______________________________________ Bronkhorst® ______________________________________

________________________________________________________________________________________________

9.17.119A MASS-STREAMTM Instruction Manual D-6400

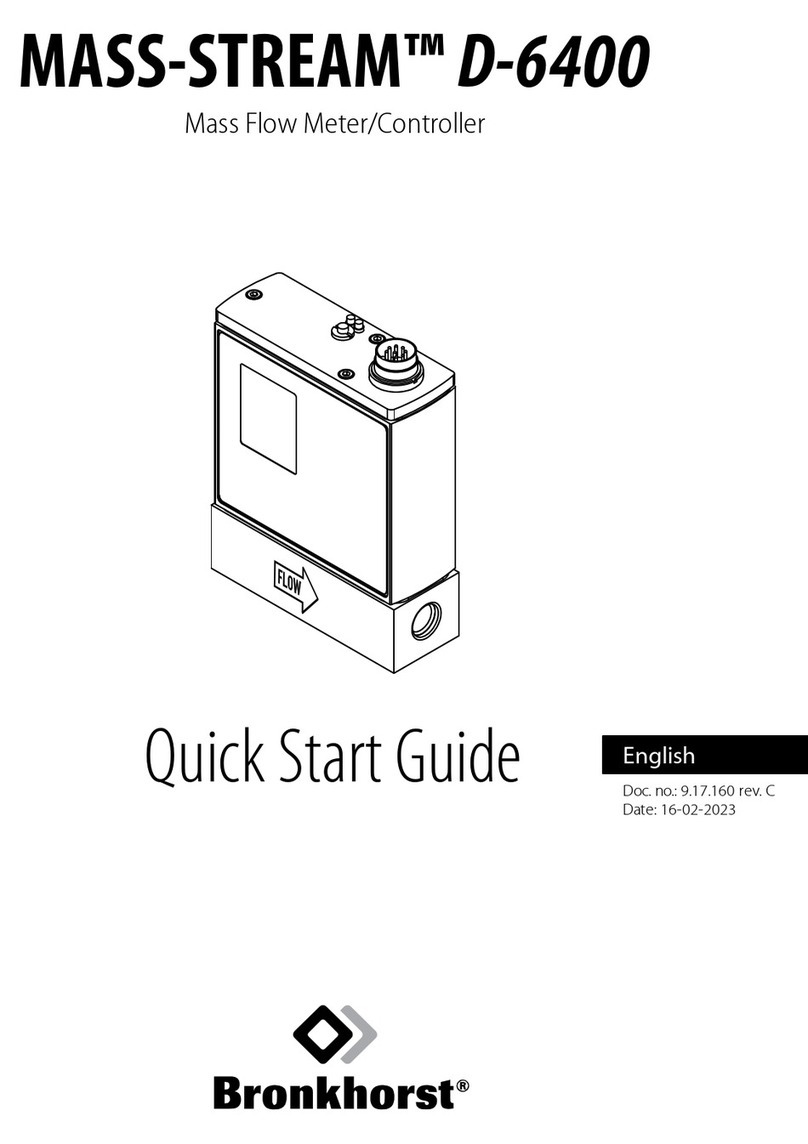

1.3.Product description

Optional connector for fieldbus

Display for readout and control

Inlet connection

LED status indicator and push button

Outlet connection

The MASS-STREAM D-6400 instruments are measurement devices for thermal mass flow and control of gases. They

are equipped with a digital electronic multi-bus pc-board and consist of a micro-controller with peripheral circuitry for

measuring, controlling and communication. The flow signal is measured directly in the gas flow, digitized and processed

by means of the internal software (firmware). The measured and processed values can be output through the analog

interface or through the digital communication line (RS232 or optional fieldbus interface).

For controllers the setting for the actuator is calculated by the firmware. The setpoint can be given through the analog

interface or through the digital communication line.

These digital instruments offer great flexibility thanks to the "multibus" concept, whereby the instruments can be

equipped with an on-board interface with DeviceNet™, PROFIBUS DP, PROFINET, Modbus, EtherCAT®, FLOW-BUS

or EtherNet-based protocols.

Numerous input/output options can be installed through the programmable 8DIN connector (see Customized I/O). In

addition to the various analog signal options and the standard RS232 communication, there are such options as RS485

communication, digital frequency/pulse output, alarm output/reset, valve purge/close and analog valve output.

The MASS-STREAM D-6400 instruments offer high flexibility due to the multi-gas/multi-range functionality. This function

is easily accessible via the FlowTune™ software or PLC; there is no need to disconnect the instrument from your

system. For additional gas types the user can calculate accurate fluid properties for conversion by means of our free,

online software tool FLUIDAT®on the Net. Users of MASS-STREAM D-6400 instruments can rescale their instruments

on site, saving time and money for dismounting and recalibration.

The micro switches and LED’s on top of the instrument can also be used for manual operation of some options.

1.4.Calibration

The MASS-STREAM D-6400 is factory calibrated. Periodical inspection, recalibration or verification of the accuracy may

be subject to individual requirements of the end user.

Bronkhorst certifies that the instrument meets the rated accuracy. Calibration has been performed using measurement

standards traceable to the Dutch Metrology Institute (VSL).

1.5.Maintenance

The MASS-STREAM D-6400 needs no regular maintenance if operated properly, with clean media, compatible with the

wetted materials, avoiding pressure and thermal shocks and vibrations. Units may be purged with a clean, dry and inert

gas.

In case of severe contamination, cleaning the inside of the device may be required. After cleaning, recalibration of the

instrument is recommended.

Inexpertly servicing instruments can lead to serious personal injury and/or damage to the instrument or

the system it is used in. Servicing must therefore be performed by trained and qualified personnel.

Contact your Bronkhorst representative for information about cleaning and calibration. Bronkhorst has

a trained staff available.