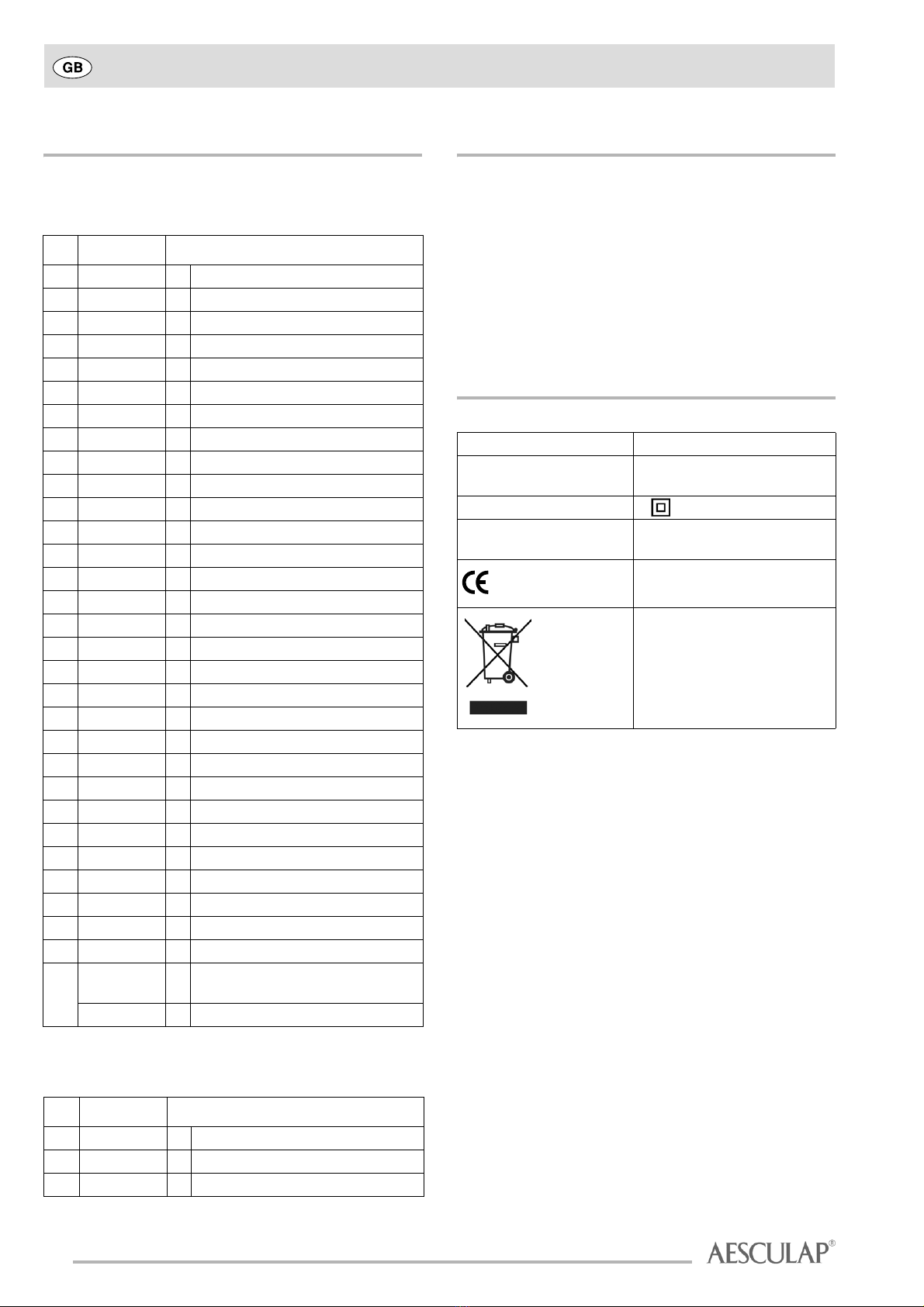

7

4. Operation

¾Before plugging in and switching on the machine, check to ensure

that the voltage on the rating plate is in accordance with the

voltage at your site (see type plate).

¾The machine can be switched on and off with one hand by means

of the sliding switch 51, which is located midway between the two

ends of the machine (see fig.).

CAUTION

¾Do not under any circumstances switch on the machine if it has

not been properly fitted out with cutter plates!

¾Always unplug the machine before carrying out any

maintenance work on it!

¾Always lay the machine on a dry surface, and store it in a dry

place!

Please note

The overload switch shuts the machine down if there is excessive

pressure on the plates, if the cutting head is jammed, or if the motor is

malfunctioning. When the overload switch is activated, the head of the

switch pops out of the back of the motor cover.

Inspect the machine with the plug disconnected from the socket, and

eliminate the cause of the shutdown. The overload switch can be

turned back on after a few minutes by pressing the head of the switch,

which is at the back of the motor.

5. Oiling the cutter head

Important

¾Oil the machine only while it is running!

¾Never immerse the cutter head in liquid of any kind!

¾Use either a light lubricating oil (see parts list for cutter head

GT 369) or SAE 20 motor oil.

¾Oiling hole A(eccentric bearing): Apply 5-10 drops of oil for every

2 hours of operation.

¾Oiling holes Band C: Apply 5-10 drops of oil every 15 minutes.

¾Cutter plates 1and 2should be kept well-oiled at all times, the

quantity of oil used varying from animal to animal (see fig.)

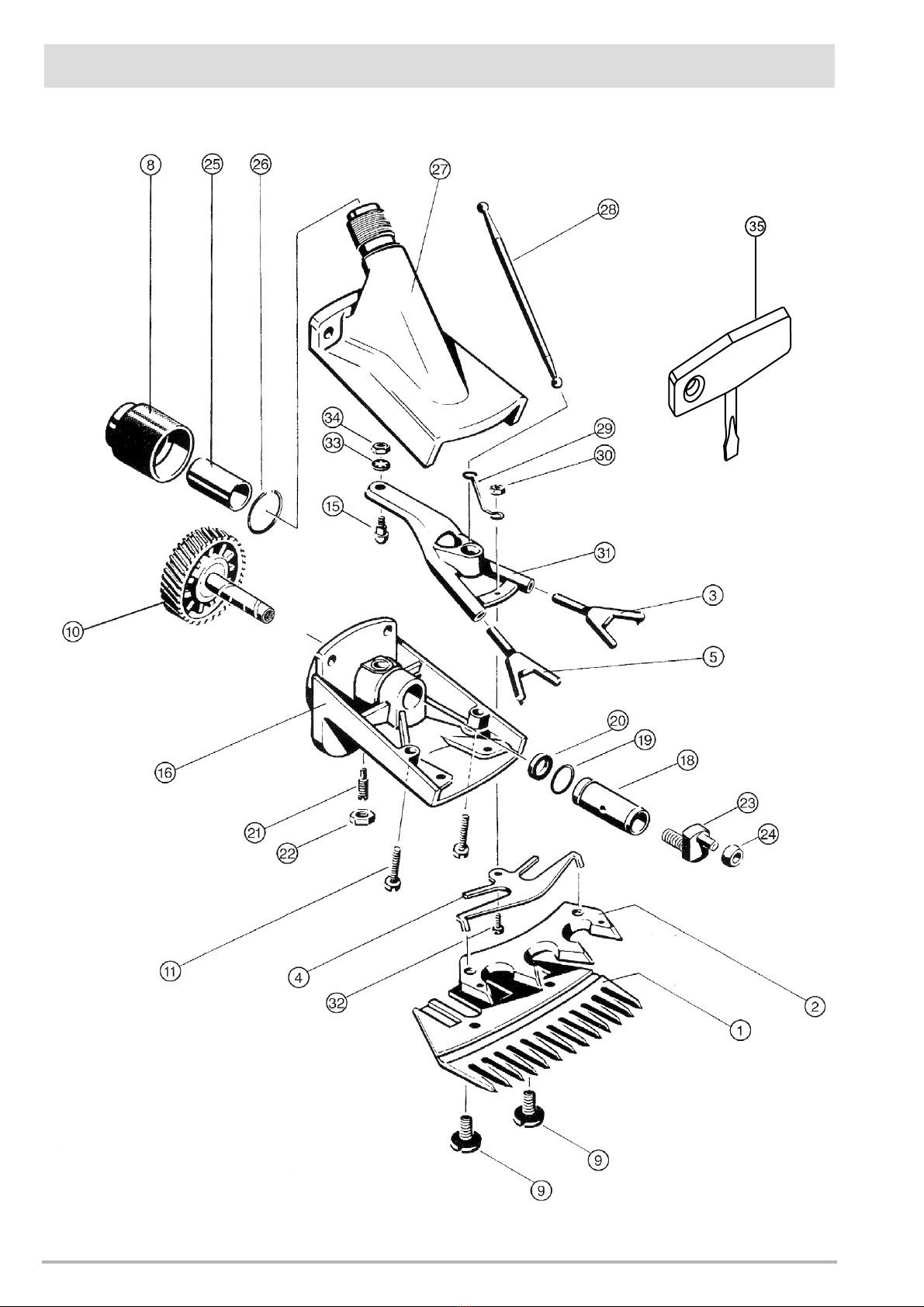

6. Greasing the cutter head

¾Use only gear grease GT 605!

1-2 times per shearing season:

¾Apply approx. 1 cm of grease to opposing points on the gear

wheel 10. Remove the cutter head (see section 9).

¾Grease the inside of both the regulating nut 8and the thrust

bearing sleeve 25.

¾Grease the clamping jaw shafts 3and 5.

7. Changing the cutter plates

¾Unplug the machine before changing the cutter plates!

¾The upper cutter plate 2needs to be changed 2-3 times more

frequently than the lower one 1.

¾To do so, loosen the regulating nut 8until the upper cutter plate 2

can be removed from beneath the clamping jaws 3and 5(see fig.).

¾Then insert the new cutter plate, ensuring that both the tips Dof

the two clamping jaws 3and 5, as well as the lugs Eand the

retaining springs 4, engage properly with their respective borings

in the upper cutter plate (see fig.).

¾Never attempt to change the lower cutter plate 1without first

loosening the regulating nut 8.

¾To do this, loosen both fixing screws 9and pull the plate out in a

forward direction (see fig.).

¾When reassembling, check to ensure that the lower cutter plate 1

extends ca. 2 mm beyond the upper cutter plate 2(see fig.).

Important notes

Keep your sheep closely huddled together just prior to shearing. Doing

this will help to soften and liquefy the lanolin in their fleece, thereby

making it easier for the cutter plates to glide through the fleece and

over the sheep's skin.

If shearing is interrupted and the lanolin congeals, causing the cutter

plates to become sticky, it is best to remove the cutting plates from the

shearer and clean them thoroughly in warm water before proceeding.

After cleaning, the cutter plates should be thoroughly dried, and then

re-oiled.

8. Adjusting cutter plate pressure

Adjustment of the cutter plates should be carried out while the

machine is running.

¾First, carefully loosen the regulating nut 8until the upper cutter

plate 2is no longer pressing against the lower cutter plate 1(the

sound of the motor becomes noticeably higher-pitched) (see fig).

¾Next, slowly turn the regulating nut 8in a clockwise direction until

the motor begins to run slower (adjustment according to motor

sound).

¾Avoid setting the pressure on the cutter plates too high, as this will

lead to excessive heat build-up, which in turn will cause the cutter

plates to wear out more quickly.

= high running speed = lower pressure on the

plates = less wear

Sheep shearing machine GT 494 and cutter head GT 369