clamps, etc. — with sanitizer prior to assembling and attaching it to

your conical dump port.

2. Attach the Flex Chamber to the bottom of the buttery valve,

keeping the buttery valve closed. Remove one black side cap

and install the KG500 ball lock adapter. Slightly loosen the other

black cap on the opposite side of the Flex Chamber so that CO2

can escape while ushing.

3. Set the regulator on your CO2tank to its lowest possible setting,

i.e. 1–2 psi, and connect your Ball Lock Gas QD to the KG500 ball

lock adapter.

4. Allow gas to ow out of the Flex Chamber for a few seconds to

ensure all the oxygen has been ushed. Tighten the black cap.

You can replace the KG500 with the black cap or leave it in place

for fermentation.

Pressure Package

WARNING: Only pressurize your Fermenter when using the

optional BrewBuilt Pressure Pack accessory kit.

WARNING: If pressurizing, never exceed 15 PSI.

WARNING: Do not alter or change the Pressure Relief Valve

(PRV) built into the lid.

WARNING: Always use an approved CO2regulator, with a

functional low pressure gauge, to apply pressure to your BrewBuilt

Fermenter.

WARNING: Before removing any tri-clamp, tting or lid clamp

connected to the conical, release pressure from conical following

the instructions in this section. Failure to release pressure from

your X1 Uni could result in a tting or lid being released under

pressure which could cause bodily harm or death.

WARNING: Before applying pressure make sure the Pressure

Relief Valve (PRV) is properly installed in the lid.

WARNING: Always conrm your Lid PRV is clean and working

properly before applying CO2pressure.

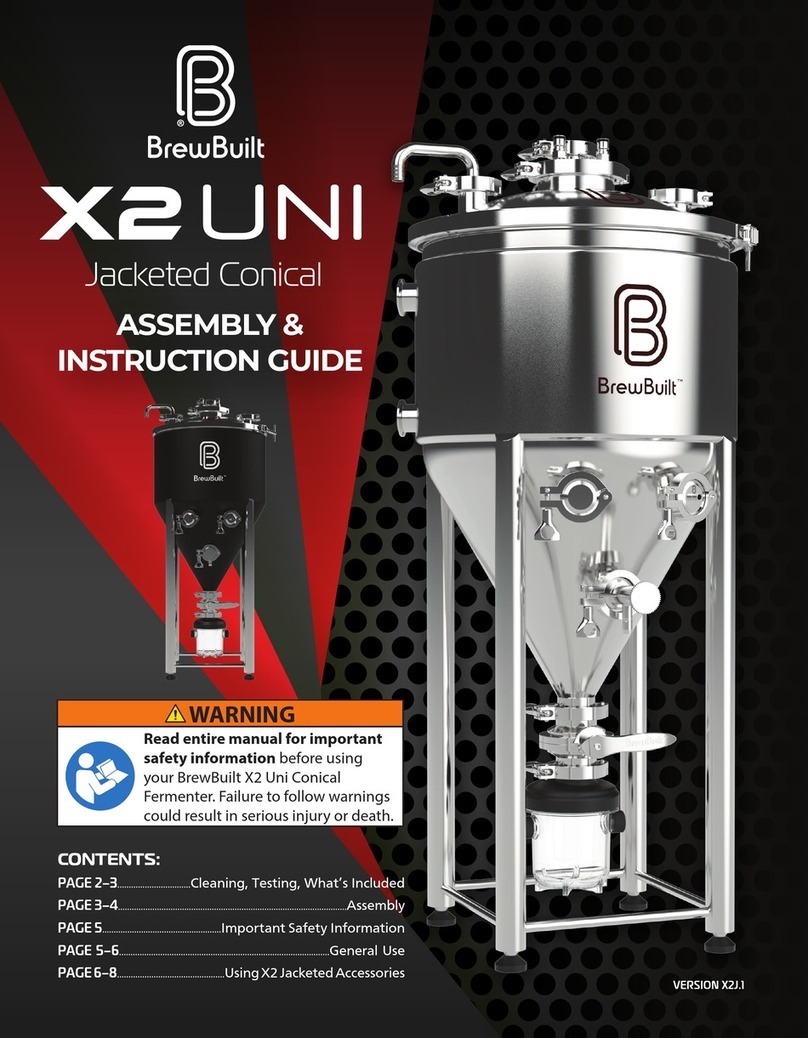

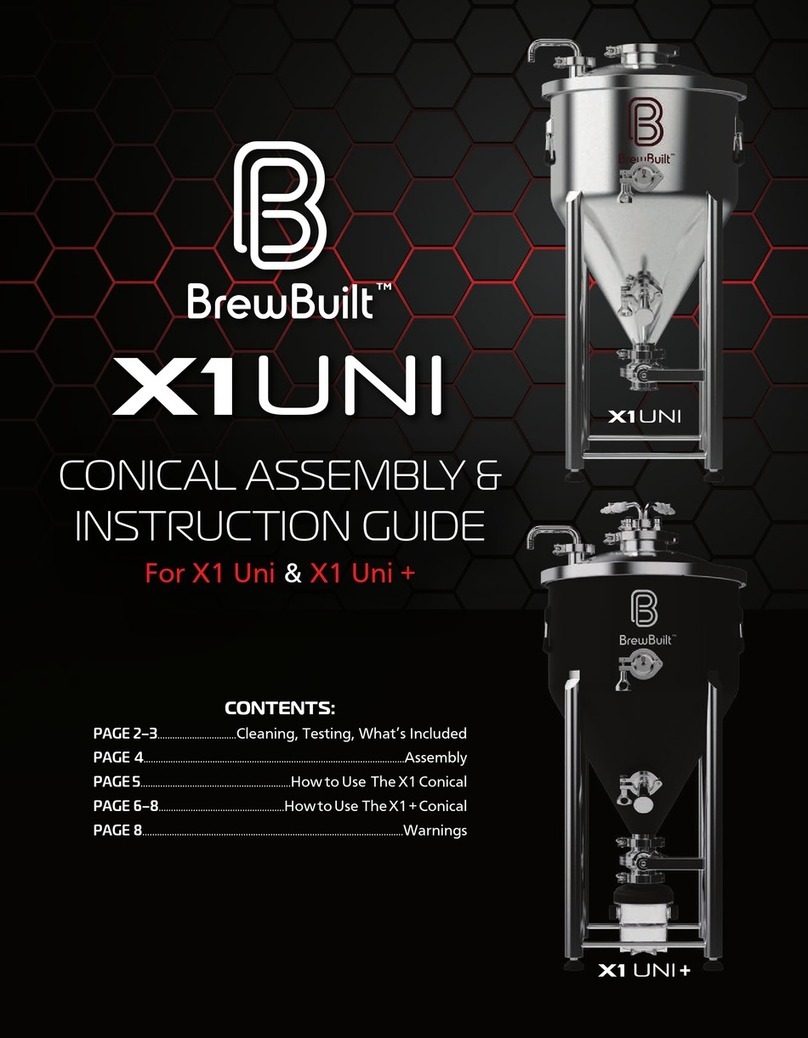

The Pressure Pack, specically designed to work

with BrewBuilt X1 Conical Unitanks, unlocks many

possibilities. Apply low pressure before cooling to

eliminate sucking oxygen back in. Use it to grab a sample

or transfer nished beer to a keg in a true oxygen-

free environment. The Clear Float allows sampling

or transferring of the clearest possible beer from

the top down! In this guide. Please read

and follow the additional instructions that

come with your Pressure Pack Kit.

NOTE: Whenever your X1 conical is under

pressure be aware that you will need to

relieve pressure before removing the lid

clamp or any tting that is attached to

your X1 fermenter. If you are using a Flex

Chamber collection vessel, make sure the

bottom buttery valve is always in the open

position when in use and when relieving

pressure from the conical.

INSTALLATION

Assemble the Pressure Pack lid per the

diagram. DO NOT USE TEFLON TAPE to

assemble threaded body connects as they seal

with the included o-rings. When attaching the

Pressure Pack lid to your X1 conical, be sure your TC

gasket is properly seated and then tighten down the TC clamp.

Follow instructions that come with your Pressure Pack lid.

TIP: A welded a hook on the bottom of the Pressure Pack Lid can be

used to hang drawstring bags for avoring additions.

APPLYING PRESSURE

FIRST TEST —First take a moment and read the warnings above.

For safety we always recommend the rst pressure test be made

while the conical is lled with water. Aer the conical is completely

lled with water, replace the u-shaped blowo with an included

tri-clamp end cap. Before connecting CO2pressure be sure you

have a working, accurate regulator with a low pressure gauge. We

recommend setting your regulator to 1–2 psi to start with, and

always less than 15 psi. Connect your gas-in ball lock QD on your

CO2dra system to the gas-in body connect located on the Pressure

Pack. The gas-in body connect has a notch on the side, while the

beverage-out body connect does not. With 1-2 psi applied to the

conical, practice releasing pressure by unthreading the PRV cap.

Read the section on releasing pressure slowly as instructed in the

section ‘Releasing Pressure’ below.

TIP: When applying pressure some brewers choose to cap the blowo

port with an optional tri-clamp pressure relief valve with a gauge.

TRANSFERRING AND SAMPLING

The bev-out tting is equipped with a unique oating dip tube that

will pull beer from the top rather than the middle or bottom of the

conical. We recommend using a ball lock jumper, a section of beer

line with a beverage-out QD at both sides, to transfer beer from

your X1 to the bottom of your keg. When applying pressure for

sampling or transferring start with a low pressure and increase only

as needed. Keep in mind that your X1 Uni and Pressure Pack lid are

rated at 15 psi and the PRV will start releasing pressure around this

point. Never apply more than 15 PSI to your X1.

TIP: Filling your keg from the bottom up will keep splashing to a

minimum as beer will ow down the beverage dip tube and gently

ll the keg from the bottom up. Lastly, pull up the PRV ring on the

keg and set it in the open position to allow air (or CO2if you pre

purged the keg) to escape as your fresh beer ows in.

RELEASING PRESSURE

WARNING: Before removing the lid clamp, TC tting, or

any accessory, it is required to rst release any pressure

from your BrewBuilt Fermenter.

Releasing pressure from your X1 can be achieved by loosening the

cap on the Pressure Relief Valve (PRV) that is built into the lid. Slowly

loosen the cap counterclockwise until you hear the release of any

CO2exiting the PRV. When the release has stopped, continue to

slowly unthread the cap. At any point while loosening the cap if

you hear additional CO2being released, stop and wait. When no

additional CO2is being released slowly remove the cap completely to

ensure that all pressure has been removed from the fermenter. Only

then is it safe to begin removing ttings or the lid clamp.

TRANSFER CLEAR BEER TO KEG UNDER PRESSURE

Push your nished beer into a keg using CO2so it never becomes

exposed to oxygen—it’s simple and fast using the Pressure Pack.

Thanks to the Clear Float stainless steel oating pick up, you’ll be

transferring the clearest beer from the top down.

Once your beer is ready to be packaged into a keg, follow these

instructions. NOTE: you will need a Corny Keg Ball Lock Jumper Line

(beverage tubing with bev-out ball lock connectors at both ends).

1. Fill your keg with sanitizer solution. Push the sanitizer out using

CO2. Open the keg pressure relief valve to let CO2exit the keg

during lling.

BREWBUILT.COM PAGE 7