8. Finishing the Chopsticks

Congratulations! Your newly made chopsticks should feel

smooth in the hand. If there are corners that feel sharp,

lightly sand with 400 grit sandpaper. You do not need to

sand the entire chopstick, just those areas that feel either

sharp or rough.

For multiple-use chopsticks, you need to apply a finish.

Included with your Chopstick Master ®is a small amount

of food-grade mineral oil. With a paper towel, apply a small

amount to each chopstick, let sit for a couple of minutes

and wipe clean. After each use, wipe your chopsticks

clean. For a thorough cleaning, wipe with rubbing alcohol.

If desired, you can hand wash your chopsticks with soap

and water, and then immediately dry and reapply mineral

oil. If the chopsticks look dull, apply another coat of food-

grade mineral oil (depending on use, this may be several

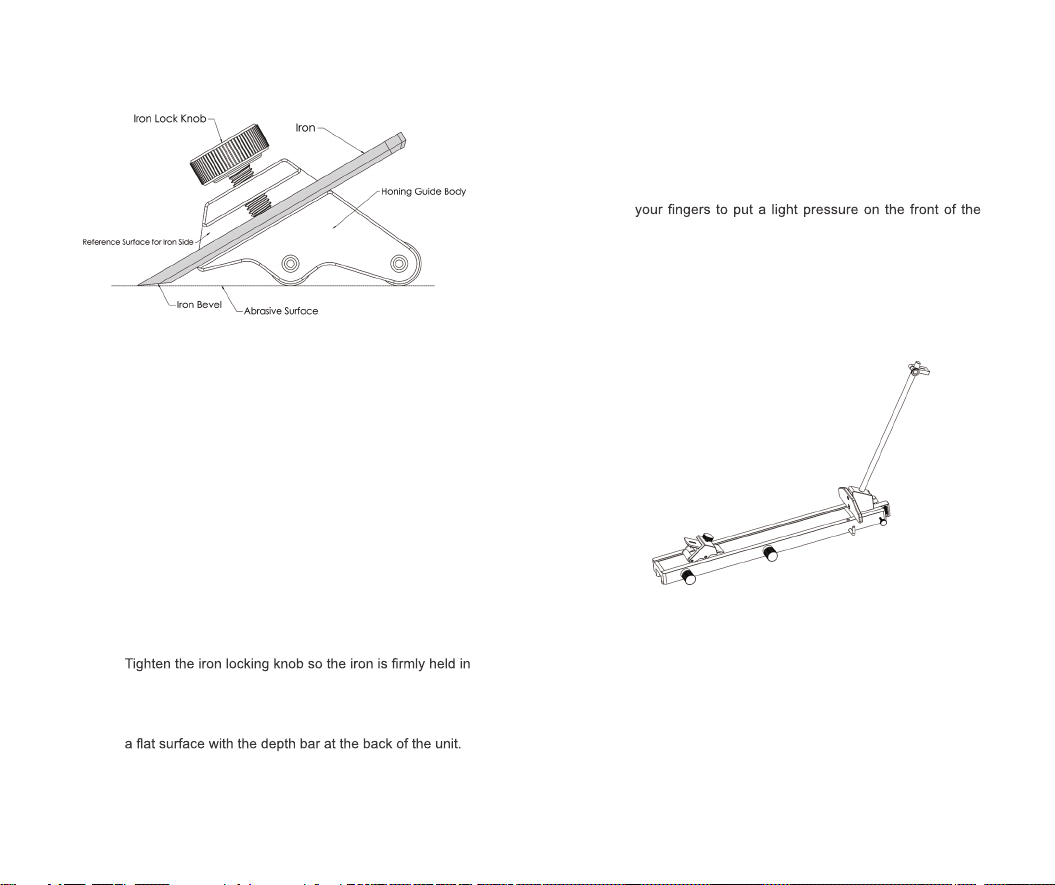

Figure 10

times a year). With proper care, a pair of handmade

chopsticks can last a lifetime.

shellac. You can also gild with metal leaf, or explore many

other decorative ideas to make your chopsticks unique!

Other finishing options include varnish, panint, lacquer, or

CONGRATULATIONS — You are now a Chopstick

Master ®!

On behalf of the Bridge City Tool Works Chopstick Master ®

design team in Portland, Oregon USA, and Harvey Industries,

our manufacturing partners in Nanjing, China, we sincerely

thank you for your purchase of the Chopstick Master ® . We

know you had a lot of fun making your chopsticks and hope

that you share this experience with your family and friends! One

really fun way to enjoy your Chopstick Master ® is by hosting a

party where your guests get to make their own chopsticks (or

they go home hungry)!

The Chopstick Master ® makes a wonderful gift for family and

friends. We can’t think of any other wood-working project that

takes 10 minutes and generates so much enthusiasm, joy, and

satisfaction. For additional Chopstick Master ® kits, chopstick

blanks, bags, and repair parts visit www.ChopstickMaster.com

to locate a distributor near you.

-17--16-

.gnittucstiuqenalpehtlitnutuc,sekortstrohsgnisU

Repeat for the other three facets.