BREN 515 User manual

BREN, Inc.BREN, Inc.

Users Manual

for the

Models 515 and 525

Stencil & Sign Cutter

Users Manual

for the

Models 515 and 525

Stencil & Sign Cutter

BREN, Inc.

8401 Covington Rd.

College Grove, TN 37046

BREN, Inc.

8401 Covington Rd.

College Grove, TN 37046

2

Chapter 1

General Descriptions

1.1 Introduction

1.2 Installation

1.3 Daily Maintenance and Care

1.4 Stand Assembly

1.1 Introduction

This manual briefly explains how to use the BREN Model 515 & 525 for cutting

applications. Drawings, illustrations and tables are provided to enable you to effectively use

the Pro-Series Cutting Plotter within a short period.

This chapter provides instructions on the installation, daily care and precautions to observe

during use.

1.2 Installation

Notes on Installation

Avoid use or storage of the cutter in places subject to direct sunlight or the direct draft

from air-conditioning systems.

Avoid locations that are extremely dusty or humid.

Prior to cutting, ensure that no obstacles are placed in the vicinity of the carriage or

material. Impeded movement of the carriage or material may prevent accurate cutting.

To prevent malfunctions of the cutter’s sensors, position the cutter at least one meter

away from electric lights, and any other sources of indoor illumination.

ØØCaution

Lubrication of the mechanisms is not required and will result in cutter malfunctions.

To avoid scratching the cutting pad, ensure that the Blade is properly extended.

While the cutter is operating, do not touch the moving parts.

When manually moving the carriage to load material, be sure to do so slowly.

1.3 Maintenance

Daily Maintenance

During the course of daily cutter operation, be sure to observe the following precautions

Never lubricate the mechanisms of the cutter.

If the cutter’s casing becomes dirty, wipe the soiled areas using a dry cloth or a cloth that

has been moistened in a neutral detergent diluted with water.

Never use thinner, benzine, alcohol, or similar solvents; they can damage the finish.

If the cutter becomes dirty, wipe soiled areas using a dry cloth or use a cloth that has

been moistened in alcohol or in a neutral detergent diluted with water.

Never use benzine, thinner, or similar solvents to clean the sensors.

3

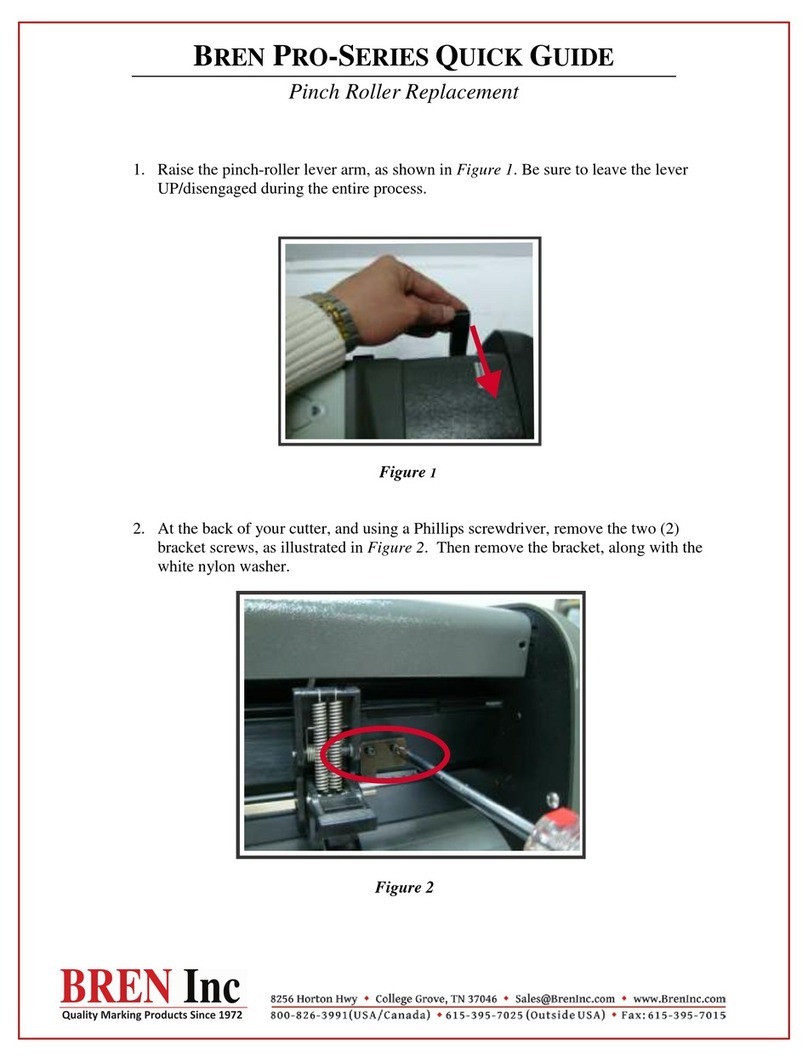

1.4 Stand Assembly

Stand for Models 515 and 525

Tools Required: Slotted Screwdriver, 7/16” Hex Wrench or adjustable Wrench

Note: Shipped with top plates and Casters pre-mounted.

¼-20 X 1½” Truss-Head Screws,

4 each. Insert through leg and

panel and secure with lockwasher

and hex nut.

Front roller has no spring and

mounts through holes in wings.

Attach with Cap Nuts on ends.

Rear Roller has Spring Brake for suspended rolls of material. This

roller drops into slot in rear of wing. When spring is on the Right side

the Brake is engaged. When Spring is on the left side the roller spins

free for supporting material on the cradle.

Cradle style supports material rolls on top of the

two (2) Rollers. When using cradle support, put

the spring on the rear roller on the Left side to

disengage the brake for free roll movement.

Suspended style supports material roll by

inserting the rear roller through the material core.

When suspending a roll use the Brake by locating

the Spring side of the roller on the right (as you

face the front of the stand).

Mounting plates are pre-attached to the

legs with ¼-20 x ½” machine screws.

Use slots in plates to mount cutter.

Parts List

2 ea. Legs with Wings

1 ea. Front Panel

4 ea. ¼-20 X 1½” Truss Head

Machine Screw.

4 ea. ¼” lock washer

4 ea. ¼” hex nuts

1 ea. Non-Brake Roller

1 ea. Brake Roller

2 ea. ¼” Cap Nutas

4 ea. Casters, (2) Brake and (2)

non-Brake pre-attached.

2 ea. Mounting Plates pre-

attached.

4 ea. 6mm x 12mm Screws for

attaching Cutter.

Casters are pre-installed but should

be checked and tightened if

necessary.

Use 4 ea. 6mm x 12mm

screws up through slots

andintobaseofcutter.

4

STAND ASSEMBLY for the Model 515/525 Pro-Series Stand

The Pro-Series Stand consists of two (2) Legs, a Front Panel, and two (2) Rollers to hold material rolls. Assembly is a

simple matter of joining the two legs by putting screws (¼-20 x 1½” Truss Head Machine Screws) through pre-drilled

holes in each leg and through matching holes in the front panel, then securing each screw with a lockwasher and a hex

nut. One Roller is provided without a Brake System (no spring), this roller installs into pre-drilled holes in the rear

“wings” which protrude from the rear of each leg. (See Diagram). The rear-most roller is provided with a Brake

System (Tension Spring on one side) which can be engaged or dis-engaged by simply locating the spring on the left or

right of the cart, (flipping the roller over and dropping it into the provided slot).

1. Select one of the legs and note the marking on the upper mounting plate (either LEFT or RIGHT). The marking

indicates on which side of the stand to put the leg, (either Left Side or Right Side as you face the short bottom arm of

the leg). NOTE: The “Wing” which protrudes toward the rear of each leg is always mounted on the “Outside” of the

leg, (i.e. the left leg has the wing on the left side).

2. From the package of fasteners, select one of the ¼-20 x 1½” machine screws and insert it through one hole in the

side of the leg and through the matching hole (top or bottom) in the front panel. The front panel mounts between the

two legs and is attached by four long screws running through pre-drilled holes in the legs. (See Layout) The label on

the inside of the panel faces the rear of the stand and is not visible from the front side of the cart after assembly.

Flanges on the front panel face to the rear. Insert each of the four (4) long screws and install a lockwasher and hex nut

on each (inside the front panel) DO NOT TIGHTEN THE SCREWS AT THIS TIME! It is necessary for the leg-to-

panel joints to be loose so that you can insert the Front Roller through the pre-drilled holes in the wings, which protrude

from the rear of each leg.

3. The Front Roller does not have a Tension Spring and is provided with a threaded shaft protruding from each end.

(See Diagram). Each end of the Front Roller is inserted through one of the holes in the leg wings, one on each side,

then the roller is secured by threading a “Cap Nut” (see parts diagram) onto each threaded shaft and snugging it against

the side of the leg wing. Once the Front Roller is installed through the leg wings, you may place the legs in an upright

position on a flat surface (either floor or table) and tighten the four (4) long screws which secure the front panel to the

legs.

4. Check that the casters are snuggly threaded into the legs, note that the front casters have brakes to secure the stand in

place. Install the Rear Roller (remaining roller with a spring) into the slots on the rear of each wing , simply lower the

roller into the slots with the Spring located on the Right Side to engage the brake or the Spring located on the Left Side

to release the break.

5. The Brake should be Engaged if you Suspend a material roll from the single rear roller, this will prevent the free

unrolling of material due to the natural tendency of a roll of material to “unwind”. BREN Stencil Material is commonly

suspended from a single roll to prevent having to bend the material backward to achieve a “feed loop”.

6. When running most thin Vinyl and Masking Materials, it is usually not necessary to suspend the rolls but rather to

“Cradle” the rolls by placing them on top of the two rollers so that the roll is supported or cradled by both rollers. When

material is cradled you will usually not require the Brake and will simply flip the rear roller over so that the Spring is

located on the Left side of the stand. (Left side as you face the front of the Stand)

7. Mount the cutter on the stand by locating the cutter on the mounting plates so that the slotted holes in the mounting

plates align with threaded holes in the bottom of the cutter. Using the four 6mm x 12mm pan head screws, attach the

cutter to the plates by running a screw up through the slot in the plate and into a threaded hole in the cutter. Use all four

screws as this will ensure that the cutter is properly aligned with the rollers and is secure to the stand.

8. USE CAUTION WHEN ROLLING THE STAND TO PREVENT IT FROM TIPPING OVER.

9. Load material rolls so that the material feeds from the top of the roll and directly into the back of the cutter, (see

diagram). Material rolls can be loaded to ride on both rollers in a cradle or can be suspended from the single rear roller

by inserting the rear roller through the core of the roll and allowing the material to hang on and be suspended by the

single rear roller. The rear roller is designed to easily lift up and drop into the two slots located on the rear of the wings.

This allows for easy removal and replacement of the rear roller.

5

Chapter 2

Descriptions of parts and functions

2.1 Nomenclature

2.2 Control panel

2.3 Selection of Functional Menu

2.1 Nomenclature

(1) Tool carriage : Moves the Blade or Pen across the material during cutting or plotting

(2) Tool holder : Holds the Blade Holder or Plotter Pen on the carriage

(3) Pinch rollers : Push the cutting or plotting material against the grit roll.

(4) Grit rollers : Feed the material forward or reverse during cutting or plotting.

(5) Cutting platen : Position the material on the platen for cutting or plotting.

(6) Roller Knob: Raise or lower the pinch rollers to enable the material to be loaded.

(7) Control panel : Use to set and use the machine’s various functions.

(8) Stand : Holds the machine and material rolls while cutting.

(9) Cutting Pad: Teflon strip on which the Blade rides for back-up while cutting.

(10) Plotting Pad: Felt strip in front of Teflon strip for back-up to plotter pen.

(11) Align Guides: Vertical white marks to aid in material alignment.

(12) Labels: Mark the location for the Pinch Rollers to be correctly placed.

9

10

11

12

6

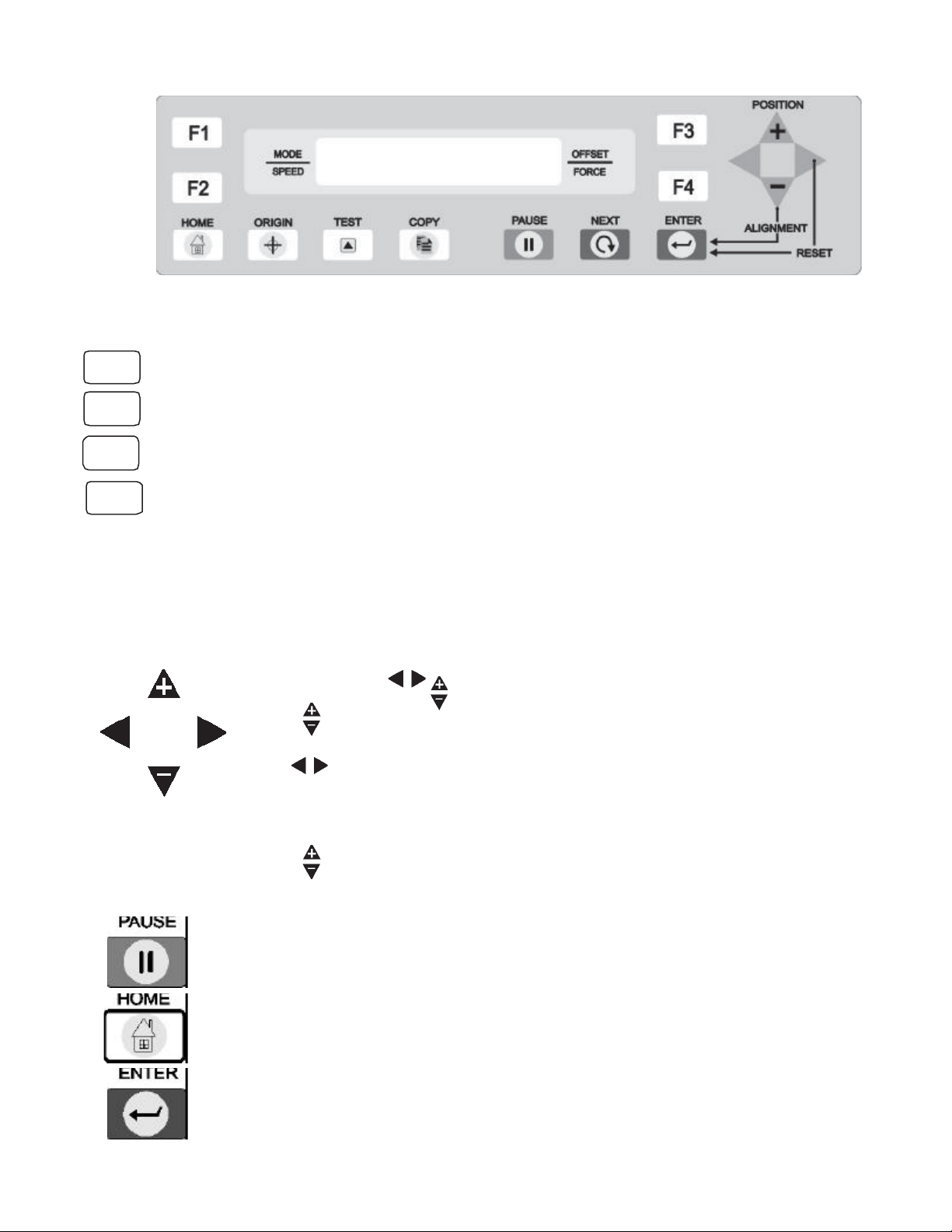

2.2 Control Panel

Selection keys

Press the F1 key to select USER MODE

Press the F2 key to change the cutting speed

Press the F3 key to change the Offset Value

Press the F4 key to change the Pen Force

When you press individual keys F2, F3, F4, the corresponding Values on the LCD will

blink. By pressing the direction keys with + or – you can change the values up or down.

Direction keys

Position

Use 4 keys , , to move the tool carriage to the desired location

keys move the material forward or backward.

keys move the carriage to the Left or to the Right.

For quick movement of the carriage, press and hold a direction key.

keys are used to increase or decrease default value on the menu.

Function Keys

Press this key to stop the cutting or plotting operation temporarily.

When you press PAUSE again, the cutting or plotting operation will continue.

Press this key to return the display to the cut-mode menu.

After setting a new value, press ENTER to register the same in memory.

F1

F2

F3

F4

7

Function Keys (cont.)

Press this key to set a new origin for cutting to begin.

Press this key to perform a Test Cut using the presently set values.

Press this key until the desired menu appears on screen.

Press this key to repeat the last completed cut or plot.

2.3 Functional Menu of Keys

8

Chapter 3

CUTTER BLADES, HOLDERS AND PENS

3.1 The Cutter Blade Installing and Replacing

3.2 Adjusting the Blade Length

3.3 Attaching the Cutting Pen

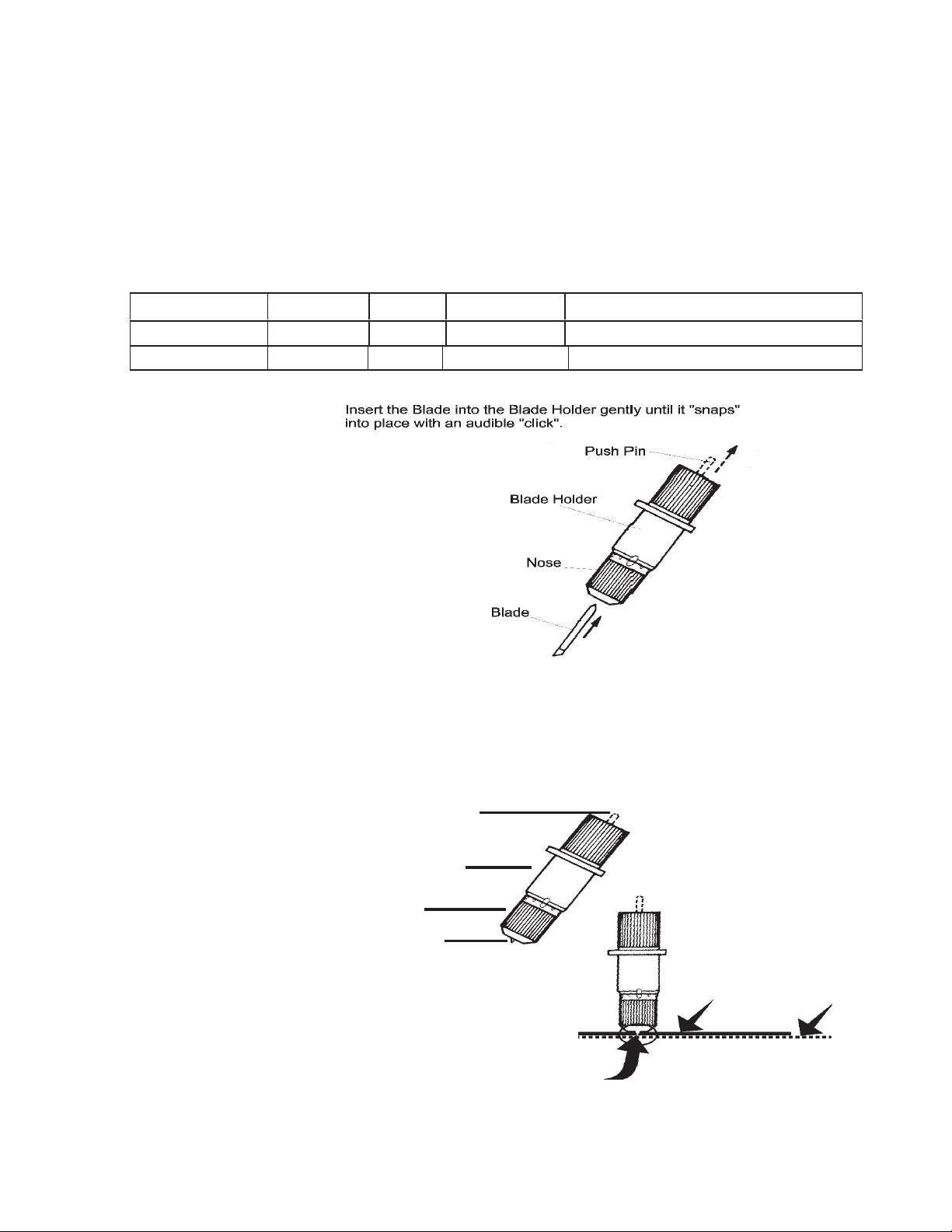

3.1 Cutter Blade Replacing

Warning : To avoid injury, handle the cutter blades carefully.

CUTTER BLADE TYPES

PURPOSE BLADE NO OFFSET HOLDER NO REMARKS

General Purpose 45DBN 0.25 Standard For most Stencil and Decal materials

Thick Material 60DBN 0.50 Standard For very Thick and some tough materials

3.2 Adjusting the Blade Length

Caution : Make sure to adjust the blade length correctly. If the blade length is too long,

you may cut through the backing sheet of vinyl and damage the cutting platen of the cutter.

Obtaining the Correct Blade Length

If the material thickness cannot be accurately determined, adjust the blade length by gradually

extending until only traces of the blade appear on the backing sheet when a cutting test is executed.

For more information about the cutting test, see Section 4.5, “Running a Cutting Test.”

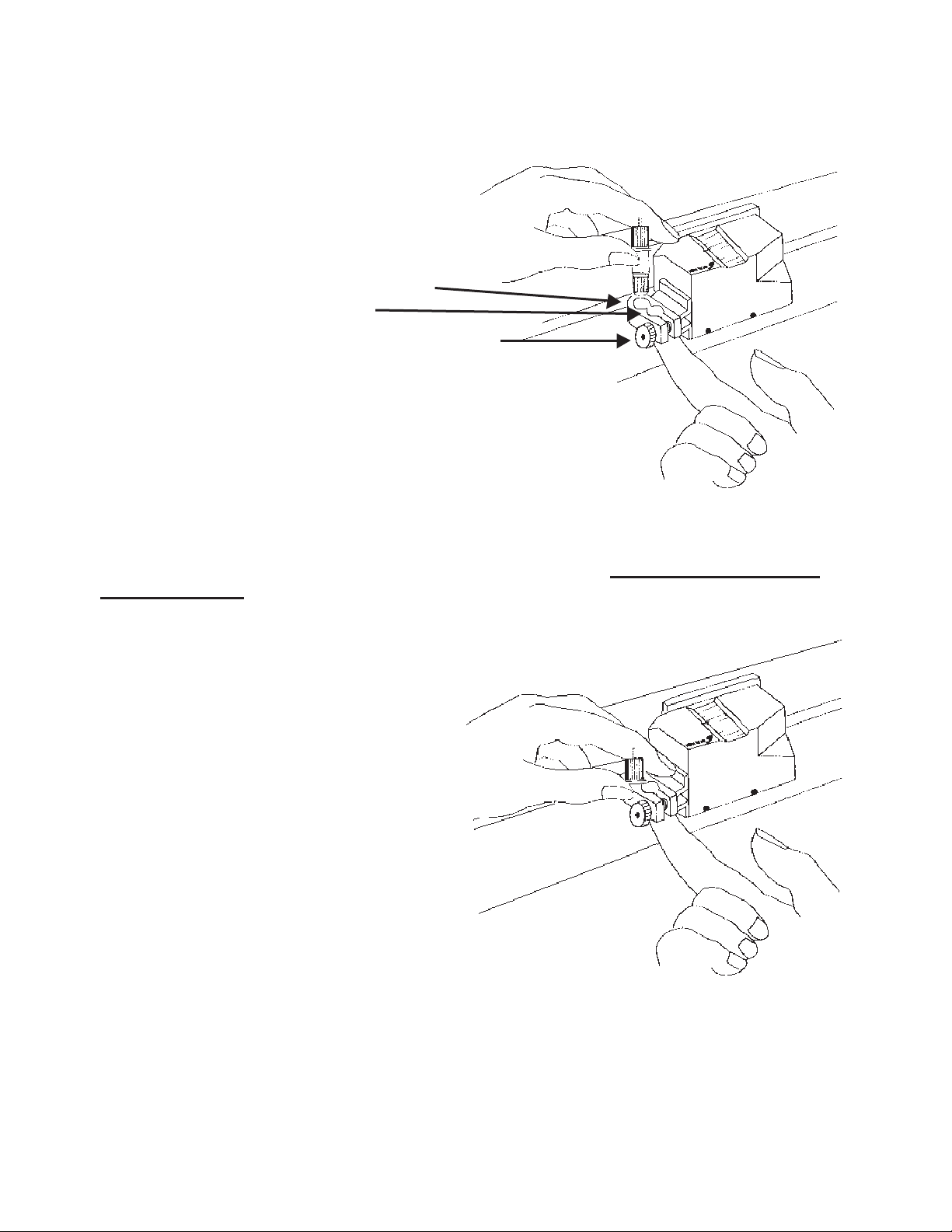

(1) To REDUCE the blade

extension, screw the Nose

counter-clockwise (out away

from the holder).

(2) To INCREASE the blade

extension, screw the Nose

clockwise (in toward the holder).

Holder

Nose

Push Pin

Blade Tip

Material Backing

Blade Tip

9

3.3 Attaching the Tool Holder with Blade

Warning! The tip of the cutter blade is sharp. When handling the cutting tool be careful.

(1) Loosen the Tool Holder screw. While supporting the tool holder upward by finger, push the

cutting pen all the way into the holder until the flange hits the stop. USE REAR HOLE for the

CUTTING TOOL, (the front hole is for the Plotter Pen Only).

(2) When the tool is fully seated, tighten the holding screw. Snug the screw finger tight only.

Remember that the REAR hole is for the Knife and the FRONT hole is for the Pen.

Holder Screw

Rear Hole for Cutting Tool

Front Hole for Pen

Tool is fully seated when Flange on

Holder or on Pen contacts the carriage.

10

Chapter 4

PREPARING TO USE THE CUTTER

4.1 Turning on the Cutter

4.2 Loading the Material

4.3 Setting the Cutting Mode

4.4 Setting the Speed, Offset and Pen Force

4.5 Running the Cutting Test

4.6 Setting the Acceleration

4.7 Setting the Scale

4.8 Setting the Measurement Unit

4.9 Axis Alignment

4.10 Setting the Cut-angle

4.11 The Copy Function

4.12 Manual Material Alignment

4.13 Over Cutting

4.1 Turning On the Cutter

Connecting the Cutter to a Power Supply

(1) Make sure that the cutter is turned off.

(2) Connect the cutter to a computer with connecting cable (either RS-232C serial cable or

the provided parallel cable)

(3) Connect one end of the power cord provided to an electrical outlet of the rated supply

voltage, connect the other end to the cutter’s AC line inlet, (located on the left side).

(4) Turn on the cutter with the power switch located on the left side next to the AC inlet.

1 Parallel Interface Connector

2 Serial Interface Connector

3 Power Switch

4 AC Line Inlet

5 BREN Mobile Stand (see page 2 for stand assembly)

6 Pinch Lever Handle

11

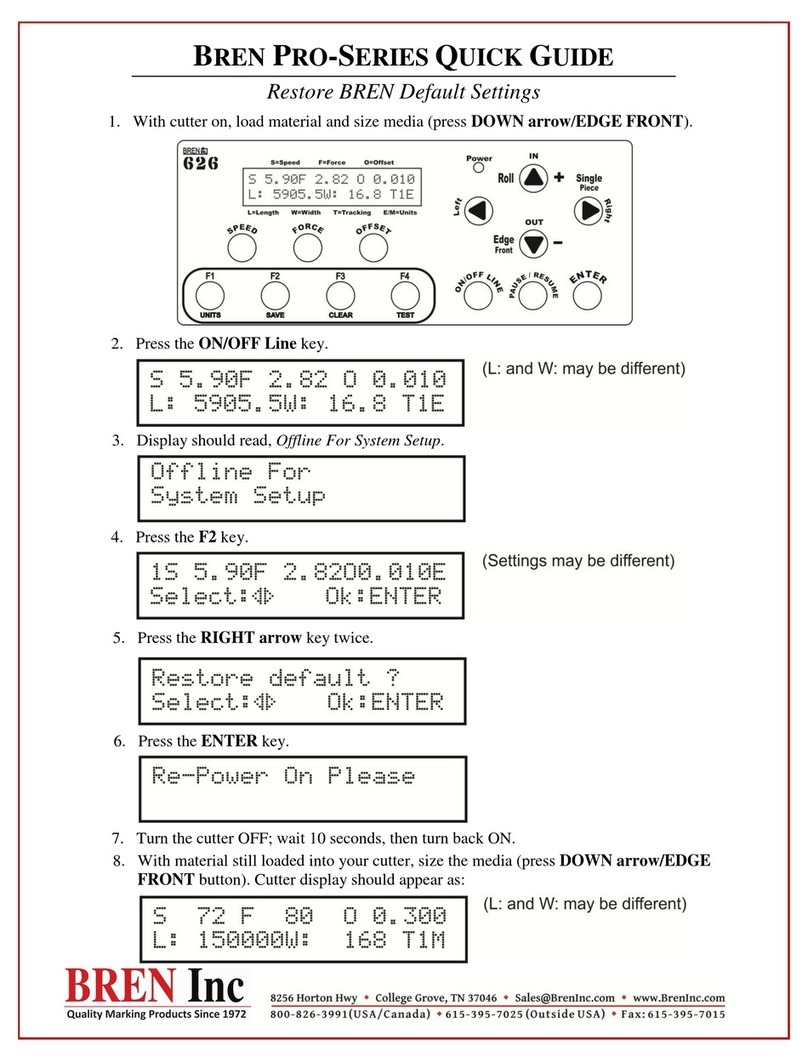

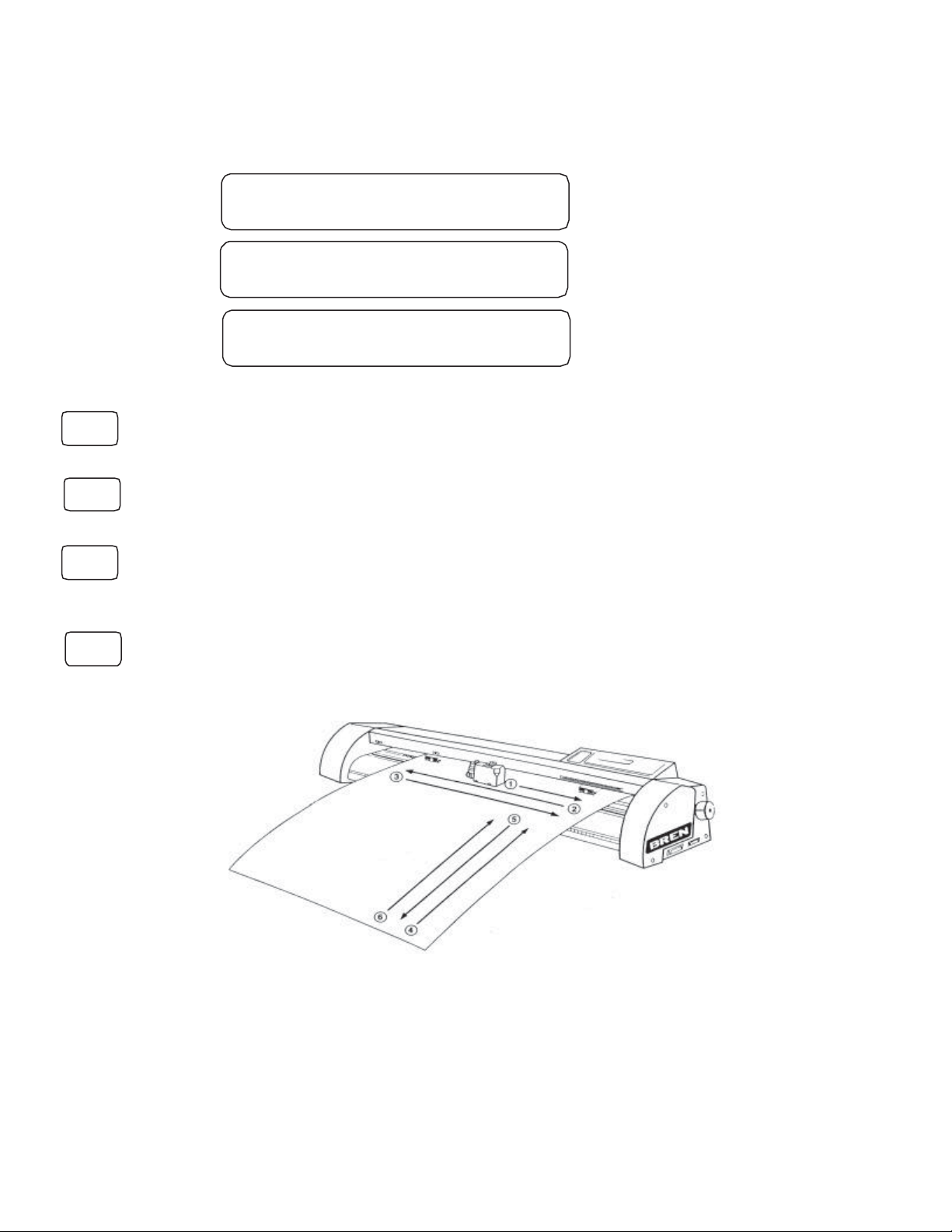

(1) When power is applied, the cutter is initialized.

(2) With the material already loaded, the material selection menu appears. If no material is

loaded, the user is prompted to do so. The material selection menu appears as soon as

the pinch lever is lowered to secure the loaded material.

(3) Initializing is as follows

(4) At the media selection menu, select the media type as described below.

ROLL 1 : The leading edge of roll material is detected and the coordinate origin

is initialized with respect to the material’s leading edge.

ROLL 2 : The leading edge of roll material is not detected and the coordinate

origin is initialized with respect to the material’s leading edge.

CUT SHEET : Select CUT SHEET for cut material, which detects both width and length of

the material. The leading and trailing edges of cut material are detected to the maximum

length 1,301mm, and the upward position on the right is the starting point

SCRAP : Select SCRAP for the small sheet of material. It detects media width only.

(5) After selecting the material, an initialization routine determines the paper size and origin

During initalizing (see the above figure), if ROLL1 is selected, the upward position of the

material is start position. The material is fed in the directions indicated by the arrows and

sequence 1, 2, 4, 3, 5, 6. If ROLL 2 is selected, the material is fed in the directions by the

arrows and sequence 1, 2, 3, 5, 6 and the current carriage position is the start position. If

CUT SHEET is selected, the material is fed to 1.3 meter in the directions of 6 indicated by

the arrows and sequence 1, 2, 4, 5, 6, 3, and the upward position is the start position. If

SCARP is selected, the material is detected with its width only in the direction of 1, 2 and

the current carriage position is the start position.

COPYRIGHT 1999

BREN INSTRUMENTS

ROLL 1 ROLL 2

CUT SHEET SCRAP

RROMTEST OK VER. 2.15

RAMTEST OK 4096K

F2

F3

F4

F1

12

4.2 Loading the Material

This section describes the steps for loading film or paper in the cutter. Note that the material can be

loaded either before or after turning on the cutter.

(1) Place the roll material onto Stand

(2) Turn backward the pinch lever handle to raise the pinch rollers. Push the roll of material

forward through the opening at the back of the cutter until the material’s leading edge is

aligned with the scale. To prevent the material from being fed at an angle, secure it in place.

Note : At this time, ensure that the material passes over the paper sensors and

that its leading edge is parallel with the front edge of the cutter.

CAUTION : When using roll material or roll paper, be sure to pull out the entire amount of

material required for the operation before you begin cutting or plotting. This is not required if

Acceleration is set to 1 and the cutting speed is set below 30.

13

Warning : If the pinch roller is not in the correct position on grit roller, an error message reading

“out of position, check pinch position” comes up on the LCD panel. Set the pinch roller correctly.

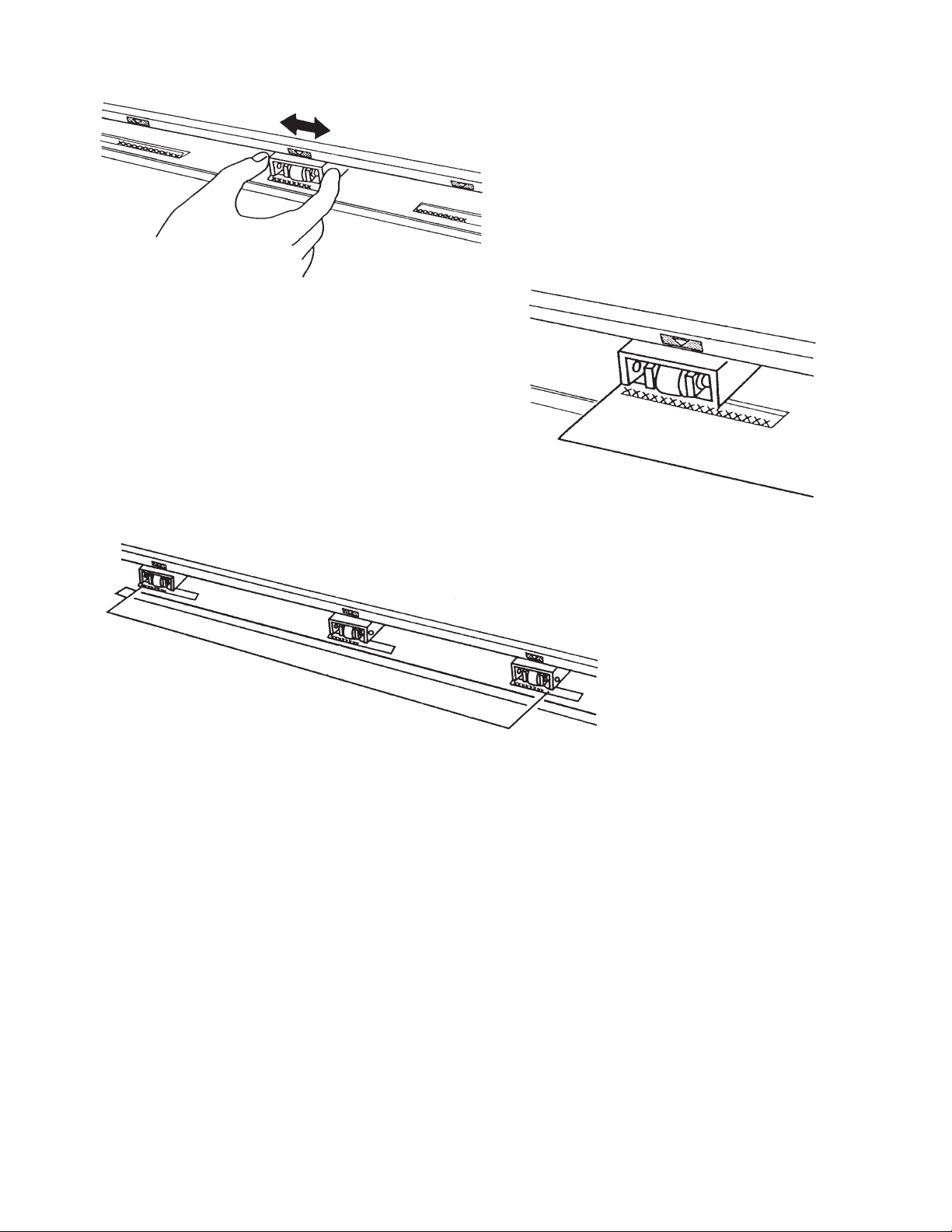

(4) Adjust the pinch roller to position on

the upper part of grit roller. And position

the pinch rollers about 2.5mm each from

the left and right sides of the loaded

material.

(5) Roller alignment seals with tmark

are positioned on the posts of grit

rollers. Line up the edge of the

material paralled to the roll.

Adjusting the pinch rollers on the left

and right edges of the film by t

mark, turn the pinch lever handle

forward to lower the pinch roller in

place.

(6) Turn on the cutter by pressing the

power switch on the left side.

Initialization is then performed when

loading the film is completed.

14

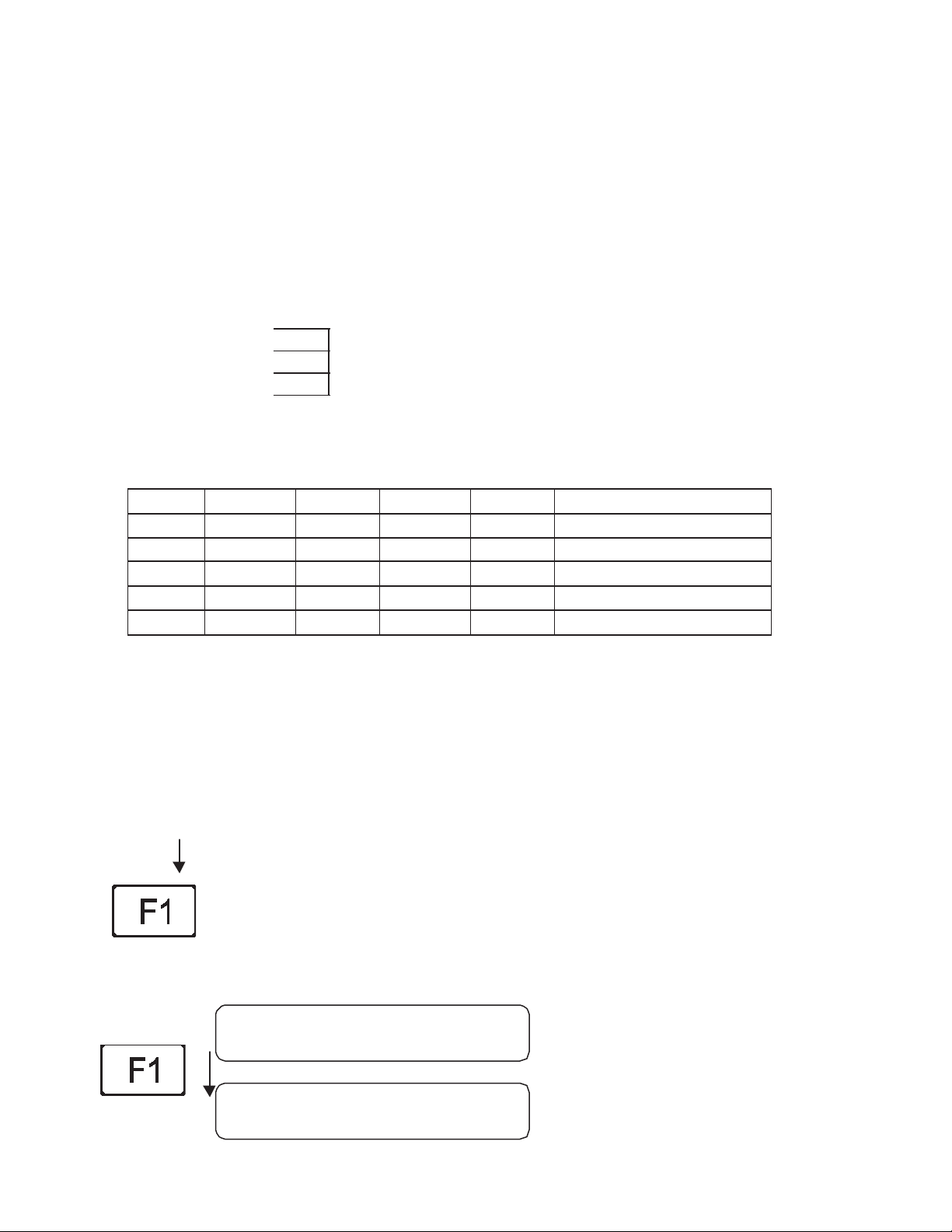

4.3 Setting the Cutting Mode

This function lets the user register four different groups of cutting conditions and pen mode in the

cutter’s memory, which is useful when using the cutter with multiple software applications. The

desired group can be quickly loaded by simply pressing the function key F1 according to the media.

The quality of cutting operations is determined by the settings of the five variables below.

Blade length and type-Adjust the blade length according to the thickness of the material.

Cutting Offset Set these conditions according to the combination

Cutting Speed of material and cutter blade you are using (see the

Cutting Force table below).

Cutting Accel

¬Default Value of Cutting Conditions

MODE OFFSET SPEED FORCE ACCEL SHEET

CUT1 0.30mm 30 step 90gm 1.00 Cast Vinyl

CUT 2 0.30mm 80 step 110gm 1.00 Calendared Vinyl, Masks

CUT 3 0.55mm 20 step 120gm 1.00 Ultra-Cut II, Reflective

CUT 4 0.30 mm 40 step 50gm 1.00 Non-Cutting

PEN 30 step 45gm 1.00 Pen, Design Plotting

Note :These selected conditions greatly affect the finished quality of cutting or plotting.

Raising the SPEED and ACCEL values results in lower precision but reduces the

overall cutting time. This is useful when testing runs.

Lowering the SPEED and ACCEL values results in higher precision but

increases the overall cutting time.

Procedure

ROLL 1 : Press the F1 key to select ROLL 1 mode

To change the settings of a group of cutting mode, CUT1, CUT2, CUT3,

CUT4, and PEN MODE, press the function key F1 corresponding to the

Type of material that is to be cut.

The upper row of the display changes as shown to the CUT1..CUT2.. to PEN MODE.

CUT 1 0.30 mm

30 step 90 gm

CUT 2 0.30 mm

80 step 110 gm

15

Press the function key F1 until selection you want is displayed.

Warning : When performing a Cutting Test or data is being transmitted from the computer,

the mode cannot be changed, and the submenu below appears.

4.4 Setting the SPEED, OFFSET and FORCE

Each item described below is displayed for CUT1-CUT4 and can be changed as shown.

SPEED F2

Set the travelling SPEED during testing (cutting speed from the computer is dominant).

OFFSET F3

Set the offset of the cutter blade’s tip from the center of the cutter pen.

The cutter comes with a preset OFFSET adjustment value for each type. To set the blade

OFFSET adjustment, select the type of cutter blade to be used. If the OFFSET valuse is set

to 0, the cutter goes into plotting mode.

FORCE F4

Set the pressure to be applied by the cutter blade or pen tip against the material after testing.

ACCEL

Set the acceleration rate of the pen during cutting or plotting.

The table below describes the specifiable range of each condition.

CONDITION RANGE REMARKS

SPEED(step) 5 to 80 5, 10, 15, …, 80

OFFSET(mm) 0.00 to 1.00 0.00, 0.05, 0.10, …, 1.00

FORCE(gm) 30 to 500 30, 35, …, 160, 170, …, 500

ACCEL 1.00 to 2.00 1.00, 2.00

CUT 3 0.55 mm

20 step 120 gm

CUT 4 0.30 mm

40 step 0.50gm

PEN MODE

30 step 0.45 gm

UNABLE TO CHANGE

WHILE PLOTTING

16

Procedure : To change the value of SPEED, OFFSET, FORCE, press the corresponding Fkey

Press the F2 key to select SPEED.

Press st keys to change and get your desired value.

Press the ENTER Key to set blinking value.

Press the F3 key to select OFFSET.

Press st keys to change and get your desired value.

Press the ENTER key to set blinking value.

Press the F4 key to select FORCE.

Press these keys to change and select the desired value

Press the ENTER key to set the blinking value.

The selected value blinks until the changed value is recorded in the memory.

When all of the displayed settings are correct, press the key to register the group of

conditions in the cutter’s internal-memory.

Note :

Before beginning actual cutting, be sure to check that the cutting conditions are suitably

set as described in Section 4.5, “Running the Cutting Test.” The FORCE and SPEED

values should be gradually raised while running cutting test.

Depending on the type and thickness of the sheet, fine adjustment of the OFFSET may

be required.

CUT 1 0.30 mm

30 step 90 gm

CUT 1 0.30 mm

30 step 90 gm

CUT 1 0.30 mm

30 step 90 gm

17

4.5 The Cutting Test

The function allows the user to check the suitability of the condition settings. If the

test results are not satisfactory, adjust the settings as described in Section 4.3.

Warning : The cutter carriage starts moving as soon as a cutting test is selected. To avoid

injury to yourself and damage to the cutter, load the material before pressing the

TEST mode and then keep your hands, and other obstacles out of the vicinity of the

cutting mat and material.

Procedure

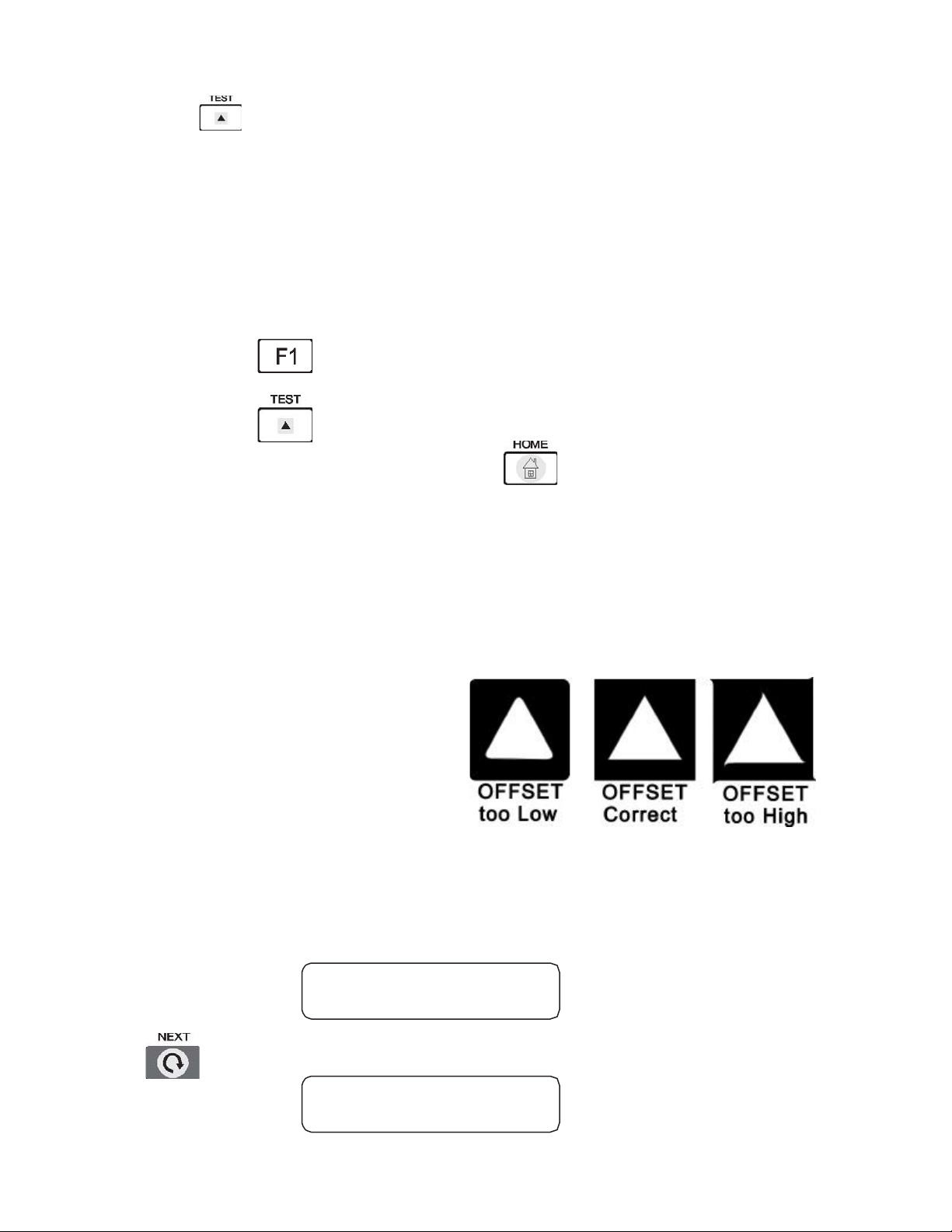

ROLL 1 : Press the key to select ROLL 1 mode.

TEST : Press the key.

If the test results are satisfactory, press the key to return to the preceding menu.

If not, proceed to the previous step.

HOME : By pressing the corresponding key, adjust the each value of 0.30mm(OFFSET)

30step(SPEED), 90gm(FORCE), in CUT1 MODE for example.

Referring to the figures of Section 4.3, gradually adjust the corresponding values while checking the

results by running a cutting test.

4.6 Setting the Acceleration

This function allows the user to set the speed at which the material movement starts.

Procedure

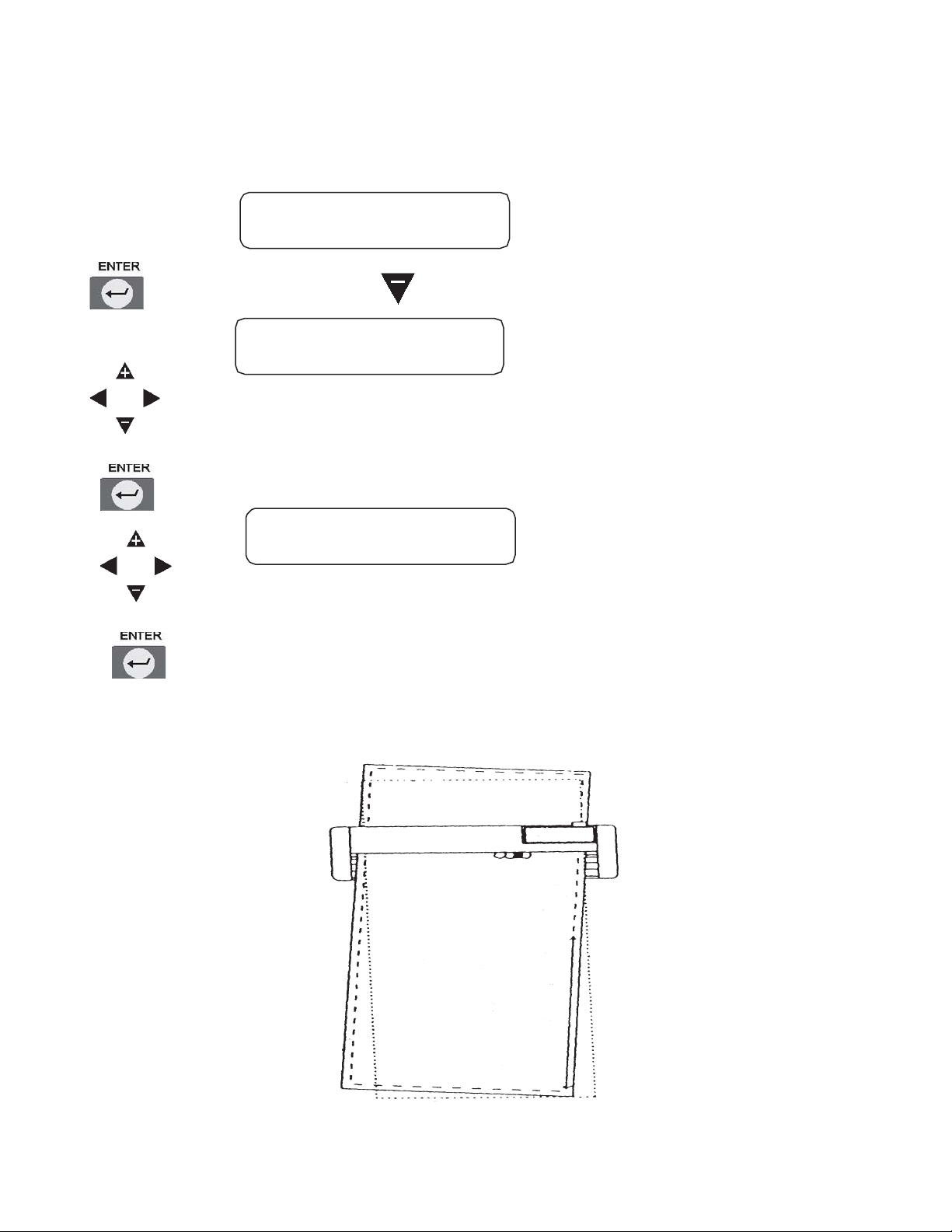

Press the NEXT key

CUT 1 0.30 mm

30 step 90 gm

ACCEL : 1.00

SCALE : 1.00

18

Press the F3 key to set the ACCEL Value, display value will blink.

Press these keys and select a value from either 1.0 or 2.0 as desired.

To register the desired value, press the ENTER key

The range of value :1.00, 2.00 refer to the Section 4.3 for the optimum

value of ACCEL

Press HOME key to return to the cutting mode.

4.7 Setting the Scale

This function allows the user to change the size of the design by scaling.

PROCEDURE

Press the NEXT key

Press the F4 key for the desired SCALE value, then LCD will blink.

Press st keys and select your desired value ranging

from 0.50…… 10.0

Press ENTER to set blinking value and register

Press HOME key to return to the cutting mode.

CUT 1 0.30 mm

30 step 90 gm

ACCEL : 1.00

SCALE : 1.00

19

4.8 Setting the Measurement Unit

This function allows the user to set the size of material in mm or inch unit in cutting or pen

plotting

PROCEDURE

Press the NEXT key

Press the NEXT key

Press the F4 key to change the measurement unit, the display unit will blink

Press the these keys and select the desired unit. SIZE will change automatically

when UNIT alters.

To register the desired value, press the ENTER key.

Press the HOME key to return to the cutting Mode.

CUT 1 0.30 mm

30 step 90 gm

ACCEL : 1.00

SCALE : 1.00

SIZE : 32004

UNIT : mm

20

4.9 Axis Alignment

This function lets the user align the cutting axes to match the pre-printed axes on the material in

order to correct any deviation in axes and origin position between the cutter and the material

PROCEDURE

Press ENTER key and Key simultaneously

Press position direction key to get ALIGN POSITION 1 value

Press ENTER key to memory ALIGN POSITION 2 value

Press position direction key to get ALIGN POSITION 2 value

Press ENTER key to memory ALIGN POSITION 2 value, then return to cut

mode.

CUT 1 0.30 mm

30 step 90 gm

ALIGN POSITION 1

X= 0 Y= 0

ALIGN POSITION 2

X= 0 Y= 0

This manual suits for next models

1

Table of contents

Other BREN Cutter manuals

Popular Cutter manuals by other brands

Würth

Würth EMS 12-A Translation of the original operating instructions

Intec

Intec ColorCut LC600 Series installation guide

Xhorse

Xhorse Dolphin XP-005L user manual

Clarke

Clarke CHT518 quick start guide

Makita

Makita CE001G instruction manual

Lincoln Electric

Lincoln Electric OPTITOME2 HPC III instruction manual