1-2

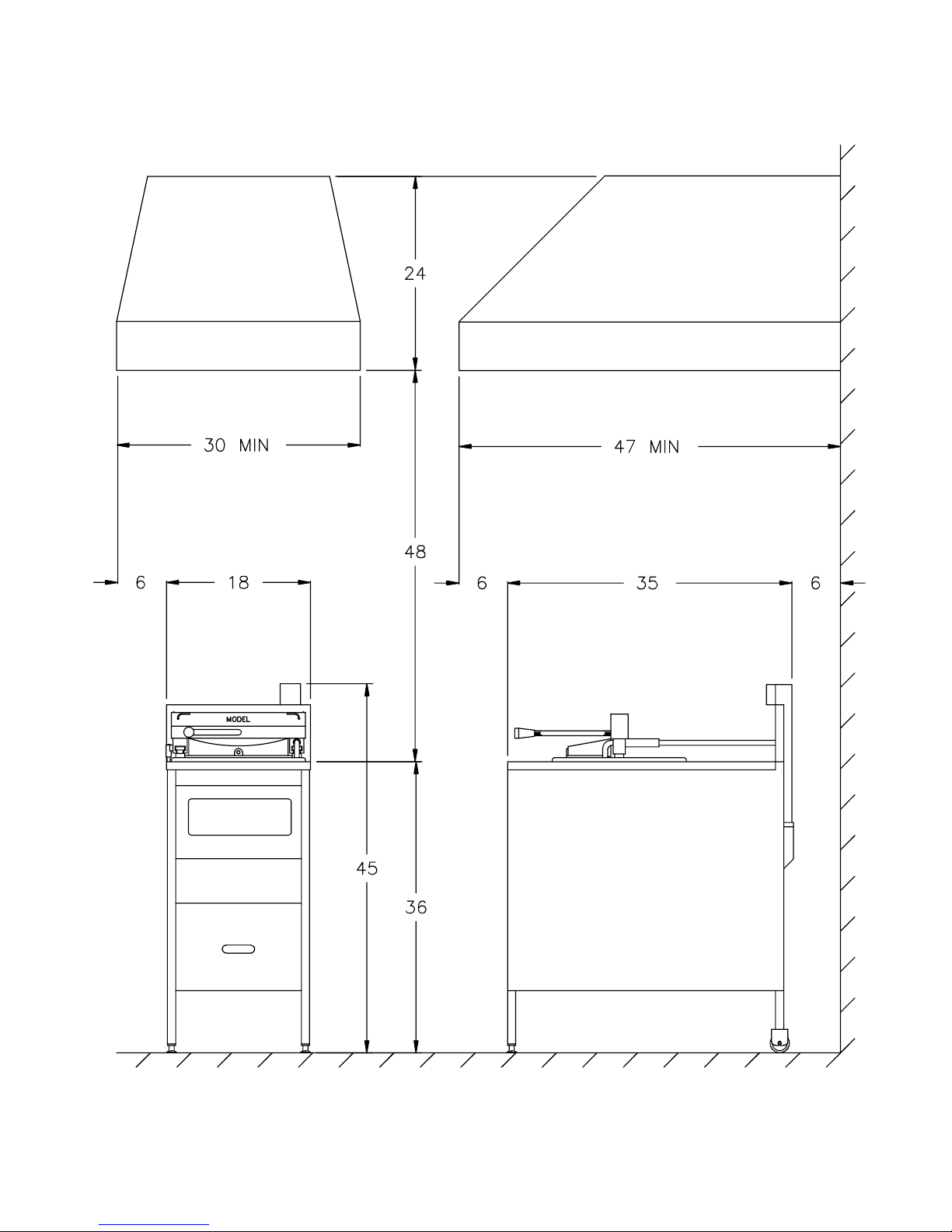

RECOMMENDED VENTILATION

REQUIREMENTS

Exhaust hood should comply with ANSI/

NFPA #96 or national, state and local

codes. All units must be under an adequate

power exhaust hood for ventilation of cook-

ing vapors and products of combustion.

Precautions should be taken in the design

of the exhaust hood to avoid interference

with operation of the unit. Consult a local

ventilation company for fire suppression,

design and installation of a hood.

DO NOT extend the

exhaust stack or exhaust

flue of any unit. Doing so may cause a neg-

ative back draft causing malfunction and

interference with burner operation on the

1800GH and improper exhausting of cook-

ing vapors on all units.

General Requirements:

1. Exhaust hood must conform to appli-

cable national, state and local codes.

2. It is recommended that requirements

of the National Fire Protection Associ-

ation (NFPA), Standard No. 96 be fol-

lowed for the design, installation and

use of exhaust system components.

This includes hoods, grease removal

devices, exhaust ducts, dampers, air

moving devices, auxiliary equipment

and fire extinguishing equipment for

the exhaust system and the cooking

equipment used therewith in commer-

cial, industrial, institutional and similar

cooking applications.

3. Hood Size: The overhead canopy

type hood should be sized to com-

pletely cover the equipment it is

designed to ventilate plus an overhang

of at least 6 inches on all sides of

equipment not immediately adjacent

to walls or other construction extend-

ing above the cooking surface. Non-

canopy, prefabricated “backshelf”

type hoods should be sized according

to the manufacturers specifications.

4. Exhaust Air Volume (minimum):

Canopy hood open on all four sides:

1800 cu. ft./minute. Canopy hood

open on three sides or less: 1200 cu.

ft./minute.

5. Exhaust Air Velocity: All exhaust

ducts should be sized to provide an air

velocity in the ducts of at least 1500

ft./minute.

broaster.com Manual #14678 1/99 Rev 2/14