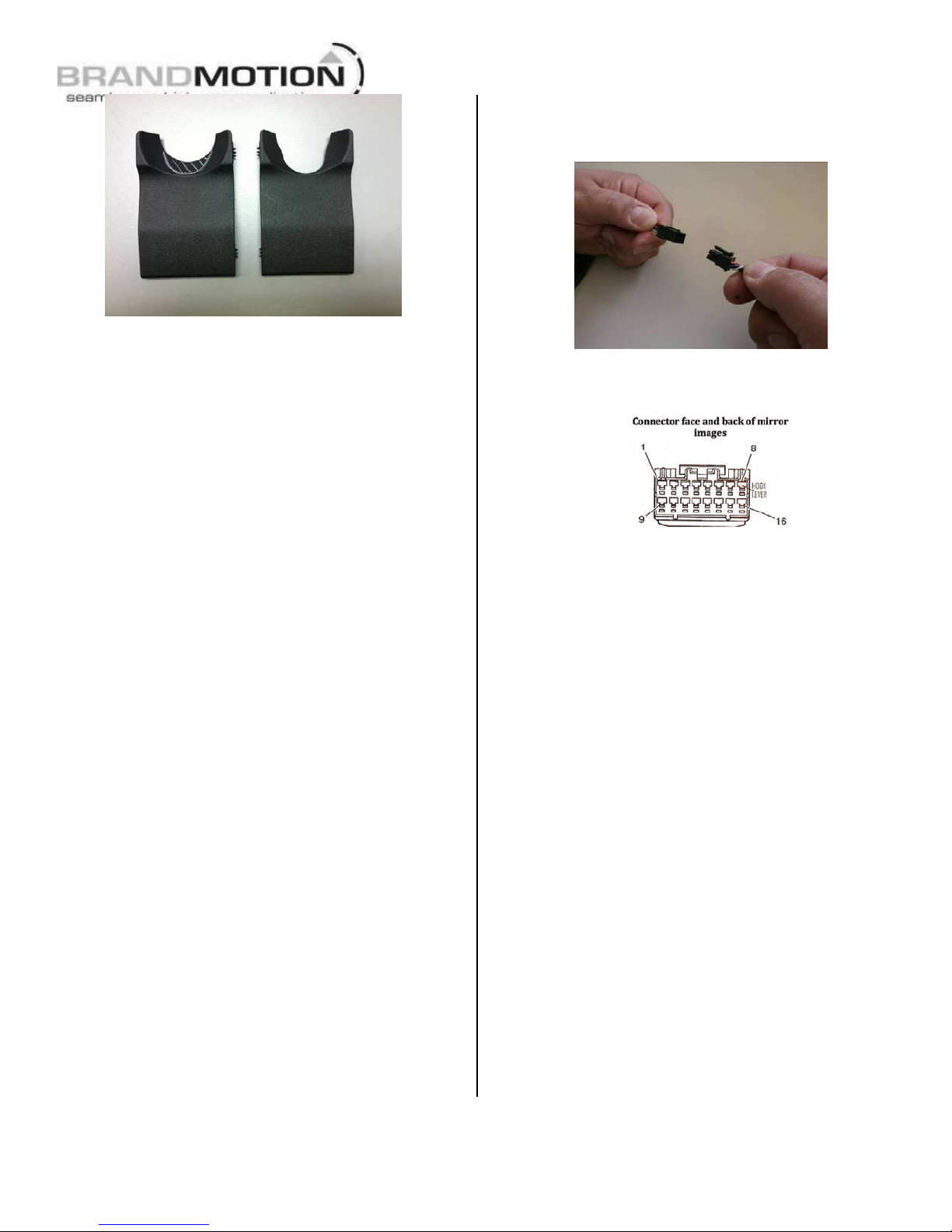

Step 13: Remove vehicle mirror. Unplug the 16-

pin connector from the rear of the vehicle’s mirror,

use a T20 Torx bit to loosen the screw securing the

mirror, and slide the mirror off the windshield

mounting tab.

CAUTION: Removing the mirror can cause

damage to the windshield.

NOTE: Some vehicles have Mirror Mounting

Covers (the 2012 Equinox is shown below).

Refer to our application guide for affected

vehicles. If equipped, remove the cover with a

plastic trim tool. If the vehicle has a center

portion, remove it.

Next, using a Roto Tool remove the striped

area of the center cover as shown below.

The reworked cover is on the right.

!"#$%&&%$!'"(!"#$)*+$!'"#(

8722 Instructions 2-9-15.doc Page 4 of 6

Step 14: Attach supplied Mirror to the

windshield using a T20 Torx Driver. This

mirror has a Wedge/ D-tab style mounting base.

Please check our compatibility chart to make sure it

is compatible with your vehicle (adapters are

available for specific applications separately).

CAUTION:Torque for the mirror screw that

attaches to the windshield tab is 1.8 Nm (16

lb-in) and cannot exceed 2.2 Nm (19.5 lb-in).

Step 15: Plug the 16-pin connector of the supplied

Mirror Harness into the supplied Mirror.

Step 16: Route the 6-pin connector end of the

Mirror Harness along with the green, red, and black

wires under the headliner.

Step 17: Route the Mirror Harness down the inside

of the A-pillar trim closest to the ignition and

reverse locations for the vehicle.

Step 18 (if required):Wiring the Mirror

Harness.

NOTE: It may not be necessary for you to use the

Green and Red supplied wires below; most GM

vehicles already have these locations populated. If

wires already exist in these locations, test the leads

using a multimeter for the correct signal).

If the wires do not exist, splice the red and green

wire leads to the wires listed for the vehicle on

Page 6. (Soldering recommended or T-taps as

optional connection method):

Red -Ignition controlled power 12v+ when key is

turned ON and 14.4v or better when vehicle is

running.

Green - Connect to Reverse + power (backup lamp).

Step 19: Attach eyelet of black chassis ground

wire of the supplied Mirror Harness to an existing

body bolt.

Step 20: Connect the 6-pin connector of the

supplied Mirror Harness to the supplied Chassis

Harness.

Tuck any excess harness beneath the headliner

taking care not to bind the wires.

White dot

identifies

cavity 1

INSTALLATION(INSTRUCTIONS(

8722 Instructions 2-9-15.doc Page 5 of 6

Mirror Harness Pinouts

6-PIN

Pin #

WIRE COLOR

16-PIN

Pin #

WIRE COLOR

FUNCTION

1 n/a

n/a

2 n/a

n/a

3 n/a

n/a

4 n/a

n/a

5 - Gray

Exterior Auto Dimming (+)

1 -White

6 - White

Video +

4 - Brown

7 - Brown

Video -

5 - Black

8 - Black

Ground

3 - Green

9 - Green

Reverse Signal 12V+

10 n/a

n/a

11 - Purple

Onstar Keypad Signal

12 - Blue

Onstar Keypad Supply Voltage

6 - Red

13 - Pink

Ignition Controlled 12V+

14 - Yellow

Onstar Keypad Green LED Signal

15 - Orange

Onstar Keypad Red LED Signal

16 - Red

Exterior Auto Dimming (-)

2 - Blue

Shield

Step 25: Test the system. Inspect that all

connections are proper and secure. Clear all loose

items removed from the area around the vehicle

and turn ignition key ON to test system. Once

reverse gear is engaged the camera image should

appear on the mirror.

Step 26: Secure Chassis Harness and Mirror

Harness with supplied Zip Ties. If necessary,

coil excess harness wire and secure with zip ties.

Attach to existing vehicle wiring where possible.

Step 27: Adjust camera aim. With the aid of an

assistant, move camera to desired view, and

tighten the screws that hold the camera in place.

Step 28: Reassemble vehicle. Follow your

disassembly steps in reverse order, taking care not

to bind the harness wiring when reinstalling trim.

OPERATING(INSTRUCTIONS(

Temporary Monitor Manual Shut Down. If while in reverse you require to turn OFF the camera

monitor, simply press and release the POWER button on the mirror. (NOTE: once reverse is disengaged the

mirror will go back to normal operation and will turn ON next time reverse is engaged).

INSTALLATION(INSTRUCTIONS(

8722 Instructions 2-9-15.doc Page 6 of 6

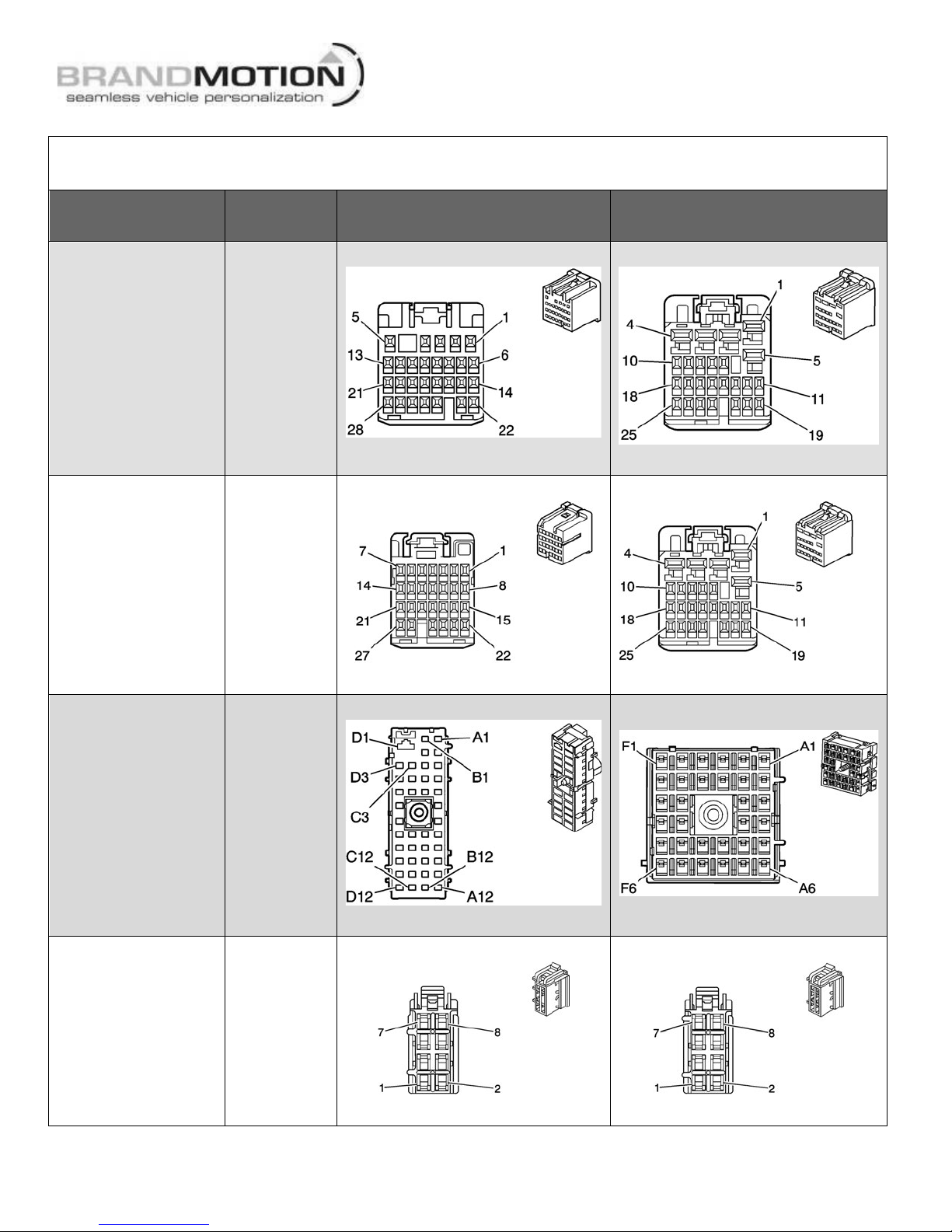

Ignition & Reverse Locations and Wire Colors

VEHICLE

LOCATION

IGNITION CONNECTOR

WIRE COLOR & PIN

REVERSE CONNECTOR

WIRE COLOR & PIN

Buick Enclave

Chevrolet

Traverse

GMC Acadia

Driver side

below IP

cluster left

of steering

column

BCM X7

Yellow- Pin 2

BCM X6

Light Green – Pin 2

Chevrolet Impala

Driver side

below IP,

left of the

steering

column

BCM X1

Pink – Pin 14

BCM X6

Light Green - Pin 2

Chevrolet Malibu

(Through 2012)

BCM X3:

Center dash

below IP

cluster

Fuse Block

- Rear X3:

Driver side

trunk

behind

wheel well

BCM X3

Pink – Pin A6

Fuse Block - Rear X3

Brown – Pin F2

Chevrolet

Silverado

Chevrolet Tahoe

Chevrolet & GMC

Suburban

GMC Sierra

GMC Yukon

Driver side

below IP

left of

steering

column

inside

Junction

Box

M-BEC X12 (Brown)

Pink – Pin 7

M-BEC X11 (Gray)

Dark Blue – Pin 5

Table of contents

Other BrandMotion Dashcam manuals

BrandMotion

BrandMotion FleetWorks FLTW-7637 User manual

BrandMotion

BrandMotion ADAS+ ADAS-1100 User manual

BrandMotion

BrandMotion 9002-2906v2 User manual

BrandMotion

BrandMotion 9002-8848 User manual

BrandMotion

BrandMotion 9002-7752 User manual

BrandMotion

BrandMotion 9002-8808 User manual

BrandMotion

BrandMotion 9002-8858 User manual

BrandMotion

BrandMotion SUTV-1010V2 User manual

BrandMotion

BrandMotion FLEETWORKS FLTW-7603 User manual

BrandMotion

BrandMotion 9002-7802 User manual