Intec ColorCut LC600 Series User manual

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 1

Digital Sheet Label Die-Cutter

ColorCut LC600 Series

Installation Guide - English

Revision: 1.4 0718

ON

LINE

/OFF

LINEENTER

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 2

Congratulations on the purchase of your Intec ColorCut

LC600 Sheet fed label cutter. Please carefully read this

operating manual to assist you in setting up, designing and

cutting your les so you can easily integrate your new Intec

LC600 Cutter into your production environment.

Any type of reproduction of this manual requires the written permission of Intec Printing Solutions Ltd

(UK). Changes, errors and omissions in the technical data and the product characteristics are accepted.

Intec Printing Solutions Ltd (UK) is not liable for any direct or indirect damages occurring as a result of

the use of this product.

Version 1.0 (15.05.2020).

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 3

Contents

Preface -THE INTEC COLORCUT FLATBED SERIES...................................5

Safety Information .....................................................................................................6

Introduction................................................................................................................7

Hardware Specications............................................................................................8

Installation of the LC600 Cutter (Overview of steps)....................................................9

Chapter 1. UNPACKING & POSITIONING THE INTEC LC600....................10

1.1 Contents of the ColorCut LC600 (Overview) .....................................................10

1.2 Contents of ColorCut LC600 (Detailed).............................................................11

1.3 Identifying the key features of your ColorCut LC600 ........................................12

Chapter 2 - SETTING UP A WI-FI HOTSPOT ..............................................15

2.1 Using Wi-Fi to connect to LC600 - Live Video Feed .........................................15

2.2 How to create a HotSpot (2 different approaches)............................................16

2.3 Method 1 - Using Windows Wi-Fi HotSpot ......................................................16

Configuring Windows Wi-Fi HotSpot. .............................................................................. 17

Setting the SSID when using Windows Wi-Fi HotSpot..................................................... 18

Starting the Windows HotSpot........................................................................................ 19

Daily Operation - Enabling Windows Wi-Fi HotSpot......................................................... 20

2.4 Method 2 - Using Wi-Fi Direct Access Point.....................................................21

Configuring Windows Wi-Fi Direct Access Point.............................................................. 22

Chapter 3. Software Installation - Intec ColorCut Pro...............................23

3.1 ColorCut Pro Overview......................................................................................23

3.2 ColorCut Pro Installation....................................................................................23

3.3 Intec ColorCut Pro - for CorelDRAW ................................................................26

3.4 Intec ColorCut Pro (Activation) ..........................................................................29

Chapter 4. Connecting and powering on the cutter...................................30

4.1 Turning the cutter on (The Initialisation Process)...............................................30

4.2 Connecting to your computer............................................................................31

4.3 ColorCut Pro - USB Connection conrmation...................................................31

4.4 ColorCut Pro - Device Type...............................................................................32

Chapter 5 - The Intec ColorCut LC600 Cutting Tool ..................................33

5.1 Cutter Blades (An overview of Blade types) ......................................................34

5.2 The Blade Holder - an introduction ...................................................................35

5.3 Replacing the blade...........................................................................................35

5.4 Blade Adjustment (Adjusting the Blade length) .................................................36

5.5 Installing Tools in your ColorCut........................................................................37

Chapter 6 Using the ColorCut LC600 Cutter ..............................................38

6.1 Overview of control Panel..................................................................................38

The HOME screen .......................................................................................................... 38

The MENU settings & options ......................................................................................... 39

The MOVE screen........................................................................................................... 40

The TEST screen ............................................................................................................ 41

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 4

6.2 Checking the Blade depth & Force....................................................................41

6.3 Calibration the Vision3 sensor offset to the Cutting Blade................................43

ColorCut Pro - Setting the Sensor Offset to the Blade..................................................... 44

6.4 The Dual Grip Roller...........................................................................................46

Changing the Dual Grip Roller ......................................................................................... 46

Graphics File Design - Creating your Artwork............................................48

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 5

Safety Information

Introduction

Specifications

Installing your LC600 (Overview of steps)

Preface

Preface -THE INTEC COLORCUT FLATBED SERIES

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 6

Safety Information

Safety measures

Please read the information and safety measures carefully prior to installation and initial

operation of the unit.

• Do not place any magnetic objects in the vicinity of the cutting head; otherwise

uniform contact pressure may not be ensured.

• Do not remove the connection cable to the computer while cutting is in

progress.

• Relieve the pressure on the pressure rollers when not in use by moving the

pressure lever up.

• Do not open or reach into the unit when it is connected to electricity supply.

• Never open the casing and do not make any modications to the unit yourself.

• Ensure that neither liquids nor metal objects are put inside the Intec LC600

Sheet Label Cutter.

• Ensure that the wall socket used is grounded.

• Ensure that the connected voltage (230V) does not deviate by more than

±10%. Otherwise install a voltage stabiliser.

• Remove the power plug from the unit if it will not be in use for a longer period

of time.

• Never reach into the unit in the vicinity of the blade holder during the cutting

operation

• Stop any cutting jobs in progress before readjusting the blade holder

• Always ensure that the Sheet Cutter is out of reach of children during

operation and never leave the unit or individual parts of it switched on without

supervision.

• Do not touch the tip of the cutting blade to avoid injury.

• Always place the unit on a stable base to prevent it from falling down.

• Disconnect from the power supply during thunderstorms; it can be damaged

or destroyed by electrical surges caused by lightning.

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 7

Introduction

INTEC COLORCUT SHEETFED - DIGITAL CUTTING SOLUTION

The Intec LC600 is designed primarily to cut label, decal and vinyl materials effectively. It

includes a 'Dual Grip' feed system, that holds the media during cutting BOTH sides of the

cutting head, enabling the LC600 to cut closer to the media edges than most other types

of cutter.

There are also additional functions for cutting using perforated and dashed cut features,

plus an additional pen calibration tool used for the initial conguration of the machine.

The ColorCut LC600 solution consists of 2 parts:

Hardware

The Intec Digital Cutting Engine

Integrated Vision3 CCD Sensor for automatic registration mark sensing

Automatic Job Recognition & Wi- Echo(Live preview) through Vision3 CCD sensor

An integrated autosheet feeder for up to 250 sheets*

An integrated, concealed exit catch tray

A separate external USB Wi- Dongle for PC systems (enabling, users to connect

non-wi- based PC’s to view the ColorCut’s Vision3 sensors’ Live Preview)

and

Software

The ColorCut Pro3 cutter control software consists of 2 parts.

The ColorCutPro plug-in. Enables you to simply add Page Registration Marks for

cut jobs and provides the ability to send projects designed in Adobe Illustrator® or

CorelDRAW® directly to the Intec ColorCut LC600 cutter (no need to convert them

to a different format). In addition the ColorCut Pro plugin can assign Job numbers

or QR codes and send jobs to the ColorCut Pro job library which can be running

on the same or a different computer.

The ColorCut Pro Job Server. A stand-alone version of ColorCut Pro, providing

simple interface enabling jobs to be cut at any time, without requiring Adobe

Illustrator or Corel Draw and without having to re-open the original le ideal for

production environments, where the ‘graphic designer’ creates the work and other

individuals within your company ‘nish’ or cut the work.

The ColorCut Pro software works in conjunction with the Vision3 CCD sensor

integrated into your ColorCut hardware, detecting the SMARTmark in a fraction

of a second and adapting the cut path to any variations in the origin, scale or

skew distortion of the print. The Vision3 CCD sensor can also read the QR code

and retrieve your cut les instantly enabling any user to cut jobs as long as they

have a QR code on them and enabling a mixed stack of jobs to be loaded for true

unattended productivity.

Please use this guide to set up your ColorCut LC600 cutter and install your ColorCut

software. For details specically on ColorCut Pro software and how to use it with your

LC600 please refer to the separate - ColorCut Pro (LC600) software guide.

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 8

Hardware Specifications

INTEC COLORCUT LC600 - SPECIFICATIONS

MEDIA HANDLING

Standard media sizes A4 (210 x 297mm), A3 (297 × 420mm),

SRA3 (320 × 450mm), A3+ (320 × 480mm)

Custom sized

label media

Width Media width (min-max): 150mm - 330mm

Length Media length (min-max):190mm - 750mm

Media thickness 0.25mm (180g/m²) - 0.35mm (350g/m²)

Auto-sheet capacity Up to 250 sheet auto-sheet feeder

Media alignment Slide adjustment with self centring guide

CUTTING CONTROL

Mountable tools Single tool holder, supports Cutting Blade (30O, 45Oor 60O) for range of

media types and also calibration pen for auto-calibration

Cutting system (force) Contour cutter, with up to 7.35N (750gf) delivered in 190 steps

programmable through Intec ColorCut Pro 3 cutting software

Maximum speed 960mm/s

SOFTWARE & CONNECTIVITY

ColorCut Pro 3

Plugin (PC)

ColorCut Pro 3 plug-in (all features available). ColorCut Pro sends projects designed

in Adobe

®

Illustrator

®

or CorelDRAW

®

directly to Intec ColorCut label cutter with

no need to convert them to a different format. Requires: PC - Adobe

®

Illustrator

®

CS1 – CS6, CC, CC2014, CC2015, CC2017, CC2018 , CC2019, or CorelDRAW

®

X4 - X8, 2017 - 2019

ColorCut Pro 3

Plugin (Mac)

ColorCut Pro 3 Plugin for Mac enables the ColorCut Pro Job Library Client. Mac

users add cut marks to Illustrator files and assign Job numbers and QR codes. The

jobs are sent to the remote ColorCut Pro Job Library on a PC for cutting. Requires:

Illustrator CC2018- 2020

ColorCut Pro 3

PC Standalone

ColorCut Pro 3 – Job Server version of ColorCut Pro is PC only and enables jobs

created by the ColorCut Pro plugin (above) to be cut at any time, without requiring

Adobe

®

Illustrator

®

or CorelDRAW

®

and without having to re-open the original file

PC minimum

specification

64-bit. 2 GB of RAM (4 GB recommended). Minimum display resolution: 960×830.

For live preview PC must have Wi-Fi capability for direct connection to Vision3

camera sensor (USB Wi-Fi dongle included)

Connectivity USB (1 connection to PC is required)

REGISTRATION CONTROL & JOB MANAGEMENT

Registration system Vision3 - High resolution CCD vision system reads registration marks on

media, automatically adjusting cut lines to correct for scale or skew.

Cut position accuracy +/- 100 micron

Auto job recognition Yes: Cut file retrieval, supported through QR code (requires ColorCut Pro 3)

Mixed job recognition Yes

GENERAL

Weight 38kgs

Power supply AC 110-220V 50/60Hz, 0.5A

Dimensions WxDxH 670 × 970 × 350mm (with media catch tray closed)

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter.......................................................................... Page No: 9

Installation of the LC600 Cutter (Overview of steps)

INSTALLATION

START

INSTALLATION

FINISHED

Unpack the Intec LC600 cutter, check the accessories. Get familiar with the key

features of the LC600. Then position the cutter with enough room to load media and

for the retractable exit tray to be opened.

Unpacking & positioning the LC600

1

Install the supplied ColorCut Pro 3 software for Illustrator or CorelDRAW.

(Install Mac client where applicable)

Install the Software

3

Using the supplied USB cable connect the cutter to your PC. Then

check in the software that the cutter can be seen.

Connect to your Computer

4

Overview of the Blade Holder, and different blade types. Setting the

blade depth. How to install the Blade and Pen Tools.

The ColorCut LC600 Tools

5

Use TEST cut to perform a cutting test and adjust blade if necessary.

Load your media and start cutting.

(Please refer to your ColorCut Pro, Cut file design & Daily Operating Manual.

Load media and perform test cut

7

Turn your cutter on, check Cutter appears on Wi-Fi Hot-Spot, launch ColorCut

Pro & calibrate the sensor to cutting position in your software.

LCD Panel & Calibrating the Cutter

6

Configure the Wi-Fi Hotspot to receive the Live video feed

(Install provided Wi-Fi dongle if your PC doesn’t have Wi-fi capabilities

Setup Wi-Fi HotSpot

2

Chapter 1. UNPACKING & POSITIONING THE INTEC LC600

Your Intec ColorCut LC600 is packed in 1

box/crate.

The box/crate contains :

The ColorCut LC600 Cutter (i))

'Dual grip' Front Standard feed roller (iia)

'Dual grip' Front Narrow feed roller (iib)

A USB Wi- Dongle (iii)

The Accessories box (iv)

And the ColorCut Pro Software (v)

NOTE: The standard 'Dual Grip' front media

feed roller will be already installed in the

LC600 cutter.

However, the supplemental narrow media

feed roller will be typically placed in the

retractable media feed tray. The narrow 'dual

grip' front feed roller enables users of narrow

label media to achieve consistent feed on

narrow media without creating uneven wear

on the standard 'dual grip' front feed roller.

The USB Wi-Fi dongle is for PC users, that

may not have Wi-Fi capabilities on their PC,

and it enables a Live Preview of the scanning

and cutting process.

The nal items found inside the accessories

box, include the power cable and USB cable

plus a disk containing your ColorCut Pro

Software. A Blade Holder, a selection of

Cutting Blades, a Calibration Pen Tool and a

Creasing Blade.

Item (i) - Intec ColorCut LC600 Cutter

Item (iib) - Narrow media feed roller

Item (iii) - USB Wi- Dongle

Item (iv) - Manuals, USB & Power Cables

ON

LINE

/OFF

LINEENTER

USB Nano USB Adapter

Wireless-N

Item (iia) - Standard media feed roller

(Pre-tted in front of LC600)

1.1 Contents of the ColorCut LC600 (Overview)

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 11

1.2 Contents of ColorCut LC600 (Detailed)

Item Qty Description / Purpose

Intec LC600 Cutter 1 Main Cutting Engine

'Dual Grip' Front Feed bar (Std.)

1

Secondary feed roller for standard

paper sizes (>210mm width), to enable

extended cutting area for standard

paper sizes - Pre-Fitted in LC600 Cutter

'Dual Grip' Front Feed bar

(Narrow) 1

Secondary feed roller for narrow paper

sizes (<210mm width), to enable

extended cutting area - shipped inside

LC600 retractable feed tray.

USB Wi-Fi dongle

1

Supplied for users that do not have a

Wi-Fi connection in their PC. Enables

LIVE VIDEO Pre-View to be recieved by

PC and shown in ColorCut Software.

Software (ColorCut Pro)

1

ColorCut Pro cutting control software

- Direct plug-in for Illustrator or

CorelDRAW

- ColorCut Pro Standalone version

(Job Server)

- Sample templates

Blade Holder 1Used for loading the blades in Tool

Holder on the cutting head.

Pen Tool

1

Used in the calibration process for

aligning the sensor to the cutting

position

Blades 3

3 x 30OBlade 0.9/1mm (Yellow)

3 x 45OBlade 0.9/1mm (Red)

3 x 60OBlade 0.9/1mm (Blue)

USB Cable 1 For connection to the computer

Power Cable 2*

1 for Digital Cutting Engine

*1 for Vacuum Pump (Not required

FB520 /220v)

5A Fuse / Spare

ON

LINE

/OFF

LINE ENTER

1.3 Identifying the key features of your ColorCut LC600

①

③

④

⑥⑦

⑧

Intec Printing Solutions - Manual for ColorCut Flatbed series FB520/FB600/FB900/FB1060 ................................................. Page No: 12

②⑤

J

J

K

L

O

MP

ONLINE

/OFF

LINE ENTER

ONLINE

/OFFLINE ENTER

BMedia Support ...................Supports media in media tray

CTool Carriage...................... Holds the Cutting tool, moving left and right.

Drives cutting tool up/down

DBlade Holder ......................Holds the Cutting tool.

EWi-Fi Antenna .................... Drawer exit tray catches cut media.

FControl Panel ..................... Used to set and use the cutter’s various functions.

GRetractable exit tray ..........Drawer exit tray catches cut media.

HMedia Feed Rollers............ Used to driver media back & forward during cutting.

IFront 'Dual Grip' rollers .....Secondary grip rollers, enable extended cutting area.

JFront 'Roller' release.......... Lever to release Front 'Dual Grip roller when changing

KMedia Tray.......................... Media is loaded in here

LMedia Guides..................... Self-Centering Media Guides to feed media straight.

M Cover Handle...................... Used to access Media Roller release lever.

N Feed Roller Release........... Media release, lifts grip rollers to remove paper jam.

O Media Feed Rollers ........... Feed rollers used to feed media into LC600 cutter

N

1.4 IDENTIFYING KEY FEATURES of your ColorCut LC600 (Rear)

P Power Switch ...................... Turns the ColorCut LC600 Digital Cutter ON/OFF.

Q Power Cable Socket ........... Used to connect the cutter to the Mains Power.

R USB Interface Connector.... Used to connect the cutter to a computer via the USB

interface.

S Cable Clamp ....................... Cable Clamp for USB cable

T Cutting Paper Path ............ Rear exit for paper in the cutting section of the 'Y'

paper path.

The LC600 uses a 'Y'( on its side ) shaped media path when feeding and cutting.

Sheets are stacked in the feeder, which represents 1 arm of the 'Y' shaped media

path. Upon receiving a feed command, the top sheet of media is fed into the cutter

and the entire length of the sheet is fed directly out of the front of the cutter, it is then

reversed back in to the cutter into the second arm of the 'Y' media path (this method

of feeding the media all the way through the device and back, is often used in digital

duplex printers - and is commonly referred to as a Peek-a-boo media path).

U SDcard ................................ (Engineering feature , not required for customer use)

Intec Printing Solutions - Manual for ColorCut Flatbed series FB520/FB600/FB900/FB1060 ................................................. Page No: 13

P

Q

R

S

T

U

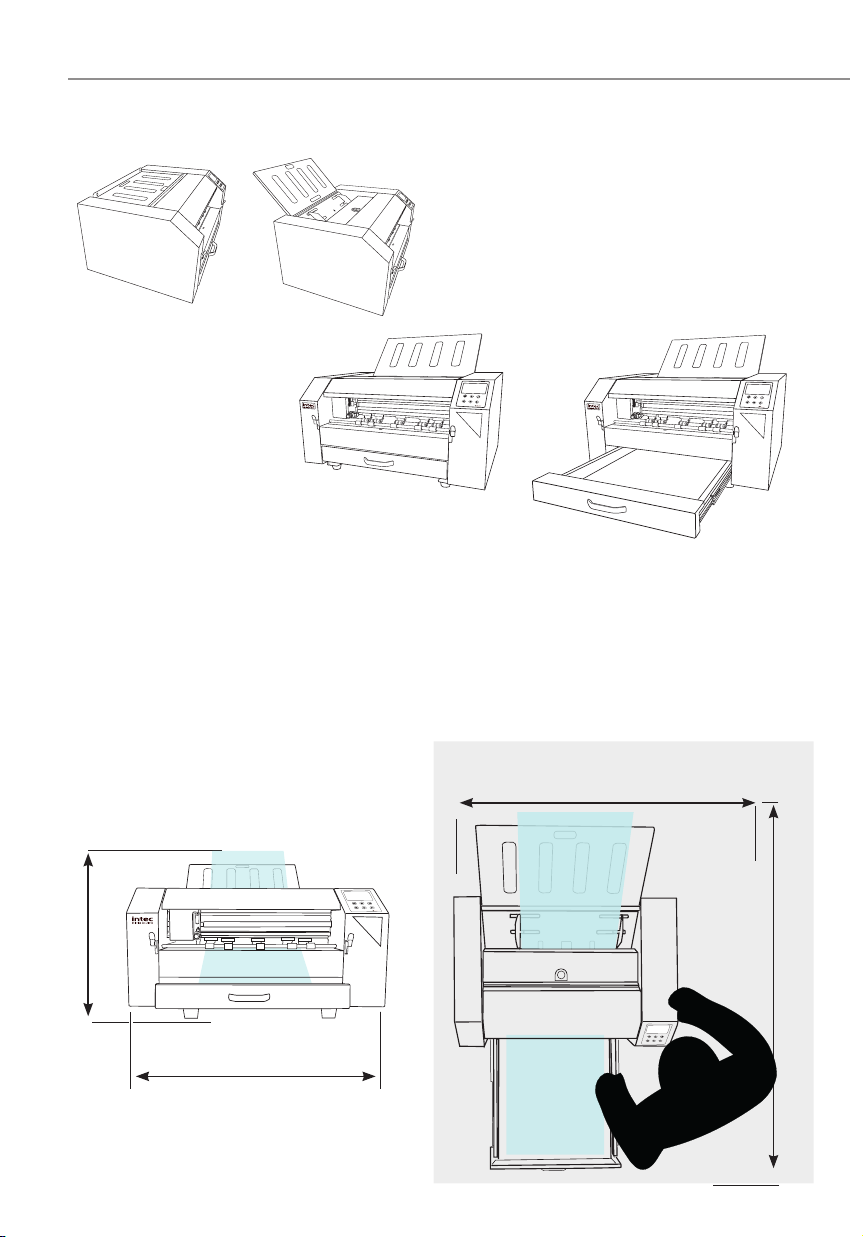

The Intec ColorCut LC600 weighs 38Kg ( 77 Lb) and should be placed on a strong &

even table.

When deciding where to position, the Intec

LC600, open the Media support tray (TOP)

ready to accept media to be cut.

Next, open the

retractable media exit

tray at the base of the

machine.

1.5 POSITIONING your ColorCut LC600

2.3.2 Positioning Requirements & Working Space

1. The Intec ColorCut LC600 weighs 38Kg ( 77 Lb) and should be placed on a strong

& even table.

2. Ensure there is sufcient space above the LC600 to easily load sheets.

3. Ensure there is space for the retractable exit tray to be opened, without causing an

obstruction to walkways.

4. Working Space is different to Machine dimensions.

SRA3 (Tabloid)

Sheet output

1,10 0 m m ( 39.5")

ONLINE

/OFFLINE ENTER

ONLINE

/OFFLINE ENTER

ONLINE

/OFFLINE ENTER

ONLINE

/OFFLINE ENTER

ONLINE

/OFFLINE ENTER

ON

LINE

/OFF

LINE

ENTER

SRA3 (Tabloid)

Sheet in Feeder

670mm (26.5")

Working Space

Sheet

in

Feeder

Sheet

on exit tray

540mm (21 1/4")

1,220mm (48")

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 15

The LC600 uses the Vision3 registration system in conjunction with the ColorCut Pro

software to identify your cutting registration marks (PageMarks), and to read the QR

code for retrieving job numbers.

Please Note: ColorCut Pro does NOT require a live video feed to do this,

your cutting will work perfectly ne with no video connection as all this is

all handled in the cutter. However, in addition to the 'on-board' registration

and QR code handling, the Vision3 registration camera's control system

includes an image echo function that broadcasts the video feed from the

Vision3 sensor over Wi-Fi. You can connect to the live video stream using

the ColorCut Pro application and view the video feed which is useful when

cutting, helping you to identify issues and so you can see while placing

sheets if you are working in a manual mode. manually, We do recommend

you do enable this feature. Please follow the guide below on how to

connect to the live video feed before launching ColorCut Pro.

2.1 Using Wi-Fi to connect to LC600 - Live Video Feed

This LC600’s Vision3 registration system has a camera image echo function, and the

live feed feed from the echo is transmitted through WLAN. To connect to the Video

feed, you will need to broadcast a Wi-Fi Direct connection from the computer that is

running ColorCut Pro.

The LC600 cutter will connect to a 2.4GHz Wi-Fi Direct connection or Wi-HotSpot

dened as follows:

SSID: H3

Password: 12345678

If your computer is not a laptop, then you may not have Wi-Fi capabilities on your PC,

therefore your Intec LC600 is supplied with a USB Wi-Fi Dongle B. to enable you to

do this.

If you are connected on a PC with a Wi-Fi connection (such as a laptop you can ignore

this step).

Chapter 2 - SETTING UP A WI-FI HOTSPOT

B

1. Insert the Wi-Fi Dongle supplied with the

LC600.

2. When the dongle is recognised, please install

the drivers (supplied in the Wi-Fi dongle box).

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 16

2.2 How to create a HotSpot (2 different approaches).

Once you have Wi-Fi enabled on your computer, there are 2 methods to connect to

your Intec LC600 atbed cutter.

1. Use the built in Windows HOTSPOT function. This is easy to use, and uses

Windows 10’s own HOTSPOT feature.

Note: Even though, you are will be connecting directly to the LC600 cutter

(and you are not using the internet for this connection), the Windows HotSpot

feature requires an internet connection before you can enable the HotSpot.

So please bear in mind, without an internet connection made via a router

the Windows HOTSPOT feature can not be enabled. If you do not have

an internet connection then we recommend creating a DIRECT connection

(Below) which is how newer devices like some TV remote controls (Roku 3 )

work, to do this use a utility like Wi-Fi Direct Access point (below).

2. Use the Wi-Fi Direct Access Point. This is a paid for utility from the

Windows Store, for Windows 10 users.

Wi-Fi Direct, makes a direct connection the the LC600’s Wi- video feed from

the Camera eliminating any routers or network management issues. It does

this using the Wi-Fi Direct standard, which enables devices to easily connect

with each other without requiring a wireless access point. Wi-Fi Direct allows

two devices to establish a direct Wi-Fi connection without requiring a wireless

router.

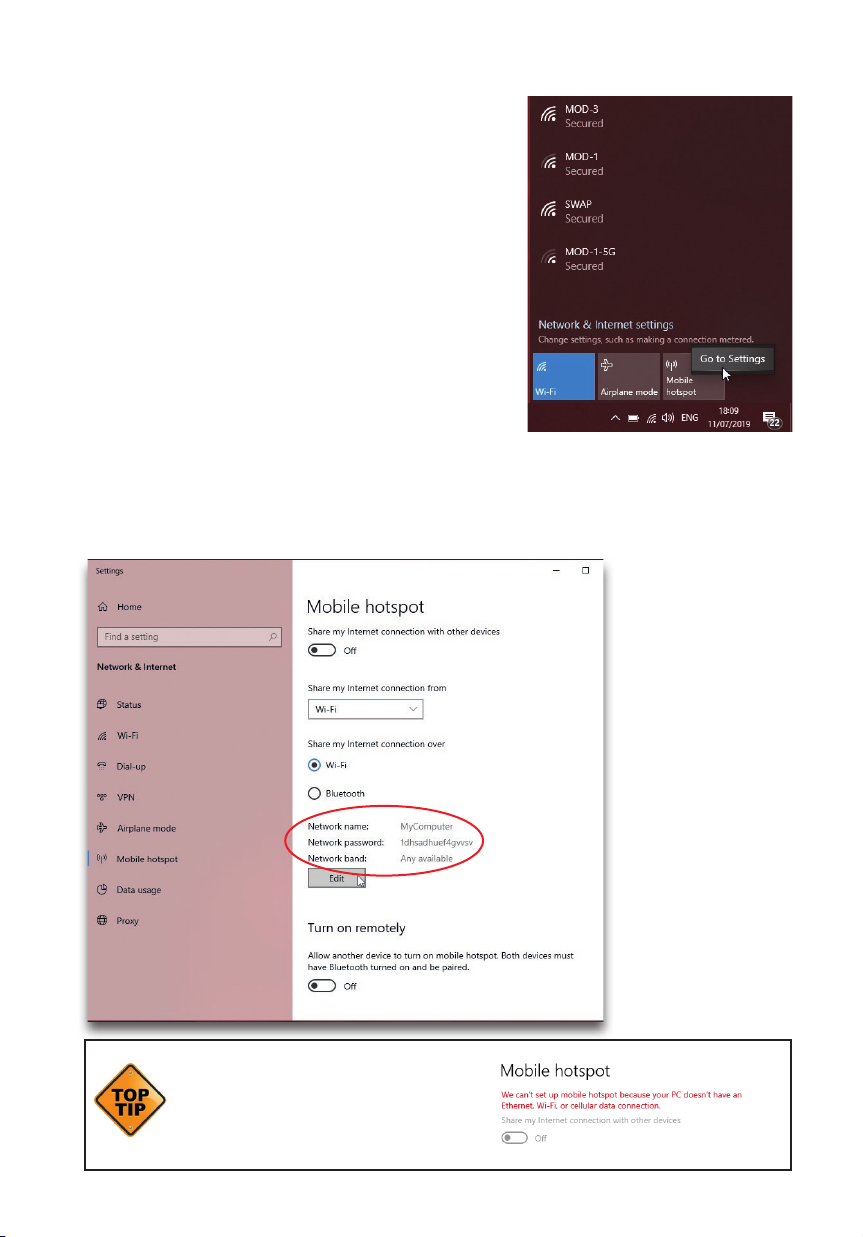

2.3 Method 1 - Using Windows Wi-Fi HotSpot

1. Check the task bar on your computer and

ensure you have an internet connection. If

NO Wi-Fi connection shows, or the “Not

connected to the Internet” icon shows C

then click on the icon and connect to your

Wi-Fi router and enter any ID or passwords

required.

2. Check the task bar on your computer and

ensure you have a the Wi-Fi connection

showing D. (This is essential to start the

Wi-Fi HotSpot)

C

D

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 17

Configuring Windows Wi-Fi HotSpot.

3. Left click on the Wi-Fi icon D in the task bar

to display the ‘Wi-Fi, Network & Internet setting’

menu, then Right mouse click over the Mobile

Hotspot E button in the lower right.

The sub menu item ‘Go to Settings’ will be

displayed. Click this.

4. The ‘Windows Mobile hotspot’ conguration menu will be displayed. This menu

is only required when initially setting up the HotSpot. Each time you activate the

HotSpot after this, the settings for the SSID, and Password will be remembered.

The Intec LC600 is

set to make a direct

connection to a

2.4GHz WLAN with

an SSID of “H3”, and

broadcasts the Live

video feed to that

connection .

You need to set up

your HotSpot to

match this SSID

name. Click Edit

F to congure yoru

Hotspot to 2.4GHz,

and set your SSID

and the password for

connection.

If you can’t activate the HotSpot and you

see the message show to the right, then

you skipped step 2. You must ensure

you have an internet connection to use

Windows HotSpot, even though the

cutter does not need one.

E

F

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 18

Setting the SSID when using Windows Wi-Fi HotSpot.

5. Under, Network Name, enter the SSID name ‘H3’ as shown G. Within the eld,

Network password, enter the password ‘12345678’H(The LC600 automatically

will connect to the SSID H3, with a password of ‘12345678’. So, these entries

must be set to match.

6. The Intec LC600’s Image Echo feature broadcasts using 2.4GHz, so it is essential

that you set the ‘Network Band’ Ito 2.4GHz, if you set it to 5GHz the cutter will

not connect to your HotSpot and you will not be able to see the Camera.

7. Click save to save nish and save your setting. These will be remembered and in

future you only need to enable or disable the connection. When you click SAVE

you will be returned to the ‘Windows Mobile hotspot’ conguration dialogue box.

H

G

I

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 19

Starting the Windows HotSpot.

8. In the ‘Windows Mobile hotspot’ conguration dialogue box, turn ON the ‘Share

my hotpot connection with other devices’ J.

At the bottom of this dialogue box, you can see the devices that connect to your

computer K. It will take approx 30 secs to 2 mins for the Intec LC600 to see the

connection and connect to your Hotspot.

9. After a short period (30 secs to 2mins)

you should see the Intec LC600 device

connect, the IP address will be shown in

the connected devices list, so you know it

has connected. L.

The setup is complete, in future, you only

need to enable and disable your HotSpot,

to connect to the cutter. (See step 10 to

understand how to do this).

J

K

L

Intec Printing Solutions - Manual for ColorCut LC600 Sheet fed Label Cutter........................................................................ Page No: 20

You can now skip to the section on Installing ColorCut Pro and calibrating your LC600

cutter.

However, if you do not have an Internet connection then follow the steps on how to set

up a direct connection to the Cutter without requiring an internet connection or router.

(Wi-Fi Direct Access Point following.)

Daily Operation - Enabling Windows Wi-Fi HotSpot.

10. During daily operation you can now enable the connection to your Intec LC600

cutter by simply clicking on the Wi-Fi icon in the Windows task bar M (Bottom

right of your screen).

Next click on the Mobile

HotSpot button N that

appears in the lower right

corner of the ‘Network and

Internet settings’ Dialogue

box/menu that appears.

The Mobile HotSpot button will

change color when it is activated,

and indicate the SSID name

(H3), and how many devices are

connected. O

After enabling the mobile Hotspot,

ensure you power ON the Intec

LC600 cutter, and allow 30 secs

- 2mins for it to connect to your

HotSpot. Your Mobile HotSpot

will show when the device is

connected. P

M

N

O

P

This manual suits for next models

4

Table of contents

Other Intec Cutter manuals

Popular Cutter manuals by other brands

Belle Group

Belle Group HDC 350 Operator's manual

Husqvarna

Husqvarna K 7000 Workshop manual

Rexel

Rexel ClassicCut CL710 specification

Celme

Celme CHEF PIZZA INOX RAVELLING MN Installation - use - maintenance

Land Pride

Land Pride RC5020 Series Operator's manual

IronCraft

IronCraft 2512 Series Operation and parts manual