W-1

All adjustments and repairs shall be made

by an authorized Broaster Company repre-

sentative.

If there is a power failure, turn power switch

OFF. Turn the gas valve OFF. DO NOT

attempt to operate unit during a power fail-

ure.

Failure to read and

understand this manual

completely could result in serious injury

or death. Be sure ALL operators read,

understand and have access to this

manual at all times.

Rags or paper containing

cooking oil can catch fire

if exposed to heat. Laundering will not

remove the oil. Dispose of all oil-soiled

papers and rags in a trash container that

is in a ventilated area away from all

cooking equipment or other heat

sources such as direct sunlight.

If at any time the

touchscreen control does

not turn off when the power switch is

moved to the OFF position, disconnect

the power to the fryer and contact your

local Broaster Company representative

for service immediately.

DO NOT operate unit

without filter pan and filter

pan cover in its proper position. Filter

pan cover must be wiped clean after

each filtering cycle.

Make sure Pressure Relief

Valve and Pressure Gauge

ports on bottom of cover are clear of any

oil or grease buildup.

The appliance, when

installed, must be

electrically grounded in accordance with

local codes, or in the absence of local

codes, with the National Electrical Code,

NFPA 70, or the Canadian Electrical

Code, CSA C22.2, as applicable.

cont’d on next page

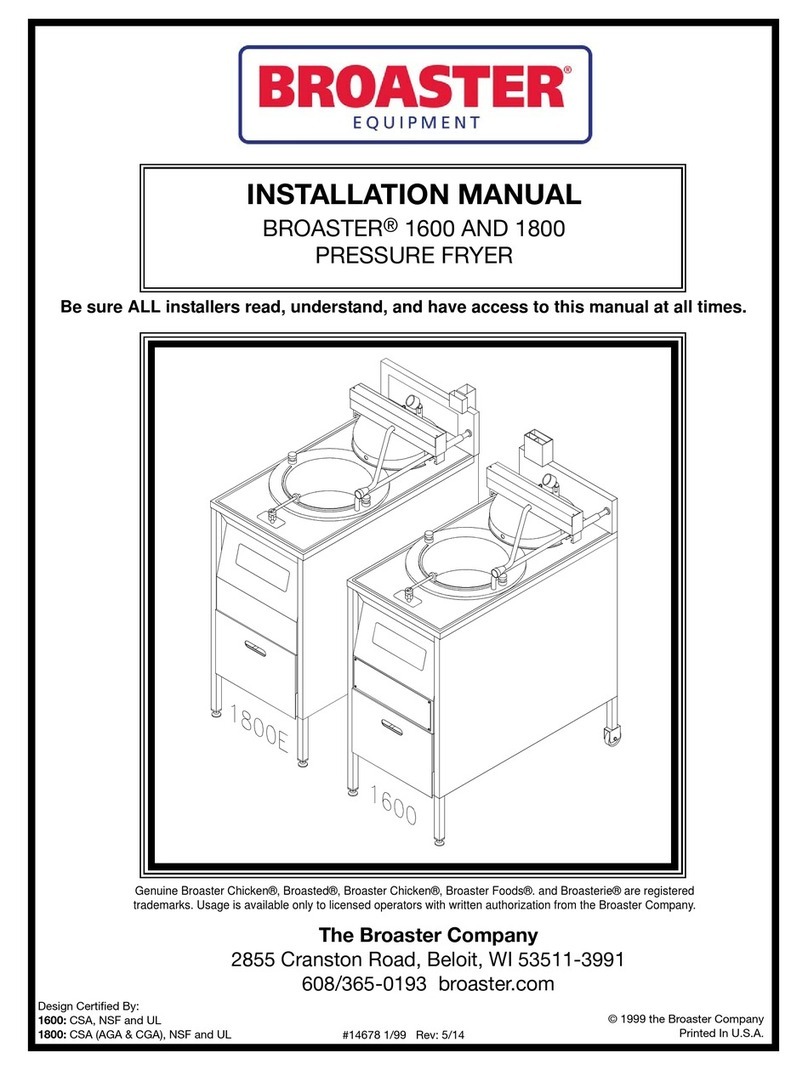

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Improper installation, adjustments, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and mainte-

nance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

Indicates an imminently hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property damage or both.

broaster.com Manual #21307 06/20 Rev: 06/20