Branick Industries, Inc. 5700E Use and care manual

REV031318 P/N: 81-0289

MODEL 5700E

Adjustable Height

Tire Spreader

Installation, Operation

& Repair Parts

Information

Branick Industries, Inc. •4245 Main Avenue •Fargo, North Dakota 58103

1

TABLE OF CONTENTS _________________________________________________________________

SAFETY INSTRUCTIONS 1

DEFINITIONS 1

SPECIFICATIONS 2

INSTALLATION INSTRUCTIONS 2

OPERATING INSTRUCTIONS 3

ADDITIONAL FEATURES 3

MAINTENANCE 3

REPAIR PARTS 4

WARRANTY 11

SAFETY INSTRUCTIONS _______________________________________________________________

▪NEVER allow unauthorized personnel to operate this product.

▪NEVER use this product for anything other than its intended use.

▪THOROUGHLY train new employees in the proper use and care of this product.

▪PROHIBIT unauthorized personnel from being in shop area while this product is in use.

DEFINITIONS __________________________________________________________________________

▪CAUTION: Indicates a potentially hazardous situation, which if not avoided, may result in damage to property or

minor personal injury.

▪HAZARD: A source of potential injury to a person.

▪MAINTENANCE: Those actions that preserve the correct and proper conditions under which the machine shall be

used. This may include adjustment, replacement of wear items, lubrication and cleaning, but not modifications or

repair of damage.

▪MAY: This word is understood to be permissive.

▪MUST: This word is understood to be mandatory.

▪OPERATION: The correct and proper use of the machine as described in this manual.

▪SAFETY ALERT SYMBOL: A symbol that indicates a potential personal safety hazard. It is composed of an

equilateral triangle surrounding an exclamation point.

▪SHALL: This word is understood to be mandatory.

▪SHOULD: This word is understood to be advisory.

▪WARNING: Indicates a potentially hazardous situation, which if not avoided, may result in death or serious

personal injury.

2

SPECIFICATIONS______________________________________________________________________

Max Compressed Air Supply: 150 psi (10.3 bar)

Dimensional data: 51 x 38 x 68 in (130 x 97 x 173 cm)

Weight: 660 lbs (300 kgs)

INSTALLATION________________________________________________________________________

1) Unpack and remove unit from shipping pallet.

2) Position the Model 5700 on a solid level floor leaving adequate clearance for operator. Anchor unit to floor using

appropriate anchor bolts (not provided) through the three bolt holes on the base of the unit.

3) Install a 1/4" NPT quick coupler nipple (not provided) into the air inlet port of regulator located at the base of the

control column.

4) Connect the shop air line to the quick coupler nipple.

5) Connect the unit and the light to any convenient 110/120V power source.

CAUTION

Before using this product, read and fully understand the operating

instructions and all decals on the product. This is necessary to prevent

injury to the operator and damage to the product.

This product is intended to be used to spread and rotate tire casings for

inspection and/or repair only.

Keep fingers and hands clear of all hooks and mechanisms during

operation.

Do not use this product if it is visibly worn, distorted or damaged.

Always wear appropriate eye protection.

WARNING

Keep feet clear of the tire lift when raising and lowering tire.

All personnel must be clear of the spread arms during operation.

3

OPERATING INSTRUCTIONS_____________________________________________________________

1) Turn the power switch to the ON position.

2) Lower the inspection platform completely using the hand control valve at the tool tray.

3) Pull the bead hooks up and away from the center of the machine.

4) Roll a tire up the ramp and center it on the rollers. Lower the bead hooks inside the tire making sure the bead rollers

are inside the tire bead. The vertical position of the bead hooks is adjustable using the quick pin release on the side

of the bead hook arm.

5) Steady the tire while raising the inspection platform to a comfortable working height.

6) Use the tire spread hand control valve at the tool tray to spread the tire as required. The light can be positioned to

view any portion of the tire.

NOTE: If the tire is lifted off the rollers when spread, release spread and move spread hooks to a lower position.

7) Rotate the tire using the foot controls. Release the foot pedal to stop rotation for inspection. Rotation speed can be

adjusted using the Speed Control dial. Repeat this operation until inspection is complete.

8) When inspection is complete, close the bead hooks fully and swing them up and out of the tire. Move the light fixture

out of the tire.

9) Lower the inspection platform completely and roll the tire off the rollers and down the ramp.

10) Turn the power switch to the OFF position.

ADDITIONAL FEATURES__________________________________________________________________

1) There are 4 air tool ports located below the tool tray. Attach a 1/4” NPT quick coupler to each port and attach air tools

as needed.

2) There are two electrical outlets located on the control column. The power switch must be in the ON position to supply

power to these outlets.

MAINTENANCE_________________________________________________________________________

MONTHLY –Inspect unit for air leaks and wear or damage on pins and rollers.

Lubricate all moving parts (bolts, hinges, rollers, etc.) with a lubricating oil.

YEARLY - Grease all bearings using grease zerks.

CAUTION

Before servicing machine disconnect air line from the unit and unplug

the power cord.

4

REPAIR PARTS ___________________________________________________________________________

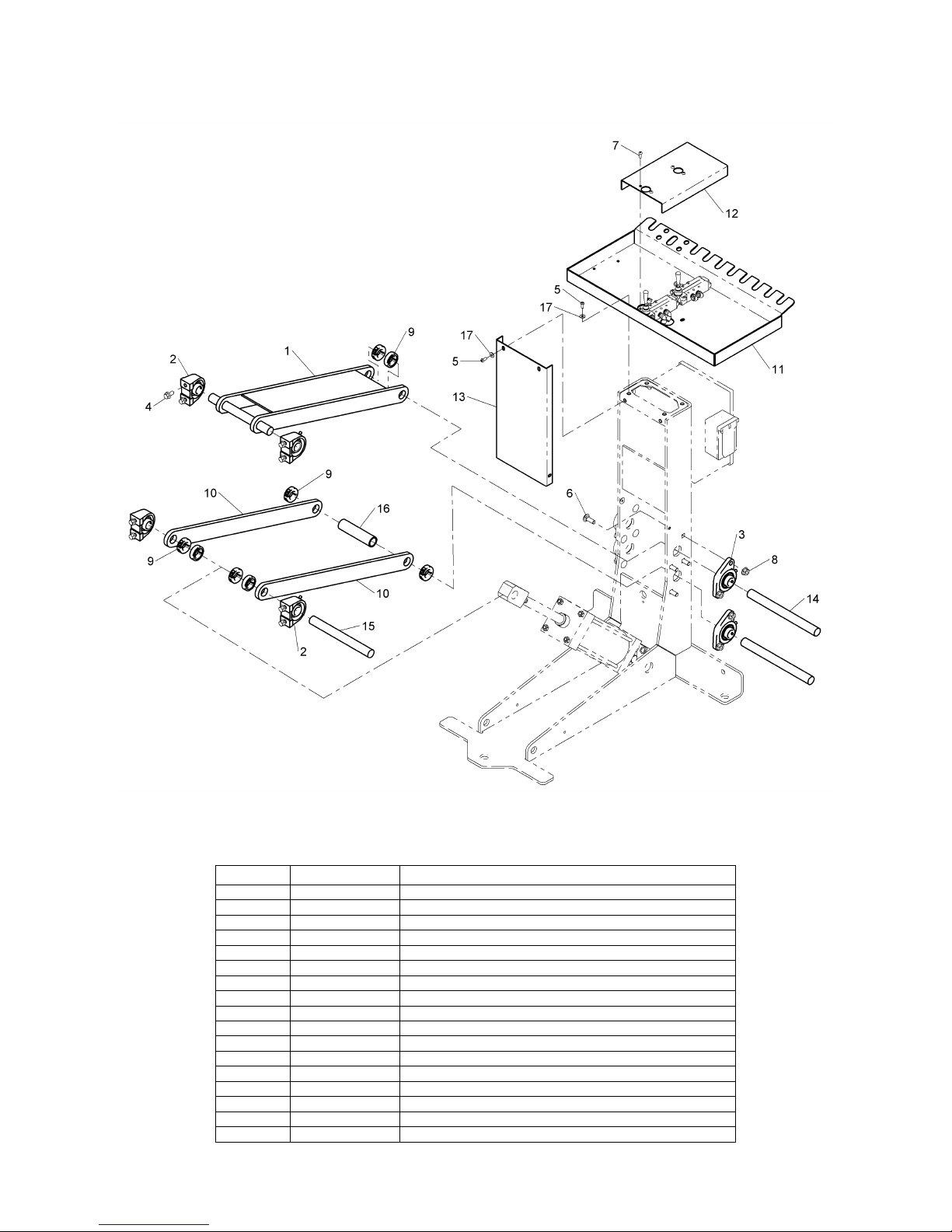

BASE ASSEMBLY

ITEM

PART NO.

DESCRIPTION

1

03-0641

UPPER LIFT ARM

2

20-0059

PILLOW BLOCK BEARING

3

20-0060

FLANGE BEARING

4

50-0065

3/8-16 X 3/4 SERRATED FLANGE SCREW

5

50-0125

1/4-20 X 5/8 BUTTON HEAD SCREW

6

50-0185

7/16-14 X 1-1/4 CARRIAGE BOLT

7

50-0186

M5 X 0.8 X 16 MACHINE SCREW

8

51-0062

7/16-14 SERRATED FLANGE LOCK NUT

9

53-0034

ONE PIECE CLAMP

10

71-0397

LIFT ARM

11

72-0537

TOOL TRAY

12

72-0538

CONTROL PANEL

13

72-0539

COLUMN PANEL

14

73-1160

LIFT ARM ROD - LONG

15

73-1161

LIFT ARM ROD - SHORT

16

74-0377

LIFT ARM SPACER

17

108-110

1/4 WASHER

5

CRADLE ASSEMBLY

6

CRADLE ASSEMBLY

ITEM

PART NO.

DESCRIPTION

1

01-0267

EQUALIZER LINKAGE

2

03-0638

CHAIN GUARD

3

03-0639

RAMP

4

03-0644

SPREAD ARM PIVOT - RIGHT

5

03-0645

SPREAD ARM PIVOT - LEFT

6

03-0646

SPREAD ARM

7

03-0647

KNURLED ROLLER - FRONT

8

03-0648

KNURLED ROLLER - REAR

9

40-0090

LED LIGHT FIXTURE

10

10-0032

BUMPER

11

11-0117

SPREAD ROLLER

12

11-0118

BEAD ROLLER

13

20-0059

PILLOW BLOCK BEARING

14

20-0061

FLANGE BUSHING

15

21-0018

1/4 X 1 KEY

16

21-0019

1/4 X 2 KEY

17

22-0018

25 TOOTH SPROCKET

18

22-0019

14 TOOTH SPROCKET

19

23-0007

#40 OFFSET LINK

20

028-161

#10-24 X 1 MACHINE SCREW

21

028-243

1/2 X 1-3/4 SHOULDER SCREW

22

50-0065

3/8-16 X 3/4 SERRATED FLANGE SCREW

23

50-0088

1/4-20 X 1-3/4 HEX HEAD SCREW

24

50-0094

3/4 X 3 SHOULDER SCREW

25

50-0125

1/4-20 X 5/8 BUTTON HEAD SCREW

26

50-0153

3/4 X 2 SHOULDER SCREW

27

50-0187

3/8 X 3/8 SHOULDER SCREW

28

50-0188

3/8 X 5/8 SHOULDER SCREW

29

51-0063

5/8-11 HEX JAM NUT

30

54-0058

RETRACTABLE PLUNGER

31

055-127

#10-24 HEX LOCK NUT

32

055-145

5/16-18 HEX LOCK NUT

33

055-154

3/8-16 HEX LOCK NUT

34

055-160

1/4-20 HEX LOCK NUT

35

062-045

#40 CONNECTING LINK

36

72-0548

CRADLE COVER

37

72-0549

SPREAD ARM GUARD

38

73-1164

SPREAD ARM PIVOT ROD

39

74-0381

ADJUSTMENT POST

40

90-0003

WHEEL

41

108-015

3/8 WASHER

42

108-110

1/4 WASHER

43

108-155

1/4 FENDER WASHER

44

B20-001

#40 ROLLER CHAIN

7

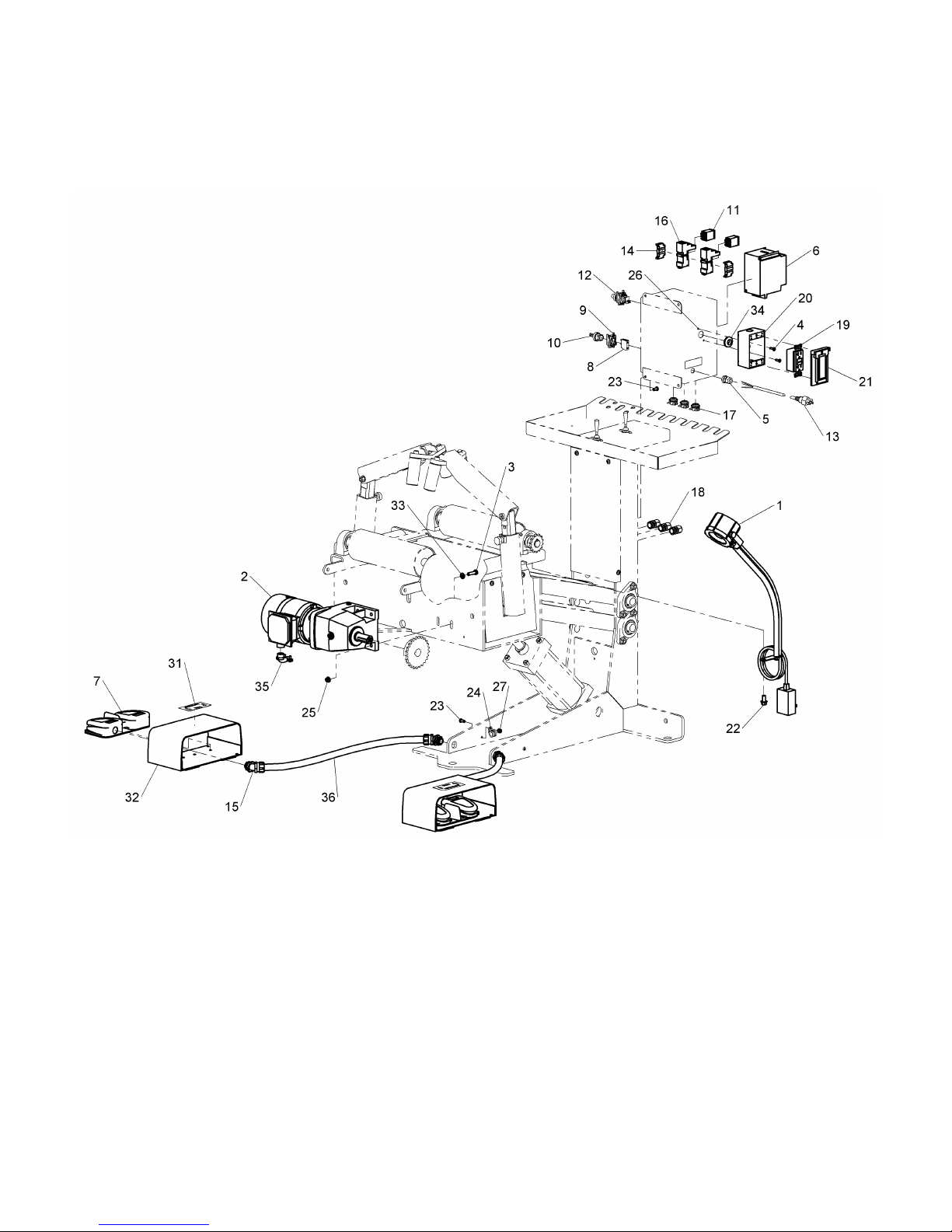

ELECTRICAL

8

ELECTRICAL

ITEM

PART NO.

DESCRIPTION

1

40-0090

LED LIGHT FIXTURE

2

24-0016

1/2 HP GEARMOTOR

3

028-059

5/16-18 X 1-1/4 HEX HEAD SCREW

4

028-155

#10-24 X 5/8 MACHINE SCREW

5

40-0083

POWER CORD CABLE GRIP

6

40-0099

VARIABLE SPEED DRIVE

7

41-0031

TWIN FOOT SWITCH

8

41-0043

N/O CONTACT

9

41-0045

CONTACT MOUNT BASE

10

41-0046

2-POSITION SWITCH

11

41-0065

MINI PLUG-IN RELAY

12

41-0066

POTENTIOMETER

13

42-0033

POWER CORD

14

43-0064

END STOP

15

43-0067

1/2 X 45° CONDUIT CONNECTOR

16

43-0068

RELAY SOCKET

17

43-0069

1/2 ROMEX CONNECTOR

18

43-0070

1/2 NPT CABLE GRIP

19

43-0071

GFCI POWER OUTLET

20

43-0072

WEATHERPROOF OUTLET BOX

21

43-0073

WEATHERPROOF OUTLET COVER

22

50-0065

3/8-16 x 3/4 SERRATED FLANGE SCREW

23

50-0125

1/4-20 X 5/8 BUTTON HEAD SCREW

24

53-0035

1/2" LOOP CLAMP

25

055-105

5/16-18 SERRATED FLANGE LOCK NUT

26

055-127

#10-24 HEX LOCK NUT

27

055-160

1/4-20 HEX LOCK NUT

28*

80-0367

OFF / ON LABEL

29*

80-0369

VOLTAGE LABEL

30*

80-0475

SPEED CONTROL LABEL

31

80-0476

TIRE ROTATION DECAL

32

99-0032

TWIN FOOT SWITCH GUARD

33

108-123

5/16 WASHER

34

808-003

GROMMET

35

980-026

90° SQUEEZE CONNECTOR

36

B40-001

1/2" LT CONDUIT

*Not Shown

9

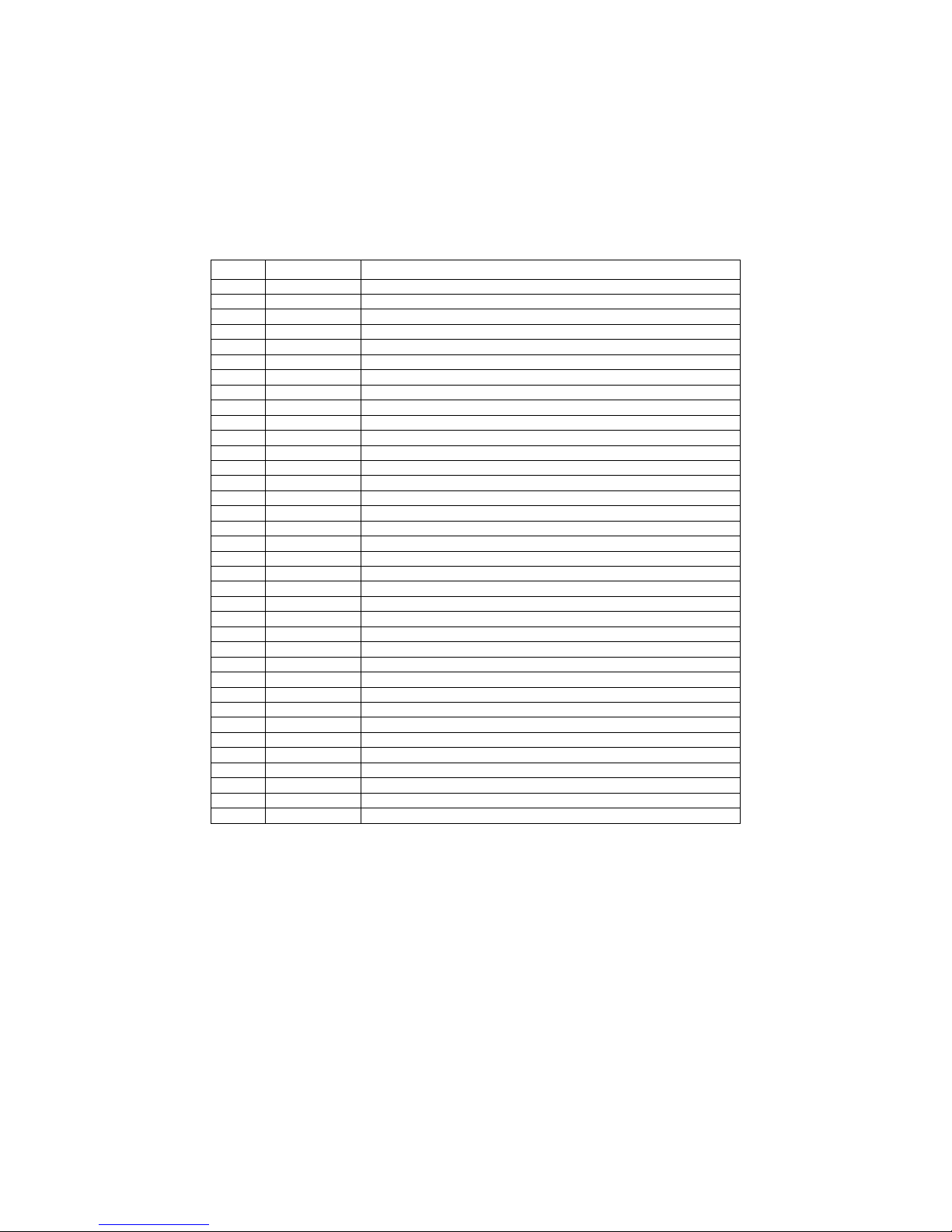

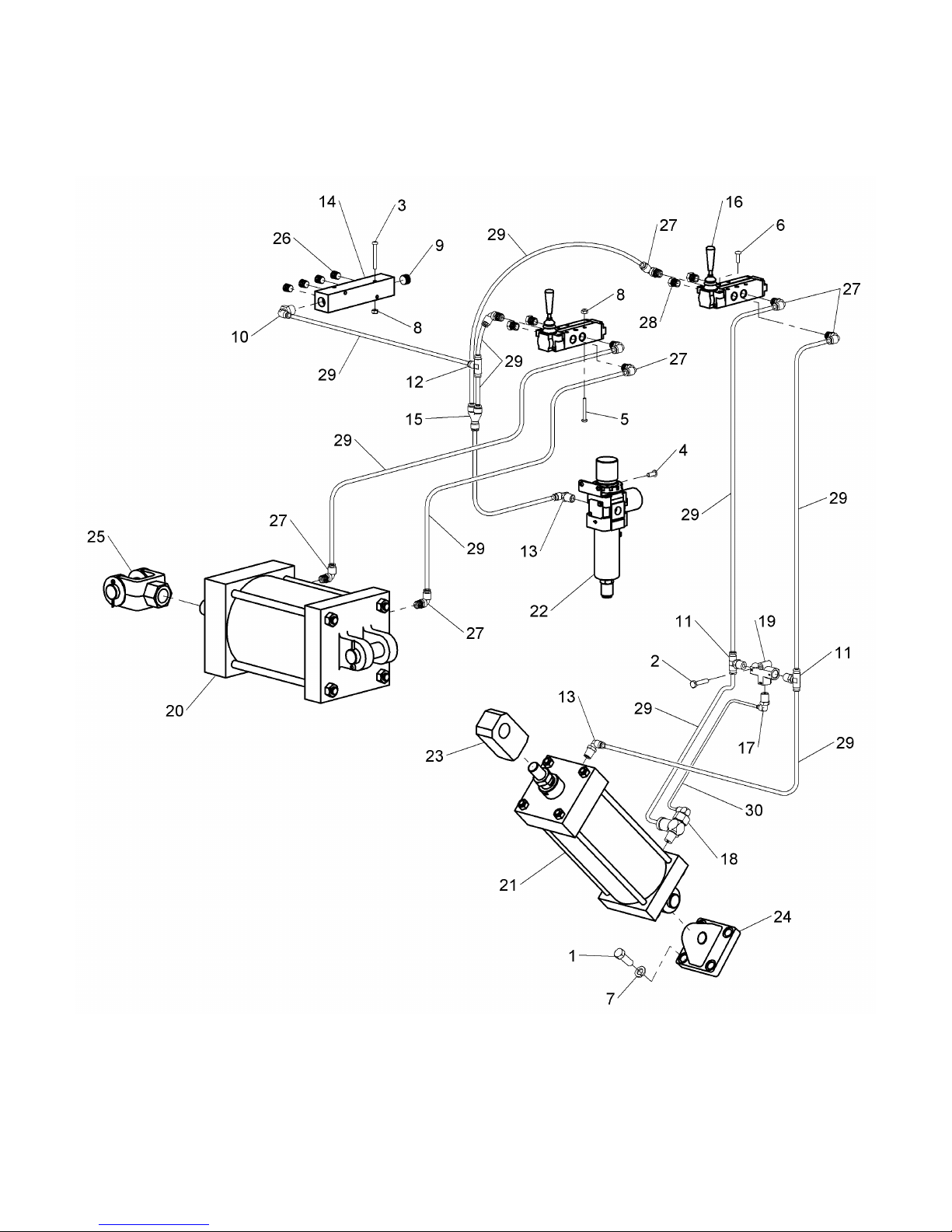

PNEUMATICS

10

PNEUMATICS

ITEM

PART NO.

DESCRIPTION

1

028-007

7/16-14 X 1-1/4 HEX HEAD SCREW

2

028-011

1/4-20 X 1-1/4 HEX HEAD SCREW

3

028-307

#10-24 X 1-3/4 MACHINE SCREW

4

50-0125

1/4-20 X 5/8 BUTTON HEAD SCREW

5

50-0178

#10-24 X 1-1/2 MACHINE SCREW

6

50-0186

M5 X 0.8 X 16 MACHINE SCREW

7

52-0057

7/16 SPLIT LOCK WASHER

8

055-127

#10-24 HEX LOCK NUT

9

60-0074

3/8 NPT PLUG

10

60-0120

3/8 NPT X 1/4 ELBOW

11

60-0164

1/4 NPT X 1/4 TEE

12

60-0171

1/4 UNION TEE

13

60-0172

1/4 NPT X 1/4 ELBOW - BRASS

14

60-0233

MANIFOLD

15

60-0307

1/4 WYE

16

60-0360

VALVE

17

60-0361

1/4 NPT X 5/32 ELBOW

18

60-0362

BLOCKING VALVE

19

60-0363

SHUTTLE VALVE

20

63-0033

SPREAD CYLINDER

21

63-0034

LIFT CYLINDER

22

64-0039

1/4 NPT FILTER/REGULATOR

23

69-0055

ROD EYE

24

69-0056

EYE BRACKET

25

69-0057

CLEVIS

26

096-004

1/4 NPT PLUG

27

096-342

1/4 NPT X 1/4 ELBOW

28

885-035

1/4 NPT BREATHER

29

D20-007

1/4 TUBE (YELLOW)

30

D20-042

5/32 TUBE (YELLOW)

11

COMMERCIAL WARRANTY

This product is warranted by BRANICK INDUSTRIES, INC. to the original user-owner against defective materials or

workmanship for a period of one year from the date of shipment. During the warranty period, at the discretion of Branick

management, if the product is found to be defective, it will be repaired or replaced without charge. For service, contact

Branick (800-437-4394) to obtain an RMA. Any product shipped to Branick must have an RMA and proof of original

shipment date. The repaired or replacement product will be returned with transportation charges prepaid by Branick.

This warranty does not cover defects in the product caused by ordinary wear and tear, abuse, misuse, overloading,

accident (including shipping damage), improper maintenance, alteration, or any other cause not the result of defective

materials or workmanship.

REPAIR OR REPLACEMENT IS THE EXCLUSIVE REMEDY FOR DEFECTIVE PRODUCT UNDER THIS WARRANTY.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANT ABILITY OR ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OF THIS

PRODUCT. BRANICK INDUSTRIES, INC. SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES.

BRANICK INDUSTRIES, INC. reserves the right to make changes in the design or construction of our products without

obligation to incorporate such changes in products already sold and without notice.

Service parts and regular repair service are available from authorized distributors of Branick products, or from:

BRANICK INDUSTRIES, INC.

4245 Main Ave.

Fargo, North Dakota 58103

Toll Free: 800-437-4394

www.branick.com

© Copyright 2018 by Branick Industries, Inc. Printed in U.S.A.

Table of contents