: :

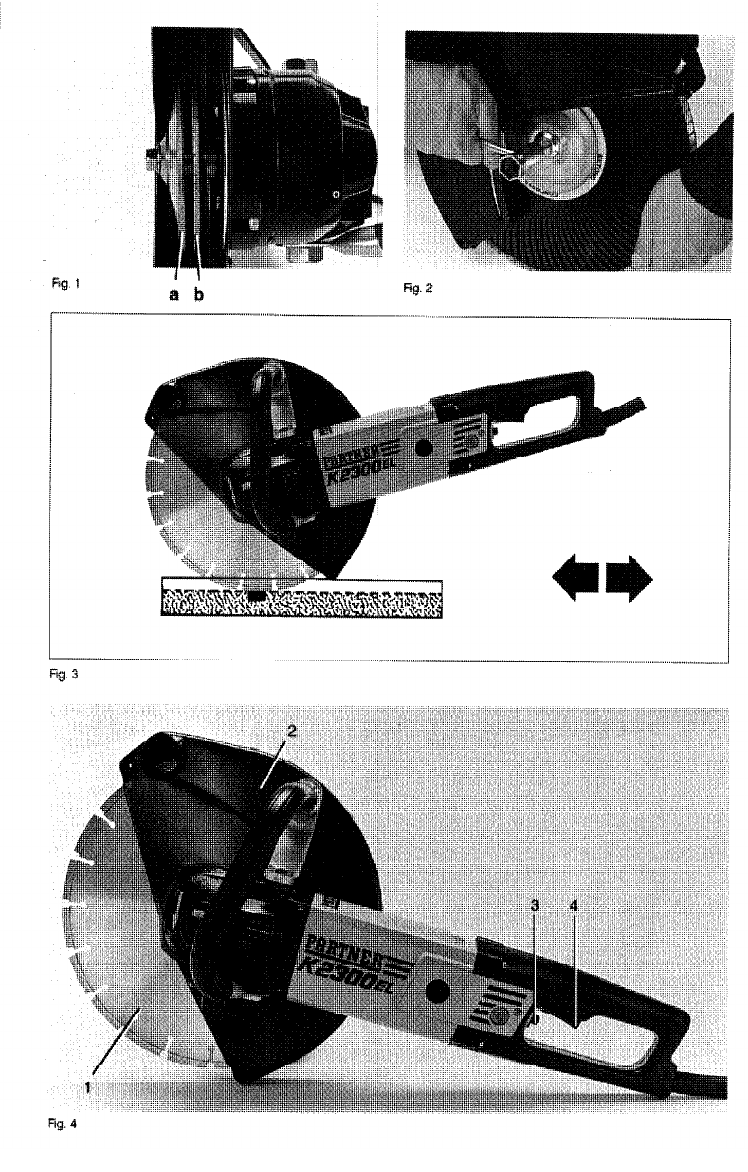

Grounding

a

WARNING: This tool must be grounded properly while in use to protect the operator from

electnc shock. 1.

The tool is equipped with an approved three-conductor cord and a three-pronged grounded type

plug to fit the proper grounding type receptacle. The green (or green and yellow) conductor in the

cord is the grounding wire. Never connect the green (or green and yellow) wire to a live terminal.

Never disassemble the tool, or try to do any rewiring in the electrical systems. Any such repair

should be performed only by an authorized Partner service center or other qualified service or-

ganization.

Voltage

A voltage decrease of more than 10 percent will cause loss of power and overheating. All Partner

tools are factory tested. If the tool does not operate, check the power supply.

CAUTION: When used on job sites, where arc or resistance welding is being performed, the cord

could be damaged by welding currents usmg the cord as a parall return path.

To maintatn the protectron the ground wire provides, the cord should be Inspected frequently and

replaced as necessary. Avoid unnecessary contact between the metallic exterior of the tool and

grounded conductive surfaces.

Extension cords

Tools that have three-wire cords requiring grounding must only be used with extensioncords that

have three-prong grounding type plugs and a three-pole receptacle. Only round-jacketed exten-

sion cords should be used, and we recommend that they be listed by Underwriter’s Laboratories

(U.L.) (CSA in Canada). If the extension cord will be used outside, it must be suitable for outdoor

use Any cord marked for outdoor use can also be used indoors. An extension cord must have

adequate size (AWG or American Wire Gauge) for safety, and to prevent loss of power or over-

heating.

Extension cord length 25 ft. -- Use 12 (A.W.G.)

Extension cord length 50 ft. - Use 10 (A.W.G.)

Do not use extension cords over 50 ft. to prevent loss of power and overheating.

Replace defecttve cords immediately.

Cleaning and changing grease

Dependrng on operating condrtrons, the grease in the gear housing must be changed after 4-6

months. Use good quality gear grease, Castro1 Spheerol EPL 1 or corresponding. The gear

housrng must contain a total of 90 grams of grease.

Too much grease can cause the machine to run warm.

In order to change the grease in the gear housrng, the following parts must be removed:

- The flange washers retaining the cutter disc

- The support flange for the protective quard (Fig. 6)

- The protective quard (Fig. 7)

- The mounhng plate together with crown wheel assembly are lifted out of the gear housing

after the four screws have been removed. (Fig. 8 & 9)

NOTE. Do not damage the gaskets since these act at the same time as spacers for gear

settings.

8