The Specialist In Drum Handling Equipment

195 Series

Power Tilt Kontrol-Karriers

Operator’s Manual for Morse 195 Series Power Tilt Kontrol-Karriers

Serial Number 176434 to 222732

MorseDrum.com

Copyright 2016 - Morse Mfg. Co., Inc. Form PL195 (176434-222732) (Updated April 21, 2016 10:15 AM) 5

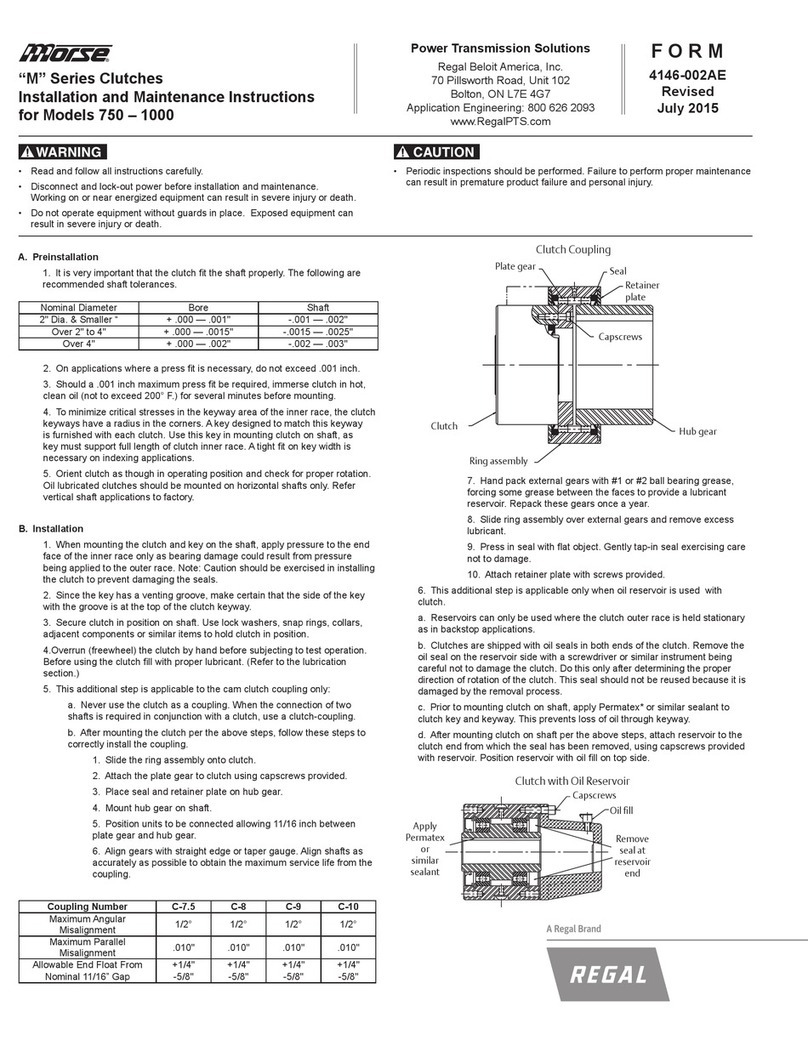

ITEM

#QTY. MODEL

SUFFIX PART # DESCRIPTION

1 1 -1, -3, -460 2801-P PENDANTASM,WIRED,195

2 1 -1 2799-P CONTROLBOX,195A-1-115

2 1 -3 2860-P CONTROLBOX,195A-3-230

2 1 -460 2859-P CONTROLBOX,195A-3-460

3 1 -1 2857-P GEARMOTOR,1PHTEFC,195A

3 1 -3, -460 2858-P GEARMOTOR,3PHTEFC,195A

3 1 -A 2889-P GEARMOTOR,AIR,195A-A,MOTOR

4 1 -A 2890-P CONTROLVALVE,195A-A

5 2 -A 2891-P HOSE,12’,SELFCOILING195A-A

6 1 -A AL458-P CARTRIDGE,MUFFLER228A290A

7 1 -A 2888-P MOUNT,CONTROLVALVE,195A-A

8 1 514-P SPEED REDUCER, 185GR

9 6 535-P HHCS,3/8-16X1-1/4GR5ZINC

10 6 1474-P WASHER,3/8SPLITLOCK

11 1 2907-P SPROCKET#3536TW/SETS,1

12 2 1326-P KEY,SQUARE,3/16X1”

13 1 -1, -3, -460 2906-P CHAIN,ROLLER,#3571PITCH

13 1 -A 2950-P CHAIN,ROLLER,#3566PITCH

14 1 -1, -3, -460 11-P SPROCKET,#3512T,3/4”BORE

14 1 -A 1116-P SPROCKET #35 17T, 1” BORE

15 1 2909-P GUARD,INSIDE,WELD195A

16 1 2910-P GUARD,OUTSIDE,195A

17 4 193-P SCREW,TEK,12-14X3/43PT

18 1 -1, -3, -460 2861-P MOUNT,GEARMOTOR,WELD195A

18 1 -A 3328-P MOUNT,GEARMOTOR,WELD195A

19 4 -1, -3, -460 1635-P BOLT,5/16-18X1-1/4WHIZ

19 4 -A 1641-P HHCS,1/4-20X1GR2

ITEM

#QTY. MODEL

SUFFIX PART # DESCRIPTION

20 4 -1, -3, -460 1634-P NUT,5/16-18WHIZLOCK

20 4 -A 1518-P NUT,1/4-20NYLONLOCK

21 1 -1, -3, -460 2853-P OVERHEADW/BEARINGS,195A,AC

21 1 -A 2881-P OVERHEADW/BEARINGS,195A-A

22 1 2854-P IDLERARMW/BEARINGS,195A

23 1 565-P HHCS,5/8-11X4-1/2GR5

24 1 1473-P NUT,5/8-11REVHEXLOCK

25 2 540-P WASHER,1-1/2SAEFL3”OD

26 1 570-P COLLAR,1-1/2”ID

27 1 525-P KEY,WOODRUFF,F,ASA12113/8”

28 2 560-P BEARING,1-1/2”IDX2”,GR

29 1 2864-P SADDLEASM,195A

30 - - SADDLEWELDMENT

(NOTSOLDSEPARATELY)

31 1 82-P HHCS,3/8-16X2-1/4GR2

32 1 1169-P NUT,3/8-16REVHEXLOCK

33 1 E14 FIBREDRUMSTRAP14”

34 1 731-P PLATE,RATCHETHINGE,A,1/4

35 1 1296-P HHCS,1/4-20X7-1/2GR5

36 1 1297-P NUT,1/4-20REVHEXLOCK

37 1 168-P PAWL,WITHDRILLEDHOLE

38 1 169-P SPRING,PAWL

39 1 170-P SCREW,3/8DIAX5/8SHOULDER

40 1 710-P RETAINER,RATCHETPUSHNUT3/4

41 1 165-P RATCHET,MALLEABLE,SADDLE

42 1 136-P GRIP,HANDLE7/8”X4-3/4”

43 1 165KIT-P KITRATCHETCHAINTIGHTENER

44 1 726-P ARATCHETPLATECPT1/4”

45 1 795-P LINK,MASTER,#35CHAIN

NOTE:Item29(SaddleAssembly)includesitem30the“SaddleWeldment”and

appropriate attached parts (items 31 - 42).