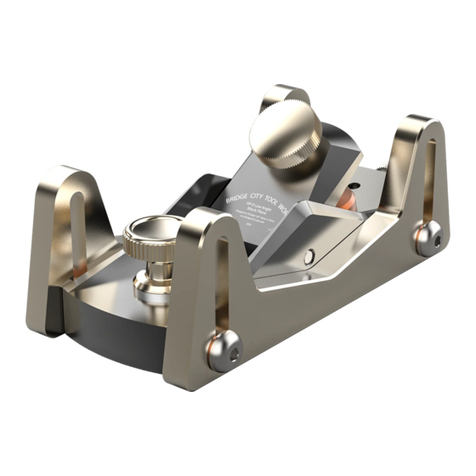

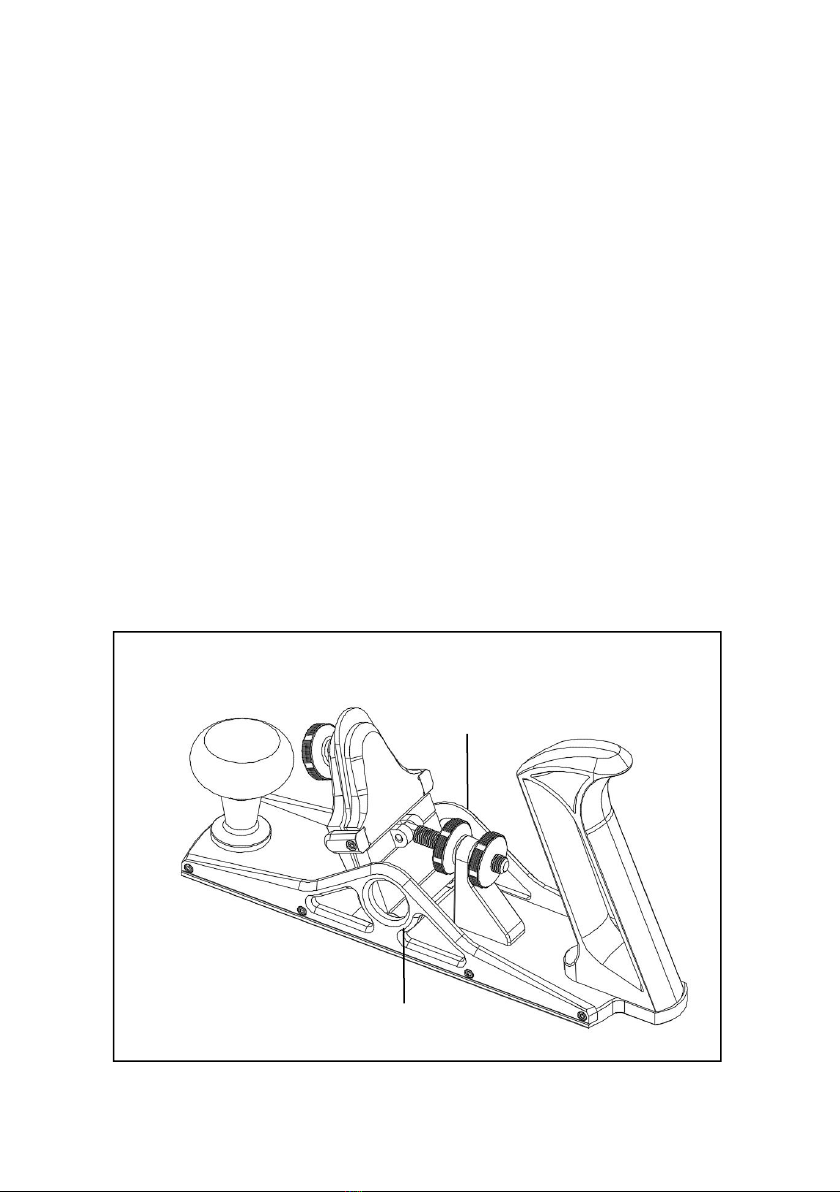

The Iron Clamping Mechanism pivots on the Frog Axle, which allows you to make angle

adjustments ranging from 88°~117°, as shown below in Fig. 4.

To raise the iron (down to 88 ° degrees), rotate the first lock wheel (near the frog)

CLOCKWISE, so that the wheel moves closer towards the frog. Then adjust the second

lock wheel (near the handle) CLOCKWISE, to raise the iron up to 88 ° degrees. Once

angle is set, rotate the first lock wheel COUNTER-CLOCKWISE to secure the Iron Angle

Adjustment Mechanism in place.

Vice versa, to lower the iron (up to 117° degrees), rotate the second lock wheel (near

the handle) COUNTER-CLOCKWISE before adjusting the first lock wheel (near the frog).

Once angle is set, rotate the tighten the second lock wheel to secure the Iron Angle

Adjustment Mechanism in place.

By rotating the lock wheel, this will adjust the scraping iron to the appropriate scraping angle,

which is based upon the hardness and roughness of the wood surface. Making test cuts will be

necessary to determine whether you have achieved the proper scraping angle. When properly

set-up, the iron should produce fine shavings rather than dust.

Fig. 4 Iron Angle Adjustment Range

Adjusting scraping depth:

A single pass of the HP-14 Scraper Plane will produce exceedingly small shavings. In most cases,

the recommended scraping depth of the iron should measure 0.01mm. There are two methods to

achieve the correct scraping depth, which can be adjusted as follows:

Method A:

Place the HP-14 Scraper Plane on a flat surface such as a workbench. Rotate the lock wheel to

raise the iron to the desired scraping angle. Loosen the iron cap knob and adjust the iron so that

the edge is flushed with the table surface, and then tighten the iron cap knob.

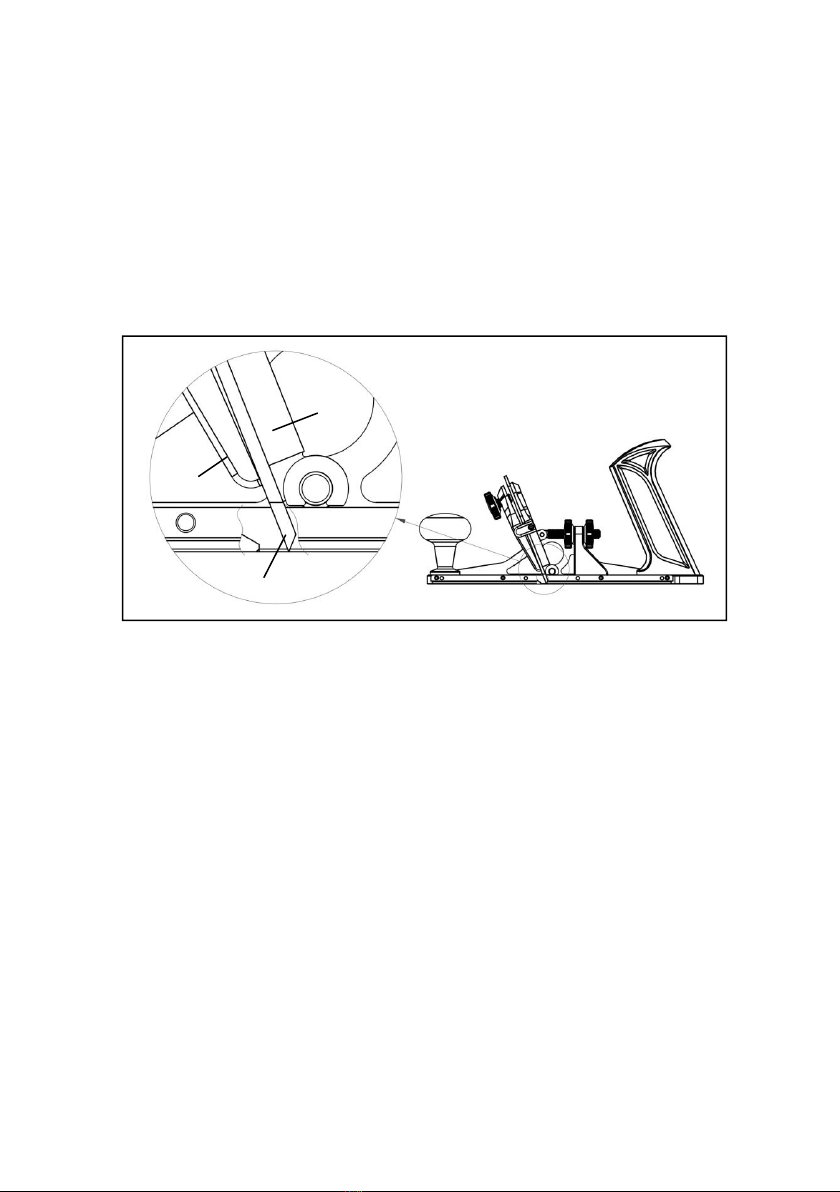

Place the HP-14 Scraper Plane on the workpiece and adjust the lock wheel again, as shown in Fig.

5. While viewing the plane from the rear, rotate the lock wheel counterclockwise to increase the

scraping depth. There are six semi-circular cuts milled around the lock wheel, which can be used

as marks to complete fine adjustment. By rotating the lock wheel by 1/3 turn counterclockwise

will increase the scraping depth by 0.04~0.01mm.