Contents

H155936_3_003 iii

Contents

1 About This Manual .............................................................................................................................5

1.1 Policy Statement .................................................................................................................5

1.2 Symbols and Conventions ..................................................................................................5

2 Introduction.........................................................................................................................................7

2.1 Concept...............................................................................................................................7

2.2 Intended Use.......................................................................................................................7

2.3 Limitation of Liability............................................................................................................8

2.4 Copyright.............................................................................................................................8

2.5 Warranty Terms ..................................................................................................................8

2.6 Customer Service ...............................................................................................................8

3 Safety...................................................................................................................................................9

3.1 System Owner's Responsibility...........................................................................................9

3.2 Personnel Requirements ..................................................................................................10

3.2.1 Unauthorized Persons ......................................................................................................11

3.2.2 Instruction .........................................................................................................................11

3.3 Personal Protective Equipment.........................................................................................11

3.4 General Workplace Dangers.............................................................................................12

4 Design and Function ........................................................................................................................15

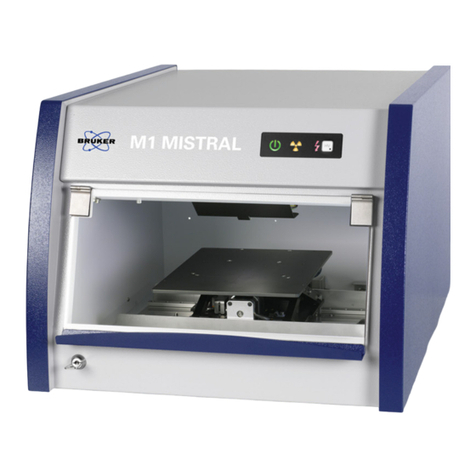

4.1 Description ........................................................................................................................15

4.2 Software............................................................................................................................17

5 Transport, Packaging and Storage .................................................................................................19

5.1 Symbols on the Packaging ...............................................................................................19

5.2 Inspection at Delivery........................................................................................................20

5.3 Packaging .........................................................................................................................20

5.4 Storage .............................................................................................................................21

6 Flow Unit Installation .......................................................................................................................23

6.1 Choose the Position of the Reactor ..................................................................................23

6.2 Connecting the Transfer Line Holder ................................................................................24

6.3 Testing the Flow Unit Prior to Inserting it into the Magnet ................................................24

6.4 Temperature Control (optional).........................................................................................26

6.5 Software Installation..........................................................................................................27

6.6 Software Configuration .....................................................................................................32

6.6.1 TopSpin Configuration ......................................................................................................32

6.6.2 InsightMR Flow Mode Configuration.................................................................................32

6.6.2.1 Recommended Settings....................................................................................................34

6.6.3 Adding a New Protonated Solvent ....................................................................................38

7 Operation...........................................................................................................................................39

7.1 Inserting and Using the Flow Unit .....................................................................................39

7.2 Acquiring NMR Data Using InsightMR Software...............................................................40

7.3 Removing the Flow Unit for Storage in the Transport Box................................................41

7.4 Returning the Spectrometer to Normal Operation ............................................................41