Page 1 of 4

Instructions for:

PETROL ENGINE TWIN CAMSHAFT &

DIESEL ENGINE SETTING / LOCKING TOOL

KIT

Model No: VS4930

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

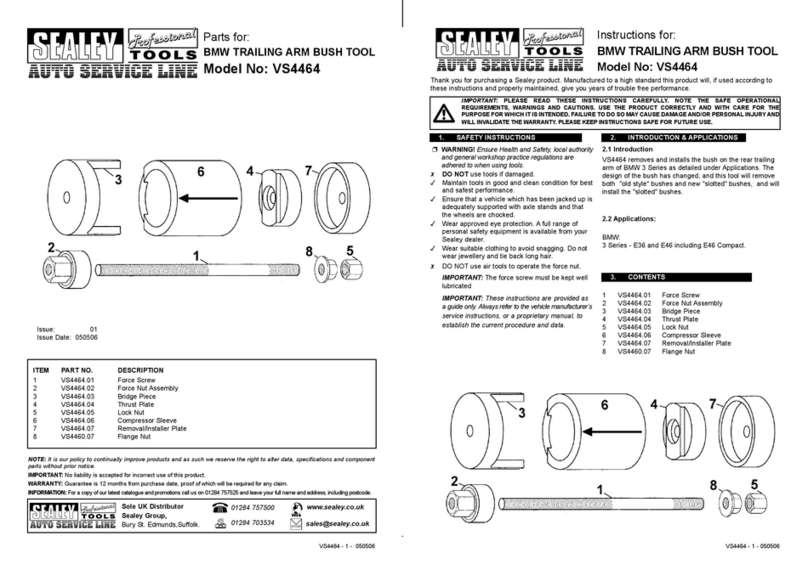

2. INTRODUCTION / APPLICATIONS

1. SAFETY INSTRUCTIONS

WARNING!Ensure Health and Safety, local authority and general

workshop practice regulations are adhered to when using tools.

DO NOT use tools if damaged.

Maintain tools in good and clean condition for best and safest

performance.

Ensure that a vehicle which has been jacked up is adequately

supported with axle stands.

Wear approved eye protection. A full range of personal safety

equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery and

tie back long hair.

Account for all tools, locking bolts, pins and parts being used and do

not leave them in or near the engine.

WARNING! Incorrect or out of phase camshaft timing can result in

contact between valve head and piston crown causing damage to the

engine.

IMPORTANT: These instructions are provided as a guide only. Always

refer to the vehicle manufacturer’s service instructions, or a proprietary

manual, to establish the current procedure and data.

WARNING: The warnings, cautions and instructions discussed in

this manual cannot cover all possible conditions and situations

that may occur. It must be understood that common sense and

caution are factors which cannot be built into this product, but

must be applied by the operator.

The Ford 1.6 16v. Ti VCT Duratec (Sigma) petrol engine was first

introduced in the Ford Focus in 2004. The engine has variable camshaft

timing (VCT) on both the inlet and exhaust camshafts.

VS4930 Setting / Locking Tool Kit provides the timing tools required for

timing belt replacement applications PLUS to cover VCT timing

adjustment.

FORD 1.6 Ti-VCT Twin Camshaft 16v. Duratec Petrol engine in

FORD

Focus C-Max Mondeo

HXDA engines

VS4930 Issue No:1 - 23/07/08