A010GB issue11

4

5.0 Temperature

Stable and correct temperature is essential for good results. Adjust with care.

Note: your incubator may not be set to the correct temperature from the factory and the following

procedure must be followed before setting eggs.

5.1 As the incubator warms up and approaches its control setting the red LED will change from continuously on to

flashing. Allow the incubator to stabilise for at least an hour before adjusting the temperature – check against the

thermometer supplied.

5.2 Rotate the red adjustment spindle on top of the control housing with a small screwdriver – clockwise to increase

temperature, anticlockwise to reduce it. 1°C (2°F) is about ¼ turn of the spindle.

5.3 When reducing temperature the red LED may go out while the incubator cools – this is normal.

5.4 Refer to the thermometer supplied to check temperature. Adjust temperature with care – small differences have

large effects on hatching performance.

Recommended temperatures: Incubation period

Hens 38.5°C 101.3°F 21 days

Pheasant 38.5°C 101.3°F 24 days

Quail 38.5°C 101.3°F 17 days

Geese 38°C 100.4°F 28-32 days

Ducks 38°C 100.4°F 28 days

5.5 Developing embryos are fairly tolerant of short term temperature drops and the user need not be concerned about

cooling that occurs when inspecting eggs. Temperature variations (e.g. day to night) or constantly low

temperatures can cause malformations or partial development of the embryo. Constantly high temperatures can

quickly have a serious detrimental effect on hatch rates and must be avoided.

6.0 Humidity and Ventilation

Short term variations in humidity are not important. The average humidity over the incubation period needs to

be near optimum to achieve the ideal weight loss. High humidity for the day or two of hatching is also important.

Beware chronic, excessive humidity.

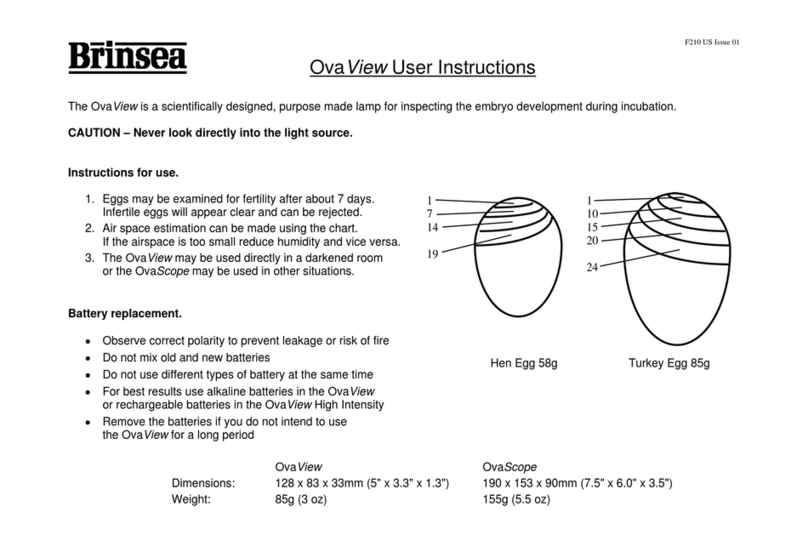

6.1 Two factors affect incubation humidity: water evaporation within the cabinet (from eggs as well as from

additional water) and levels of ventilation. The water content of the air being drawn through the incubator will

also have an effect.

6.2 There are two methods available to achieve correct humidity levels in still air incubators:

a) Follow manufacturers guidelines for water and ventilation levels (see below).

b) Monitor egg weight loss which varies as a direct result of humidity and correct against

published weight loss figures for the species.

a) As a general guide for poultry and waterfowl set the eggs with 100:1 Brinsea Incubation Disinfectant

solution in just one reservoir (moulded into the yellow tray just inside the door). Check and top up

water in that reservoir every few days during incubation and add water to the second reservoir 2 days

before the eggs are due to hatch. Higher humidity levels are needed for hatching to prevent membranes

drying too quickly. Never block both vents.

The recommendation above will give good results in most conditions but humidity can be varied by

running the incubator dry for periods to reduce average humidity, or with both pans for increased

humidity. Blocking one vent with tape will also increase humidity – NEVER BLOCK BOTH VENTS.

Caution: excessive humidity can cause problems!