Dual Microphone Supply Type 5935

User Guide

BE1300−12 0−3

Contents

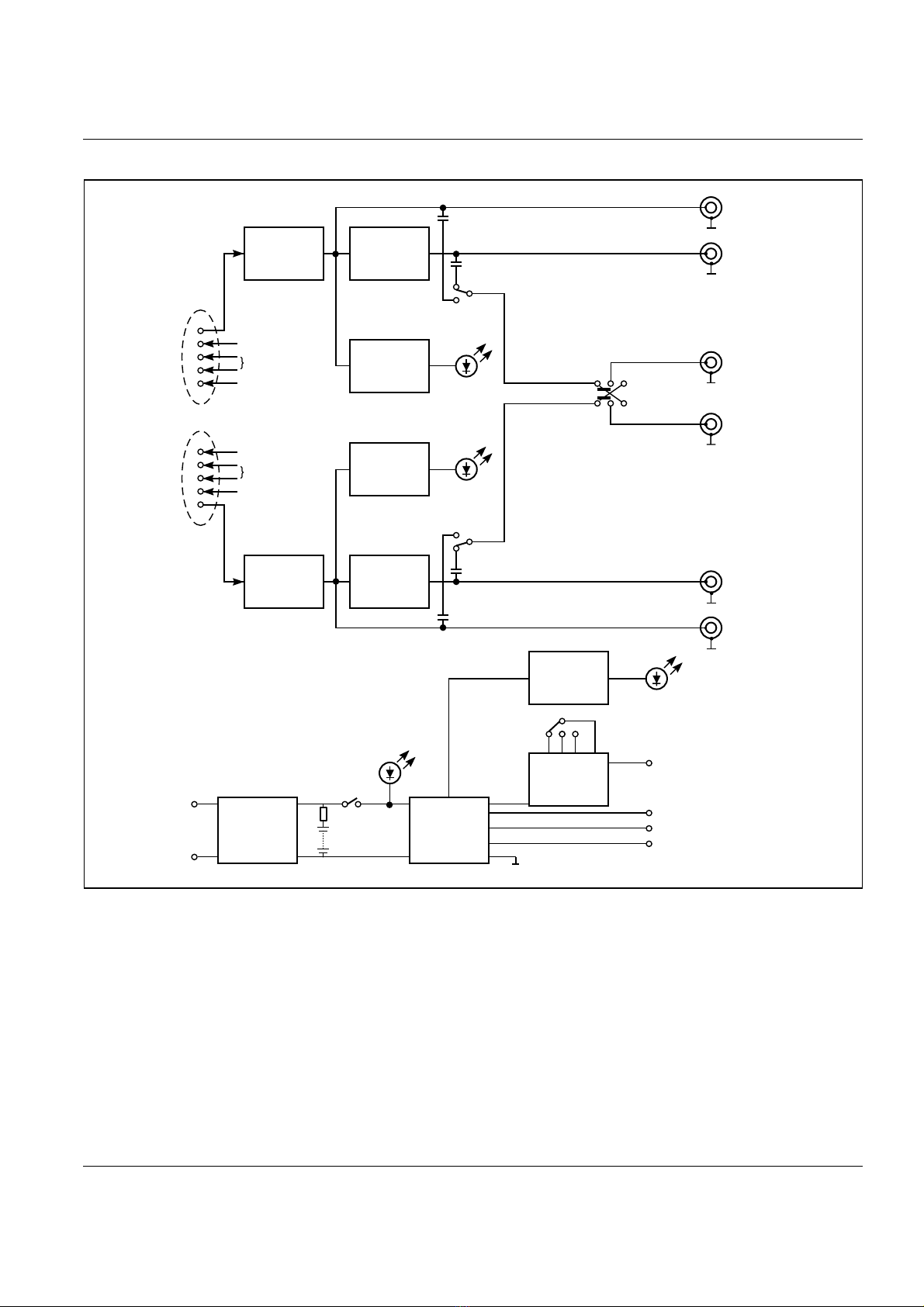

1. Functional Description................................................................................................. 5

1.1 Overview ........................................................................................................................... 6

1.2 Power Source .................................................................................................................... 6

1.3 DC/DC Converter ............................................................................................................. 6

1.4 Channel Amplifier and Weighting Filter........................................................................ 8

1.5 Output Sockets ................................................................................................................. 8

2. Controls and Connections.......................................................................................... 9

2.1 Front Panel ..................................................................................................................... 10

Warning Indicators.................................................................................................... 10

Switches ..................................................................................................................... 11

Gain Adjustment ....................................................................................................... 11

Signal Connectors...................................................................................................... 11

2.2 Rear Panel ...................................................................................................................... 12

Battery Cover............................................................................................................. 12

Power Input Sockets.................................................................................................. 12

Output Sockets .......................................................................................................... 13

2.3 Bottom Panel .................................................................................................................. 13

3. Operation................................................................................................................................ 15

3.1 Applying Power .............................................................................................................. 16

Power Sources............................................................................................................ 16

Fitting Internal Batteries ......................................................................................... 16

External Supply......................................................................................................... 17

3.2 Grounding Considerations............................................................................................. 18

3.3 Polarization Voltage....................................................................................................... 18

3.4 Output Connection ......................................................................................................... 18

3.5 Input Connection............................................................................................................ 19

3.6 Setting the Gain ............................................................................................................. 20

3.7 Overload.......................................................................................................................... 21

4. Specifications ...................................................................................................................... 23

4.1 Amplifier Stages ............................................................................................................. 24

4.2 Power Supply.................................................................................................................. 25

5. Service and Repair ....................................................................................................... 5–1