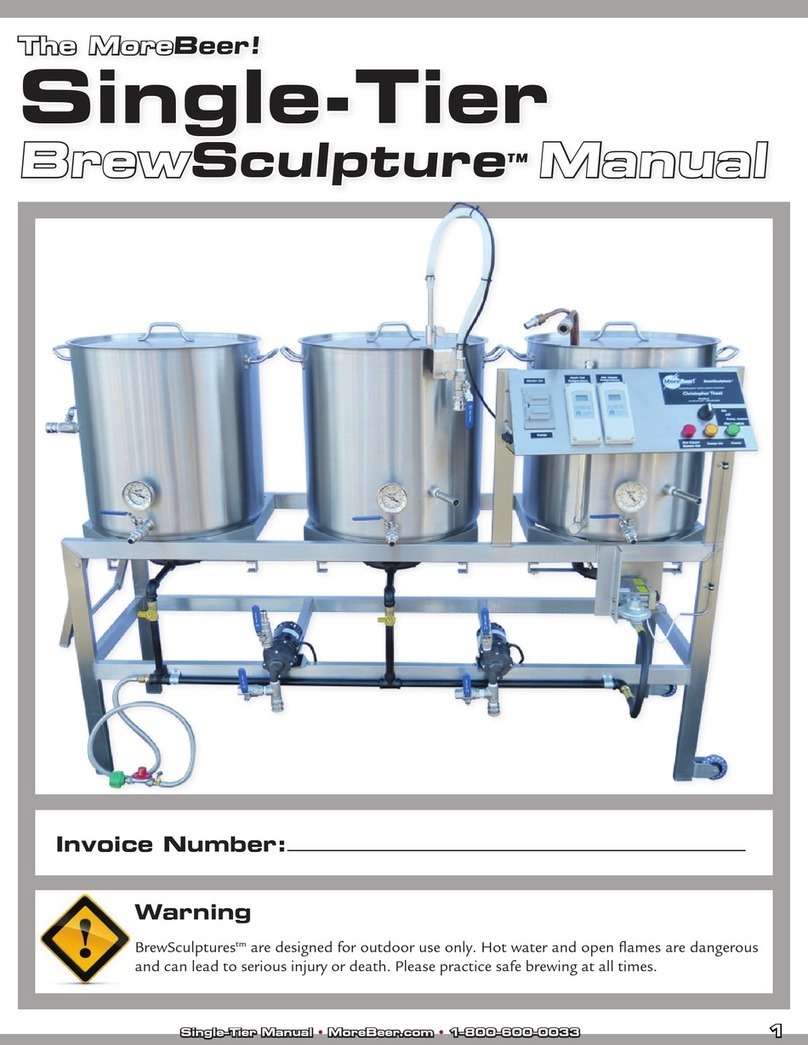

Install the Pump Assembly by sliding the pump’s base into the bracket on the lower left front of the sculpture frame, with the

pump head (the part with the fittings attached) facing RIGHT.

Connect an extension cord to the control panel and plug it in to the wall., and, finally, connect to your fuel source. Aways

ensure that the main valve and the valves for the individual burners are in the Off position when the system is not in use.

EMoreFlavor, Inc. very strongly recommends that you have a professional plumber run the lines and provide the

connection to your household natural gas system, and that a master shut-off valve be installed between the home gas

system and your Brew Sculpture.

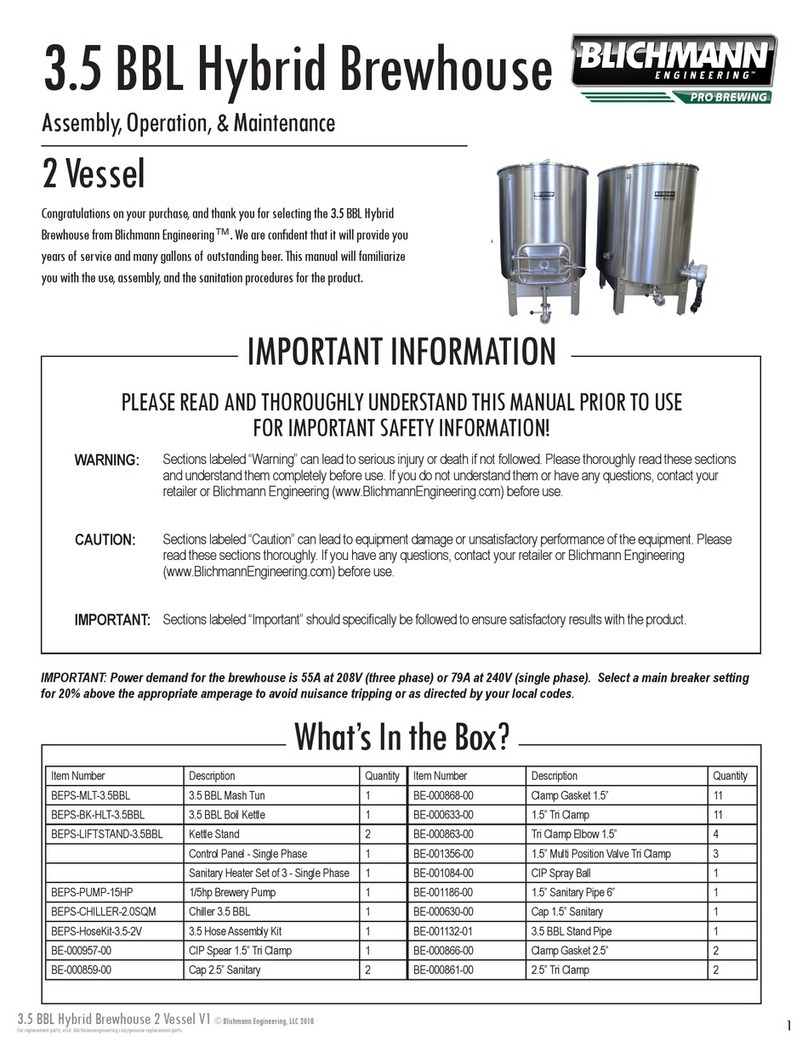

Second, assemble the Mash Tun

1. Install the ball valve onto the male-threaded fitting on the bottom front of the kettle.

2. Install the ermometer into the female-threaded port on the exterior of the kettle, directly above the ball valve.

3. Install the shielded thermowell into the port to the right of the analog thermometer in the Mash Tun.

4. Install the Sparge Arm on the upper lip of the kettle and tighten it in place.

5. e Mash Tun installs above the upper burner. Place the Tippy Supports into their cradles on the stand with the valve

facing left, towards the Boil Kettle. You may want to ask a friend to help by pulling out the set pin while you set the

kettle in place.

6. Once the Mash Tun is in place on the Sculpture Frame, insert the Mash Tun Temperature Probe into the thermowell.

Next assemble the Hot Liquor Tank

1. Install the ball valve onto the male-threaded fitting on the bottom front of the kettle.

2. Install the ermometer into the female-threaded port on the exterior of the kettle.

3. Insert the copper Heat Exchanger into the Hot Liquor Tank, taking care to avoid damaging the ermometer’s probe.

4. e Hot Liquor Tank installs on the remaining, lowest burner on the stand.

5. Install the Float Switch/Temperature Sensor in the Hot Liquor Tank by hanging it over the kettle’s rim. Remove the

silicone plug from the kettle lid’s notch to accommodate the sensor’s bracket.

Mount the Control Panel to the frame

Tri-Clamp connections are a type of pipe fitting used in most commercial breweries in the US. e Tri-Camp system consists

of two flanged fittings that both have a grooved face, which are pressed together with a ridged gasket between them such

that the gasket’s ridge fills the fittings’ grooves. A clamp is then secured around the outside of the connected fittings to hold

them in place.

1. Connect one of the 1.5” Tri-Clamp Tees to the Sculpture Frame, with the “long” side connected to the frame and the

“tee” portion pointing to the right, parallel with the ground.

2. Connect the 1.5” Tri-Clamp Elbow on the end of the Tee opposite the Sculpture Frame so that it points upward.

3. Connect the second 1.5” Tri-Clamp Tee to the other side of the elbow via the “long” side of the tee, and with the “tee”

portion facing outwards, away from the Sculpture Frame.

4. Finally, connect the Control Panel to the end of the Tee that is facing upwards.

Connect the Wiring

Connect the wires coming from the Temperature Sensors, Sparge Arm and the Digital Hot Liquor Burner to their respective

leads on the Control Panel. e connections are color coded as follows:

1. Green: Mash Tun Temperature Sensor

2. Red: Mash Tun Float (Sparge Arm)

3. White: Boil Kettle Temperature Sensor

4. Blue: Hot Liquor Tank Temperature Sensor/Float Switch Combo

5. Yellow: Digital Hot Liquor Burner

6. Plug the Pump’s power cord into the 110V outlet lead labeled PUMP 2.

*Note: You can wrap the connecting wires around the open ends of the 1.5” Tri-Clamp Tees that form the support for the Control Panel. is will keep the cables tidy and out

of the way of the system’s flames

BrewSculptures™ is a trademark of

MoreFlavor!

™

Inc. This document is copy written by

MoreFlavor!

™

Inc.