For example, if the sound pressure of the calibrator at 1 kHz is 94.0 dB, the sound level meter without the Response

Linearisation Filter (see below) should be adjusted to a reading of 94.0 dB −0.17 dB = 93.83 dB.

Note, that the correction is automatically taken care of in the calibration routines of Brüel & Kjær Sound Level Meters and Noise

Monitoring Terminals supporting Outdoor Microphone Type 4952.

Remote Verification with CIC

The preamplifier in the transducer part of Outdoor Microphone Type 4952 is designed with Brüel & Kjær’s patented Charge

Injection Calibration facility, CIC. With CIC the complete signal path with the microphone can be remotely verified.

Details on verification with the CIC technique can be found in Brüel & Kjær Microphone Handbook, Volume 1 (BE1447-11),

Chapters 4 and 6. The Microphone Handbook can be viewed from the Literature section of the Brüel & Kjær Internet Site

www.bksv.com.

Maintenance

Outdoor Microphone Type 4952 is designed for unattended outdoor use for long periods of time. In periods where the

microphone is used unattended, it is recommended that it is verified regularly with CIC, see above. Once calibrated in a setup,

the CIC gain at 1 kHz should not change by more than 0.2 dB.

In aggressive environments like cities with heavy traffic, chemical industry plants, near railway or near coasts (salt water) the

likelihood of corrosion is large as compared with normal outdoor environments. If used in such environments, it is recommended

that the microphone is initially inspected at short intervals, say, every two to four weeks. When it is clear that the microphone

does not corrode, the interval can be increased.

The grid on the transducer unit may become discoloured with time, especially in aggressive environments such as those

mentioned above. This does not affect the performance of the microphone as long as the diaphragm – partially visible below the

grid – does not appear to be damaged.

At least once per year the microphone should be inspected and calibrated. Preferably, the frequency response and system

noise should also be verified. Calibration and verification services are available from Brüel Kjær Service Centres and include

replacement of the windscreen.

Note

The windscreen should never be removed, except when it is being replaced.

Replacement of the windscreen is recommended whenever needed and at least once every 24 months.

Spare windscreens are available as UA-1700 and UA-1701 (pack of 6 windscreens)

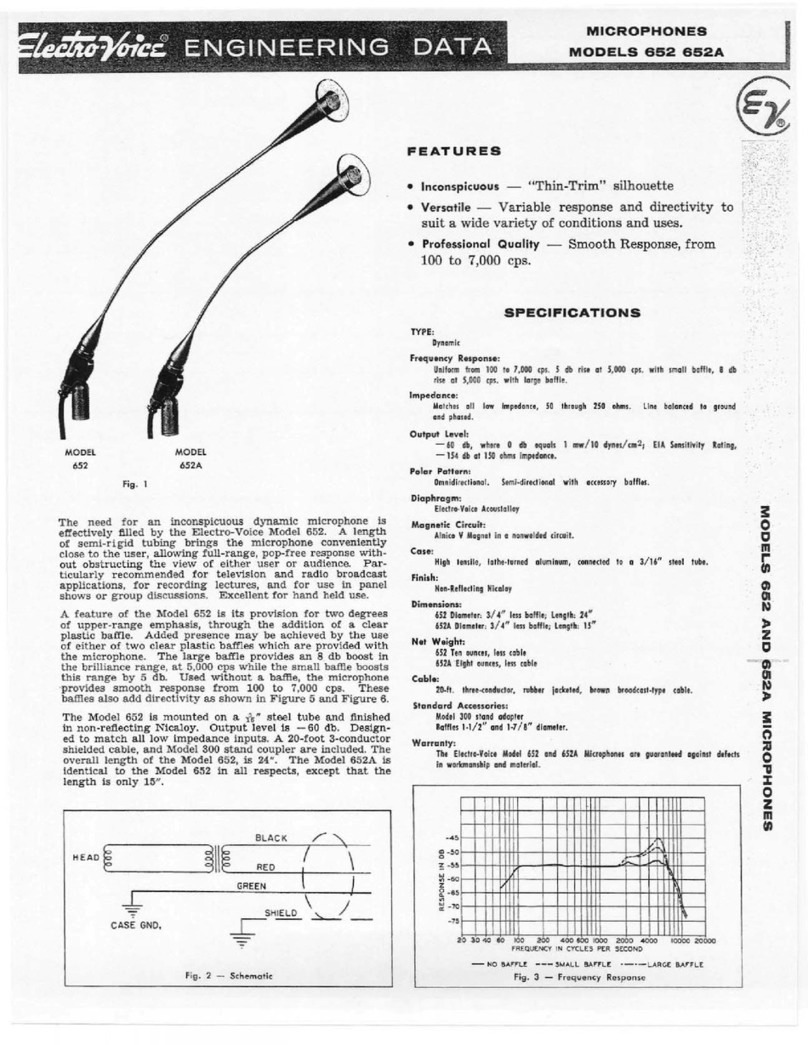

Response Linearisation Filter

In order for Outdoor Microphone Type 4952 to have a flat frequency response as specified in the Product Data for reference

directions 0° and 90°, a frequency weighting filter as defined below must be used.

Brüel & Kjær offers different solutions with the appropriate frequency weighting.

Note, that Brüel & Kjær does not assume any responsibility for the combined response of Type 4952 and filters not made by

Brüel & Kjær.

Recommended Filter Responses

Frequency Filter, dB Frequency Filter, dB

Hz 0° 90° Tol. Hz 0° 90° Tol.

20 0.00 0.00 ±0.15 4000 -1.00 1.05 ±0.15

250 0.00 0.00 ±0.15 4500 -1.00 1.40 ±0.20

315 -0.05 0.00 ±0.15 5000 -0.90 1.85 ±0.20

400 -0.10 0.00 ±0.15 5600 -1.00 2.25 ±0.20

500 -0.15 0.00 ±0.15 6300 -1.10 2.10 ±0.30

630 -0.20 0.00 ±0.15 7100 -1.30 1.70 ±0.40

800 -0.40 0.00 ±0.15 8000 -1.60 1.50 ±0.50

1000 -0.50 0.00 ±0.15 9000 -1.80 1.20 ±0.50

1250 -0.70 0.00 ±0.15 10000 -2.10 1.20 ±0.60

1600 -0.85 0.00 ±0.15 11200 -2.30 1.50 ±0.80

2000 -0.90 0.00 ±0.15 12500 -1.20 3.10 ±1.00

2500 -0.95 0.05 ±0.15 14000 0.70 5.10 ±2.00

2800 -0.95 0.10 ±0.15 16000 0.90 4.80 ±5.00

3150 -1.00 0.30 ±0.15 18000 -0.20 3.00 ±10.00

3550 -1.00 0.68 ±0.15 20000 -3.30 -2.00 ±15.00

2BR1733-11